Abstract

Iron aluminides based on Fe3Al intermetallic structure are known by their good corrosion and oxidation resistance. However, the hydrogen embrittlement is an issue generated by passive Al2O3 formation due to Al reaction with atmospheric water vapor. Thus, the main aim of this study was to evaluate the effects of loading rate, heat treatment and temperature of test on the mechanical properties of a Fe–Al–C alloy. Mechanical properties analysis and the incidence of hydrogen embrittlement were performed in a Fe3Al–C alloy (Fe–15.2Al–1.1C wt%), which was melted and remelted in an induction furnace. Tensile and Charpy impact tests were carried out at room temperature (as-cast and heat-treated conditions) and temperatures up to 600 °C, in order to evaluate the influence of different temperatures, heat treatment, and load rates (tensile and impact) on hydrogen embrittlement. Furthermore, the fractography was performed by SEM, helping to understand the fracture mechanisms. The heat treatment generated specimens with higher tensile resistance, however, with no effect on impact resistance, demonstrating that hydrogen embrittlement generates more damage in lower load rate tests. The tests at higher temperatures demonstrated improvement in the impact and tensile properties and regarding all conditions the fracture after tensile tests presented more brittle aspects than after impact tests.

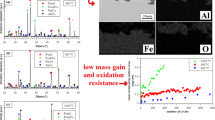

Graphic Abstract

Similar content being viewed by others

Availability of Data and Material

The authors declare that the data used are available.

References

U. Prakash U, Intermetallic matrix composites based on iron aluminides (2018), pp. 21–35. https://doi.org/10.1016/B978-0-85709-346-2.00002-9.

C.G. McKamey, C.T. Liu, J.V. Cathcart, S. David, E.H. Lee, Evaluation of mechanical and metallurgical properties of Fe3Al-based aluminides. Oak Ridge Natl. Lab. (1986)

E. Godlewska, S. Szczepanik, R. Mania, J. Krawiarz, S. Koziñski, FeAl materials from intermetallic powders. Intermetallics 11, 307–312 (2003)

M. Martinez, B. Viguier, P. Maugis, J. Lacaze, Relation between composition, microstructure and oxidation in iron aluminides. Intermetallics 14, 1214–1220 (2006)

M.R. Hajaligol, C. Scorey, V.K. Sikka, S.C. Deevi, G. Fleishhauer, A.C. Lilly Jr, R.M. German, Method of manufacturing aluminide sheet by thermomechanical processing of aluminide powders (2000)

R. Balasubramaniam, Hydrogen in iron aluminides. J. Alloys Compd. 330, 506–510 (2002)

C.L. Fu, G.S. Painter, First principles investigation of hydrogen embrittlement in FeAl. J. Mater. Res. 6, 719–723 (1991)

C.T. Liu, V.K. Sikka, C.G. McKamey, Alloy development of FeAl aluminide alloys for structural use in corrosive environments. Oak Ridge Natl. Lab., TN (United States) (1993). https://doi.org/10.2172/6136151.

C.G. McKamey, C.T. Liu, Environmental embrittlement of iron aluminides in moisture-containing atmospheres. U.S. Dep. Energy Off. Sci. Tech. Inf. (1991)

N.S. Stoloff, C.T. Liu, Environmental embrittlement of iron aluminides. Intermetallics 2, 75–87 (1994)

P. Dymáček, F. Dobeš, Y. Jirásková, N. Pizúrová, M. Friák, Tensile, creep and fracture testing of prospective Fe–Al-based alloys using miniature specimens. Theor. Appl. Fract. Mech. (2018). https://doi.org/10.1016/j.tafmec.2018.11.005

M. Chen, D. Lin, Y. Xia, C.T. Liu, Strain rate sensitivity of ductility and fracture behaviors in a Fe–28Al alloy. Mater. Sci. Eng. A. 239–240, 317–323 (1997)

D.B. Kasul, L.A. Heldt, Effect of environment on the mechanical properties of an Fe-246Al alloy. Scr. Metall. Mater. 25, 1047–1051 (1991)

G. Rosas, R. Esparza, A. Bedolla-Jacuinde, R. Pérez, Room temperature mechanical properties of Fe3Al intermetallic alloys with Li and Ni additions. J. Mater. Eng. Perform. 18, 57–61 (2009)

R.M. Aikin, The mechanical properties of in-situ composites. JOM. 49, 35 (1997)

R. Kant, U. Prakash, V. Agarwala, V.S. Prasad, Microstructure and wear behaviour of FeAl-based composites containing in-situ carbides. Bull. Mater. Sci. 39, 1827–1834 (2016)

U. Prakash, Development of iron aluminides containing carbon. Trans. Indian Inst. Met. 61, 193–199 (2008)

R.S. Sundar, S.C. Deevi, Effect of carbon addition on the strength and creep resistance of FeAl alloys. Metall. Mater. Trans. A. 34, 2233–2246 (2003)

L.N. Bartlett, R. Rahman, A. Torres, Minimizing phosphorus pickup during melting and casting of lightweight Fe–Mn–Al–C steels. Int. J. Met. 12, 164–181 (2018). https://doi.org/10.1007/s40962-017-0152-9

R. Vaz Penna, L.N. Bartlett, T. Constance, Understanding the role of inclusions on the dynamic fracture toughness of high strength lightweight FeMnAl steels. Int. J. Met. 13, 286–299 (2019). https://doi.org/10.1007/s40962-018-0273-9

L.N. Bartlett, S. Serino, Nitriding of lightweight high manganese and aluminum steels. Int. J. Met. 10, 190–200 (2016). https://doi.org/10.1007/s40962-016-0022-x

R. Vaz Penna, L.N. Bartlett, R. O’Malley, Influence of TiN additions on the microstructure of a lightweight Fe–Mn–Al steel. Int. J. Met. 14, 342–355 (2020). https://doi.org/10.1007/s40962-019-00373-6

N.B. Ballal, Effect of carbides on embrittlement of Fe3Al based intermetallic alloys. Scr. Mater. 36, 667–671 (1997)

A. Schneider, L. Falat, G. Sauthoff, G. Frommeyer, Microstructures and mechanical properties of Fe3Al-based Fe–Al–C alloys. Intermetallics 13, 1322–1331 (2005)

M. Sen, R. Balasubramaniam, Hydrogen trapping at carbide-matrix interfaces in Fe3Al–C intermetallics. Scr. Mater. 44, 619–623 (2001)

N. Parvathavarthini, U. Prakash, R.K. Dayal, Effect of carbon addition on hydrogen permeation in an Fe3Al-based intermetallic alloy. Intermetallics 10, 329–332 (2002)

V.S. Rao, Fe3Al-Fe3AlC intermetallics for high temperature applications: An assessment. J. Mater. Sci. 39, 4193–4198 (2004)

M.N. Verona, D. Setti, R.S.C. Paredes, Microstructure and properties of Fe3Al-fe3ALCx composite prepared by reactive liquid processing. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 49, 529–536 (2018)

R.G. Baligidad, U. Prakash, A. Radhakrishna, Processing of high carbon Fe3Al based intermetallic alloy. Intermetallics 6, 765–769 (1998)

V.K. Sikka. Processing and apllications of iron aluminides, in 1994 TMS Annual Meeting Proceedings Publication (1994), pp. 1–16

R.G. Baligidad, U. Prakash, A. Radhakrishna, High temperature tensile and creep properties of a cast aim and ESR intermetallic alloy based on Fe3Al. Mater. Sci. Eng. A. 231, 206–210 (1997)

R.G. Baligidad, U. Prakash, A. Radhakrishna, V. Ramakrishna Rao, P.K. Rao, N.B. Ballal, Effect of carbon content on high temperature tensile properties of Fe3Al based intermetallic alloys. Scr. Mater. 36, 105–109 (1997)

A.M.S. Malafaia, M.T. Milan, M. Omar, R.M. Muñoz Riofano, M.F. De Oliveira, Oxidation and abrasive wear of Fe–Si and Fe–Al intermetallic alloys. J. Mater. Sci. 45, 5393–5397 (2010)

K. Balasubramanian, L.N. Bartlett, R. O’Malley, S. Chakraborty, M. Xu, Filtration efficiency of inclusions in lightweight FeMnAl steels. Int. J. Met. 14, 328–341 (2020). https://doi.org/10.1007/s40962-019-00372-7

C.G. McKamey, J.H. DeVan, P.F. Tortorelli, V.K. Sikka, A review of recent developments in Fe3Al-based alloys. J. Mater. Res. 6, 1779–1805 (1991)

R.G. Baligidad, K.S. Prasad, Effect of Al and C on structure and mechanical properties of Fe–Al–C alloys. Mater. Sci. Technol. 23, 38–44 (2007)

R.G. Baligidad, U. Prakash, V. Ramakrishna Rao, P.K. Rao, N.B. Ballal, Effect of carbon content on mechanical properties of electroslag remelted Fe3Al based intermetallic alloys. ISIJ Int. 36, 1453–1458 (1996)

S.M. Zhu, X.S. Guan, K. Shibata, K. Iwasaki, Microstructure and mechanical and tribological properties of high carbon Fe3Al and FeAl intermetallic alloys. Mater. Trans. 43, 36–41 (2002)

J. Yang, P. La, W. Liu, Y. Hao, Microstructure and properties of Fe3Al–Fe3 AlC05 composites prepared by self-propagating high temperature synthesis casting. Mater. Sci. Eng. A 382, 8–14 (2004)

R.V. Shankar, Some observations on the hydrogen embrittlement of Fe3Al–Fe 3AlC intermetallic compounds. Mater. Res. Bull. 39, 169–174 (2004)

Z. Wang, Y. Zhou, Y. Xia, Effect of strain rate on behaviour of Fe3Al under tensile impact. J. Mater. Sci. 32, 2387–2390 (1997)

Z.R. Zhang, W.X. Liu, Mechanical properties of Fe3Al-based alloys with addition of carbon, niobium and titanium. Mater. Sci. Eng. A. 423, 343–349 (2006)

Acknowledgements

The authors acknowledge the MIB – Materials Institute of Brazil by the partnership during the D.Sc. thesis development as also the support of the National Council of Technological and Scientific Development—CNPq—Brazil through a PhD scholarship (2009–2013), Process Number: 140634/2009-6. The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

Funding

This study received financial support from National Council of Technological and Scientific Development—CNPq—Brazil through a PhD scholarship (2009–2013), process number: 140634/2009-6

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Sousa Malafaia, A.M., Maestro, C.A.R. & de Oliveira, M.F. Alternative Air Induction Melt–Remelt Processing of an Fe3Al–C Intermetallic Alloy: Part I—Mechanical Properties and the Effects of Loading Rate, Heat Treatment and Test Temperatures. Inter Metalcast 16, 1265–1275 (2022). https://doi.org/10.1007/s40962-021-00679-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00679-4