Abstract

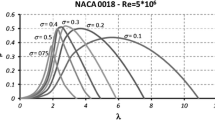

The recovery and utilization of waste wind is an important way to construct a green mine. In this paper, the power generation technology of air kinetic energy recovery in mine return air-head was numerically studied. Through the theoretical analysis of mine return air power generation, the key parameters of wind turbine were designed and determined. FLUENT and QBlade were used to simulate the local and overall performance of the wind turbine, respectively. The results show that NACA4412 airfoil blades have good rotating performance and aerodynamic performance since the pressure difference between pressure surface and suction surface is large by analyzing the pressure field. When the tip speed ratio is between 4 and 7. The wind energy utilization coefficient reaches the maximum value in the range of 7–8, and the maximum power coefficient can reach 0.501. The wind turbine can maintain a high-power coefficient in a wide range, and the effect is relatively ideal. In addition, under the rated wind speed of 10 m s−1, the torque of wind turbine is 17 N m which is relative large. The thrust and thrust coefficient are 150 N and 0.72, respectively, so the thrust and thrust coefficient are small. In general, the wind turbine has high wind energy utilization rate and structural stability. It is feasible to recover the air kinetic energy from the mine shaft. And the research results provide a reference for the recovery and utilization of air kinetic energy in mine return air wellhead.

Similar content being viewed by others

References

Yang, J.: Design and optimization of breeze power generation system structure, Academic Dissertation, Southwest University of Science and Technology, China (2015)

Yang, Z.; Ren, H.: Design of three-dimensional visualization ventilation system in mines. China. Min. Ind. 28, 226–228 (2019)

Dong, Z.; Du, C.; Liu, J.; Meng, G.; Yang, H.; Gu, Y.: Study on the effect of spray height of mine return air spray heat exchanger on heat transfer efficiency. Coal Sci. Technol. 41, 97–100 (2013). https://doi.org/10.13199/j.cst.2013.05.107.dongzhf.027

Lv, X.; Li, Y.; Bao, L.: Application research on recovery of low-temperature waste heat from mine return air based on heat pipe heat exchange technology. Coal Technol. 38, 117–120 (2019). https://doi.org/10.13301/j.cnki.ct.2019.03.040

Ma, Y.; Li, J.; Li, J.: Analysis of coal mine ventilation power generation methods. Coal Eng. 49, 33–37 (2017)

Gosiewski, K.; Pawlaczyk, A.: Catalytic or thermal reversed flow combustion of coal mine ventilation air methane: what is better choice and when? Chem. Eng. J. 238, 78–85 (2014). https://doi.org/10.1016/j.cej.2013.07.039

Xiang, W.: Experimental research and numerical simulation of mine ventilated wind power generation, Academic Dissertation, China University of Mining and Technology, China (2019)

Carothers, P.; Schultz, L.H.; Talkington, C.C.: Mitigation of methane emissions from coal mine ventilation air: an up date [R], (2003)

Xu, L.: The Research on the Power of Mine Ventilation Residual Kinetic Energy, Academic Dissertation, Liaoning Technical University, China (2011)

Mohammad, H.B.A.; Yang, Z.: Numerical study of the coupling between the instantaneous blade loading/power of an axial wind turbine and upstream turbulence at high Reynolds numbers. Energy 20, 1–14 (2020). https://doi.org/10.1016/j.energy.2020.118167

Moussa, M.: Experimental and numerical performances analysis of a small three blades wind turbine. Energy 203, 5109–5124 (2020). https://doi.org/10.1016/j.energy.2020.117807

Regodeseves, P.; Morros, C.: Unsteady numerical investigation of the full geometry of a horizontal axis wind turbine: flow through the rotor and wake. Energy 202, 1–15 (2020). https://doi.org/10.1016/j.energy.2020.117674

Li, X.X.; Zhang, L.; Song, J.J.; Bian, F.J.; Yang, K.: Airfoil design for large horizontal axis wind turbines in low wind speed regions Renewable. Renew. Energy 145, 2345–2357 (2020). https://doi.org/10.1016/j.renene.2019.07.163

Zhu, C.Y.; Qiu, Y.N.; Wang, T.G.: Dynamic stall of the wind turbine airfoil and blade undergoing pitch oscillations: a comparative study. Energy 222, 1–14 (2021). https://doi.org/10.1016/J.ENERGY.2021.120004

Abdelsalam, A.M.; El-Askary, W.A.; Kotb, M.A.; Sakr, I.M.: Experimental study on small scale horizontal axis wind turbine of analytically-optimized blade with linearized chord twist angle profile. Energy (2021). https://doi.org/10.1016/J.ENERGY.2020.119304

Sedighi, H.; Akbarzadeh, P.; Salavatipour, A.: Aerodynamic performance enhancement of horizontal axis wind turbines by dimples on blades: Numerical investigation. Energy (2020). https://doi.org/10.1016/j.energy.2020.117056

Miao, S.: Discussion on the status quo and problems of wind power generation technology. Shandong Ind. Technol. 07, 185 (2018). https://doi.org/10.16640/j.cnki.37-1222/t.2018.07.171

Peng, J.X.; Zhao, R.P.; Chen, J.C.: Mine waste wind power generation device [P]. Chinese Patent: CN103075302A, 2013-05-01

Zheng, B.; Li, J.; Ji, W.: Research on the grid connection of mine waste wind power generation. Enterp. Technol. Dev. 16, 50–51 (2012). https://doi.org/10.14165/j.cnki.hunansci.2012.16.062

Tian, C.; Huang, H.; Wang, Z.: Evaluation index system of metal and non-metallic underground mine ventilation system. Nonferrous Met. Sci. Eng. 4, 67–71 (2013). https://doi.org/10.13264/j.cnki.ysjskx.2013.01.011

Ke, M.; Deng, Q.; Zhang, Q.; Xiang, S.; Long, X.: Research on the method of weakening the cogging torque of the axial magnetic field permanent magnet synchronous wind turbine. J. Hunan Inst. Technol. 4, 1–7 (2019). https://doi.org/10.15987/j.cnki.hgbjbz.2019.04.001

Gong, T.; Li, H.: Optimal design of direct-drive permanent magnet synchronous wind turbine stator windings based on multiphysics coupling. Electr. Mach. Control Appl. 7, 67–71 (2019)

He, D.X.: Wind engineering and industrial aerodynamics [M]. National Defense Industry Press, Beijing (2006)

Wang, H.; Li, W.: Numerical simulation research and application of mine main fan diffuser ventilation flow field. J. Xiangtan Min. Inst. 17, 9–11 (2002)

Zhang, H.: Shape design and aerodynamic analysis of 2MW wind turbine blades based on Ye Su theory. Sci. Technol. Innov. 14, 122–124 (2016)

Ma, P.: Numerical simulation of aerodynamic characteristics of small wind turbine blades based on S823/S822 airfoil, Academic Dissertation, Guangxi University, China (2008) https://doi.org/10.15913/j.cnki.kjycx.2016.14.122

Jenkins, P.; Wilson, A.: Analysis of a diffuser-augmented, multi-rotor wind turbine system. J. Energy Power Eng. 12, 419–435 (2018). https://doi.org/10.17265/1934-8975/2018.09.001

Liu, Z.: Optimal design and fluid-structure coupling analysis of small wind turbine blades, Academic Dissertation, Qingdao university of science and technology, China (2020). https://doi.org/10.27264/d.cnki.gqdhc.2020.000418

Fan, Z.: Blade design and simulation analysis of vertical-axis breeze generator, Academic Dissertation, Xiamen University, China (2008)

Zhou, J.; Xu, G.; Zhang, H.: FLUENT engineering technology and case analysis[M]. China Water Power Press, Beijing (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gui, X. Research on Numerical Simulation of Wind Kinetic Energy Recovery Power Generation at Mine Return Air Wellhead. Arab J Sci Eng 46, 12743–12754 (2021). https://doi.org/10.1007/s13369-021-06143-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06143-z