Abstract

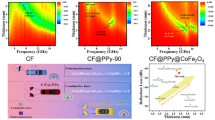

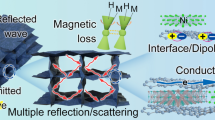

In this study, the polyurethane (PU) foam-based microwave absorbing materials filled with graphene (GP) and flaky carbonyl iron (FCI) particles were fabricated, and the effects of GP content and morphology structure on the microwave absorption (MA) properties were investigated. Scanning electron microscopy (SEM) and vector network analyzer (VNA) were used to elucidate the morphology structure and electromagnetic properties of the composite samples. The results showed that the absorption bandwidth of the materials could be improved by increasing the cell density. In particular, for a composite with 1.5 wt.% of GP and 70 wt.% of FCI, the minimum reflection loss (RL) of −53.8 dB was achieved at 9.4 GHz with the thickness of 2.2 mm, and the effective absorbing bandwidth (RL < -10 dB) of 8.1 GHz (9.9–18 GHz) was achieved with the thickness of 1.7 mm. The excellent MA properties of these materials were ascribed to the synergistic effect between the GP and FCI particles and the improved impedance matching resulting from the porous structure.

Similar content being viewed by others

Availability of data and material

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

L.B. Kong, Z.W. Li, L. Liu, R. Huang, M. Abshinova, Z.H. Yang, C.B. Tang, P.K. Tan, C.R. Deng, S. Matitsine, Int. Mater. Rev. 58, 203 (2013)

X. Li, H. Yi, J. Zhang, J. Feng, F. Li, D. Xue, H. Zhang, Y. Peng, N.J. Mellors, J. Nanopart. Res. 15, 1472 (2013)

Y.C. Qing, W.C. Zhou, F. Luo, D.M. Zhu, Carbon 48, 4074 (2010)

Y. Zou, J. Wang, B. Zhang, X.G. Su, S.Q. Huo, S. Yang, W. Chen, X. Wang, J.P. Wang, J. Mater. Sci. Mater. Electron. 30, 10321 (2019)

A.A. Balandin, S. Ghosh, W. Bao, I. Calizo, D. Teweldebrhan, F. Miao, C.N. Lau, Nano Lett. 8, 902 (2008)

A.K. Geim, Science 324, 1530 (2009)

S. Stankovich, D.A. Dikin, G.H. Dommett, K.M. Kohlhaas, E.J. Zimney, E.A. Stach, R.D. Piner, S.T. Nguyen, R.S. Ruoff, Nature 442, 282 (2006)

S. Hosseinabadi, Z. Sheykhifard, S. M. Mohseni, M. Kokabi, L. Jamilpanah, M. Hajali and M. Jafari, Mater. Chem. Phys. 260, 124155 (2020).

S. Qilong, S. Lei, C. Yingying, Y. Wei, X. Sijun, J. Tao, Y. Guoqiu, Ceram. Int. 45, 18298 (2019)

X. Gao, Y. Wang, Q. Wang, X. Wu, W. Zhang, M. Zong, L. Zhang, Ceram. Int. 45, 3325 (2019)

X. Wang, Y. Lu, T. Zhu, S. Chang and W. Wang, Chem. Eng. J. 388, 124317 (2020).

H. Lv, G. Ji, X. Liang, H. Zhang, Y. Du, J. Mater. Chem. C 3, 5056 (2015)

T. Wang, Z. Liu, M. Lu, B. Wen, Q. Ouyang, Y. Chen, C. Zhu, P. Gao, C. Li, M. Cao and L. Qi, J. Appl. Phys. 113, 024314.1 (2013).

S. Yang, D.W. Xu, P. Chen, H.F. Qiu, X. Guo, J. Mater. Sci. Mater. Electron. 29, 19443 (2018)

K. Xu, W.H. Ma, Y.A. Liu, Y.F. Bai, J.W. Xue, Y. Liu, G.Z. Zhao, Y.Q. Liu, J. Mater. Sci. Mater. Electron. 30, 9133 (2019)

S. Li, Y. Huang, D. Ling, N. Zhang, M. Zong, X. Qin, P. Liu, J. Colloid Interface Sci. 544, 188 (2019)

O. Khani, M.Z. Shoushtaria, K. Ackland, P. Stamenov, J. Magn. Magn. Mater. 428, 28 (2017)

F. Wen, W. Zuo, H. Yi, N. Wang, L. Qiao, F. Li, Phys. B 404, 3567 (2009)

C.-C. Chen, W.-F. Liang, Y.-H. Nien, H.-K. Liu, R.-B. Yang, Mater. Res. Bull. 96, 81 (2017)

C. Liu, Y. Duan, J. Cai, X. Li, D. Zhang, J. Gao and Y. Che, Mater. Res. Express. 6, 106114 (2019).

Z. Zhu, X. Sun, H. Xue, H. Guo, X. Fan, X. Pan, J. He, J. Mater. Chem. C 2, 6582 (2014)

A. Kausar, Polym.-Plast. Technol. Eng. 57, 346 (2017)

N. Vu-Bac, T. Lahmer, X. Zhuang, T. Nguyen-Thoi, T. Rabczuk, Adv Eng Softw 100, 19 (2016)

V. Mishra, S. Puthucheri, D. Singh, IEEE Trans. Magn. 53, 1 (2017)

J.L. Wallace, IEEE Trans. Magn. 29, 4209 (1993)

A.N. Lagarkov, A.K. Sarychev, Phys. Rev. B 53, 6318 (1996)

C.W. Nan, Prog. Mater Sci. 37, 1 (1993)

J.P. Calame, J. Appl. Phys. 97, 5945 (2005)

H. Lv, G. Ji, W. Liu, H. Zhang, Y. Du, J. Mater. Chem. C 3, 10232 (2015)

W. Xu, G.-S. Wang, P.-G. Yin, Carbon 139, 759 (2018)

H. Qiu, X. Zhu, P. Chen, N. Li and X. Zhu, J. Alloys Compd. 868, 159260 (2021).

M. Dai, Y. Zhai, L. Wu, Y. Zhang, Carbon 152, 661 (2019)

Y.C. Qing, D.D. Min, Y.Y. Zhou, F. Luo, W.C. Zhou, Carbon 86, 98 (2015)

F. Wen, H. Yi, L. Qiao, H. Zheng, D. Zhou and F. Li, Appl. Phys. Lett. 92, 042507 (2008).

X. F. Zhang, X. L. Dong, H. Huang, Y. Y. Liu, W. N. Wang, X. G. Zhu, B. Lv, J. P. Lei and C. G. Lee, Appl. Phys. Lett. 89, 053115 (2006).

G. Korneva, H. Ye, Y. Gogotsi, D. Halverson, G. Friedman, J.C. Bradley, K.G. Kornev, Nano Lett. 5, 879 (2005)

Z.G. Fang, X.M. Cao, C.S. Li, H.T. Zhang, J.S. Zhang, H.Y. Zhang, Carbon 44, 3368 (2006)

J. Fang, T. Liu, Z. Chen, Y. Wang, W. Wei, X. Yue, Z. Jiang, Nanoscale 8, 8899 (2016)

X. Zhu, H. Qiu, P. Chen, G. Chen, W. Min, Carbon 173, 1 (2021)

R. Rafiee, M.H. Sabour, A. Nikfarjam, M. Taheri, J. Electron. Mater. 43, 3477 (2014)

B. Zhao, G. Shao, B. Fan, W. Zhao, Z. Rui, PCCP 17, 2531 (2015)

H. Lv, X. Liang, G. Ji, H. Zhang, Y. Du, A.C.S. Appl, Mater. Interfaces 7, 9776 (2015)

F. Yan, S. Zhang, X. Zhang, C.Y. Li, C.L. Zhu, X.T. Zhang, Y.J. Chen, J. Mater. Chem. C 6, 12781 (2018)

G. Ma, Y. Zeng, X. Yang, Y. Liu, Y. Duan, J. Mater. Sci. Mater. Electron. 31, 8627 (2020)

S. Gao, S.H. Yang, H.Y. Wang, G.S. Wang, P.G. Yin, Carbon 162, 438 (2020)

L. Lyu, F. Wang, B. Li, X. Zhang, J. Qiao, Y. Yang, J. Liu, J. Colloid Interface Sci. 586, 613 (2021)

Y. Li, S. Li, T. Zhang, L.L. Shi, S.T. Liu, Y. Zhao, J. Alloys Compd. 792, 424 (2019)

H. Xu, X. Yin, M. Zhu, M. Han, Z. Hou, X. Li, L. Zhang, L. Cheng, A.C.S. Appl, Mater. Interfaces 9, 6332 (2017)

Acknowledgements

The authors would like to thank Yubin Chen for help.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by SW, XH, and WZ. The first draft of the manuscript was written by SW, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, S., Huang, X. & Zhang, W. Preparation of graphene/flaky carbonyl iron/polyurethane foam composites and research on their microwave absorption properties. Appl. Phys. A 127, 742 (2021). https://doi.org/10.1007/s00339-021-04894-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04894-y