Abstract

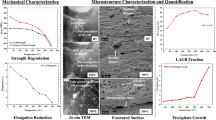

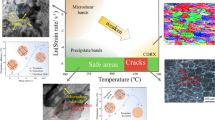

The microstructure evolution and hot deformation behavior of a Li-containing aluminum alloy AA2060 with different initial microstructure (homogenized vs. pre-rolled) were studied by isothermal hot deformation. The tests were performed within a wide range of deformation temperatures of 370–490 ℃ and strain rates of 0.01–10 s−1. Results show that the stress drop ratio of the pre-rolled specimen is higher than that of the homogenized one under the same deformation condition. Microstructure were analyzed on the thermal processing maps in unstable and optimum processing domain, and a higher dynamic recrystallization fraction can be observed in the pre-rolled specimen that has more substructures and smaller grains. Four types of the dynamic recrystallization were observed and the mechanism for deformation softening was discussed in this work.

Graphic Abstract

Similar content being viewed by others

References

R.J.H. Wanhill, G.H. Bray, Chapter 2-Aerostructural Design and Its Application to Aluminum-Lithium Alloys. in Aluminumlithium Alloys, Processing, Properties and Applications, ed. by N.E. Prasad, A.A. Gokhale, R.J.H. Wanhill Butterworth-Heinemann (Butterworth-Heinemann, Oxford, 2014), pp. 27–58

A.A. El-Aty, Y. Xu, X.Z. Guo, S.H. Zhang, Y. Ma, D.Y. Chen, J. Adv. Res. 10, 49 (2018)

X. Sheng, L.D. Yang, Z.R. Hua, L.J. Feng, C.Y. Lai, Z.X. Hu, T. Nonferr. Metal. Soc. 25, 3855 (2015)

Z. Fei, S. Jian, Y.X. dong, S.J. lin, Rare Metal. Mat. Eng. 43, 1312 (2014)

X. Huang, H. Zhang, Y. Han, W. Wu, J. Chen, Mater. Sci. Eng. A 527, 485 (2010)

H.Z. Li, Z. Li, M. Song, X.P. Liang, F.F. Guo, Mater. Design 31, 2171 (2010)

O. Ling, Z.Q. Zheng, Y.F. Nie, H.G. Jian, J. Alloy. Compd. 648, 681 (2015)

R. Zhu, Q. Liu, J. Li, S. Xiang, Y. Chen, X. Zhang, J. Alloy. Compd. 650, 75 (2015)

Q. Yang, X. Wang, X. Li, Z. Deng, Z. Jia, Z. Zhang, G. Huang, Q. Liu, Mater. Charact. 131, 500 (2017)

L.F. Cao, B. Liao, X.D. Wu, C.Y. Li, G.J. Huang, N.P. Cheng, Curr. Comput.-Aid. Drug 10, 416 (2020)

W.C. Yu, H.Y. Li, R. Du, W. You, M.C. Zhao, Z.A. Wang, Mater. Charact. 145, 53 (2018)

G. Avramovic-Cingara, D.D. Perovic, H.J. McQueen, Metall. Mater. Trans. A 27, 3478 (1996)

L.Y. Ye, X.M. Zhang, Y.W. Liu, J.G. Tang, D.W. Zheng, Mater. Sci. Technol. 27, 125 (2011)

T.J. Ruggles, D.T. Fullwood, Ultramicroscopy 133, 8 (2013)

W.X. Ya, J.J. Tang, L.G. Ai, W.X. Ming, S. Jian, Z. Liang, J. Alloy. Compd. 815, 152469 (2020)

J. Humphreys, G.S. Rohrer, A. Rollett, Chapter 9 - Recrystallization of Two-Phase Alloys, in Recrystallization and Related Annealing Phenomena, 3rd ed. (Elsevier, Amsterdam, 2017), pp. 321–359

H.J. McQueen, Mater. Sci. Eng. A 387–389, 203 (2004)

C.J. Shi, J. Lai, X.G. Chen, Materials 7, 244 (2014)

Y. Wang, G. Zhao, X. Xu, X. Chen, C. Zhang, J. Alloy. Compd. 779, 735 (2019)

C.M. Sellars, W.J.M. Tegart, Acta Metall. 14, 1136 (1966)

H.L. He, Y.P. Yi, J.D. Cui, S.Q. Huang, Vacuum 160, 293 (2019)

B. Li, Q. Pan, Z. Yin, Mater. Sci. Eng. A 614, 199 (2014)

B. Shen, L. Deng, X. Wang, Mater. Sci. Eng. A 625, 288 (2015)

X. Yang, W. Huang, X. Zhu, R. Zhang, F. Guo, L. Hu, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00800-y

S.V. Mehtonen, L.P. Karjalainen, D.A. Porter, Mater. Sci. Eng. A 571, 1 (2013)

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metall. Trans. A 15, 1883 (1984)

X.-X. Yu, Y.-R. Zhang, D.-F. Yin, Z.-M. Yu, S.-F. Li, Acta Metall. Sinica Engl. 28,817 (2015)

G.J. Reddy, N. Srinivasan, A.A. Gokhale, B.P. Kashyap, J. Mater. Prcocess. Tech. 209, 5964 (2009)

Y.V.R.K Prasad, Indian J. Technol. 28, 435 (1990)

H. Garmestani, S. Lin, B.L. Adams, S. Ahzi, J. Mech. Phys. Solids. 49, 589 (2001)

A. Ma, F. Roters, Acta Mater. 52, 3603 (2004)

S. Mandal, A.K. Bhaduri, V.S. Sarma, Metall. Mater. Trans. A 42, 1062 (2011)

W.J. He, C.H. Li, B.F. Luan, R.S. Qiu, K. Wang, Z.Q. Li, Q. Liu, T. Nonferr. Metal. Soc. 25, 3578 (2015)

A. Godfrey, W.Q. Cao, Q. Liu, N. Hansen, Metall. Mater. Trans. A 36, 2371 (2005)

A. Godfrey, N. Hansen, D.J. Jensen, Metall. Mater. Trans. A 38, 2329 (2007)

X. Yang, W. Huang, X. Zhu, F. Guo, Y. Ma, L. Chai, R. Zhang, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00670-4

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang, L.T. Li, J. Alloy. Compd. 640, 101 (2015)

K. Huang, R.E. Logé, Mater. Design 111, 548 (2016)

A. Halfpenny, J. Prior, P.J. Wheeler, Tectonophysics 427, 3 (2006)

I. Shimizu, J. Struct. Geol. 30, 899 (2008)

J.K. Solberg, H.J. McQueen, N. Ryum, E. Nes, Philos. Mag. A 60, 447 (1989)

H.R. Rezaei Ashtiani, M.H. Parsa, H. Bisadi, Mater. Design 42,478 (2012)

M.H. Maghsoudi, A. Zarei-Hanzaki, P. Changizian, A. Marandi, Mater. Design 57, 487 (2014)

Acknowledgements

The authors acknowledged the financial support by the National Natural Science Foundation of China (51421001); the Open Fund of National Key Laboratory of Science and Technology on High-strength Structure Materials, Central South University; and the Fundamental Research Funds for the Central Universities (2020CDJDCL001).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Huang, G., Cao, L. et al. Effect of Initial Microstructure on the Hot Deformation Behavior and Microstructure Evolution of Aluminum Alloy AA2060. Met. Mater. Int. 28, 1561–1574 (2022). https://doi.org/10.1007/s12540-021-01025-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01025-3