Abstract

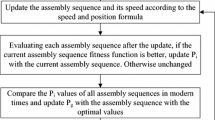

To improve the efficiency of complex assemblies in large-scale assembly sequence planning, an intelligent sequence planning method for constructing an assembly hybrid G-diagram model to realize the hierarchy of assembly structures is proposed. The assembly hybrid G-diagram model is constructed according to the assembly relationship semantics, and the assembly relationship semantics can be transformed into the corresponding assembly connection matrix and assembly priority matrix. Subassembly discriminant conditions are given to realize subassembly and isolated parts extraction, and the assembly structure is divided into part-level and subassembly-level. According to the assembly hybrid G-diagram, all feasible assembly sequences of part-level (within subassembly) and subassembly-level (subassembly as a whole) are solved, respectively. The particle swarm algorithm is used to optimize the assembly sequence with the goal of aggregation and redirection. The optimal sequence of part-level and subassembly-level is obtained, respectively. The sequence information is integrated to obtain the complete assembly sequence with the highest assembly efficiency under parallel planning. The feasibility and effectiveness of the assembly sequence optimization method are verified using a V-type dual-cylinder engine as an example. This planning method can greatly reduce the search space and avoid infeasible sequences when solving assembly sequences. In parallel planning, the sequence optimization process can be greatly shortened to ensure the assembly efficiency.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Gulivindala AK, Bahubalendruni MVAR, Varupala SSVP et al (2020) A heuristic method with a novel stability concept to perform parallel assembly sequence planning by subassembly detection. Assem Autom 40, 5:779–787

Liu XJ, Ni ZH, Liu JF et al (2016) Assembly process modeling mechanism based on the product hierarchy. Int J Adv Manuf Technol 82(1-4):391–405

Belhadj I, Trigui M, Benamara A (2016) Subassembly generation algorithm from a CAD model. Int J Adv Manuf Technol 87(9-12):2829–2840

Zhang C, Zhou GH, Lu Q et al (2018) Generating significant subassemblies from 3D assembly models for design reuse. Int J Prod Res 56(14):4744–4761

Shi XL, Tian XT, Wang GF et al (2020) Semantic-based subassembly identification considering non-geometric structure attributes and assembly process factors. Int J Adv Manuf Technol 110(1-2):439–455

Yang G, Wang CG, Ma MX et al (2016) Research on products’ disassembly sequence planning based on graph theory. Mach Des Res 32(05):92–95

Wu Q, Huang WJ, Wang TN (2018) A subassembly automatic generation algorithm in assembly sequence planning. Mach Des Res 34(01):161–163+187

Chen J, Zhang SL, Li X et al (2016) Identifying and generating subassemblies in disassembly sequence planning. Chin J Eng Des 23(01):1–7

Hao L, Mo R, Wei BB et al (2021) Application of rough set theory in identification of key functional parts. J Harbin Inst Technol 53(02):61–70

Yang Y, Liu Y, Lv X, et al (2021). Anthropomorphism and customers’ willingness to use artificial intelligence service agents. J Hosp Mark Manag (2):1–23. https://doi.org/10.1080/19368623.2021.1926037

Cai K, Chen H, Ai W et al (2021) Feedback convolutional network for intelligent data fusion based on near-infrared collaborative IoT technology. IEEE Trans Industr Inform 99:1–1

Shariati M, Mafipour MS, Haido JH et al (2020) Identification of the most influencing parameters on the properties of corroded concrete beams using an adaptive neuro-fuzzy inference system (ANFIS). Steel Compos Struct 34(1):155–170

Shariati M, Mafipour MS, Mehrabi P et al (2020) Prediction of concrete strength in presence of furnace slag and fly ash using hybrid ANN-GA (artificial neural network-genetic algorithm). Smart Struct Syst 25(2):183–195

Trung NT, Shahgoli AF, Zandi Y et al (2019) Moment-rotation prediction of precast beam-to-column connections using extreme learning machine. Struct Eng Mech 70(5):639–647

Li HW, Xu BS, Lu GL, et al (2021). Multi-objective optimization of PEM fuel cell by coupled significant variables recognition, surrogate models and a multi-objective genetic algorithm. Energy Convers Manag, 236. https://doi.org/10.1016/J.ENCONMAN.2021.114063

Mishra A, Deb S (2019) Assembly sequence optimization using a flower pollination algorithm-based approach. J Intell Manuf 30(2):461–482

Ozmen O, Batbat T, Ozen T, et al (2018). Optimum assembly sequence planning system using discrete artificial bee colony algorithm. Math Prob Eng,(pt.4):1-14. https://doi.org/10.1155/2018/3407646

Rashid A, Faisae MF (2017) A hybrid ant-wolf algorithm to optimize assembly sequence planning problem. Assem Autom 37(2):238–248

Dehmer M, Emmert-Streib F, Shi YT (2017) Quantitative graph theory: a new branch of graph theory and network science. Inf Sci 418:575–580

Zhao HM, Cai JX, Fu B et al (2019) Research of assembly sequence planning of RV-E reducer. J Mech Trans 43(09):1–8

Hwai-En T, Chien-Cheng C, Lee S-C et al (2019) Hybrid bidirectional ant colony optimization (hybrid BACO): an algorithm for disassembly sequence planning. Eng Appl Artif Intell 83:45–56

Zhang XF, Yu G, Wang L et al (2015) Parallel disassembly sequence planning for complex products based on genetic algorithm. J Comput-Aid Desig Comput Grap 27(07):1327–1333

Liu XY, Wang JY, Liu EF et al (2019) Research on hierarchical assembly relation matrix for concurrent assembly planning. Hebei J Ind Sci Technol 36(03):176–182

Ju WJ, Wang XP, An LL (2020). A disassembly sequence planning method based on discrete cuckoo search algorithm. Modular machine tool & automatic manufacturing technique,(10):14-17+22. https://doi.org/10.13462/j.cnki.mmtamt.2020.10.004

Acknowledgements

The authors acknowledge the National Natural Science Foundation of China (Grant: 51705392).

Funding

This study was funded by National Natural Science Foundation of China (Grant: 51705392).

Author information

Authors and Affiliations

Contributions

Kou Xiaoxi: writing—original draft preparation, data curation, software, validation

Cao Yan: conceptualization, methodology, reviewing and editing

Qiao Hu: methodology, reviewing and editing

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection: New Intelligent Manufacturing Technologies through the Integration of Industry 4.0 and Advanced Manufacturing.

Rights and permissions

About this article

Cite this article

Kou, X., Cao, Y. & Qiao, H. A method for intelligently optimizing hierarchical assembly structure sequences by assembly hybrid G-diagram. Int J Adv Manuf Technol 122, 27–39 (2022). https://doi.org/10.1007/s00170-021-07951-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07951-1