Abstract

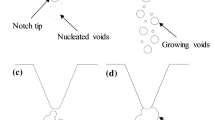

The Gurson–Tvergaard–Needleman damage model (GTN) describes the three stages of ductile tearing of steel: nucleation, growth and coalescence of micro-voids. This work is divided into two main parts. In the first part, based on the inverse analysis and the comparison between the experimental and numerical data, the parameters of the GTN damage model in conjunction with the hardening law are determined. The identification is broadened to include a considerable number of experimental tests drawn from our previous works and other works done at ALFAPIPE Ghardaia laboratory. In the second part, an Artificial Neural Network model is developed to predict the parameters of the (GTN) model coupled with the hardening law that goes through the prediction of traction and impact properties of API X70 steel pipe depending on its chemical composition. The weight of the chemical elements in percentages is considered as the inputs and the GTN parameters are considered as the outputs. In order to validate the obtained ANNGTN parameters, traction and impact tests are simulated. The numerical results are compared with the experimental ones and revealed that the developed model is very precise and has the potential to capture the interaction of GTN parameters coupled with hardening law and chemical composition of steel pipelines.

Graphic Abstract

Similar content being viewed by others

References

H. Klippel, M. Gerstgrasser, D. Smolenicki, E. Cadoni, H. Roelofs, P. Wegener, arXiv (2020). https://arxiv.org/abs/2007.14087

D. Madhusudhan, S. Chand, S. Ganesh, U. Saibhargavi, IOP Conf. Ser. Mat. Sci. 330, 012013 (2018)

A. Nazari, Comp. Mater. Sci. 51, 225 (2012)

K. Senthil, M.A. Iqbal, P. Bhargava, N.K. Gupta, Procedia Engineer. 173, 369 (2017)

X.L. Zhang, Y.M. Mi, T. Ji, H.X. Xu, Y.T. Xie, Y. Shen, Adv. Mater. Res. 97-101, 278 (2010)

V. Tvergaard, A. Needleman, Acta Metall. 32, 157 (1984)

A.L. Gurson, J. Eng. Mater. Technol. 99, 2–15 (1977)

V. Tvergaard, Int. J. Fracture 17, 389 (1981)

V. Tvergaard, Int. J. Fracture 18, 237 (1982)

J. Hancock, A. Mackenzie, J. Mech. Phys. Solids 24, 147 (1976)

E.J. Seo, L. Cho, Y. Estrin, B.C. De Cooman, Acta Mater. 113, 124 (2016)

L. Sharma, R. Chhibber, Int. J. Pres. Ves. Pip. 171, 51 (2019)

J. Lu, O. Omotoso, J.B. Wiskel, D.G. Ivey, H. Henein, Metall. Mater. Trans. A 43, 3043 (2012)

A. Saoudi, M. Fellah, A. Sedik, D. Lerari, F. Khamouli, L. Atoui, K. Bachari, Eng. Sci. Technol. 23, 452 (2020)

P.S. Bandyopadhyay, S. Kundu, S.K. Ghosh, S. Chatterjee, Metall. Mater. Trans. A 42, 1051 (2011)

W.W. Bose-Filho, A.L.M. Carvalho, M. Strangwood, Mater. Charact. 58, 29 (2007)

Y. Zou, Y.B. Xu, Z.P. Hu, X.L. Gu, F. Peng, X.D. Tan, S.Q. Chen, D.T. Han, R.D.K. Misra, G.D. Wang, Mater. Sci. Eng. A 675, 153 (2016)

B.K. Show, R. Veerababu, R. Balamuralikrishnan, G. Malakondaiah, Mater. Sci. Eng. A 527, 1595 (2010)

P. Gong, E.J. Palmiere, W.M. Rainforth, Acta Mater. 97, 392 (2015)

M.S. Mohebbi, M. Rezayat, M.H. Parsa, Š Nagy, M. Nosko, Mater. Sci. Eng. A 723, 194 (2018)

C. Wang, X. Wu, J. Liu, N. Xu, Mater. Sci. Eng. A 438–440, 267 (2006)

M. Asadipoor, J. Kadkhodapour, A.P. Anaraki, S.M.H. Sharifi, A.C. Darabi, A. Barnoush, Met. Mater. Int. https://doi.org/10.1007/s12540-020-00681-1

N. Amirjani, M. Ketabchi, M. Eskandari, M. Hizombor, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00841-3

T.-W. Hong, S.-I. Lee, J.-H. Shim, M.-G. Lee, J. Lee, B. Hwang, Met. Mater. Int. (2021). https://doi.org/10.1007/s12540-021-00982-z

A.F.A. El-Rehim, D.M. Habashy, H.Y. Zahran, H.N. Soliman, Met. Mater. Int. (2021). https://doi.org/10.1007/s12540-020-00940-1

L. Xue, Ductile fracture modeling : theory, experimental investigation and numerical verification, Ph.D. Thesis, Massachusetts Institute of Technology (2007). http://hdl.handle.net/1721.1/40876

A. Needleman, V. Tvergaard, Int. J. Fracture 101, 73 (2000)

M.H. Miloud, I. Zidane, M. Mendas, Frat. Integrità Strutt. 13, 630 (2019)

Abaqus, Analysis user’s manual, Version 6.12 (2012)

A. Gavrus, Identification automatique des paramètres rhéologiques par analyse inverse, Ph.D. Thesis, École Nationale Supérieure des Mines de Paris (1996)

S. Diot, D. Guines, A. Gavrus, E. Ragneau, J. Eng. Mater. Technol. 131, 011001 (2009)

M. Kuna, M. Springmann, in Fracture of Nano and Engineering Materials and Structures, ed. by E.E. Gdoutos (Springer, Berlin, 2006), pp. 535-536

M. Djouabi, A. Ati, P.-Y. Manach, Int. J. Damage Mech 28, 427 (2019)

B. Paermentier, R. Hojjati Talemi, Frat. Integrità Strutt. 52, 105 (2020)

Y. Ledoux, S. Samper, H. Favreliere, F. Formosa, E. Pairel, R. Arrieux, Arch. Civ Mech. Eng. 6, 5 (2006)

F. Abbassi, T. Belhadj, S. Mistou, A. Zghal, Mater. Design 45, 605 (2013)

D.J. Higham, N.J. Higham, MATLAB Guide, 3rd ed. (SIAM, Philadelphia, 2016)

S. Nanthakumar, T. Lahmer, X. Zhuang, G. Zi, T. Rabczuk, Inverse Probl. Sci. En. 24, 153 (2016)

M.O. Mbereick, O. Bouledroua, Z. Azari, M.H. Meliani, Revue Nature et Technologie 7, 27 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ouladbrahim, A., Belaidi, I., Khatir, S. et al. Prediction of Gurson Damage Model Parameters Coupled with Hardening Law Identification of Steel X70 Pipeline Using Neural Network. Met. Mater. Int. 28, 370–384 (2022). https://doi.org/10.1007/s12540-021-01024-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01024-4