Abstract

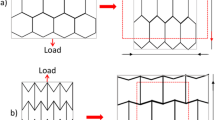

In this study, a kind of honeycomb-structured woven fabric was investigated and the effect of yarn size and fabric layer on the compression property of the fabric-reinforced polyurethane elastomer composites was discussed. The honeycomb-structured fabric was analyzed from the cross-sectional view of combined regular hexagonal cells. The three-layer fabric and four-layer fabric were designed and fabricated using three different finenesses of weft yarns. After that, polyurethane elastomer was used as matrix resin and the 3D honeycomb-structured fabrics were composited. In-plane compression test was conducted to investigate the cushioning property. For samples with doubled weft yarns, such as 3L-2W, the stress value when compressed to 65% of its initial thickness (CV65%), energy absorption (EA), and specific energy absorption (SEA) showed higher values than 3L-1W and 3L-1.5W. It was concluded that the weft yarn fineness had an important effect on the compression property of fabric composites. The thicker yarn size, the stronger cell wall, and the lightweight honeycomb-structure composite was difficult to be compressed. As to the fabric layers, three-layer composites showed a higher compression property than four-layer ones. The reason for this was considered to be the fiber volume content, which was the key parameter affecting composite mechanical properties. As the real fiber volume content in a three-layer fabric composite was higher than that of a four-layer fabric composite, it was resulted in a higher allowable safe stress and energy absorption ability. It can be concluded that the yarn fineness and fabric layers had an influence on the compression property, which can be seemed as the design parameters of honeycomb-structured fabrics for cushion applications.

Similar content being viewed by others

Data Availability Statements

The datasets generated during and/or analyzed during the current study are not publicly available due to the patent application but are available from the corresponding author on reasonable request.

References

Antony, S., Cherouat, A., Montay, G.: Fabrication and Characterization of Hemp Fibre Based 3D Printed Honeycomb Sandwich Structure by FDM Process. Appl Compos Mater. 27, 935–953 (2020)

Aminanda, Y., Castanié, B., Barrau, J.J., Thevenet, P.: Experimental Analysis and Modeling of the Crushing of Honeycomb Cores. Appl Compos Mater. 12, 213–227 (2005)

Chen, X.: Advances in 3D Textiles, 1st edn. Woodhead Publishing, Cambridge (2015)

Chen, X., Taylor, L.W., Tsai, L.-J.: An overview on fabrication of three-dimensional woven textile preforms for composites. Text Res J. 81, 932–944 (2011)

Khokar, N.: 3D-Weaving: Theory and Practice. J Text I(92), 193–207 (2001)

Tao, X.M., Xue, P., Yu, T.X.: New Development of Cellular Textile Composites for Energy-Absorption Applications. J Ind Text. 33, 15–31 (2003)

Lam, S.W., Tao, X.M., Yu, T.X.: Comparison of different thermoplastic cellular textile composites on their energy absorption capacity. Compos Sci Technol. 64, 2177–2184 (2004)

Chen, X., Wang, H.: Modelling and computer-aided design of 3D hollow woven reinforcement for composites. J Text I(97), 79–87 (2006)

Li, M., Wang, S., Zhang, Z., Wu, B.: Effect of Structure on the Mechanical Behaviors of Three-Dimensional Spacer Fabric Composites. Appl Compos Mater. 16, 1–14 (2008)

Neje, G., Behera, B.K.: Lateral Compressive Properties of Spacer Fabric Composites with Different Cell Shapes. Appl Compos Mater. 25, 725–734 (2018)

Zhu, C., Shi, J., Hayashi, K., Morikawa, H., Sakaguchi, A., Ni, Q.: Effect of design parameters on the cushioning property of cellular fabric composites. Text Res J. 89, 3692–3699 (2018)

Chen, X., Sun, Y., Gong, X.: Design, Manufacture, and Experimental Analysis of 3D Honeycomb Textile Composites Part I: Design and Manufacture. Text Res J. 78, 771–781 (2008)

Chen, X., Sun, Y., Gong, X.: Design, Manufacture, and Experimental Analysis of 3D Honeycomb Textile Composites, Part II: Experimental Analysis. Text Res J. 78, 1011–1021 (2008)

Tan, X., Chen, X.: Parameters affecting energy absorption and deformation in textile composite cellular structures. Mater Design. 26, 424–438 (2005)

Ufodike, C.O., Wang, H., Ahmed, M.F., Dolzyk, G., Jung, S.: Design and modeling of bamboo biomorphic structure for in-plane energy absorption improvement. Mater Design. 205, 109736 (2021)

Masters, I.G., Evans, K.E.: Models for the elastic deformation of honeycombs. Compos Struct. 35, 403–422 (1996)

Acknowledgements

This work was supported by JSPS KAKENHI (Grant number JP19K14032, JP20H00288).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, C., Mori, T., Miyamoto, T. et al. Compression Property of Three-dimensional Honeycomb-structured Fabric Composites. Appl Compos Mater 29, 373–385 (2022). https://doi.org/10.1007/s10443-021-09965-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09965-0