Abstract

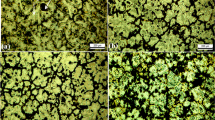

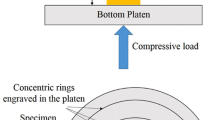

Increasing nanoparticle volume fraction has been proved to be effective in improving the strength of nanoparticle reinforced Al matrix nanocomposite. However, the underlying mechanisms for the ultrahigh strength of those nanocomposites with high volume fraction (> 10 vol.%) nanoparticles are short of experimental research. In this study, the strengthening mechanisms of high strength Al matrix nanocomposite reinforced with 15 vol.% Al2O3 nanoparticles were investigated experimentally and analyzed theoretically. The results show that the thermal mismatch induced geometrically necessary dislocations exhibit a negligible strengthening effect, because of their low density in the nanocomposite that is contradiction to the conventional dislocation punch model. Orowan mechanism makes a major strengthening contribution in view of the deformation process dominated by nanoparticle-dislocation interactions due to the extreme pinning effect of nanoparticles on dislocation motion. In addition, the several mechanisms including grain boundary strengthening, load transfer strengthening, and elastic modulus mismatch induced dislocation strengthening contribute to the strength increase.

Similar content being viewed by others

References

R. Geng, F. Qiu, Q.C. Jiang, Adv. Eng. Mater. 20, 1701089 (2018)

Z.H. Zhang, T. Topping, Y. Li, R. Vogt, Y.Z. Zhou, C. Haines, J. Paras, D. Kapoor, J.M. Schoenung, E.J. Lavernia, Scr. Mater. 65, 652 (2011)

M.J. Li, K.K. Ma, L. Jiang, H. Yang, E.J. Lavernia, L.M. Zhang, J.M. Schoenung, Mater. Sci. Eng. A 656, 241 (2016)

X. Yao, Z. Zhang, Y.F. Zheng, C. Kong, M.Z. Quadir, J.M. Liang, Y.H. Chen, P. Munroe, D.L. Zhang, J. Mater. Sci. Technol. 33, 1023 (2017)

D. Poirier, R.A.L. Drew, M.L. Trudeau, R. Gauvin, Mater. Sci. Eng. A 527, 7605 (2010)

J. Hemanth, Mater. Sci. Eng. A 507, 110 (2009)

A. Sanaty-Zadeh, Mater. Sci. Eng. A 531, 112 (2012)

A. Mazahery, H. Abdizadeh, H.R. Baharvandi, Mater. Sci. Eng. A 518, 61 (2009)

Y.C. Kang, S.L. Chan, Mater. Chem. Phys. 85, 438 (2004)

H. Su, W.L. Gao, Z.H. Feng, Z. Lu, Mater. Des. 36, 590 (2012)

A.B. Li, G.S. Wang, X.X. Zhang, Y.Q. Li, X. Gao, H. Sun, M.F. Qian, X.P. Cui, L. Geng, G.H. Fan, Mater. Sci. Eng. A 745, 10 (2019)

J.L. Liu, X.Y. Huang, K. Zhao, Z.W. Zhu, X.X. Zhu, L.N. An, J. Alloys Compd. 797, 1367 (2019)

L.N. An, J. Qu, J.S. Luo, Y. Fan, L.G. Zhang, J.L. Liu, C.Y. Xu, P.J. Blau, J. Mater. Res. 26, 2479 (2011)

L.Y. Chen, J.Y. Peng, J.Q. Xu, H. Choi, X.C. Li, Scr. Mater. 69, 634 (2013)

J.F. Guo, J. Liu, C.N. Sun, S. Maleksaeedi, G. Bi, M.J. Tan, J. Wei, Mater. Sci. Eng. A 602, 143 (2014)

J. Liu, Z. Chen, F.G. Zhang, G. Ji, M.L. Wang, Y. Ma, V. Ji, S.Y. Zhong, Y. Wu, H.W. Wang, Mater. Res. Lett. 6, 406 (2018)

Z. Zhang, D.L. Chen, Scr. Mater. 54, 1321 (2006)

T.C. Lin, C.Z. Cao, M. Sokoluk, L. Jiang, X. Wang, J.M. Schoenung, E.J. Lavernia, X.C. Li, Nat. Commun. 10, 4124 (2019)

S. Scudino, G. Liu, K.G. Prashanth, B. Bartusch, K.B. Surreddi, B.S. Murty, J. Eckert, Acta Mater. 57, 2029 (2009)

S. Scudino, G. Liu, M. Sakaliyska, K.B. Surreddi, J. Eckert, Acta Mater. 57, 4529 (2009)

M. Yuan, D.C. Zhang, C.G. Tan, Z.C. Luo, Y.F. Mao, J.G. Lin, Mater. Sci. Eng. A 590, 301 (2014)

C.S. Marchi, F. Cao, M. Kouzeli, A. Mortensen, Mater. Sci. Eng. A 337, 202 (2002)

M. Rahimian, N. Parvin, N. Ehsani, Mater. Sci. Eng. A 527, 1031 (2010)

M. Kouzeli, D.C. Dunand, Acta Mater. 51, 6105 (2003)

T. Sakamoto, S. Kukeya, H. Ohfuji, Mater. Sci. Eng. A 748, 428 (2019)

M.R. Mattli, P.R. Matli, A. Shakoor, A.M.A. Mohamed, Ceramics 2, 126 (2019)

B.Y. Cao, S.P. Joshi, K.T. Ramesh, Scr. Mater. 60, 619 (2009)

R.J. Arsenault, N. Shi, Mater. Sci. Eng. 81, 175 (1986)

D. Dunand, A. Mortensen, Mater. Sci. Eng. A 135, 179 (1991)

A.M. Redsten, E.M. Klier, A.M. Brown, D.C. Dunand, Mater. Sci. Eng. A 201, 88 (1995)

L. Jiang, H. Yang, J.K. Yee, X. Mo, T. Topping, E.J. Lavernia, J.M. Schoenung, Acta Mater. 103, 128 (2016)

L.H. Dai, Z. Ling, Y.L. Bai, Compos. Sci. Technol. 61, 1057 (2001)

Y.F. Liu, F. Wang, Y. Cao, J.F. Nie, H. Zhou, H.B. Yang, X.F. Liu, X.H. An, X.Z. Liao, Y.H. Zhao, Y.T. Zhu, Scr. Mater. 162, 316 (2019)

A. Kelly, R.B. Nicholson, Strengthening Methods in Crystals (Elsevier, Amsterdam, 1971), p. 9

Acknowledgements

This work was financially supported by the Key Research and Development Project in Sichuan Province (Grant No. 2020YFG0140), the Fundamental Research Funds for the Central Universities (Grant No. 2682020CX47), and the China Postdoctoral Science Foundation (Grant No. 2020M683349).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Zhao, K., Duan, Z., Liu, J. et al. Strengthening Mechanisms of 15 vol.% Al2O3 Nanoparticles Reinforced Aluminum Matrix Nanocomposite Fabricated by High Energy Ball Milling and Vacuum Hot Pressing. Acta Metall. Sin. (Engl. Lett.) 35, 915–921 (2022). https://doi.org/10.1007/s40195-021-01306-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01306-1