Abstract

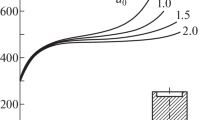

In this paper, methodological approaches to improving the accuracy of calculating the complex little-studied technological process of torsion forging based on computer simulation are provided. A method for setting the inverse problem for one of the known types of compression tests for aluminum alloy samples is presented. The results of simulation tests and their comparison with the data obtained during the experiments are presented. A compression test of solid cylindrical samples is considered. The scheme of realization of the inverse problem (inverse method) is presented. The results can be applied when preparing initial data at the stage of development or optimizing the technological process of torsion forging based on computer simulation in specialized programs, for example, the QFORM program.

Similar content being viewed by others

REFERENCES

Subich, V.N., Demin, V.A., Shestakov, N.A., and Vlasov, A.V., Shtampovka s krucheniem. Monografiya (Forging with Torsion), Moscow: MGIU, 2008.

Khvan, A.D., Strengthening of materials by reverse plastic shear, Izv. Tul. Gos. Univ., Tekh. Nauki, 2019, no. 5, pp. 114–120.

Petrov, P., Matveev, A., Kulikov, M., Stepanov, B., Petrov, M., Burlakov, I., and Dixit, U.Sh. Finite-element modelling of forging with torsion: Investigation of heat effect, Procedia Manuf., 2020, vol. 47, pp. 274–281. https://doi.org/10.1016/j.promfg.2020.04.221

Krivitskii, B.A., Investigation of strain heating of the sample under torsion testing, Kuznechno-Shtampovochnoe Proizvod.–Obrab. Mater. Davleniem, 2011, no. 6, pp. 36–37.

Sukhorukov, R.Yu., Simulation of technology for the production of axisymmetric parts for gas turbine engines made of heat resistant alloys by means of reeling under superplastic conditions, J. Mach. Manuf. Reliab., 2020, vol. 49, no. 2, pp. 150–158. https://doi.org/10.3103/S1052618820020132

Alisin, V.V. and Roshchin, M.N., Numerical analysis of heat flows in the process of laser melting of coatings, J. Mach. Manuf. Reliab., 2019, vol. 48, no. 4, pp. 361–367. https://doi.org/10.3103/S1052618819040046

Pietrzyk, M., Madej, L., Rauch, L., and Szeliga, D., Computational Materials Engineering: Achieving High Accuracy and Efficiency in Metals Processing Simulations, Amsterdam: Butterworth-Heinemann, 2015.

Bodunrin, M.O., Flow stress prediction using hyperbolic-sine Arrhenius constants optimised by simple generalised reduced gradient refinement, J. Mater. Res. Technol., 2020, vol. 9, no. 2, pp. 2376–2386. https://doi.org/10.1016/j.jmrt.2019.12.070

Voronkov, V.I., Potapenko, K.E., Petrov, P.A., and Vydumkina, S.V., Obtaining specified data on plastic deformation resistance of aluminum alloys AD35 and AD31 at hot forging, Aviatsionnye Mater. Tekhnol., 2017, no. 1, pp. 3–10. https://doi.org/10.18577/2071-9140-2017-0-1-3-10

Funding

This work is part of the joint Russian–Indian project “Experimental and Numerical Study of Contact Friction in the Process of Plastic Deformation by Compression with Torsion.” This work was supported by the Russian Foundation for Basic Research, project no. 19-58-45020\19, and the Department of Science and Technology, grant no. INT/RUS/RFBR/388.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by A. Ivanov

About this article

Cite this article

Petrov, P.A., Matveev, A.G., Saprykin, B.Y. et al. Increased Reliability of the Technological Torsion Forging Process for Products from Aluminum Alloys. J. Mach. Manuf. Reliab. 50, 324–331 (2021). https://doi.org/10.3103/S1052618821040117

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618821040117