Abstract

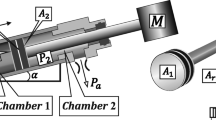

An electrohydraulic servo actuator is used as an example to show how numerical data on the parameters of the components and assembly units supplied to the assembly section allow control of the assembly process, its qualitative transformation, and refinement of the characteristics of finished products. The described approach to the arrangement of the assembly process may be applied to any product both to ensure that nondefective items are assembled in manufacturing components with apparently extended parameter tolerance ranges and to enhance the characteristics and reduce labor input in the adjustment of products.

Similar content being viewed by others

Notes

In the example considered here, the performer, a specialist who guides the assembly process, is not excluded from the control procedure and makes decisions based on the situation with assembling the current product batch. Later on, when the technology is mastered to a sufficient extent, the performer may be excluded from the control process by performing the actions recommended by the regulator.

REFERENCES

Sazanov, A.A., Improvement of efficiency of fabrication of fuel-injection nozzles of gas-turbine engines using functional-oriented assembly, Cand. Sci. (Eng.) Dissertation, Rybinsk: Rybinsk State Aviation Tech. Univ., 2014.

Smirnova, E.V., Development and study of adaptive-selective assembly technology for multielement infrared receivers, Cand. Sci. (Eng.) Dissertation, St. Petersburg: ITMO Univ., 2011.

Kannan, R. and Selladurai, V., Optimization of characteristic parameters of turbocharger assembly using GA, Manuf. Ind. Eng., 2011, no. 1, p. 39.

Bez"yazychnyi, V.F., Nepomiluev, V.V., and Semenov, A.N., Obespechenie kachestva izdelii pri sborke (Quality Assurance of Products at Assembly), Moscow: Spektr, 2012.

Nedaivoda, A.K., Tekhnologicheskie osnovy obespecheniya kachestva raketno-kosmicheskoi tekhniki (Technological Foundations of Quality Assurance in Rockets and Spacecraft), Moscow: Mashinostroenie, 1998.

Sorokin, M.N. and Anurov, Yu.N., Assemblability analysis of products of type shaft-plug at selective assembly, Sborka Mashinostr. Priborostr., 2012, no. 1, pp. 23–26.

Nepomiluev, V.V., Research of opportunities of improvement of product quality at assembly, Sborka Mashinostr. Priborostr., 2007, no. 10, pp. 9–13.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that there is no conflict of interest.

Additional information

Translated by M. Shmatikov

About this article

Cite this article

Medvedev, A.V., Zaramenskii, I.Y. & Khalatov, E.M. Control of Product Assembly Processes Using Data on the Parameters of Components and Assembly Units. J. Mach. Manuf. Reliab. 50, 351–356 (2021). https://doi.org/10.3103/S1052618821040087

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618821040087