Abstract

Grafting by pre-irradiation technique is rarely reported in recent literature. In this respect, natural rubber latex (NRL) films and its blends with potato starch (NRL/P.St) were prepared at various compositions using solution casting technique. Pre-irradiated NRL films with gamma radiation at doses from 30 to 100 kGy were grafted with hydrophilic monomers namely, acrylic acid (AAc) and acrylamide (AAm) to enhance NRL hydrophilicity. The grafted films of NRL and NRL/P.St blends were structurally and morphologically characterized by different techniques including FTIR spectroscopy and scanning electron microscopy (SEM). Hydrophilicity properties of grafted films were studied intensively through evaluating water absorption percentage of the grafted films. The water absorption study concluded that NRL and NRL/P.St blend films grafted with acrylamide have higher water affinity than those grafted with acrylic acid monomer. Enhancing the hydrophilicity of NRL and NRL/P.St blend films make it possible to study the biodegradability of the prepared films. Studying the effect of incubation time in soil on the weight loss of samples showed that the biodegradability of NRL-g-AAm and NRL/P.St (70/30)-g-AAm is higher than their counterparts grafted with AAc. The results showed that the microbial activity inside the specimens in the case of grafted NRL films with AAm monomer was accelerated in the first 10 days in soil burial test. Calculation of the weight loss and digital photographs of the films showed significant differences after 90 days of incubation in soil and the films grafted with AAm have higher weight loss than those grafted with AAc.

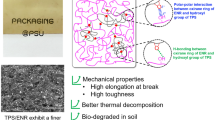

Graphic abstract

Similar content being viewed by others

References

Kurečič M, Majda SS, Karin SK (2012) UV polymerization of poly (N-isopropylacrylamide) hydrogel. Mater Tehnol 46:87–91

Wei F, Yu H, Zeng Z, Liu H, Wang Q, Wang J, Li S (2014) Preparation and structural characterization of hydroxylethyl methacrylate grafted natural rubber latex. Polimeros 24:283–290

Sirirat T, Vatanatham T, Hansupalak N, Rempel GL, and ArayapraneeW (2015) Kinetics and modeling of methyl methacrylate graft copolymerization in the presence of natural rubber latex. Kor J Chem Eng 32:980-992

Kangwansupamonkon W, Gilbert RG, Kiatkamjornwong S (2005) Modification of natural rubber by grafting with hydrophilic vinyl monomers. Macromol Chem Phys 206:2450–2460

Riyajan SA, Sasithornsonti Y, Phinyocheep P (2012) Green natural rubber-g-modified starch for controlling urea release. Carbohydr Polym 89:251–258

Floriano JF, Da Mota LSLS, Furtado EL, Rossetto VJV, Graeff CFO (2014) Biocompatibility studies of natural rubber latex from different tree clones and collection methods. J Mater Sci Mater Med 25:461–470

Roslim R, Hashim MYA, Augurio PT (2012) Natural latex foam. J. Eng Sci 8:15–27

Mohapatra S, Nando GB (2013) Chemical modification of natural rubber in the latex stage by grafting cardanol, a waste from the cashew industry and a renewable resource. Ind Eng Chem Res 52:5951–5957

Piyaauksornsak S, Paosawatyanyong B, Hinchiranan N (2010) Graft copolymerization of methyl methacrylate onto natural rubber by microwave irradiation. Adv Mater Res 93–94:39–42

Boondamnoen O, Rashid Azura A, Ohshima M, Chuayjuljit S, Ariffin A (2013) Effect of blend ratio and compatibilizer on solution casted treated waste natural rubber latex/polystyrene blends. Songklanakarin J Sci Technol 35:547–555

Johns J, Rao V (2008) Characterization of natural rubber latex/chitosan blends. Int J Polym Anal Charact 13:280–291

Carvalho AJF, Job AE, Alves N, CurveloaAAS GA (2003) Thermoplastic starch/natural rubber blends. Carbohydr Polym 53:95–99

Vudjung C, Chaisuwan U, Pangan U, Chaipugdee N, Boonyod S, Santawitee O, Saengsuwan S (2014) Effect of natural rubber contents on biodegradation and water absorption of interpenetrating polymer network (IPN) hydrogel from natural rubber and cassava starch. Energy Procedia 56:255-263

Vudjung C, Saengsuwan S (2017) Synthesis and properties of biodegradable hydrogels based on cross-linked natural rubber and cassava starch. J Elastomers Plast 49:574–594

Nguyen TN, Duy HN, Anh DT, Thi TN, Nguyen TH, Van NN, Quang TT, Huy TN, Thi TT (2020) Improvement of thermal and mechanical properties of vietnam deproteinized natural rubber via graft copolymerization with methyl methacrylate. Int J Polym Sci 14:2020

Jayathilaka LPI, Ariyadasa TU, Egodage SM (2020) Development of biodegradable natural rubber latex composites by employing corn derivative bio-fillers. J Appl Polym Sci 137:1–15

Dorati R, Colonna C, Serra M, Genta I, Modena T, Pavanetto F, Perugini P, Conti B (2008) γ-Irradiation of PEGd, lPLA and PEG-PLGA multiblock copolymers: I. effect of irradiation doses. AAPS PharmSciTech 9:718–725

Brunella V, Paganini MC (2015) EPR study of the relationship between ultra high molecular weight polyethylene structure and radicals formed during irradiation with high energy sources. Magn Reson Chem 53:194–199

Kadir ZA, Yoshii F, Makuuchi K, Ishigaki I (1990) Durability of radiation-sterilized polymers: XIII. The effects of nucleating agent on the oxidative degradation of poly(propylene-co-ethylene). Die Angew Makromol Chemie 174:131–140

Forster AL, Tsinas Z, Al-Sheikhly M (2019) Effect of irradiation and detection of long-lived polyenyl radicals in highly crystalline ultra-high molar mass polyethylene (UHMMPE) fibers. Polymers 11:924

Riyajan S (2012) Acrylic acid grafting on natural rubber and epoxidized natural rubber sheet by uv-irradiation. KGK, Kaut Gummi Kunstst 65:51–55

Taghizadeh MT, Khosravy M (2003) Kinetics and mechanism of graft copolymerization of vinyl monomers (acrylamide, acrylic acid, and methacrylate) onto starch by potassium dichromate as redox initiator. Iran Polym J 12:497–505

Gautam J, Pal MK, Singh B, Bhatnagar U (2011) Thermal and electrical properties of acrylic acid grafted onto starch by ceric ammonium nitrate and potassium permanganate initiator. Int J Plast Technol 15:188–198

Palacios O, Aliev R, Burillo G (2003) Radiation graft copolymerization of acrylic acid and N-isopropylacrylamide from binary mixtures. Polym Bull 197:191–197

Wongthep W, Ruksakulpiwat C, Amnuaypanich S (2010) Membranes prepared from a blend of poly(acrylic acid) and natural rubber-graft-poly(vinyl alcohol) (PAA/NR-g-PVA). Adv Mater Res 93–94:268–271

Van Tran V, Park D, Lee YC (2018) Hydrogel applications for adsorption of contaminants in water and wastewater treatment. Environ Sci Pollut Res 25:24569–24599

Sabnam T, Monir B, Afroz S, Khan RA , Miah MY, Takafuji M, Ashraful Alam Md (2019) pH-Sensitive hydrogel from polyethylene oxide and acrylic acid by gamma radiation.J Compos Sci 3:58–70

Dweik H, Sultan W, Sowwan M, Makharza S (2008) Analysis characterization and some properties of polyacrylamide copper complexes. Int J Polym Mater 57:228–244

Cesar MB, Borges FA, Bilck AP, Yamashita F, Paulino CG, Herculano RD (2020) Development and characterization of natural rubber latex and polylactic acid membranes for biomedical application. J Polym Environ 28:220–230

Ngo TD, Le TMH, Nguyen TH, Nguyen TV, Nguyen TA, Le TL, Nguyen TT, Van TTV, Le Thi BT, Doan NH (2016) Antibacterial nanocomposites based on Fe3O4–Ag hybrid nanoparticles and natural rubber-polyethylene blends. Int J Polym Sci 24:2016

Erizal (2012) Synthesis of poly(acrylamide-co-acrylic acid)-starch based superabsorbent hydrogels by gamma radiation: study its swelling behavior. Indones J Chem 12:113-118

Sareena C, Sreejith MP, Ramesan MT, Purushothaman E (2014) Biodegradation behaviour of natural rubber composites reinforced with natural resource fillers:monitoring by soil burial test. J Reinf Plast Compos 33:412–429

Afiq MM, Rashid AA (2013) Utilization of starch to accelerate the growth of degrading microorganisms on the surface of natural rubber latex films. J Chem Chem Eng 7:137–144

Iskandar S (2011) Graft copolymerization of methyl methacrylate monomer onto starch and natural rubber latex initiated by gamma irradiation. Atom Indones 37:24–28

Raju G, Mas Haris MRH, Azura AR, Ahmed Mohamed Eid AM (2020) Chitosan epoxidized natural rubber biocomposites for sorption and biodegradability studies. ACS Omega 5:28760–28766

Daud S, Ismail H, Abu Bakar A (2016) Soil burial study of palm kernel shell-filled natural rubber composites: the effect of filler loading and presence of silane coupling agent. BioResources 11:8686–8702

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahmoud, M.M., Fadl, F.I.A.E., Mohamed, M.A. et al. Improvement of hydrophilicity of Natural Rubber Latex/Potato-Starch blend by grafting with hydrophilic monomers. Iran Polym J 30, 1273–1284 (2021). https://doi.org/10.1007/s13726-021-00974-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00974-1