Abstract

Tocopherols are a mixture of antioxidants which are commonly referred to as vitamin E. Tocopheramines differ from tocopherols by an amino function in lieu of the phenolic OH group. They are potent antioxidants which are used in biomedical scenarios as well as stabilizers for polymers against aging. While in aqueous media α-tocopheramine is mainly oxidized to α-tocopherylquinone and N-oxidized by-products, oxidation in apolar media or in polymeric matrices mainly leads to dimeric compounds of hitherto unknown structure. In the present study, we synthesized the whole array of N,N-dimerization product of α-tocopheramine, including the hydrazo, azo, and azoxy derivatives for the first time, and provided comprehensive analytical data as well as general protocols to access the compounds in straightforward syntheses. These results can now be used to identify the common oxidation by-products of α -tocopheramine in different reaction systems.

Graphic abstract

Similar content being viewed by others

Introduction

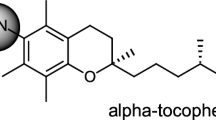

Tocopheramines can be regarded as amino derivatives of tocopherols, the class of bioactive compounds usually summarized as “vitamin E”. While tocopherols are phenolic antioxidants, the tocopheramines – synthetic compounds having otherwise the same structure – are distinguished by an amino group replacing the tocopherols´ phenolic OH group. As in the case of tocopherols, the α-homolog, i.e., the compound permethylated at positions 5, 7, and 8 of the aromatic ring, is by far the most common representative in the group [1, 2]. The tocopherols and tocopheramines share the properties of being fully biocompatible and non-toxic [2, 3] and of being excellent antioxidants. Having been reported first in 1942, α-tocopheramine (1) has led a life in the shadow of its big brother, α-tocopherol (2), which is produced and used on a large industrial scale [4], while such applications of tocopheramine are still hampered by the absence of a comparable large-scale access [5]. Still, tocopheramines have been the subject of extensive research due to their antioxidant properties, having been studied and evaluated as food and feed additives [6, 7] and polymer stabilizer [8, 9]. In the biomedical field, its promising anticancer and proapoptotic activities were studied [10,11,12,13] and the suitability to treat ophthalmological and reproduction disorders [14, 15]. In several cases, the tocopheramines were reported to behave superior to their phenolic counterparts [16,17,18] with regard to the studied bioactivities.

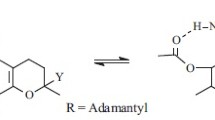

With regard to stabilization of polymers during processing, tocopherols have the drawback of poor miscibility with thermoplastic materials and phase separation, limiting extrudability and processing in melts in general. Tocopheramines are largely free from these disadvantages. With regard to application in the chemistry of renewable resources, their potential to stabilize mixtures of lignin and polylactic acid, cellulose suspensions for 3D-printing [19, 20] or cellulose dopes in fiber manufacture according to the lyocell process (cellulose solutions in a melt of N-methylmorpholine-N-oxide monohydrate at approx. 100 °C processing temperature) is notable [21, 22]. In this regard, it is also important that the oxidation stability of α-tocopheramine at elevated temperatures up to 150 °C by far exceeds that of tocopherols. In response to the increasing demand that follows from these beneficial properties, we are currently working on a facile and green conversion of α-tocopherol into α-tocopheramine based on redox chemistry without involvement of transition metal catalysts and without solvents that would be regarded environmentally incompatible.

Oxidation of 1 in aqueous media generates para-tocopherylquinone (3) as the main product [23, 24], which is not formed directly but via a para-quinone imine which is immediately hydrolyzed under release of NH3 [11, 18] (Scheme 1). This reaction is always accompanied by the formation of several N-oxidation products, such as hydroxylamino (4), nitroso (5), and nitro (6) derivative, Scheme 1. The structure of these N-oxidized by-products has been elucidated in a recent work which provided comprehensive analytical data to support their identification in different systems [25]. The oxidation chemistry of α-tocopherol is rather straightforward by comparison, leading quantitatively to quinone 3 when oxidized in aqueous media, largely independent of the oxidant used. In aprotic media, the products are derived from the intermediate 5a-ortho-quinone methide (7)[26, 27] which immediately undergoes a hetero Diels–Alder reaction with inverse electron demand to the spiro-dimer of α-tocopherol (8) [28, 29] as the main oxidation product, Scheme 1. The formation of these main oxidation products is quite general, while other by-products are obtained only under special conditions or with special coreactants.

Research on the reactions of tocopheramines in non-aqueous media, trying to simulate the conditions either in lipophilic cell compartments or in polymeric matrices, has addressed the interaction with different radicals and stated the occurrence of EPR-detectable, rather stable nitroxide radical intermediates [30], but the final oxidation products have not been identified. Apart from a report on a nitroxide radical with a well-resolved EPR spectrum [31], and a UV/Vis-active by-product of red color [32,33,34], none of the oxidation products of α-tocopheramine in non-aqueous media have been characterized, although the identification of these oxidation products would obviously be an important prerequisite for the wider usage of this antioxidant as polymer stabilizers.

In this account, we communicate the identification of all N-coupled, dimeric derivatives of α-tocopheramine, the synthesis of authentic samples in the 100 mg/1 g scale according to procedures compatible with green chemistry principles, and comprehensive analytical data to facilitate identification by compound comparison in unknown reaction mixtures in future studies.

Results and discussion

Generally, N–N-coupled oxidation products of aromatic amines can be hydrazo (–NH–NH–), azo (–N = N–), or azoxy (–N+(O−) = N–) derivatives. Our attempts to synthesize the hydrazo (9), azo (10), and azoxy (11) derivatives of α -tocopheramine generally aimed at high-yield procedures that would afford compounds without the need of chromatographic purification and without involvement of more demanding synthesis techniques or hazardous reagents, so that the protocols would be applicable also in laboratories not especially equipped for organic synthesis. However, conventional oxidants and conditions always provided a complex mixture of at least four main components and lots of minor degradation products (GC/MS). Another self-imposed restriction concerned the preference of conditions compatible with the green chemistry principles, which meant avoiding environmentally malign auxiliaries, solvents (e.g., [35,36,37]) and transition metal catalysts (e.g., [38, 39]) as far as possible.

With increasing amounts of water being present, the para-tocopherylquinone (3) became more dominant, which excluded aqueous phase transfer systems as options. Interestingly, the yields of 3, as a function of the water content, were quite independent of the oxidant used, which allows approximating the para-quinone yield from 1 for any aqueous oxidation system, Scheme 1. Already at water contents of 5% in a binary solvent system, the yields of 3 exceeded 80%; at 20% water, it became nearly quantitative.

Initial tests thus started with non-aqueous systems and oxidants known either in tocopherol chemistry or for the production of N–N-coupled derivatives from aromatic amines. More than 16 different oxidants in combination with different solvents, concentrations, and reaction temperatures were tested in a screening system. The oxidants included hydrogen peroxide and its complexes (percarbonate, urea complex, perborate), organic and inorganic peracids, organic (DDQ, NMMO) and inorganic oxidants (permanganate, periodate, K3[Fe(CN)6], ClO2, CeIV and PbIV salts). General problems occurred when solubilization of (inorganic) reagents required the presence of at least some water, which inevitably rendered the para-quinone 3 the dominant product. Generally, all three of the target compounds were formed as a mixture, mostly azoxy and azo compound as the main components with some hydrazo component being present or the azo/hydrazo couple accompanied by some azoxy by-product. There were two interesting exceptions: K3[Fe(CN)6], under phase transfer conditions with n-heptane, afforded approximately 28% of azo-tocopherol (10) without any azoxy or hydrazo accompaniments, besides 72% of quinone 3. Ozone in dichloromethane gave a quite remarkable result by providing azoxy-tocopherol (11) in very good 92% yield. However, ozonation conditions were regarded as too specialized to be generally applicable in laboratories concerned with biomedical and polymer stabilization studies, the main application fields of tocopheramines.

Our studies on ozone regeneration of spent periodate [40] in combination with periodate oxidation of cellulosic materials [41, 42] led us to the observation that also tetrabutylammonium periodate is able to oxidize 1 selectively to the azoxy compound 11. Optimization of the reaction conditions succeeded in terms of a quantitative yield when working in chloroform and with a fivefold molar excess of the oxidant at room temperature. Notably, no nitroso (5) or nitro (6) by-products were observed. However, the use of the halogenated solvents as well as the ecotoxic quaternary ammonium salts was considered disadvantageous. In a previous work, we had encountered examples that in non-aqueous solvent systems quaternary ammonium salts of halides and permanganate can be replaced by conventional sodium or potassium salts that were finely dispersed on alumina without significant losses in reactivity [43, 44]. Fortunately, this proved to be true also in the periodate case: a concentrated aqueous sodium periodate solution was used to impregnate neutral alumina (Brockmann grade 3), which after freeze-drying and cryomilling provided 20% NaIO4@Al2O3 as white, free-flowing powder. Using a tenfold molar excess of this oxidant in 1,4-dioxane at r.t. provided azoxy-tocopherol (11) in quantitative yield (Scheme 2), eliminating the need for subsequent purification steps. The oxidant and solvent were simply removable by filtration and evaporation, respectively.

Two reasonable mechanisms can be proposed for this process, the first one involving the direct reaction between the intermediately formed nitroso (5) and hydroxylamine (4) derivatives. When these two compounds were mixed under otherwise identical conditions, 5-nitrotocopherol (6, 65%) and azoxy-tocopherol (11, 34%) were the main products. When neutral alumina – without adsorbed periodate – was used, the azoxy compound 11 was obtained in 48% besides unreacted starting material, but notably without nitro derivative formation. The second mechanistic option, the direct oxidation of α-tocopheramine (1) to azoxy-tocopherol (11), was more likely, which would involve a stepwise process proceeding via the intermediate stages of hydrazo-tocopherol (9) and azo-tocopherol (10). Both 9 and 10, when employed as the starting material instead of 1 under otherwise identical conditions, gave quantitative yields of azoxy compound 11, which supported the direct oxidation mechanism. Apparently, the oxidation of 1 was the slowest step. Only traces of hydrazo and azo compound were found when 1 was used in excess relative to the oxidant, implying that intermediates, once formed, were faster converted to the azoxy compound 11 than the remaining unreacted 1 was oxidized.

Since we did not find a direct way to quantitatively prepare hydrazo-tocopherol and azo-tocopherol from 1, we resorted to the “detour” via the azoxy derivative 11 as the starting material, because it became accessible in gram quantities according to the above one-pot synthesis. The reductive conversion of azoxy-benzenes proceeds generally to the azo compound, then further to the hydrazo compound and, eventually, under N–N cleavage, to the amines. The difficulty in the present case consisted in finding reductants and conditions that allowed a sharp separation between individual stages, considering the general oxidative lability of the tocopherol system. After extensive screening, a quantitative deoxygenation of azoxy-tocopherol (11) to azo-tocopherol (10) without any overreduction to the hydrazo stage (or even the amine) was achieved by finely powdered sodium hypophosphite at room temperature (Scheme 2). The same solvent as that employed for the synthesis of azoxy-tocopherol, 1,4-dioxane, was usable so that the whole sequence from α-tocopheramine (1) to azo-tocopherol was feasible as a one-pot procedure. Short reaction times of 5 min were sufficient at a tenfold NaH2PO2 excess and temperatures around 0 °C. At higher temperatures, the formation of the hydrazo by-product 9 set in and increased with reaction time and temperature: 7%, 12%, and 27% at r.t., 40 °C, and 60 °C, respectively, at a tenfold oxidant excess.

The reduction of the azoxy compound can make use of stronger reductants when the azo step is skipped and the hydrazo compound is targeted directly. However, reduction under acidic conditions (metals and acids) was too drastic so that N–N cleavage occurred and the tocopheramine was regenerated as the main product. Also reductions with LiAlH4, although milder and non-acidic, were always accompanied by amine formation, even at low temperatures (− 78 °C). Sodium borohydride gave superior results, and optimization of the conditions showed a 5:1 (v/v) solvent mixture of 1,4-dioxane and 2-propanol at room temperature to be optimal (Scheme 2). The reductant was added to the azoxy-tocopherol (11) in 2-propanol such that the resulting solvent ratio was 5:1. Room temperature was sufficient to achieve completion of the reaction within 2 h; the temperature can be increased up to 60 °C without the danger of by-product formation. The yield of ditocopherylhydrazine (9) was quantitative, so that purification of the product by chromatography was not necessary.

All three N–N-coupled tocopherol derivatives are completely stable when stored under an inert gas in the dark; no chemical changes have been detected after storage for more than 8 months. The same is true for degassed (oxygen-free) solutions in n-hexane or 1,4-dioxane. When stored under air, azo-tocopherol (10) appeared to be indefinitely stable, while ditocopherylhydrazine (9) and azoxy-tocopherol (11) showed signs of degradation (dark discoloration) after a few days, although the decomposition products were not further studied.

NMR data and complete 1H and 13C resonance assignments of compounds 9–11, in comparison to the starting amine 1, are summarized in Table 1. The effects of the different N–N-moieties in position 6 of the chroman skeleton are smaller than in the case of the monomeric nitro, nitroso, and hydroxylamine derivatives [25]. The hydrazino (9) and azo (10) derivatives are symmetric and the two tocopherol “halves” are equivalent and show only one set of resonances, while they become distinguishable in the non-symmetric azoxy derivative 11. The change of the N-oxidation state has minor effects on the shifts of the protons and carbons of the aromatic methyl groups, which – by analogy to tocopherols – are most pronounced for C-5a, followed by C-7a and C-8b. The largest effect is seen for C-5a on the N-oxygenated side of azoxy-tocopherol (11), with an 1H/13C shift of 2.19/17.4 ppm. Azo-tocopherol (10) and azoxy-tocopherol (11) show a significant down-field shift of about 6 ppm for C-6 and C-8a in the 13C domain, and of about 4 ppm for the two ortho-positions C-5 and C-7a, which are not seen for the hydrazino compound 9. In general, the shifts of the hydrazo compound are close to those of the starting amine, and also the shift differences between the corresponding nuclei of azo-tocopherol (10) and the non-N-oxygenated tocopherol side in 11 are minor.

Azo-tocopherol (10) must be assumed to occur in the trans-configuration only since the cis-form would suffer too severe steric repulsion between the aromatic methyl groups to render the compound stable. Molecular modeling on the DFT level of theory (B3LYP, 6-31G*) predicts a dihedral angle of only 154.3° for the hypothetical cis-azo-tocopherol, compared to the dihedral angle of 173.5° for cis-azobenzene [45, 46]. Illumination of the red 1 mM chloroform solution with UV light (320–380 nm) caused no color change and no spectral changes (1H NMR), whereas 380 nm irradiation of the red trans-azobenzene causes isomerization into the metastable, orange cis-counterpart. For the same steric reasons, we have to assume that the two tocopherol moieties in azoxy-tocopherol (11) are trans-configured, so that – from the perspective of formally correct nomenclature – compound 11 must be denoted as cis-azoxy-tocopherol.

While the high stability of azo-tocopherol (10) toward acids (1 mM up to 10 M H2SO4) was to be expected from the behavior of its parent azobenzene, it should be mentioned that also ditocopherylhydrazine (9) was stable toward acids, without any sign of undergoing benzidine rearrangements typical of phenylhydrazines [47]. Also, azoxy-tocopherol (11) was insensitive toward acids, whereas azoxy-benzenes readily undergo Wallach rearrangements [48].

Interestingly, in aqueous medium the reduction of azo-tocopherol (10) proceeded already under very mild, nearly physiological conditions, albeit rather slowly, with the only product being the hydrazo compound 9. Treatment of a 0.01 M solution of 10 at pH 6 with 10 equivalents of ascorbate (or at pH 7 with the same excess of sodium sulfite) showed complete conversion to 9 without any formation of by-products after 14 h and 36 h, respectively. Such a reaction behavior, well known from tocopherol chemistry [43], was indicative of the involvement of intermediate ortho-quinoid structures which are quite easily reduced to the hydroquinone counterparts. To test this hypothesis, the reduction was carried out in D2O. The product, 5a-monodeutero-hydrazo-tocopherol (9-D), proved incorporation of one D at one of the two 5a-CH3 groups, showing a triplet at 14.4 ppm (JC,D = 22 Hz) in 13C NMR, together with a small isotopic shift of 0.2 ppm in comparison to the non-deuterated 5a-methyl group (14.2 ppm), Table 1. This deuteration was highly regioselective – the higher reactivity of the 5a-methyl group in α-tocopherol derivatives compared to the fellow methyl groups at C-7a and C-8b is a fundamental phenomenon in tocopherol chemistry and accounted for by the theory of strain-induced bond localization (SIBL) [27, 44] – and it occurred only at one of the two 5a-methyls, in agreement with the mechanism shown in Scheme 3.

The syntheses in Scheme 2 were repeated with the truncated model compound 1a, in which the isoprenoid C16H33 side chain is replaced by a methyl group. It is the amine counterpart of the common α-tocopherol model compound 2,2,5,7,8-pentamethylchroman-6-ol [49]. Compound 1a was available from previous work [50] as the 15 N-isotopically labeled derivative. The N–N-coupled hydrazino-, azo-, and azoxy derivatives (9a, 10a, and 11a respectively) were characterized by 15 N NMR [51], Scheme 4. The shifts fell in the expectable ranges, confirming the NMR data of the non-truncated compounds in the 1H and 13C domain (Table 1). While the two nitrogen atoms in the hydrazino (9a) and azo compound (10a) were magnetically equivalent, they were distinguishable in the azoxy derivative (11a). The large downfield shift for the azo compound and the smaller effect for the azoxy group can be readily understood if the groupings are thought of as heteroanalogous ene/enol or carbonyl/carboxyl moieties.

Conclusion

In the present study, we have described the synthesis of the N–N-coupled oxidation products of α-tocopheramine (1) which frequently occur as products when this compound is used as stabilizer and antioxidant for polymer melts or in fiber processing. Care was taken to optimize protocols in a way that can be readily repeated and utilized also in laboratories not specialized in organic synthesis, without the need of chromatographic purifications. This will ensure that the compounds can be widely used as standards for compound identification. Together with the previously reported monomeric hydroxylamino (4), nitroso (5), and nitro (6) derivatives, the dimeric hydrazino (9), azo (10), and azoxy (11) derivatives reported in this study now complete the set of all N-oxidation products of α-tocopheramine (1). This can also be visualized by means of formal oxidation numbers for the nitrogen in the order of increasing oxidation: tocopheramine (–3) →hydrazino (–2/–2) → azo (–1/–1) → hydroxylamino (–1) → azoxy (–1/ + 1) → nitroso (+ 1) → nitro (+ 3) derivative. Nitroxide-type radical species directly derived from α-tocopheramine are highly unstable [11], in contrast to the nitroxide derived from N-methyl- α-tocopheramine, and the N-oxide derived from the corresponding N,N-dimethyl derivative. The chemistry of these compounds will be covered in an upcoming report.

Experimental

All chemicals were of the highest purity available and used without further purification. HPLC-grade solvents were used for all non-aqueous steps, including extractions and workup procedures. Bidistilled water was used for all aqueous solutions, extractions and washing steps. 1,4-Dioxane, n-heptane, ethyl acetate, and toluene used in chromatography were distilled before use. α-Tocopheramine (1) was of the [R,R,R]-type; however, the maintenance of stereochemical integrity over the reactions performed was not further checked.

TLC was performed using Merck silica gel 60 F254 pre-coated plates and flash chromatography on Baker silica gel (40 µm particle size). All products were purified to homogeneity by TLC/GC analysis; yields refer to isolated, pure products with satisfying elemental analysis data (± 0.2%). Elemental analyses were performed at the Microanalytical Laboratory of the University of Vienna. The melting points are corrected (benzophenone 48–49 °C, benzoic acid 122–123 °C), determined on a Kofler-type micro hot stage with Reichert-Biovar microscope.

1H NMR spectra were recorded at 300.13 MHz for 1H, 75.47 MHz for 13C, and 30.40 MHz for 15 N NMR in CDCl3 if not otherwise stated. Chemical shifts, relative to TMS as internal standard, are given in δ values, coupling constants in Hz. 13C peaks were assigned by means of APT, HMQC, and HMBC spectra, with “d.i.” denoting peaks with double intensity. The nomenclature and atom numbering of tocopherols and chromanols as recommended by IUPAC were used throughout [52, 53]. 1H and 13C NMR resonances of the isoprenoid side chain of tocopherols are only insignificantly influenced (∆ < 0.05 ppm) by modifications of the chroman ring [54, 55] and are thus listed only once: δ = 19.7 (C-4a’), 19.8 (C-8a’), 21.2 (C-2’), 22.7 (C-13’), 22.8 (C-12a’), 24.6 (C-6’), 24.8 (C-10’), 28.0 (C-12’), 32.6 (C-8’), 32.8 (C-4’), 37.3 (C-7’), 37.4 (C-9’), 37.5 (C-5’), 37.5 (C-3’), 39.3 (C-11’), 39.9 (C-1’) ppm. The analytical data [2] and NMR data [5] for α-tocopheramine (1) were in agreement with the literature, as well as the data for the 15 N-labeled model compound 1a [50].

6-[(Z)-(R )-2-[(4 R ,8 R )-4,8,12-Trimethyltridecyl]-2,5,7,8-tetramethyl-6-chromanyl-azoxy]- (R)- 2-[(4 R, 8 R )-4,8,12-trimethyltridecyl]-2,5,7,8-tetramethylchroman (azoxy-(6-desoxy-tocopherol), “azoxy-tocopherol”, 11, C 58 H 98 N 2 O 3 )

Sodium periodate (21.4 g, 100 mmol) was dissolved in as little water as possible at r.t. The solution was added dropwise to a suspension of 85.6 g of neutral alumina (Brockmann grade 1, 150 mesh) in 500 cm3 of dry methanol. The solution was evaporated in vacuo, taking care that the temperature did not exceed 40 °C (degradation of the periodate) and the remainder freeze-dried overnight and cryomilled for 10 min to provide periodate@Al2O3 (20%) a white, free-flowing powder.

[R,R,R]-α-Tocopheramine (1, 0.43 g, 1.00 mmol) was dissolved in 100 cm3 of freshly distilled 1,4-dioxane and the periodate@Al2O3 oxidant (20%, 5.25 g, 5 eq.) was added. The mixture was stirred vigorously for 2 h at r.t., and the color of the mixture changed to bright orange. Solids were removed by filtration and washed with 1,4-dioxane (2 × 50 cm3). The organic phases were combined and the solvent was removed under reduced pressure to afford 11 as a waxy, orange solid (0.43 g, 98%). The synthesis was repeated several times to afford sufficient starting material for compounds 9 and 10. M.p.: 48–49 °C; Rf (toluene) = 0.50; 1H NMR and 13C NMR: Table 1; HRMS: m/z = 870.7590 (calcd. 870.7572); [α]D20 = + 27.0° cm2 g−1 (c = 1, ethanol); UV–Vis (1,4-dioxane, c = 10 µM): λmax = 262, 294, 448 nm.

1,2-Bis[( R )-2-[(4 R ,8 R )-4,8,12-trimethyltridecyl]-2,5,7,8-tetramethyl-6-chromanyl]hydrazine ( N,N ´-di(6-desoxy-6-tocopheryl)hydrazine, “ditocopherylhydrazine”, 9, C 58 H 100 N 2 O 2 )

A solution of azoxy-tocopherol (11, 0.5 mmol) in 100 cm3 of 1,4-dioxane as obtained according to the above protocol was reduced to a volume of 25 cm3. A suspension of 0.038 g of fresh sodium borohydride (1 mmol) in 5 cm3 of 2-propanol was added at once and the mixture stirred for 2 h at r.t. Acetone (2 cm3) was added and the stirring continued for 30 min at r.t. and 10 min at 50 °C. The mixture was cooled to r.t., filtered through a layer of celite (washing with 10 cm3 of 1,4-dioxane) and the solvent was removed under reduced pressure to afford 0.42 g (98%) of 9 as a colorless wax. Rf (toluene) = 0.44; 1H NMR and 13C NMR, Table 1; HRMS: m/z = 856.7772 (calcd. 856.7780); [α]D20 = + 12.7° cm2 g−1 (c = 1, ethanol); UV–Vis (1,4-dioxane, c = 1 mM): λmax = 289 nm.

Data of the 5a-monodeuterated compound 9-D: NMR: Table 1, JC,D = 22 Hz; HRMS: m/z = 857.7848 (calcd. 857.7842).

6-[( E )-( R )-2-[(4 R ,8 R )-4,8,12-Trimethyltridecyl]-2,5,7,8-tetramethyl-6-chromanylazo]-( R )-2-[(4 R, 8 R )-4,8,12-trimethyltridecyl]-2,5,7,8-tetramethylchroman (azo-(6-desoxy-tocopherol), “azo-tocopherol”, 10, C 58 H 98 N 2 O 2 )

A solution of azoxy-tocopherol (11, 0.5 mmol) in 100 cm3 of 1,4-dioxane as obtained according to the above protocol was cooled to 0 °C in an ice bath. Freshly powdered sodium hypophosphite (sodium phosphate, 0.88 g, 10 mmol) was added at once. The solution turned colorless immediately. After vigorously stirring the mixture for 5 min, the solids were removed by filtration and washed with 1,4-dioxane (2 × 10 cm3). The organic phases were combined and the solvent was removed under reduced pressure to afford 10 as a deeply red solid (0.41 g, 96%). M.p.: 82–84 °C; Rf (toluene) = 0.68; 1H NMR and 13C NMR, Table 1; HRMS: m/z = 854.7630 (calcd. 854.7623); [α]D20 = + 114.9° cm2 g−1 (c = 1, ethanol); UV–Vis (1,4-dioxane, c = 10 µM): λmax = 268, 338, 474 nm.

6-[( Z )-2,2,5,7,8-Pentamethyl-6-chromanyl-( N , N '- 15 N 2 )-azoxy]-2,2,5,7,8-pentamethylchroman (11a, C 28 H 38 15 N 2 O 3 )

The procedure follows the above protocol for the preparation of 11, employing 0.44 g of model compound 1a (2 mmol) instead of the [R,R,R]-α-tocopheramine (1). Evaporation of the solvent in vacuo afforded a yellow-to-orange powder that was recrystallized twice from n-heptane to give 11a as an amorphous light orange solid (0.40 g, 92%). The synthesis was repeated several times to afford sufficient starting material for compounds 9a and 10a. M.p.: 128–129 °C; Rf (n-heptane/ethyl acetate, v/v = 10:1) = 0.39; HRMS: m/z = 452.2809 (calcd. 452.2823); 1H NMR: δ = 2.64 (4H, 4-CH2, 4´-CH2), 2.21 (s, 3H, 5a-CH3), 2.14 (s, 3H, 7a´-CH3), 2.12 (s, 3H, 5a´-CH3), 2.11 (s, 3H, 7a´-CH3), 2.09 (s, 6H, 8b-CH3, 8b´-CH3), 1.82 (t, br, 4H, 3-CH2, 3´-CH2), 1.35 (s, 12H, 2a-CH3) ppm; 13C NMR: δ = 152.9 (C-8a), 150.3 (C-8a´), 144.2 (d, C-6, JC,N = 3.2 Hz), 140.8 (d, C-6´, JC,N = 18.6 Hz), 124.8 (C-7), 123.8 (C-5), 123.0 (C-4a´), 121.6 (C-8), 121.4 (C-4a), 121.0 (C-7´), 120.2 (C-8´), 119.0 (C.5´), 74.3 (d.i., C-2), 32.2 (d.i., C-3), 27.8 (d.i., C-2a, d.i., C-2a´), 21.3/21.2 (C-4/C-4´), 17.2 (C-5a), 15.3 (C-7a), 13.3 (C-8b), 13.0 (C-5a´), 12.4 (C-7a´), 12.1 (C-8b´) ppm (atoms in the not N-oxygenated part are indicated by “´”); 15 N NMR: δ = –62.8/–50.5 ppm; EI-MS (70 eV): m/z (%) = 237 (MH+, 85), 236 (22), 219 (23), 203 (40), 182 (16), 181 (100), 179 (22), 164 (30), 163 (12), 91 (10), 77 (10).

1,2-Bis(2,2,5,7,8-pentamethyl-6-chromanyl)( N , N '- 15 N 2 )-hydrazine (9a, C 28 H 40 15 N 2 O 2 )

The procedure follows the above protocol for the preparation of 9, employing 0.45 g of model compound 11a (1.00 mmol) instead of azoxy derivative 11. Evaporation of the solvent in vacuo afforded a solid that was crystallized from n-heptane to afford 0.40 g (92%) of 9a as a glassy solid. M.p.: 72–74 °C; Rf (n-heptane/ethyl acetate, v/v = 10:1) = 0.28; HRMS: m/z = 438.3031 (calcd. 438.3030); 1H NMR: δ = 2.62 (2H, t, 3 J = 7.0 Hz, 4-CH2), 2.15 (s, 3H, 5a-CH3), 2.13 (s, 3H, 7a-CH3), 2.10 (s, 3H, 8b-CH3), 1.83 (t, 2H, 3 J = 6.80 Hz, 3-CH2), 1.34 (s, 6H, 2a-CH3) ppm; 13C NMR: δ = 146.0 (C-8a), 133.4 (C-6, d, C-6, JC,N = 26.4 Hz), 122.0 (C-4a), 120.3 (C-8), 116.2 (C-7), 115.5 (C-5), 74.2 (C-2), 32.9 (C-3), 27.3 (d.i., C-2a), 21.7 (C-4), 14.6 (C-5a), 13.2 (C-7a), 12.0 (C-8b) ppm; 15 N NMR: δ = –315.4 ppm.

6-[( E )-2,2,5,7,8-Pentamethyl-6-chromanyl- 15 N 2 -azo]-2,2,5,7,8-pentamethylchroman (10a, C 28 H 38 15 N 2 O 2 )

The procedure follows the above protocol for the preparation of 10, applying 0.45 g of model compound 11a (1.00 mmol) instead of azoxy derivative 11. Evaporation of the solvent in vacuo afforded an amorphous red solid that was recrystallized from n-heptane to give 10a (0.39 g, 89%, dark red columns). M.p.: 149–152 °C; Rf (n-heptane/ethyl acetate, v/v = 10:1) = 0.51; HRMS: m/z = 436.2881 (calcd. 436.2874); 1H NMR: δ = 2.60 (2H, “t”, 4-CH2), 2.20 (s, 3H, 5a-CH3), 2.14 (s, 3H, 7a-CH3), 2.12 (s, 3H, 8b-CH3), 1.80 (t, 2H, 3-CH2), 1.33 (s, 6H, 2a-CH3) ppm; 13C NMR: δ = 153.2 (C-8a), 141.4 (d, C-6, JC,N = 18.0 Hz), 122.3 (C-7), 122.0 (C-4a), 121.1 (C-5), 119.5 (C-8), 74.0 (C-2), 32.6 (C-3), 27.2 (C-2a), 22.5 (C-4), 15.8 (C-5a), 14.0 (C-7a), 12.2 (C-8b) ppm; 15 N NMR: δ = + 98.7 ppm.

References

Smith LI, Renfrow WB, Opie JW (1942) J Am Chem Soc 64:1082

Mayer H, Isler O (1971) Tocopheramines and tocopherthiols. In: Colowick SP, Kaplan NO (eds) Methods in enzymology. Academic Press, pp 275–334

Blomstrand R, Forsgren L (1968) Int J Vit Res 38:328

Preedy VR, Watson RR (2007) Encyclopedia of Vitamin E. CABI Publishing

Mazzini F, Netscher T, Salvadori P (2009) Eur J Org Chem 13:2063

Schlegel W, Schwieter U, Tamm R (1969) Non-toxic antioxidants, based on chromane derivatives. US Patent 3458637, Jul 29, 1969; (1968). Chem Abstr 69:21909

Søndergaard E, Dam H (1970) Zeitschr Ernährungswiss 10:71

Tokuwame M (1991) Synergistic antioxidant-heat stabilizer systems for polyolefins. JP Patent 03043458, Feb 25, 1991; (1991). Chem Abstr 115:73015

Rosenau T, Potthast A, Milacher W, Adorjan I, Hofinger A, Kosma P (2005) Cellulose 12:197

Tomic-Vatic A, Eytina J, Chapman J, Mahdavian E, Neuzil J, Salvatore BA (2005) Int J Cancer 117:188

Gille L, Stamberg W, Patel A, Böhmdorfer S, Rosenau T (2012) Free Rad Biol Med 53:100

Zingg JM (2007) Mini Rev Med Chem 7:545

Neuzil J, Tomasetti M, Zhao Y, Dong LF, Birringer M, Wang XF, Low P, Wu K, Salvatore BA, Ralph SJ (2007) Mol Pharmacol 71:1185

Tanito M, Yoshida Y, Kaidzu S, Chen ZH, Cynshi O, Jishage KI, Niki E, Ohira A (2007) Investig Ophthalm Visual Sci 48:396

Bieri JG, Mason KE (1968) J Nutr 96:192

Bieri JG, Prival EL (1967) Biochem and references cited therein. 6:2153

Itoh S, Nagaoka S, Mukai K, Ikesu S, Kaneko Y (1994) Lipids 29:799

Gruber J, Staniek K, Krewenka C, Moldzio R, Patel A, Böhmdorfer S, Rosenau T, Gille L (2014) Bioorg Med Chem 22:684

Mimini V, Sykacek E, Ain Syed Hashim SN, Holzweber J, Hettegger H, Fackler K, Potthast A, Mundigler N, Rosenau T (2019) J Wood Chem Technol 39:14

Xu C, Zhang B, Wang X, Cheng F, Xu W, Molino P, Bacher M, Su D, Rosenau T, Willför S, Wallace G (2018) J Mat Chem B 6:7066

Henniges U, Hasani M, Potthast A, Westman G, Rosenau T (2013) Materials 6(5):1584

Rosenau T, Potthast A, Kosma P, Chen CL, Gratzl JS (1999) J Org Chem 64:2166

Rüegg R, Mayer H, Schudel P, Schwieter U, Tamm R, Isler R (1967) Veröffentl Deut Ges Ernährung 16:22

Machlin LJ (1980) Vitamin E: a comprehensive treatise. Marcel Dekker Inc.

Patel A, Hofinger A, Rosenau T (2021). Monatsh Chem. https://doi.org/10.1007/s00706-021-02805-8

Rosenau T, Potthast A, Elder T, Kosma P (2002) Org Lett 4:4285

Rosenau T, Böhmdorfer S (2009) ortho-Quinone methides in tocopherol chemistry. In: Rokita S (ed) Wiley series on reactive intermediates in chemistry and biology, vol 1. Wiley, p 163

Schudel P, Mayer H, Metzger J, Rüegg R, Isler O (1963) Helv Chim Acta 46:636

Schröder H, Netscher T (2001) Magn Reson Chem 39:701

Bamonti L, Hosoya T, Pirker K, Böhmdorfer S, Mazzini F, Galli F, Netscher T, Rosenau T, Gille L (2013) Bioorg Med Chem 21:5039

Murphy PA, Lin JS, Olcott HS, Windle JJ (1976) Lipids 11:296

Boguth W, Hackel R (1965) Hoppe-Seyler Zeitschr Physiol Chem 342:172

Igarashi O (1977) J Nutr Sci Vitaminol 23:169

Quaife ML (1948) J Biol Chem 175:605

Das SS, Nath U, Deb D, Das PJ (2004) Synth Commun 34:2359

Gowenlock BG, Richter-Addo GB (2004) Chem Rev 104:3315

Vančik H (2013) Aromatic C-nitroso compounds. Springer

Nguyen THL, Gigant N, Delarue-Cochin S, Joseph D (2016) J Org Chem 81:1850

Seok WK, Meyer TJ (2004) Inorg Chem 43:5205

Koprivica S, Siller M, Hosoya T, Roggenstein W, Rosenau T, Potthast A (2016) Chemsuschem 9:825

Siller M, Amer H, Bacher M, Rosenau T, Potthast A (2015) Cellulose 22:2245

Potthast A, Kostic M, Schiehser S, Kosma P, Rosenau T (2007) Holzforschung 61:662

Patel A, Liebner F, Netscher T, Mereiter K, Rosenau T (2007) J Org Chem 72:6504

Rosenau T, Ebner G, Stanger A, Perl S, Nuri L (2005) Chem Eur J 11:280

Mostad A, Rømming C (1971) Acta Chem Scand 25:3561

Harada J, Ogawa K, Tomoda S (1997) Acta Crystallogr B 53:662

Mundy BP, Ellerd MG, Favaloro FG Jr (2005) Name reactions and reagents in organic synthesis, 2nd edn. John Wiley & Sons Inc., p 84

Wang Z (2009) Comprehensive organic name reactions and reagents. John Wiley & Sons, p 2942

Rosenau T (2007) 2,2,5,7,8-Pentamethylchroman-6-ol (PMC) and related model compounds. In: Preedy VR, Watson RR (eds) Encyclopedia of Vitamin E. CABI Publishing, p 21

Böhmdorfer S, Gille L, Rosenau T (2010) Lett Org Chem 7:335

Mason J (2009) NMR spectroscopy of Azo, Azoxy, and Hydrazo compounds. In: Patai´s chemistry of functional groups. John Wiley & Sons

IUPAC-IUB Commission on Biochemical Nomenclature (CBN) (1982) Eur J Biochem 123:473

IUPAC-IUB Commission on Biochemical Nomenclature (CBN) (1974) Arch Biochim Biophys 165:1

Urano S, Hattori Y, Yamanoi S, Matsuo M (1980) Chem Pharm Bull 28:1992

Brownstein S, Ingold KU (1989) J Org Chem 54:560

Acknowledgements

The financial support of the Austrian Biorefinery Center Tulln (ABCT) is gratefully acknowledged.

Funding

Open access funding provided by University of Natural Resources and Life Sciences Vienna (BOKU).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Patel, A., Rosenau, T. Synthesis and analytical characterization of all N–N-coupled, dimeric oxidation products of α-tocopheramine: hydrazo-, azo-, and azoxy-tocopherol. Monatsh Chem 152, 1231–1239 (2021). https://doi.org/10.1007/s00706-021-02833-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-021-02833-4