Abstract

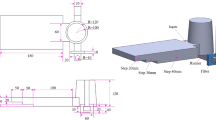

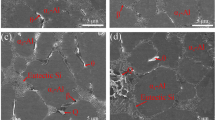

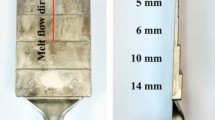

An ultrasonic vibration-assisted air-cooled stirring rod process (ACSR + UV) was used to efficiently prepare a large-volume semisolid slurry with a mass of more than 40 kg. A low-cost Al–Si–Fe–Mg–Cu–Zn die-casted alloy with high thermal conductivity, high plasticity and medium strength was developed. The alloy was used to manufacture large, thin-walled parts for 5G base stations by using the ACSR + UV rheological die-casting (ACSR + UV R-DC) process. Investigations were performed on the microstructure, porosity, mechanical properties, fracture behaviour and thermal conductivity of the ACSR + UV R-DC alloy, which was then compared to traditionally die-casted (T-DC) and ACSR R-DC alloys. The mechanisms for the microstructural refinement and enhancement of the mechanical and thermal conductivity performances of the ACSR + UV R-DC alloy were also analysed. The results showed that the ACSR + UV process increased the nucleation rate of the melt due to the increase in the nucleation area and the generation of cavitation bubbles. A radial- and an axial-forced convection was also generated inside the melt under the combined effects of acoustic flow and mechanical stirring, thereby homogenising the melt composition field and the temperature field. Therefore, the ACSR + UV R-DC process not only refined the primary α-Al (α1-Al), the eutectic silicon and the secondary α-Al (α2-Al), but also greatly improved the morphology and the distribution of the β-Al5FeSi phase. The mechanical properties of the ACSR + UV R-DC alloy were higher than those of the T-DC and the ACSR R-DC alloys. Compared to the T-DC alloy, the ultimate tensile strength, elongation and yield strength of the ACSR + UV R-DC alloy were increased by 34%, 122% and 19%, respectively. This was because the ACSR + UV R-DC technique gave the alloy the characteristics of high density, fine spherical α1-Al grain and a fine and uniform β-phase, which improved the fracture behaviour of the alloy. The thermal conductivity of the ACSR + UV R-DC alloy was 184 W/(m K), which was 10.2% and 3.4% higher than that of T-DC and ACSR R-DC alloys, respectively. This was because the refined eutectic silicon and β phases in the ACSR + UV R-DC alloy facilitated an easier electron flow through the eutectic region, and the decrease in porosity increased the effective area of heat conduction.

Similar content being viewed by others

References

C. Zhang, Y. Du, S.H. Liu, Y.L. Liu, B. Sundman, Thermochim. Acta 635, 8 (2016)

M.F. Qi, Y.L. Kang, Q.Q. Qiu, W.C. Tang, J.Y. Li, B.S. Li, J. Alloys Compd. 749, 487 (2018)

M.W. Wu, L. Hua, J.X. Zhou, Y.J. Yin, Mater. Rev. 32, 1486 (2018)

X.X. Dong, X.Z. Zhu, S.X. Ji, J. Mater. Process. Technol. 266, 105 (2019)

Z.Q. Hu, X.J. Zhang, S.S. Wu, Acta Metall. Sin. -Engl. Lett. 28, 1344 (2015)

H.D. Zhao, Y.F. Bai, X.X. Ouyang, P.Y. Dong, Trans. Nonferrous Met. Soc. China 20, 2064 (2010)

P. Das, B. Bhuniya, S.K. Samanta, P. Dutta, J. Mater. Process. Technol. 271, 293 (2019)

X.J. Yang, J. Liu, Acta Metall. Sin. -Engl. Lett. 15, 511 (2002)

C. Xu, J.W. Zhao, A. Guo, H. Li, G.Z. Dai, X. Zhang, J. Mater. Process. Technol. 249, 167 (2017)

M.F. Qi, Y.L. Kang, B. Zhou, W.N. Liao, G.M. Zhu, Y.D. Li, W.R. Li, J. Mater. Process. Technol. 234, 353 (2016)

M.F. Qi, Y.L. Kang, B. Zhou, G.M. Zhu, H.H. Zhang, Acta Metall. Sin. (in Chinese) 51, 668 (2015)

M.F. Qi, Y.L. Kang, W.C. Tang, Q.Q. Qiu, B.S. Li, Mater. Lett. 213, 378 (2018)

A.E.W. Jarfors, J.C. Zheng, L. Chen, J. Yang, Solid State Phenom. 285, 405 (2018)

J.S. Zheng, RSF semisolid forming technology and application. Paper presented at the 7th International Symposium on Controlled Solidification and Forming Engineering and Semisolid Technology and Application, Shenzhen, 22–23 October 2018

Y. Zhang, L.D. Wang, P.P. Xu, Q.F. Wang, H.C. Cao, J.S. Zheng, Z.H. Luo, Spec. Cast. Nonferrous Alloys 36, 165 (2016)

M.F. Qi, Y.L. Kang, G.M. Zhu, Trans. Nonferrous Met. Soc. China 27, 1939 (2017)

M.F. Qi, Y.L. Kang, J.Y. Li, B.Y. Shang, J. Mater. Process. Technol. 279, 116586 (2020)

S.L. Lü, S.S. Wu, C. Lin, P. An, Acta Metall. Sin. -Engl. Lett. 27, 862 (2014)

H. Yan, Y.S. Rao, R. He, J. Mater. Process. Technol. 214, 612 (2014)

J.Y. Li, S.L. Lü, S.S. Wu, Q. Gao, Ultrason. Sonochem. 42, 814 (2018)

P. Madhukar, N. Selvaraj, R. Gujjala, C.S.P. Rao, Ultrason. Sonochem. 58, 104665 (2019)

X. Yang, S.S. Wu, S.L. Lü, L.Y. Hao, X.G. Fang, Ultrason. Sonochem. 40, 472 (2018)

H. Kaya, A. Aker, J. Alloys Compd. 694, 145 (2017)

Q. Tang, J.H. Zhao, T. Wang, J. Chen, K. He, J. Alloys Compd. 741, 161 (2018)

T. Gao, Z.Q. Li, Y.X. Zhang, X.F. Liu, Acta Metall. Sin. -Engl. Lett. 31, 48 (2018)

Y. Yang, K.L. Yu, Y.G. Li, D.G. Zhao, X.F. Liu, Mater. Des. 33, 220 (2012)

X.C. Song, H. Yan, X.J. Zhang, J. Rare Earth 35, 412 (2017)

A.M. Cardinale, D. Maccio, G. Luciano, E. Canepa, P. Traverso, J. Alloys Compd. 695, 2180 (2017)

C. Lin, S.S. Wu, S.L. Lü, P. An, L. Wan, Intermetallics 32, 176 (2013)

C. Lin, S.S. Wu, S.L. Lü, P. An, L. Wan, J. Alloys Compd. 568, 42 (2013)

Y.H. Zhang, Y.C. Liu, Y.J. Han, C. Wei, Z.M. Gao, J. Alloys Compd. 473, 442 (2009)

ASTM International, ASTM E8–09 Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, 2009

J.F. Jiang, Y. Wang, H.V. Atkinson, Mater. Charact. 90, 52 (2014)

J.F. Jiang, Y. Wang, Mater. Sci. Eng. A 639, 350 (2015)

J.S. Shin, S.H. Ko, K.T. Kim, J. Alloys Compd. 644, 673 (2015)

R.N. Lumley, I.J. Polmear, H. Groot, J. Ferrier, Scr. Mater. 58, 1006 (2008)

F.F. Chen, H.D. Zhao, G. Zhu, P.X. Fu, L.J. Xia, Exp. Therm. Fluid Sci. 68, 39 (2015)

E. Vandersluis, A. Lombardi, C. Ravindran, A. Bois-Brochu, F. Chiesa, R. MacKay, Mater. Sci. Eng. A 648, 401 (2015)

M.F. Qi, Y.L. Kang, J.Y. Li, Z. Wulabieke, Y.Z. Xu, Y.D. Li, A.S. Liu, J.C. Chen, J. Mater. Process. Technol. 285, 116800 (2020)

W. Khalifa, Y. Tsunekawa, M. Okumiya, J. Mater. Process. Technol. 210, 2178 (2010)

Z.Y. Liu, Dissertation, University of Science and Technology Beijing (2015)

C.G. Kang, P.K. Seo, S.S. Kang, J. Mater. Process. Technol. 176, 32 (2006)

K. Du, Dissertation, General Research Institute for Nonferrous Metals (2017)

W.J. Hou, Dissertation, Hebei University of Science and Technology (2010)

L.Q. Yang, Y.L. Kang, F. Zhang, J. Xu, Trans. Nonferrous Met. Soc. China 20, 862 (2010)

A.K. Dahle, L. Arnberg, Acta Mater. 45, 547 (1997)

Q.J. Wu, H. Yan, P.X. Zhang, X.Q. Zhu, Q. Nie, Acta Metall. Sin. -Engl. Lett. 31, 523 (2018)

L.F. Mondolfo, Aluminum Alloys: Structure and Properties (Butter Worth Publication, Boston, 1976).

X.G. Fang, Dissertation, Huazhong University of Science & Technology (2017)

C. Lin, Dissertation, Huazhong University of Science & Technology (2014)

R. Trivedi, J. Cryst. Growth 48, 93 (1980)

M. Sha, Dissertation, Huazhong University of Science & Technology (2014)

Z.Y. Zhao, R.G. Guan, J.H. Zhang, Z.Y. Zhao, P.K. Bai, Acta Metall. Sin. -Engl. Lett. 30, 66 (2017)

X.L. Cui, Dissertation, Shandong University (2016)

J.K. Chen, H.Y. Hung, C.F. Wang, N.K. Tang, Int. J. Heat Mass Transf. 105, 189 (2017)

Y. Han, Dissertation, North China Electric Power University (2017)

X. Li, S.M. Xiong, Z. Guo, Mater. Sci. Eng. A 633, 35 (2015)

B. Lin, W.W. Zhang, Z.H. Lou, D.T. Zhang, Y.Y. Li, Mater. Des. 59, 10 (2014)

J. Kubásek, D. Dvorský, J. Veselý, P. Minárik, M. Zemková, D. Vojtěch, Acta Metall. Sin. -Engl. Lett. 32, 321 (2019)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 52005034 and 52027805), the Fundamental Research Funds for the Central Universities (No. FRF-TP-18-043A1), the Zhuhai Industry-University-Research Cooperation Project (No. ZH22017001200176PWC) and the China Postdoctoral Science Foundation Funded Project (No. 2019M650486).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Qi, M., Kang, Y., Li, J. et al. Synchronously Improving the Thermal Conductivity and Mechanical Properties of Al–Si–Fe–Mg–Cu–Zn Alloy Die Castings Through Ultrasonic-Assisted Rheoforming. Acta Metall. Sin. (Engl. Lett.) 34, 1331–1344 (2021). https://doi.org/10.1007/s40195-021-01231-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01231-3