Abstract

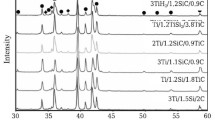

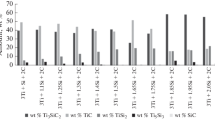

Ti3SiC2 was synthesized by hot pressing at 1400°С for 15 and 30 min at a pressure of 30 MPa from powder mixtures, mainly from Ti/Si/TiC and Ti/TiSi2/TiC. The amount of the Ti3SiC2 phase synthesized from these mixtures was 94.0 and 95.9 vol %, respectively (1400°С, 30 min). The Ti3SiC2 phase crystallized as elongated grains. The effect of the hot pressing time on the formation of the Ti3SiC2 phase from the starting Ti/Si/TiC powders was determined. The final products contained titanium carbide and a small amount of silicon carbide as intermediate phases (for composites containing the starting silicon carbide powders). An excess of silicon leads to the formation of the largest amount of the Ti3SiC2 phase.

Similar content being viewed by others

REFERENCES

N. I. Medvedeva, A. N. Enyashin, and A. L. Ivanovskii, J. Struct. Chem. 52, 785 (2011). https://doi.org/10.1134/S0022476611040226

E. I. Istomina, P. V. Istomin, and A. V. Nadutkin, Russ. J. Inorg. Chem. 57, 1058 (2012). https://doi.org/10.1134/S0036023612080062

E. I. Istomina, P. V. Istomin, and A. V. Nadutkin, Russ. J. Inorg. Chem. 58, 624 (2013). https://doi.org/10.1134/S0036023613060119

K. R. Whittle, M. G. Blackford, R. D. Aughterson, et al., Acta Mater. 58, 4362 (2010). https://doi.org/10.1016/j.actamat.2010.04.029

M. Le Flem, X. Liu, S. Doriot, et al., Int. J. Appl. Ceram. Technol. 7, 766 (2010). https://doi.org/10.1111/j.1744-7402.2010.02523.x

M. Utili, M. Agostini, G. Coccoluto, et al., Nucl. Eng. Des. 241, 1295 (2011). https://doi.org/10.1016/j.nucengdes.2010.07.038

Q. Wang, C. Hu, S. Cai, et al., Int. J. Appl. Ceram. Technol. 11, 911 (2014). https://doi.org/10.1111/ijac.12065

Y. Zhu, A. Zhou, Y. Ji, et al., Ceram. Int. 41, 6950 (2015). https://doi.org/10.1016/j.ceramint.2015.01.150

I. A. Rumyantsev and S. N. Perevislov, Refract. Ind. Ceram. 58, 405 (2017). https://doi.org/10.1007/s11148-017-0119-7

D. D. Nesmelov, O. A. Kozhevnikov, S. S. Ordan’yan, et al., Glass Ceram. 74, 43 (2017). https://doi.org/10.1007/s10717-017-9925-0

M. G. Frolova, A. V. Leonov, Y. F. Kargin, et al., Inorg. Mater. 9, 675 (2018). https://doi.org/10.1134/S2075113318040123

S. N. Perevislov, I. B. Panteleev, A. P. Shevchik, et al., Refract. Ind. Ceram. 58, 577 (2018). https://doi.org/10.1007/s11148-018-0148-x

S. N. Perevislov, A. S. Lysenkov, and S. V. Vikhman, Inorg. Mater. 53, 376 (2017). https://doi.org/10.1134/S0020168517040148

S. N. Perevislov, P. V. Shcherbak, and M. V. Tomkovich, Refract. Ind. Ceram. 59, 32 (2018). https://doi.org/10.1007/s11148-018-0178-4

S. N. Perevislov, P. V. Shcherbak, and M. V. Tomkovich, Refract. Ind. Ceram. 59, 179 (2018). https://doi.org/10.1007/s11148-018-0202-8

S. N. Perevislov, Refract. Ind. Ceram. 60, 168 (2019). https://doi.org/10.1007/s11148-019-00330-0

O. A. Lukianova, A. N. Khmara, S. N. Perevislov, et al., Ceram. Int. 45, 9497 (2019). https://doi.org/10.1016/j.ceramint.2018.09.198

S. Jacques, H. Fakih, and J. C. Viala, Thin Solid Films 518, 5071 (2010). https://doi.org/10.1016/j.tsf.2010.02.059

F. Meng, B. Liang, and M. Wang, Int. J. Refract. Met. Hard Mater. 41, 152 (2013). https://doi.org/10.1016/j.ijrmhm.2013.03.005

Y. Y. Zhu, J. Jia, A. G. Zhou, et al., Key Eng. Mater. 655, 68 (2015). https://doi.org/10.4028/www.scientific.net/KEM.655.68

Z. F. Zhang, Z. M. Sun, and H. Hashimoto, Metall. Mater. Trans. A 33, 3321 (2002). https://doi.org/10.1007/s11661-002-0320-1

B. Y. Islak and E. Ayas, Ceram. Int. 45, 12297 (2019). https://doi.org/10.1016/j.ceramint.2019.03.144

C. Magnus, J. Sharp, and W. M. Rainforth, Tribol. Trans. 63, 38 (2020). https://doi.org/10.1080/10402004.2019.1657534

Y. Zhou, Z. Sun, S. Chen, et al., Mater. Res. Innovations 2, 142 (1998). https://doi.org/10.1007/s100190050076

J. C. Viala, N. Peillon, F. Bosselet, et al., Mater. Sci. Eng., A 229, 95 (1997). https://doi.org/10.1016/S0921-5093(97)00002-6

I. Kero, M. L. Antti, and M. Odén, in International Conference on Advanced Ceramics and Composites, Ed. by J. Salem, G. Hilmas, and W. Fahrenholtz (John Wiley & Sons, 2009). https://doi.org/10.1002/9780470456361.ch3

C. Racault, F. Langlais, and R. Naslain, J. Mater. Sci. 29, 3384 (1994). https://doi.org/10.1007/BF00352037

Z. Sun, Y. Zou, S. Tada, et al., Scr. Mater. 55, 1011 (2006). https://doi.org/10.1016/j.scriptamat.2006.08.019

X. Fan, X. Yin, L. Wang, et al., Int. J. Refract. Met. Hard Mater. 45, 1 (2014). https://doi.org/10.1016/j.ijrmhm.2014.02.006

Funding

This study was financially supported by the Russian Foundation for Basic Research (grant no. 20-21-00056 of RFBR–Rosatom).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

CONFLICT OF INTEREST

The authors declare that they have no conflicts of interest.

ADDITIONAL INFORMATION

This paper was presented at the Sixth Interdisciplinary Scientific Forum with international participation “New Materials and Advanced Technologies,” Moscow, November 23–26, 2020, https://n-materials.ru.

Additional information

Translated by L. Smolina

Rights and permissions

About this article

Cite this article

Perevislov, S.N., Semenova, V.V. & Lysenkov, A.S. Synthesis, Structure, and Properties of the Ti3SiC2 MAX Phases Obtained by Hot Pressing. Russ. J. Inorg. Chem. 66, 1100–1106 (2021). https://doi.org/10.1134/S0036023621080210

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036023621080210