Abstract

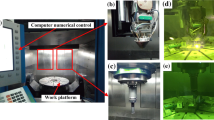

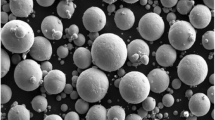

Graded structural materials (GSMs) with variable performance and composition have a full application in the aerospace industry. Hybrid additive and subtractive manufacturing is very convenient to fabricate GSM by adjusting the composition of the deposited materials, removing the excess parts and improving the overall dimensions. Crack is a very significant defect in blocky GSM components because of the excessive heat accumulation and uneven distribution of residual stress. To analyze the reason and effects of cracks, blocky and thin-walled GSMs were fabricated. By analyzing the crack morphology, microstructures, element distribution and oxidation, results show that IN718 had much better oxidation resistance than 316L, which led to cracks appearing on the side of 316L. By adjusting the blocky structures to thin-walled structures, huge cracks almost disappeared. However, the poor bonding strength of the interface resulted in worse tensile strength of GSM than single 316L or IN718 by laser depositing.

Similar content being viewed by others

Abbreviations

- GSM:

-

Graded structural material

- HASM:

-

Hybrid additive and subtractive manufacturing

- 316L:

-

316L stainless steel

- IN718:

-

Inconel 718

- DED:

-

Directed energy deposition

- AM:

-

Additive manufacturing

- SM:

-

Subtractive machining

- SEM:

-

Scanning electron microscope

- EDS:

-

Energy-dispersive spectroscopy

References

C. Zhang, F. Chen, Z. Huang, M. Jia, G. Chen, Y. Ye, Y. Lin, W. Liu, B. Chen, Q. Shen, L. Zhang, and E.J. Lavernia, Mater. Sci. Eng. A 764, 138209. (2019).

W. Meng, Y. Xiaohui, W. Zhang, F. Junfei, G. Lijie, M. Qunshuang, and C. Bing, J. Mater. Process. Technol. 275, 116368. (2020).

J. Nie, L. Wei, D. Li, L. Zhao, Y. Jiang, and Q. Li, Addit. Manuf. 35, 101295. (2020).

Y. Su, B. Chen, C. Tan, X. Song, and J. Feng, J. Mater. Process. Technol. 283, 116702. (2020).

C. Tan, Y. Chew, G. Bi, D. Wang, W. Ma, Y. Yang, and K. Zhou, J. Mater. Sci. Technol. 72, 217. (2021).

J.M. Flynn, A. Shokrani, S.T. Newman, and V. Dhokia, Int. J. Mach. Tools Manuf. 101, 79. (2016).

J. Moritz, A. Seidel, M. Kopper, J. Bretschneider, J. Gumpinger, T. Finaske, M. Riede, M. Schneeweiß, E. López, F. Brückner, C. Leyens, T. Rohr, and T. Ghidini, Int. J. Adv. Manuf. Technol. 107, 2995. (2020).

B. Onuike, and A. Bandyopadhyay, Mater. Lett. 252, 256. (2019).

T. Yamazaki, Procedia CIRP 42, 81. (2016).

Z. Zhu, V. Dhokia, A. Nassehi, and S.T. Newman, Robot. Comput. Integr. Manuf. 37, 23. (2016).

Y. Zhao, J. Sun, J. Li, P. Wang, Z. Zheng, J. Chen, and Y. Yan, J. Alloys Compd. 769, 898. (2018).

K. Salonitis, L. D’Alvise, B. Schoinochoritis, and D. Chantzis, Int. J. Adv. Manuf. Technol. 85, 2401. (2016).

Z. Ye, Z. Zhang, X. Jin, M.Z. Xiao, and J. Su, Int. J. Adv. Manuf. Technol. 88, 2237. (2017).

K.P. Karunakaran, S. Suryakumar, V. Pushpa, and S. Akula, Int. J. Adv. Manuf. Technol. 45, 690. (2009).

S. Kapil, F. Legesse, S. Negi, K.P. Karunakaran, and S. Bag, Prog. Addit. Manuf. 5, 183. (2020).

P. Li, Y. Gong, Y. Xu, Y. Qi, Y. Sun, and H. Zhang, Arch. Civ. Mech. Eng. 19, 820. (2019).

P. Prabhakar, W.J. Sames, R. Dehoff, and S.S. Babu, Addit. Manuf. 7, 83. (2015).

P. Li, Y. Gong, X. Wen, B. Xin, Y. Liu, and S. Qu, Int. J. Adv. Manuf. Technol. 98, 687. (2018).

C. Juillet, A. Oudriss, J. Balmain, X. Feaugas, and F. Pedraza, Corros. Sci. 142, 266. (2018).

P. Nie, O.A. Ojo, and Z. Li, Acta Mater. 77, 85. (2014).

X. Wang, P.W. Liu, Y. Ji, Y. Liu, M.H. Horstemeyer, and L. Chen, J. Mater. Eng. Perform. 28, 657. (2019).

M. Akbari, and R. Kovacevic, Addit. Manuf. 23, 487. (2018).

A. Riemer, S. Leuders, M. Thöne, H.A. Richard, T. Tröster, and T. Niendorf, Eng. Fract. Mech. 120, 15. (2014).

T. Vilaro, C. Colin, J.D. Bartout, L. Nazé, and M. Sennour, Mater. Sci. Eng. A 534, 446. (2012).

F. Liu, X. Lin, G. Yang, M. Song, J. Chen, and W. Huang, Opt. Laser Technol. 43, 208. (2011).

S. Chen, J. Huang, J. Xia, X. Zhao, and S. Lin, J. Mater. Process. Technol. 222, 43. (2015).

P. Li, H. Dong, Y. Xia, X. Hao, S. Wang, L. Pan, and J. Zhou, J. Manuf. Process. 33, 54. (2018).

S. Chandrasekaran, S. Hari, and M. Amirthalingam, Mater. Sci. Eng. A 792, 139530. (2020).

S. Shakerin, A. Hadadzadeh, B.S. Amirkhiz, S. Shamsdini, J. Li, and M. Mohammadi, Addit. Manuf. 29, 100797. (2019).

L. Liu, Z. Zhuang, F. Liu, and M. Zhu, Int. J. Adv. Manuf. Technol. 69, 2131. (2013).

M.H. Ghoncheh, M. Sanjari, E. Cyr, J. Kelly, H. Pirgazi, S. Shakerin, A. Hadadzadeh, B.S. Amirkhiz, L.A.I. Kestens, and M. Mohammadi, Int. J. Plast. 133, 102840. (2020).

H.C. Dey, M. Ashfaq, A.K. Bhaduri, and K.P. Rao, J. Mater. Process. Technol. 209, 5862. (2009).

M. Velu, and S. Bhat, Mater. Des. 47, 793. (2013).

H. Naffakh, M. Shamanian, and F. Ashrafizadeh, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 39, 2403. (2008).

Acknowledgements

This work was supported by the National Key of Research and Development Plan: Research on common key technologies of clean cutting (No. 2019YFB2005401), the National Natural Science Foundation of China (Nos. 51775250 and 51875265), the Demonstration and Extension Project of Jiangsu Provincial Modern Agricultural Equipment and Technology (No. NJ2019-20), the Six Major Talent Peaks of Jiangsu Province (No. 2019−GDZB−251), and the Synergistic Innovation Project of Jiangsu Modern Agricultural Equipment and Technology (No. 4091600011).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, P., Zhou, J., Li, L. et al. Cracks Analysis of Graded Structural Material Fabricated by Hybrid Additive and Subtractive Manufacturing. JOM 73, 2859–2867 (2021). https://doi.org/10.1007/s11837-021-04834-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04834-4