Abstract

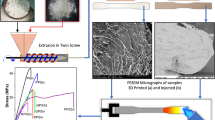

As additively manufactured components move away from short-term usability, such as single-use prototypes, towards commercial products used for longer periods of time, the long-term material properties, such as ageing and creep, are becoming increasingly important design considerations. Moreover, when additively manufactured components are designed for outdoor use, environmental stressors affect these long-term material properties in a process known as ‘weathering’. In this research paper, an initial set of experiments assessed the flexural creep behaviour of pellet-printed PETG after exposure to three accelerated environmental stressors: UV radiation, temperature and humidity. The outcomes thereof indicated that UV exposure was the only stressor to increase the creep compliance. A subsequent set of experiments increase the UV exposure duration from 100 to 200 h and excluded the effects of ageing on creep behaviour during creep tests. The outcome of this second series of experiments showed that the increase in creep compliance can be attributed to the effects of UV alone.

Similar content being viewed by others

Availability of data and material

The data that support the findings of this study are available from Mineral Technologies but restrictions apply to the availability of this data, which were used under license for the current study, and so are not publicly available. Data are however available from the authors upon reasonable request and with permission of Mineral Technologies.

References

Chevali VS, Dean DR, Janowski GM (2010) Effect of environmental weathering on flexural creep behavior of long fiber-reinforced thermoplastic composites. Polym Degrad Stab 95(12):2628–2640

ASTM G113–16 (2016) Standard terminology relating to natural and artificial weathering tests of nonmetallic materials. ASTM International West Conshohocken PA. https://doi.org/10.1520/G0113-16, www.astm.org

Wu H (2018) Chapter 6 - highly accelerated uv weathering: when and how to use it, in service life prediction of polymers and plastics exposed to outdoor weathering. C.C. White, K.M. White, and J.E. Pickett, Editors. William Andrew Publishing. p 79–94

Fedor GR, Brennan PJ (1996) Comparison between natural weathering and fluorescent uv exposures: UVA-340 lamp test results. R.J. Herling, Editor. ASTM International: West Conshohocken, PA. p 91–105

White KM et al (2018) Chapter 7 - assessing the effects of accelerated weathering stresses used to predict service life, in service life prediction of polymers and plastics exposed to outdoor weathering. C.C. White, K.M. White, and J.E. Pickett, Editors. William Andrew Publishing. p 95–115

Startsev VO et al (2018) Effect of outdoor exposure on the moisture diffusion and mechanical properties of epoxy polymers. Polym Testing 65:281–296

Harris AM, Lee EC (2010) Heat and humidity performance of injection molded PLA for durable applications. J Appl Polym Sci 115(3):1380–1389

Barbero EJ (2009) Prediction of Long-term Creep of Composites from Doubly-shifted Polymer Creep Data. J Compos Mater 43(19):2109–2124

Philip M, Al-Azzawi F (2018) Effects of natural and artificial weathering on the physical properties of recycled poly(ethylene terephthalate). J Polym Environ 26(8):3139–3148

Pintar AL et al (2018) Chapter 9 - predicting field degradation of sealants using accelerated tests from the NIST solar sphere, in service life prediction of polymers and plastics exposed to outdoor weathering. C.C. White, K.M. White, and J.E. Pickett, Editors. William Andrew Publishing. p 135–159

White CC, White KM, Pickett JE (2018) Chapter 17 - summary of the discussions following each session of the 6th international conference on service life prediction of polymer materials: over the horizon, in service life prediction of polymers and plastics exposed to outdoor weathering. C.C. White, K.M. White, and J.E. Pickett, Editors. William Andrew Publishing. p 301–309

Türk D-A et al (2017) Mechanical characterization of 3D printed polymers for fiber reinforced polymers processing. Mater Des 118:256–265

Altaf K (2011) Investigation of the effect of relative humidity on additive manufactured polymers by depth sensing indentation. Loughborough University (United Kingdom), Ann Arbor

Struik LCE (1978) Physical aging in amorphous polymers and other materials. Vol 106

ASTM C1850 (2017) Standard guide for improved laboratory accelerated tests to predict the weathering and for use in developing protocols to predict the design life of building sealant systems. ASTM International West Conshohocken PA. https://doi.org/10.1520/C1850-17, www.astm.org

Lehrer J, Scanlon M (2017) The development of a sustainable technology for 3D printing using recycled materials

ASTM D2990–17 (2017) Standard test methods for tensile, compressive, and flexural creep and creep-rupture of plastics. ASTM International West Conshohocken PA. https://doi.org/10.1520/D2990-17, www.astm.org

ASTM D790–17 (2017) Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. ASTM International West Conshohocken PA. https://doi.org/10.1520/D0790-17, www.astm.org

ASTM G151–19 (2019) Standard practice for exposing nonmetallic materials in accelerated test devices that use laboratory light sources. ASTM International West Conshohocken PA. https://doi.org/10.1520/G0151-19, www.astm.org

ASTM G154–16 (2016) Standard practice for operating fluorescent ultraviolet (UV) lamp apparatus for exposure of nonmetallic materials. ASTM International West Conshohocken PA. https://doi.org/10.1520/G0154-16, www.astm.org

Testex (2019) UV accelerated weather tester instruction manual. Dongguan, P.R. China.: TESTEX Instrument LTD

Allara DL (1975) Aging of polymers. Environ Health Perspect 11:29–33

Allen NS et al (1991) Hydrolytic degradation of poly(ethylene terephthalate): Importance of chain scission versus crystallinity. Eur Polymer J 27(12):1373–1378

Arhant M et al (2019) Impact of hydrolytic degradation on mechanical properties of PET - Towards an understanding of microplastics formation. Polym Degrad Stab 161:175–182

Asadi H et al (2021) Artificial Weathering Mechanisms of Uncoated Structural Polyethylene Terephthalate Fabrics with Focus on Tensile Strength Degradation. Materials 14:618

Sang T et al (2020) Polyethylene terephthalate degradation under natural and accelerated weathering conditions. Eur Polymer J 136:109873

Gonzalez-Gutierrez J et al (2015) Viscosity and creep compliance of polyoxymethylene copolymers of various average molecular weights. Polimery -Warsaw- 60:620

Navarro RF, d’Almeida JRM, Rabello MS (2007) Elastic properties of degraded polypropylene. J Mater Sci 42(6):2167–2174

Acknowledgements

The researchers would like to thank UTS:Rapido, in particular, Hervé Harvard for establishing this overall research activity, and Martin Do for his assistance setting up and conducting the experiments.

Funding

The research study described herein is supported by an Australian Government Research Training Program Scholarship and is co-funded by the Department of Industry, Innovation and Science (Innovative Manufacturing CRC Ltd), the University of Technology Sydney (UTS) and Downer, via its subsidiary Mineral Technologies Pty Ltd (IMCRC/MTC/290418). The funding bodies were not involved in the study design; in the collection, analysis and interpretation of data; in the writing of the report; or in the decision to submit the article for publication.

Author information

Authors and Affiliations

Contributions

Conceptualization: Thomas Romeijn; Methodology: Thomas Romeijn; Investigation: Karanvir Singh; Validation: Thomas Romeijn, Karanvir Singh; Formal analysis: Thomas Romeijn; Data Curation: Thomas Romeijn, Karanvir Singh; Writing—original draft preparation: Thomas Romeijn, Karanvir Singh; Writing—review and editing: Gavin Paul, Michael Behrens; Supervision: Gavin Paul, Michael Behrens; Project Administration: Gavin Paul, Michael Behrens.

Corresponding author

Ethics declarations

Conflicts of interest/Competing interests

The authors declare that they have no conflict of interest or competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Romeijn, T., Singh, K., Behrens, M. et al. Effect of accelerated weathering on the creep behaviour of additively manufactured Polyethylene Terephthalate Glycol (PETG). J Polym Res 28, 352 (2021). https://doi.org/10.1007/s10965-021-02707-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02707-7