Abstract

This paper presents a novel robust optimal design for parallel manipulators to optimize the performance indices subject to the unavoidable effect of the uncertainties. The robust optimization proposed in the present contribution consists of a multi-objective optimization problem that aims at maximizing the performance index and robustness criterion simultaneously. The design variables should be adjusted to minimize the effects of the uncertainties and maximize the performance index. The single-objective optimization problem is also carried out to evaluate the optimal design obtained by using the proposed robust optimization approach. Numerical results illustrate the benefits of the proposed robust optimization applied to the optimal kinematic design of a parallel Cartesian manipulator with clearances and the optimal dynamic design of a Stewart–Gough platform.

Similar content being viewed by others

References

Dixon WE, Walker ID, Dawson DM, Hartranft JP (2000) Fault detection for robot manipulators with parametric uncertainty: a prediction-error-based approach. IEEE Trans Robot Autom 16(6):689–699

Lara-Molina FA, Koroishi EH, Steffen V, Martins LA (2018) Kinematic performance of planar 5R symmetrical parallel mechanism subjected to clearances and uncertainties. J Braz Soc Mech Sci Eng 40(4):189

Zang C, Friswell MI, Mottershead JE (2005) A review of robust optimal design and its application in dynamics. Comput Struct 83(4–5):315–326

Du X, Venigella PK, Liu D (2009) Robust mechanism synthesis with random and interval variables. Mech Mach Theory 44(7):1231–1337

Luo K, Wang J, Du X (2012) Robust mechanism synthesis with truncated dimension variables and interval clearance variables. Mech Mach Theory 57:71–83

Heling B, Schleich B, Wartzack S (2018) Robust-Design-Optimization of mechanisms based on kinematic requirements considering uncertainties. Proc CIRP 75:27–32

Sun D, Shi Y, Zhang B (2018) Robust optimization of constrained mechanical system with joint clearance and random parameters using multi-objective particle swarm optimization. Struct Multidiscip Optim 58(5):2073–2084

Rothenhofer G, Walsh C, Slocum A (2010) Robust optimization of constrained mechanical system with joint clearance and random parameters using multi-objective particle swarm optimization. Precis Eng 34(4):790–797

Shi Z, Yang X, Yang W, Cheng Q (2005) Robust synthesis of path generating linkages. Mech Mach Theory 40(1):45–54

Caro S, Bennis F, Wenger P (2005) Tolerance synthesis of mechanisms: a robust design approach. J Mech Des 127(1):86–94

Jørgensen TB, Wolniakowski A, Petersen HG, Debrabant K, Krüger N (2018) Robust optimization with applications to design of context specific robot solutions. Robot Comput Integr Manuf 53:162–177

Pickard J, Carretero J, Merlet J-P (2020) Appropriate synthesis of the four-bar linkage. Mech Mach Theory 153:103965

Brahmia A, Kelaiaia R, Chemori A, Company O (2021) On robust mechanical design of PAR2 delta-like parallel kinematic manipulator. ASME J Mech Robot 14(1):011001

Ur-Rehman R, Caro S, Chablat D, Wenger P (2010) Multi-objective path placement optimization of parallel kinematics machines based on energy consumption, shaking forces and maximum actuator torques: Application to the Orthoglide. Mech Mach Theory 45(8):1125–1141

Lara-Molina FA, Rosario JM, Dumur D (2011) Multi-objective optimization of Stewart–Gough manipulator using global indices. In: 2011 IEEE/ASME international conference on advanced intelligent mechatronics (AIM), pp 79–85

Zhang D, Gao Z (2012) Forward kinematics, performance analysis, and multi-objective optimization of a bio-inspired parallel manipulator. Robot Comput Integr Manuf 28(4):484–492

Nabavi SN, Shariatee M, Enferadi J, Akbarzadeh A (2020) Parametric design and multi-objective optimization of a general 6-PUS parallel manipulator. Mech Mach Theory 103913

Chi Z, Zhang D, Xia L, Gao Z (2013) Multi-objective optimization of stiffness and workspace for a parallel kinematic machine. Int J Mech Mater Des 9(3):281–293

Kelaiaia Ridha, Company Olivier, Zaatri Abdelouahab (2012) Multiobjective optimization of a linear Delta parallel robot. Mech Mach Theory 50:159–178

Wang C, Fang Y, Guo S (2015) Multi-objective optimization of a parallel ankle rehabilitation robot using modified differential evolution algorithm. Chin J Mech Eng 28(4):702–715

Bolzon VR, Lara-Molina FA (2018) Optimal kinematic and elastodynamic design of planar parallel robot with flexible joints. IEEE Latin Am Trans 16(5):1343–1352

Bounab B (2016) Multi-objective optimal design based kineto-elastostatic performance for the delta parallel mechanism. Robotica 34(2):258–273

Lara-Molina FA, Dumur D, Assolari Takano, K (2018) Multi-objective optimal design of flexible-joint parallel robot. Eng Comput 35(8):2775–2801

Liu Xin-Jun, Wang J, Pritschow G (2006) Performance atlases and optimum design of planar 5R symmetrical parallel mechanisms. Mech Mach Theory 41(2):119–144

Siciliano B, Sciavicco L, Villani L, Oriolo G (2009) Robotics: modelling, planning and control. Springer

Zhan Z, Zhang X, Jian Z, Zhang H (2018) Error modelling and motion reliability analysis of a planar parallel manipulator with multiple uncertainties. Mech Mach Theory 124:55–72

Wu L, Wang G, Liu H, Huang T (2018) An approach for elastodynamic modeling of hybrid robots based on substructure synthesis technique. Mech Mach Theory 123:124–136

Villarreal-Cervantes MG, Cruz-Villar CA, Alvarez-Gallegos J, Portilla-Flores EA (2010) Differential evolution techniques for the structure-control design of a five-bar parallel robot. Eng Optim 42(6):535–565

Lara-Molina FA, Dumur D, Koroishi EH (2016) Structure-control optimal design of 6-DOF fully parallel robot. In: Santos Osório F, Sales Gonçalves R (eds) Robotics. SBR 2016, LARS 2016. Communications in Computer and Information Science, vol 619. Springer, Cham

Deb K, Pratap A, Agarwal S, Meyarivan TAMT (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput 6(2):182–197

Yusoff Y, Ngadiman MS, Zain AM (2011) Overview of NSGA-II for optimizing machining process parameters. Proc Eng 15:3978–3983

Monsef H, Naghashzadegan M, Jamali A, Farmani R (2019) Comparison of evolutionary multi objective optimization algorithms in optimum design of water distribution network. Ain Shams Eng J 10(1):103–111

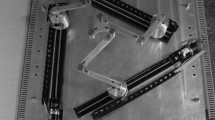

Gosselin CM, Masouleh MT, Duchaine V, Richard PL, Foucault S, Kong X (2007) Parallel mechanisms of the multipteron family: kinematic architectures and benchmarking. In: Proceedings 2007 IEEE international conference on robotics and automation, pp 555–560

Gosselin C (2009) Compact dynamic models for the Tripteron and Quadrupteron parallel manipulators. Proc Inst Mech Eng Part I J Syst Control Eng 223(1):1–12

Kim Han Sung, Tsai Lung-Wen (2003) Design optimization of a Cartesian parallel manipulator. J Mech Des 125(1):43–51

Yen PL, Lai CC (2009) Dynamic modeling and control of a 3-DOF Cartesian parallel manipulator. Mechatronics 19(3):390–398

Lara-Molina F, Dumur D (2021) A fuzzy approach for the kinematic reliability assessment of robotic manipulators. Robotica. https://doi.org/10.1017/S0263574721000187

Zhu J, Ting KL (2000) Uncertainty analysis of planar and spatial robots with joint clearances. Mech Mach Theory 35(9):1239–1256

Varedi SM, Daniali HM, Dardel M, Fathi A (2015) Optimal dynamic design of a planar slider-crank mechanism with a joint clearance. Mech Mach Theory 86:191–200

Liu K, Fitzgerald JM, Lewis FL (1993) Kinematic analysis of a Stewart platform manipulator. IEEE Trans Ind Electron 40(2):282–293

Masory O, Wang J (1994) Workspace evaluation of Stewart platforms. Adv Robot 9(4):443–461

Dasgupta B, Mruthyunjaya TS (1998) Closed-form dynamic equations of the general Stewart platform through the Newton–Euler approach. Mech Mach Theory 33(7):993–1012

Liu MJ, Li CX, Li CN (2000) Dynamics analysis of the Gough–Stewart platform manipulator. IEEE Trans Robot Autom 16(1):94–98

St-Onge BM, Gosselin CM (2000) Singularity analysis and representation of the general Gough–Stewart platform. Int J Robot Res 19(3):271–288

Asada H (1983) A geometrical representation of manipulator dynamics and its application to arm design. J Dyn Syst Meas Control 105(3):131–142

Paccot Flavien, Andreff Nicolas, Martinet Philippe (2009) A review on the dynamic control of parallel kinematic machines: theory and experiments. Int J Robot Res 28(3):395–416

Zhao R, Wu L, Chen YH (2020) Robust control for nonlinear delta parallel robot with uncertainty: an online estimation approach. IEEE Access 8(3):97604–97617

Cheng C, Xu W, Shang J (2015) Distributed-torque-based independent joint tracking control of a redundantly actuated parallel robot with two higher kinematic pairs. IEEE Trans Ind Electron 63(2):1062–1070

Gosselin Clement, Angeles Jorge (1991) A global performance index for the kinematic optimization of robotic manipulators. J Mech Des 113(3):220–226

Acknowledgements

The authors are thankful for the financial support provided by CNPq (Process 427204/2018-6), and CAPES.

Funding

This study was funded by National Council for Scientific and Technological Development - Brazil (grant number 427204/2018-6).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Monte Carlo simulation

Appendix: Monte Carlo simulation

The Monte Carlo simulation (MCS) to evaluate the robustness criteria of \(\gamma =\varvec{\Gamma }\left( {\mathbf {t}},\varvec{\lambda }, {\mathbf {u}} \right) \) consists of three main steps: i) sampling of the uncertain parameters of the uncertain parameters \({\mathbf {u}}\) (see Eq. (1)) to obtain a set of \(n_s\) random inputs; ii) the output of the system \(\gamma \) is computed for each random input. iii) a statical analysis is carried out to find the mean and standard deviation of the output. The algorithm of MCS is presented in Fig. 12. It is worth to mention that the pose of the end-effector \({\mathbf {t}}\) and the design variables \(\varvec{\lambda }\) are considered as constants in this procedure.

where the operators \(\overline{(.)}\) and \(\sigma {(.)}\) denotes the mean and standard deviation, respectively.

Rights and permissions

About this article

Cite this article

Lara-Molina, F.A., Dumur, D. Robust multi-objective optimization of parallel manipulators. Meccanica 56, 2843–2860 (2021). https://doi.org/10.1007/s11012-021-01418-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-021-01418-z