Abstract

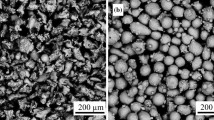

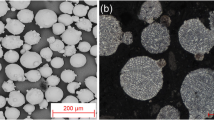

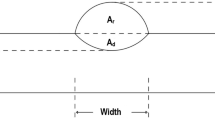

AISI 431 bead-on-plates were deposited on AISI 1010 by laser cladding, since it is a well-known corrosion-resistant material. The effects of laser power, scanning speed, powder feed rate and focal distance on the coatings’ geometry and dilution ratios, as well as microstructure evolution, iron dilution and microhardness of the beads were evaluated by optical and electron scanning microscopes, the last one coupled with x-ray energy dispersive spectroscopy, and microhardness test. The results showed that the clad height is mainly influenced by the scanning speed, while for the width, laser power, scanning speed and focal distance were crucial. Changing laser power has a more marked effect on the dilution than on the aspect ratio, while changing scanning speeds and focal distance shows a marked effect on both dilution and aspect ratio. The microstructure of coating zone is mainly composed by lath martensite. Furthermore, the average hardness by microindentation of the AISI 431 stainless steel cladding coating was about 5 times higher than that of the substrate.

Similar content being viewed by others

References

T. Bell, Surf. Eng. 6, 31. (1990).

L. Sexton, S. Lavin, G. Byrne, and A. Kennedy, J. Mater. Process. Technol. 122, 63. (2002).

C. Sudha, P. Shankar, R.V. Subba Rao, R. Thirumurugesan, M. Vijayalakshmi, and B. Raj, Surf. Coat. Technol. 202, 2103. (2008).

A.S. Khanna, S. Kumari, S. Kanungo, and A. Gasser, Int J Refract Hard Met. 27, 485. (2009).

G. Madhusudhan Reddy, and A. Rajasekhar, Adv. Mat. Res. 794, 289. (2013).

I. Hemmati, V. Ocelik, J. Th, and M. De Hosson, J. Mater. Sci. 46, 3405. (2011).

I. Hemmati, V. Ocelik, J. Th, and M. De Hosson, Surf. Coat. Technol. 205, 5235. (2011).

J. Liu, J. Li, H. Xu Cheng, and Wang, , Surf. Coat. Technol. 325, 352. (2017).

B. Song, T. Hussain, and K. Voisey, Phys. Procedia 83, 706. (2016).

E.W.A. Figueredo, L.H.R. Apolinario, M.V. Santos, A.C.S. Silva, J.A. Avila, M.S.F. Lima, and T.F.A. Santos, J. Mater. Eng. Perfom. 30, 3298. (2021).

S. Zanzarin, Laser cladding with metallic powders, Doctoral dissertation, University of Trento, Trento, 2015.

P. Murkute, S. Pasebani, and O. BurkanIsgor, J. Mater. Process. Technol. 273, 116243. (2019).

I. Manna, J. Dutta Majumdar, B. Ramesh Chandra, S. Nayak, and N.B. Dahotre, Surf. Coat. Technol. 201, 434. (2006).

D. Tanigawa, N. Abe, M. Tsukamoto, Y. Hayashi, H. Yumazaki, Y. Tatsumi, and M. Yoneyama, Opt. Lasers Eng. 101, 23. (2018).

L. Reddy, S.P. Preston, P.H. Shipway, C. Davis, and T. Hussain, Surf. Coat. Technol. 349, 198. (2018).

G.R. Desale, C.P. Paul, B.K. Gandhi, and S.C. Jain, Wear 266, 975. (2009).

L.H.R. Apolinario, D. Wallerstein, M.A. Montealegre, S.L. Urtiga Filho, E.A. Torres, T.F.C. Hermenegildo, and T.F.A. Santos, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 50, 3617. (2019).

U. de Oliveira, V. Ocelik, J. Th, and M. De Hosson, Surf. Coat. Technol. 197, 127. (2005).

J.T.M. de Hosson, V. Ocelik, U. de Oliveira, and D.I. Vainchtein, Int. J. Mat. Res. 100, 1343. (2009).

B. Graf, S. Ammer, A. Gumenyuk, and M. Rethmeier, Procedia CIRP. 11, 245. (2013).

B. Bax, R. Rajput, R. Keller, and M. Reisacher, Addit Manuf. 21, 487. (2018).

A. Fathi, E. Toyserkani, A. Khajepour, and M. Durali, J. Phys. D Appl. Phys. 39, 2613. (2006).

P. Alvarez, M. Ángeles Montealegre, J.F. Pulido-Jiménez, and J.I. Arrizubieta, J. Manuf. Mater. Process. 2, 55. (2018).

F. Bourahima, A.L. Helbert, M. Rege, V. Ji, D. Solas, and T. Baudin, J. Alloys Compd. 771, 1018. (2019).

A. Riquelme, P. Rodrigo, M.D. Escalera, and J. Rams, Opt. Lasers Eng. 78, 165. (2016).

G. Telasang, J. Dutta Majumdar, G. Padmanabham, M. Tak, and I. Manna, Surf. Coat. Technol. 258, 1108. (2014).

F. Shu, B. Zhang, T. Liu, S. Sui, Y. Liu, P. He, B. Liu, and B. Xu, Surf. Coat. Technol. 358, 667. (2019).

M. Reis, S. Estanislao, A. Cabral, P. Peças, and H. Gouveia, Rev. Metal Madrid. 34, 154. (1998).

T. Gabriel, D. Rommel, F. Scherm, M. Gorywoda, and U. Glatezel, Materials. 10, 279. (2017).

M. Moradi, H. Arabi, S.J. Nasab, and K.Y. Benyounis, Opt. Laser Technol. 111, 347. (2019).

Heat treater’s guide: practices and procedures for irons and steels, 2nd edn. ASM International, 1995.

J. Yao, J. Zhang, G. Wu, L. Wang, Q. Zhang, and R. Liu, Opt. Laser Technol. 101, 520. (2018).

V. Ocelik, I. Hemmati, J. Th, and M. De Hosson, Surface Effects Contact Mech. Include. Tribol. XII. 91, 93. (2015).

Acknowledgements

The authors would like to acknowledge the Universidade Federal de Pernambuco (UFPE) laboratory (COMPOLAB), Brazilian Institute for Materials Joining and Coating Technologies (INTM), CNPQ, CAPES, and FACEPE for financial support and providing all the conditions required to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Do Vale, N.L., Fernandes, C.A., Santos, R.d.A. et al. Effect of Laser Parameters on the Characteristics of a Laser Clad AISI 431 Stainless Steel Coating on Carbon Steel Substrate. JOM 73, 2868–2877 (2021). https://doi.org/10.1007/s11837-021-04835-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04835-3