Abstract

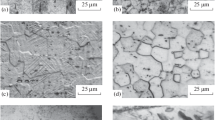

The deformation- and thermal-cycle resistance of titanium nickelide-based alloys is considered. We proposed to estimate these characteristics using both fracture and the degradation of the functional characteristics of the material (shape recovery temperature, unrecoverable strain, etc.). The functional characteristics are found to be determined by the critical stresses and strains of the material, which depend on its structure and the test temperature.

Similar content being viewed by others

REFERENCES

V. S. Zolotorevskii, Mechanical Properties of Metals: Textbook for Universities, 2nd ed. (Metallurgiya, Moscow, 1983).

R. Landgraf, “The resistance of metals to cyclic deformation,” in Achievement of High Fatigue Resistance in Metals and Alloys (Amer. Soc. Test. Mater., 1970), pp. 3–36.

B. Farahmand, G. Bockrath, and J. Glassco, Fatigue and Fracture Mechanics of High Risk Parts: Application of LEFM & FMDM Theory (Springer, 1997).

L. Lecce and A. Concilio, Shape Memory Alloy Engineering for Aerospace, Structural and Biomedical Applications (Elsevier, 2015).

K. Otsuka and X. Ren, “Physical metallurgy of Ti–Ni-based shape memory alloys,” Prog. Mater. Sci., No. 5(50), 511–678 (2005).

H. A. Mohamed and J. Washburn, “Deformation behaviour and shape memory effect of near equiatomic NiTi alloy,” J. Mater. Sci. 12, 469–480 (1977).

K. N. Melton and O. Mercier, “Deformation behavior of NiTi-based alloys,” Met. Trans. A 9, 1487–1488 (1978).

J. X. Zhang, M. Sato, and A. Ishida, “Deformation mechanism of martensite in Ti-rich Ti–Ni shape memory alloy thin films,” Acta Materialia 54, 1185–1198 (2006).

A. Lotkov, V. Grishkov, V. Timkin, A. Baturin, and D. Zhapova, “Yield stress in titanium nickelide-based alloys with thermoelastic martensitic transformations,” Mater. Sci. Eng. A 744, 74–78 (2019).

S. W. Robertson, A. R. Pelton, and R. O. Ritchie, “Mechanical fatigue and fracture of Nitinol,” Int. Mater. Rev. 57 (1), 1–36 (2012).

O. Benafan, J. Brown, and F. T. Calkins, “Shape memory alloy actuator design: CASMART collaborative best practices and case studies,” Int. J. Mech. Mater. Des. 10, 1–42 (2014).

M. Yu. Kollerov, A. A. Ilyin, D. E. Gusev, and D. A. Lamzin “Effect of deformation mechanisms on the fatigue properties of metallic materials,” Metally, No. 5, 72–79 (2008).

V. E. Gunter, A. N. Matyunin, and L. A. Monasevich, “Deformational cyclic resistance of medical shape memory alloys,” Implanty Pamyat’yu Formy, No. 1, 42–44 (1993).

V. E. Gunter, V. N. Khodorenko, Yu. F. Yasenchuk, et al., Titanium Nickelide. Next-Generation Medical Material (Izd. MITs, Tomsk, 2006).

G. Eggeler, E. Hornbogen, A. Yawny, A. Heckmann, and M. Wagner, “Structural and functional fatigue of NiTi shape memory alloys,” Mater. Sci. Eng. A 378, 24–33 (2004).

D. C. Lagoudas, D. A. Miller, L. Rong, and P. K. Kumar, “Thermomechanical fatigue of shape memory alloys,” Smart Mater. Struct. 18, 085021–085033 (2009).

M. Yu. Kollerov and A. A. Il’in, “Production and application of biologically and mechanically compatible implants made of titanium nickelide,” Titan, No. 1 (59), 47–54 (2018).

T. Yoneyama and S. Mayazaki, Shape Memory Alloys for Biomedical Applications (Woodhead Publ. Ltd., 2009).

E. A. Lukina, “The influence of anodic oxidation on NiTi/Ti6Al4V fretting corrosion behavior,” J. Phys.: Conf. Ser. 1396 (1), 012030 (2019).

R. Ashwin, A. R. Srinivasa, and J. N. Reddy, Design of Shape Memory Alloy (SMA) Actuators (Springer, 2015).

K. Otsuka and X. Ren, “Physical metallurgy of Ti–Ni-based shape memory alloys,” Progr. Mater. Sci., No. 5 (50), 511–678 (2005).

D. E. Gusev, M. Yu. Kollerov, and R. E. Vinogradov, “Effect of structure and test conditions on the critical strains and stresses in titanium nickelide-based alloys,” Deform. Razrushenie Mater., No. 7, 17–23 (2018).

A. Stebner, S. Padula, R. Noebe, B. Lerch, and D. Quinn, “Development, characterization, and design considerations of Ni19.5Ti50.5Pd25Pt5 high-temperature shape memory alloy helical actuators,” J. Intel. Mater. Sys. Struct. 20 (17), 2107–2126 (2009).

Physical Metallurgy, Ed. by R. W. Cahn and P. T. Haasen (Metallurgiya, Moscow, 1987), Vol. 2.

D. Norfleet, P. Sarosi, S. Manchiraju, M. Wagner, M. Uchic, P. Anderson, and M. Mills, “Transformation-induced plasticity during pseudoelastic deformation in Ni–Ti microcrystals,” Acta Materialia 57 (12), 3549–3561 (2009).

T. Simon, A. Kroger, C. Somsen, A. Dlouhy, and G. Eggeler, “On the multiplication of dislocations during martensitic transformations in NiTi shape memory alloys,” Acta Materialia 58, 1850–1860 (2010).

R. Delville, B. Malard, J. Pilch, P. Sittner, and D. Schryvers, “Electron microscopy investigation of dislocation slip during superelastic cycling of Ni–Ti wires,” Int. J. Plast. 27, 282–297 (2011).

E. Hornbogen, “Review of thermo-mechanical fatigue of shape memory alloys,” J. Mater. Sci. 39, 385–399 (2004).

M. Kollerov, E. Lukina, D. Gusev, P. Mason, and P. Wagstaff, “Impact of material structure on the fatigue behavior of NiTi leading to a modified Coffin–Manson equation,” Mater. Sci. Eng. A 585, 356–362 (2013).

Funding

This work was carried out within the framework of the basic part of the state assignment for higher education institutions no. FSFF-2020-0017 using the equipment of the resource center Aerospace Materials and Technologies of the Moscow Aviation Institute.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Kollerov, M.Y., Gusev, D.E. & Vinogradov, R.E. Deformation- and Thermal-Cycle Resistance of Titanium Nickelide-Based Alloys. Russ. Metall. 2021, 856–863 (2021). https://doi.org/10.1134/S0036029521070041

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521070041