Abstract

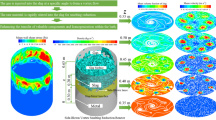

A particle-free surface coupled model has been developed using the Eulerian–Eulerian approach for revealing the gas–steel–slag multiphase flow in the vacuum chamber of a 210-ton RH degasser. The particle submodel preferred to predict the gas–steel and gas–slag interpenetrating phenomena, while the free surface submodel focused on tracking the steel–slag interface flow. The mesh sensitivity analysis has been investigated, and the coupled model was validated by the measured values. Using this coupled model, some previously unknown problems about multiphase flow in the vacuum chamber were revealed, such as the effect of the free surface fluctuation, variation of the liquid level, and slag flow behavior.

Similar content being viewed by others

References

D.Q. Geng, J.X. Zheng, K. Wang, P. Wang, R.Q. Liang, H.T. Liu, H. Lei, and J.C. He, Metall. Mater. Trans. B 46, 1484 (2015).

J. Zhang, L. Liu, X. Zhao, S. Lei, and Q. Dong, ISIJ Int. 54, 1560 (2014).

K. Steneholm, M. Andersson, A. Tilliander, and P.G. Jonsson, Ironmak. Steelmak. 40, 199 (2013).

H. Ling, F. Li, L. Zhang, and A.N. Conejo, Metall. Mater. Trans. B 47, 1950 (2016).

H. Ling, and L. Zhang, Metall. Mater. Trans. B 49, 2709 (2018).

H. Ling, L. Zhang, and C. Liu, Ironmak. Steelmak. 45, 145 (2018).

G. Chen, S. He, and Y. Li, Metall. Mater. Trans. B 48, 2176 (2017).

S. He, G. Chen, and C. Guo, Ironmak. Steelmak. 46, 771 (2019).

Y. Sheng, and G. Irons, Metall. Mater. Trans. B 24, 695 (1993).

W. Lou, and M. Zhu, Metall. Mater. Trans. B 44, 1251 (2013).

J.H. Wei, and H.T. Hu, Steel Res. Int. 77, 32 (2006).

B. Zhu, Q. Liu, D. Dong, S. Ren, M. Xu, B. Yang, and B. Hu, Steel Res. Int. 87, 136 (2016).

B. Zhu, Q. Liu, M. Kong, J. Yang, D. Li, and K. Chattopadhyay, Metall. Mater. Trans. B 48, 2620 (2017).

K. Feng, A. Liu, K. Dai, S. Feng, J. Ma, J. Xie, B. Wang, Y. Yu, and J. Zhang, Powder Technol. 314, 649 (2017).

G. Chen, S. He, Y. Li, Y. Guo, and Q. Wang, JOM 68, 2138 (2016).

M. Sano, and K. Mori, Trans. ISIJ 20, 675 (1980).

D.Q. Geng, L. Hong, and J.C. He, Metall. Mater. Trans. B 41, 234 (2010).

Y. Sato, M. Sadatomi, and K. Sekoguchi, Int. J. Multiphase. Flow 7, 167 (1981).

L. Schiller, and A. Naumann, Vdi Zeitung 77, 51 (1935).

T. Kuwabara, K. Umezawa, K. Mori, and H. Watanabe, Trans. ISIJ 28, 305 (1988).

J.J.M. Peixoto, W.V. Gabriel, T.A.S.D. Oliveira, and C.A.D. Silva, Metall. Mater. Trans. B 49, 2421 (2018).

R.D. Morales, F.A. Calderon-Hurtado, and K. Chattopadhyay, ISIJ Int. 59, 1224 (2019).

Acknowledgements

The authors are grateful for support from the Scientific Research Project of Hunan Education Department (Grant No.20C0598).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, B., Zhu, B. & Zhang, B. Numerical Simulation of Gas–Steel–Slag Multiphase Flow in the Vacuum Chamber of the RH Degasser. JOM 73, 2920–2928 (2021). https://doi.org/10.1007/s11837-021-04816-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04816-6