Abstract

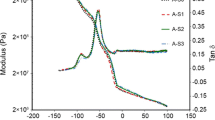

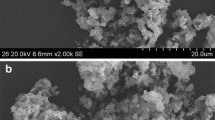

Rubber materials are utilized in automotive industry as anti-vibration bushes, engine mounts, and shock absorbers especially for the vibration, noise and shock absorbing purposes. General purpose elastomers are blended with each other to combine their individual properties in one material. It is worth mentioning here that with increasing demand in performance requirement, the usage of blends is almost inevitable. In this study, four natural rubber (NR)/styrene butadiene rubber (SBR) blends were formulated with different rubber ratios to produce anti-vibration bushings and to examine the effect of NR/SBR ratio on the performance of bushings. Dispersion of the rubber was also examined to observe the filling distribution of rubber recipes. The prepared rubber formulations were characterized by the rheological and physico-mechanical tests. It was found that the dispersibility and tensile strength of the rubber mixture increased by increasing NR ratio. The rubber formulations were vulcanized at 190 °C and 540–600 s, determined after some rheological and physico-mechanical tests. After vulcanization, static and dynamic mechanical tests on anti-vibration bushings were carried out to examine the effect of elastomer ratio on durability properties of products. We found that increasing NR ratio up to 70% is enough for lowest hysteresis and longer life-time for the anti-vibration products.

Graphical abstract

Similar content being viewed by others

References

Han T, Nagarajan S, Zhao H, Sun C, Wen S, Zhao S, Zhao S, Zhang L (2020) Novel reinforcement behavior in nanofilled natural rubber (NR)/butadiene-acrylonitrile rubber (NBR) blends: filling-polymer network and supernanosphere. Polymer 186:122005

Sae-oui P, Suchiva K, Thepsuwan U, Intiya W, Yodjun P, Sirisinha C (2016) Effects of blend ratio and SBR type on properties of silica-filled SBR/NR tire tread compounds. Rubber Chem Technol 89:240–250

Blanchard R, Ogunsona EO, Hojabr S, Berry R, Mekonnen TH (2020) Synergistic cross-linking and reinforcing enhancement of rubber latex with cellulose nanocrystals for glove applications. ACS Appl Polym Mater 2:887–898

Luo RK, Wang W, Xu Q, Li X (2017) An energy dissipation approach on complete loading-unloading and dynamic impact predictions with experimental verification for rubber anti-vibration component. Polym Test 63:314–322

Burelo M, Martínez A, Cruz-Morales JA, Tlenkopatchev MA, GutiérrezaS, (2019) Metathesis reaction from bio-based resources: synthesis of diols and macrodiols using fatty alcohols, β-citronellol and natural rubber. Polym Degrad Stab 166:202–212

Martínez A, Tlenkopatchev MA, Gutiérrez S, Burelo M, Vargas J, Jiménez-Regalado E (2019) Synthesis of unsaturated esters by cross-metathesis of terpenes and natural rubber using Ru-alkylidene catalysts. Curr Org Chem 23:1356–1364

Longseng R, Khaokong C (2020) Hexamethylene diamine-modified epoxidized natural rubber and its effect on cure characteristics and properties of natural rubber blends. Iran Polym J 29:1113–1121

Thomas S (2014) Vibration and sound damping in polymers. Resonance 19:821–833

Prasad VBSR, DrG VenkataRao, Idrees M (2020) Identification of damping characteristics of EPDM-Rubberwith applications to sandwiched beams and considerations to engine mounts for performance evaluation. Mater Today Proc 24:628–640

Östberg M, Jerrelind J, Kari L (2014) A study of the influence of rubber bushings on the audible frequency behaviour of a truck damper. Int J Heavy Veh Syst 21:281–294

Lee HS, Shin JK, Msolli S, Kim HS (2019) Prediction of the dynamic equivalent stiffness for a rubber bushing using the finite element method and empirical modeling. Int J Mech Mater Des 15:77–91

Kutlak H, Uygur İ (2014) Fatigue life analysis of a commercial vehicle sheet metal Wishbone system by using finite element method. Düzce Univ J Sci Technol 2:235–250

Carleo F, Plagge J, Whear R, Busfield J, Klüppel M (2020) Modeling the full time-dependent phenomenology of filled rubber for use in anti-vibration design. Polymers (Basel) 12:841

Banić M, Stamenković D, Miltenović A, Jovanovic D, Tica M (2020) Procedure for the selection of rubber compound in rubber-metal springs for vibration isolation. Polymers (Basel) 12:1737

García Tárrago MJ, Kari L, Vinolas J, Gil-Negrete N (2007) Frequency and amplitude dependence of the axial and radial stiffness of carbon-black filled rubber bushings. Polym Test 26:629–638

Tárrago MJG, Kari L, Viñolas J, Gil-Negrete N (2007) Torsion stiffness of a rubber bushing: a simple engineering design formula including the amplitude dependence. J Strain Anal Eng Des 42:13–21

Joseph R, George KE, Francis DJ (1988) Studies on the cure characteristics and vulcanizate properties of 50/50 NR/SBR blend. J Appl Polym Sci 35:1003–1017

Eken YF, Kokangül A (2018) Optimization of vulcanization’s parameters for rubber industry. Çukurova Univ J Fac Eng Archit 35:126–140

ISO 11345:2006 (2006) Rubber- Assessment of carbon black and carbon black/silica dispersion- Rapid comparative methods

ASTM D5289 (2015) Rubber Property - Vulcanization using rotorless cure meters

ASTM D2240–15 (2017) Standard Test Method for Rubber Property — Durometer Hardness

TS ISO 2781 (2015) Rubber, vulcanized – Determination of density

ASTM D412–16 (2016) Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM Int West Conshohocken, PA, pp 1–14

Darı ME, Akyüz S, Bingöl Ö (2018) Experimental investigation of hysteresis loss in antivibration bushings related to rubber formulations. In: Otekon’09, 9th Int Automotive Technol Cong, Bursa, pp 1068–1075

Doma AS, Hassan HH (2017) Curing parameters and mechanical properties of NR/SBR blends. Am J Condens Matter Phys 7:87–92

Jovanović S, Jovanović V, Marković G, Samaržija-JovanovićS MZ, Marinović-Cincović M, Budinski-Simendić J (2019) Elastomers based on NR/BR/SBR ternary rubber blend: morphological, mechanical and thermal properties. Chem Ind Chem Eng Q 25:31–38

Findik F, Yilmaz R, Köksal T (2004) Investigation of mechanical and physical properties of several industrial rubbers. Mater Des 25:269–276

Robertson CG, Hardman NJ (2021) Nature of carbon black reinforcement of rubber: perspective on the original polymer nanocomposite. Polymers (Basel) 13:538

Soyubol B (2006) Examining static and dynamic properties of elastomers. Master Thesis, Uludag University, Turkey

Ramezani M, Ripin ZM (2012) Characteristics of elastomer materials. In: Rubber-Pad Forming Processes. Elsevier, pp 43–64

Dzierzek S (2000) Experiment-based modeling of cylindrical rubber bushings for the simulation of wheel suspension dynamic behavior. In: SAE Technical Papers. SAE International, USA

Nafeesa MS, Azura AR (2018) The influence of different types of rubber on curing behaviour and dynamic properties of rubber compound. J Phys Conf Ser 1082:12010

Albouy P-A, Sotta P (2017) Strain-induced crystallization in natural rubber BT - polymer crystallization. II: From chain microstructure to processing. In: Auriemma F, Alfonso GC, de Rosa C (Eds.). Springer International Publishing, Cham, 167–205

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The part of the rubber formula except NR/SBR rubber and carbon black is confidential to the Yamas Inc. and details of the formula could not be shared.

Rights and permissions

About this article

Cite this article

Akyüz, S., Darı, M.E., Esiyok, Y.E. et al. Effects of NR/SBR ratio on mechanical properties and artificial mechanical performance of anti-vibration bushings. Iran Polym J 30, 1317–1328 (2021). https://doi.org/10.1007/s13726-021-00971-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00971-4