Abstract

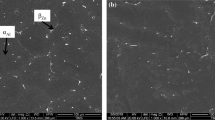

Microstructure refinement is known to have a significant effect on the electrochemical properties of the metallic alloys. The current research investigated the electrochemical properties of Zn–0.5 wt% Al alloy as influenced by the microstructure changes due to Mg addition. Magnesium was added as alloying element during the melting process in amounts that ranged between 0.1 and 0.9 wt%. Some specimens (0.2, 0.5, 0.7, 0.8, 0.9 wt% Mg) with obvious microstructure changes were selected to evaluate their electrochemical properties. The samples were immersed in 3.5% NaCl solution for 3, 8 and 30 days, and the corrosion rate was then calculated based on the weight loss after removing the corrosion products. Polarization tests were also performed, and both of Tafel curves and impedance circles were recorded. It was observed that Mg additions refined Zn dendrites and significantly reduced their size from 165 μm without Mg down to 20 μm with 0.7 wt% Mg where the dendritic morphology changed to the polygonal shape. However, the dendritic morphology was retained with further increase in Mg content. As a result of microstructure refinement and the observed uniform distribution of Al in the interdendritic regions with Mg addition, the corrosion resistance of (Zn–0.5Al) alloy increased and the corrosion rate was reduced from (~ 0.00099 mm/year) without Mg down to (~ 0.0005 mm/year) at 0.7 wt% Mg. Increasing the amount of Mg to 0.8 wt% raised the corrosion rate to (~ 0.0015 mm/year) and affected negatively the corrosion resistance of the alloy.

Similar content being viewed by others

References

G. Zeng, S. McDonald, K. Nogita, Development of high-temperature solders: Review. Microelectron. Reliab. 52, 1306–1322 (2012). https://doi.org/10.1016/j.microrel.2012.02.018

T. Gancarz, G. Cempura, W. Skuza, Characterization of Zn–Al cast alloys with Na addition. Mater. Char. 111, 147–153 (2016). https://doi.org/10.1016/j.matchar.2015.11.025

Y. He, D. Li, D. Wang, Z. Zhang, H. Qi, W. Gao, Corrosion resistance of Zn–Al co-cementation coatings on carbon steels. Mater. Lett. 56, 554–559 (2002). https://doi.org/10.1016/S0167-577X(02)00551-7

M. Azevedo, C. Allely, K. Ogle, P. Volovitch, Corrosion mechanisms of Zn (Mg, Al) coated steel: 2. The effect of Mg and Al alloying on the formation and properties of corrosion products in different electrolytes. Corros. Sci. 90, 482–490 (2015). https://doi.org/10.1016/j.corsci.2014.07.042

Cottis, R.A., Graham, M.J., Lindsay, R., Lyon, S.B., Richardson, J.A., Scantlebury, J.D., Stott, F.H., Management and Control of Corrosion, Shreir's Corrosion, vol. 4, Elsevier, Amsterdam, 2764 (2010).

S. El-Hadad, M.E. Moussa, M. Waly, Effects of Alloying with Sn and Mg on the Microstructure and Electrochemical Behavior of Cast Aluminum Sacrificial Anodes. Inter Metalcast 15, 548–565 (2021). https://doi.org/10.1007/s40962-020-00483-6

P.S. Kumar, V. Kavimani, K.S. Prakash, Effect of TiB2 on the corrosion resistance behavior of in situ Al composites. Inter Metalcast 14, 84–91 (2020). https://doi.org/10.1007/s40962-019-00330-3

C.R. Barbosa, T.C. Silva, H.M. Azevedo, Correlation between unsteady-state solidification and electrochemical corrosion parameters of an AlSiMg alloy. Inter Metalcast (2021). https://doi.org/10.1007/s40962-021-00571-1

A. Kordijazi, D. Weiss, S. Das, S. Behera, M. Roshan, H., Rohatgi, P. , Effect of solidification time on microstructure, wettability, and corrosion properties of A205–T7 aluminum alloys. Inter Metalcast 15, 2–12 (2021). https://doi.org/10.1007/s40962-020-00457-8

W.R. Osório, C.M. Freire, A. Garcia, The effect of the dendritic microstructure on the corrosion resistance of Zn–Al alloys. J. Alloys Compd. 397, 179–191 (2005). https://doi.org/10.1016/j.jallcom.2005.01.035

M.M. Lachowicz, M.B. Lachowicz, Intergranular Corrosion of the as Cast Hypoeutectic Zinc-Aluminium Alloy. Archives of Foundry. 17, 79–84 (2017)

A.E. Ares, L.M. Gassa, Corrosion susceptibility of Zn–Al alloys with different grains and dendritic microstructures in Nacl solutions. Corr. Sci. 59, 290–306 (2012). https://doi.org/10.1016/j.corsci.2012.03.015

T. Prosek, J. Hagström, D. Persson, N. Fuertes, F. Lindberg, O. Chocolatý, C. Taxén, J. Šerák, D. Thierry, Effect of the microstructure of Zn–Al and Zn–Al–Mg model alloys on corrosion stability. Corr. Sci. 110, 71–81 (2016). https://doi.org/10.1016/j.corsci.2016.04.022

ASTM, Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens, ASTM Standard G1-03. Annual Book of ASTM Standards 03.02 ASTM, Philadelphia. PA, (2011).

H.R. Bakhsheshi-Rad, E. Hamzah, H.T. Low, M. Kasiri-Asgarani, S. Farahany, E. Akbar, M.H. Cho, Fabrication of biodegradable Zn–Al–Mg alloy: Mechanical properties, corrosion behavior, cytotoxicity and antibacterial activities. Mater. Sci. Eng., C 73, 215–219 (2017)

K.C. Yu, J. Li, X. Liu, J.G. Li, X.H. Xue, Microstructure of hot-dip galvanized Zn–Al–Mg alloy coating. J. Shanghai Jiaotong Univ. 17, 663–667 (2012). https://doi.org/10.1007/s12204-012-1342-5

M. Arndt, J. Duchoslav, H. Itani, G. Hesser, C.K. Riener, G. Angeli, K. Preis, D. Stifter, K. Hingerl, Nanoscale analysis of surface oxides on ZnMgAl hot-dipcoated steel sheets. Anal. Bioanal. Chem. 403, 651–661 (2012)

S. Farahany, L.H. Tat, E. Hamzah, H.R. Bakhsheshi-Rad, M.H. Cho, Microstructure development, phase reaction characteristics and properties of quaternary Zn–0.5Al–0.5Mg–xBi hot dipped coating alloy under slow and fast cooling rates. Surf. Coat. Techn. 315, 112–122 (2017). https://doi.org/10.1016/j.surfcoat.2017.01.074

W.R. Osório, J.E. Spinelli, C.M. Freire, A. Garcia, The role of macrostructural and microstructural morphologies on the corrosion resistance of Zn and a Zn–4% Al alloy. Mater. Manuf. Process. 22, 341–345 (2007). https://doi.org/10.1080/10426910701190386

S.E. Offerman, N.H. van Dijk, J. Sietsma, S. Grigull, E.M. Lauridsen, L. Margulies, H.F. Poulsen, M.T. Rekveldt, S. van der Zwaag, Grain Nucleation and Growth During Phase Transformations. Science 298, 1003–1005 (2002)

Z.L. Liu, Review of Grain Refinement of Cast Metals Through Inoculation: Theories and Developments. Metall. Mater. Trans. A 48A, 4755–4776 (2017)

Y. Meng, L. Liu, D. Zhang, C. Dong, Y. Yan, A.A. Volinsky, L.N. Wang, Initial formation of corrosion products on pure zinc in saline solution. Bioactive Mater. 4, 87–96 (2019). https://doi.org/10.1016/j.bioactmat.2018.08.003

Acknowledgments

The authors acknowledge the fund from the Central Metallurgical Research and Development Institute (CMRDI) “internal project No. 2019/2020.” The corresponding author would like to acknowledge the partial fund from the Science Technology and Development Fund-Egypt, grant No. 26565.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moussa, M.E., El-Hadad, S. & Shoeib, M. Influence of Dendritic Fragmentation through Mg Addition on the Electrochemical Characteristics of Zn–0.5 wt% Al Alloy. Inter Metalcast 16, 1034–1044 (2022). https://doi.org/10.1007/s40962-021-00662-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00662-z