Abstract

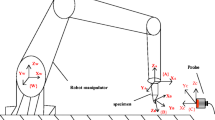

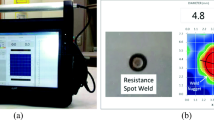

Automation is a topical issue in the development of methods and equipment for ultrasonic nondestructive testing. The conditions of modern industrial production require the development of ultrasonic testing equipment that would be sufficiently flexible for a wide and changing range of manufactured products, which, as a rule, have a complex shape. This paper proposes a technology for ultrasonic flaw detection of complex shaped objects. Within the framework of this technology, it is proposed to use six-axis robotic manipulators to ensure the required angle of input of ultrasonic waves into the test object at each measuring position. The correct trajectory of robot’s movement during scanning is ensured by reconstructing the surface profile of the test object using optical profilometry and determining the location of the test object relative to the robotic manipulator using an electric probe. The effectiveness of the developed technology is verified experimentally within the framework of this work.

Similar content being viewed by others

REFERENCES

Ermolov, I.N., Teoriya i praktika ul’trazvukovogo kontrolya (Theory and Practice of Ultrasonic Testing), Moscow: Mashinostroenie, 1981.

Ermolov, I.N. and Lange, Yu.V., Nerazrushayushchii control’. Spravochnik v 7 tomakh (Nondestructive Testing. A Handbook in 7 volumes), Moscow: Mashinostroenie, 2004, vol. 3.

Vatul’yan, A.O. and Belyak, O.A., Inverse problem of identifying a small defect based on an asymptotic method, Russ. J. Nondes. Test., 2020, vol. 56, no. 7, pp. 549–555. https://doi.org/10.1134/S1061830920070074

Marusina, M.Ya., Fedorov, A.V., Prokhorovich, V.E., Berkutov, I.V., Bychenok, V.A., Tkacheva, N.V., and Maerov, A.L., Development of acoustic methods for monitoring the stress-strain state of threaded connections, Izmer. Tekh., 2018, no. 3, pp. 60–64. https://doi.org/10.1007/s11018-018-1424-3

Aleshin, N.P., Mogilner, L.Yu., and Krysko, N.V., On Interaction of elastic waves with “semitransparent” defects, Russ. J. Nondestr. Test., 2020, vol. 56, no. 6, pp. 469–478.https://doi.org/10.1134/S1061830920060030

Dolmatov, D.O. and Abramets, V., Application of frequency-domain algorithms in ultrasound imaging of composite materials, IV Russ. Forum Young Sci. Int. Participation “Space Eng.”, Tomsk, 2016, vol. 48, article ID 3004. https://doi.org/10.1051/matecconf/20164803004

Xiao, Z., Xu, C., Xiao, D., Liu, F., and Yin, M., An optimized robotic scanning scheme for ultrasonic NDT of complex structures, Exp. Tech., 2017, vol. 41, no. 4, pp. 389–398. https://doi.org/10.1007/s40799-017-0182-5

Mineo, C., Herbert, D., Morozov, M., and Pierce, S.G., Robotic non-destructive inspection, 51st Annu. Conf. Br. Inst. NDT, (Northhampton, 2012), pp. 345–352.

Zhen, X., Yong, Y., Guang, X.C., Guo, X.D., Fang, L.F., and Liang, L.X., Profile tracking with ultrasonic alignment for automatic non-destructive testing of complex structures, Rob. Comp.-Integr. Manuf., 2018, vol. 49, pp. 134–142. https://doi.org/10.1016/j.rcim.2017.06.007

Hu, H., Ye, C., Wang, X., and Xu, N., Multi-angle spatial compound imaging in ultrasonic immersion testing using a single transducer, J. Instrum., 2018, vol. 13, no. 7, article ID P07004. https://doi.org/10.1088/1748-0221/13/07/P07004

Stetson, J.T. and de Odorico, W., Robotic inspection of fiber reinforced composites using phased array UT, Am. Inst. Phys., Conf. Proc., 2014, vol. 1581, no. 1, pp. 1889–1895. https://doi.org/10.1063/1.4865054

Dolmatov, D., Zhvyrblya, V., Filippov, G., Salchak, Y., and Sedanova, E., Advanced ultrasonic testing of complex shaped composite structures, IOP Conf. Ser.: Mater. Sci. Eng., 2016, vol. 135, article no. 012010. https://doi.org/10.1088/1757-899X/135/1/012010

Zhvyrblya, V.Y., Filippov, G.A., Sedanova, E., and Salchak, Y.A., Ultrasonic tomography of complex shaped carbon fiber composites, IV Russ. Forum Young Sci. Int. Participation “Space Eng.,” Tomsk, 2016, vol. 48, article ID 3005. https://doi.org/10.1051/confmatec/20164803005

Truel, R., Elbaum, C., and Chick, B., Ultrasonic Methods in Solid State Physics, New York: Academic Press, 1969.

Kretov, E.F., Ul’trazvukovaya Defektoskopiya v Energomashinostroenii (Ultrasonic Flaw Detection in Power Engineering), St. Petersburg: SVEN, 2014.

Funding

The study was carried out using the scientific equipment of the TPU Shared Use Center and with the financial support of the State Assignment “Science,” project no. FSWW-2020-0014, as well as the Competitiveness Improvement Program of Tomsk Polytechnic University.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Larionov, V.V., Lider, A.M., Dolmatov, D.O. et al. Ultrasonic Testing for Defects in Complex Shaped Metal Products. Russ J Nondestruct Test 57, 369–374 (2021). https://doi.org/10.1134/S1061830921050090

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830921050090