Abstract

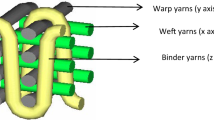

This research paper presented recent advancements on the manufacturing technique of the 3D warp interlock fabrics (3DWIFs) as fibrous material. Four different types of 3DWIFs are designed by WiseTex© and DB-WEAVE software: Angle interlock/through-the-thickness binding (A/T), Angle interlock/layer-to-layer binding (A/L), Orthogonal interlock/through-the-thickness binding (O/T), Orthogonal interlock/ layer-to-layer binding (O/L). These kinds of 3DWIFs are woven by high molecular weight polyethylene (HMWPE) yarns with 50 twists per meter (tpm) on a dobby DORNIER weaving machine. The paper also presented and discussed the problems and solutions during the weaving process, such as regulating yarn tension. Besides, the yarn abrasion during the manufacturing process is studied. It was found that the average breaking force of weft yarns were reduced by 6.2—11.8%, the binding warp yarns after weaving are reduced by 2.8—8.9% and the yarn strength degradation of stuffer warp yarns is 9.9—15.2%.

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this published article.

References

Li, M., Wang, P., Boussu, F., Soulat, D.: A review on the mechanical performance of three-dimensional warp interlock woven fabrics as reinforcement in composites. (2020) J. Ind. Text. https://doi.org/10.1177/1528083719894389

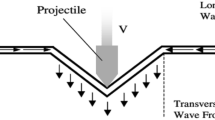

Jia, X., Sun, B., Gu, B.: Ballistic penetration of conically cylindrical steel projectile into 3D orthogonal woven composite: a finite element study at microstructure level. J. Compos. Mater. 45, 965–987 (2011). https://doi.org/10.1177/0021998310381150

Li, M., Wang, P.: Dynamic stab resistance of multi-ply three-dimensional warp interlock fabrics with polyethylene yarns for protective applications. J. Ind. Text. (2020). https://doi.org/10.1177/1528083720965685

Li, M., Wang, P., Boussu, F., Soulat, D.: Investigation of impact performance of 3-dimensional interlock polymer fabrics in double and multi-angle pass stabbing. Mater. Des. (2021). https://doi.org/10.1016/j.matdes.2021.109775

Bandaru, A.K., Sachan, Y., Ahmad, S., Alagirusamy, R., Bhatnagar, N.: On the mechanical response of 2D plain woven and 3D angle-interlock fabrics. Compos. Part B Eng. 118, 135–148 (2017). https://doi.org/10.1016/j.compositesb.2017.03.011

Ha-Minh, C., Imad, A., Boussu, F., Kanit, T.: Experimental and numerical investigation of a 3D woven fabric subjected to a ballistic impact. Int. J. Impact Eng. 88, 91–101 (2015). https://doi.org/10.1016/j.ijimpeng.2015.08.011

Hu, J.: Introduction to three-dimensional fi brous assemblies. 3-D Fibrous Assem. (2008). https://doi.org/10.1533/B978-1-84569-377-0.50001-1

Cox, B.N., Dadkhah, M.S., Morris, W.L.: On the tensile failure of 3D woven composites. Compos. Part A Appl. Sci. Manuf. 27, 447–458 (1996). https://doi.org/10.1016/1359-835X(95)00053-5

Behera, B.K., Mishra, R.: 3-Dimensional weaving. Indian J. Fibre Text. Res. 33, 274–287 (2008)

Dufour, C., Wang, P., Boussu, F., Soulat, D.: Experimental Investigation About Stamping Behaviour of 3D Warp Interlock Composite Preforms. Appl. Compos. Mater. 21, 725–738 (2014). https://doi.org/10.1007/s10443-013-9369-9

Abtew, M.A., Boussu, F., Bruniaux, P., Loghin, C., Cristian, I., Chen, Y., Wang, L.: Yarn degradation during weaving process and its effect on the mechanical behaviours of 3D warp interlock p-aramid fabric for industrial applications, Journal of Industrial Textiles. 1-24 (2020). https://doi.org/10.1177/1528083720937288

Lee, B., Leong, K.H., Herszberg, I.: Effect of weaving on the tensile properties of carbon fibre tows and woven composites. J. Reinf. Plast. Compos. 20, 652–670 (2001). https://doi.org/10.1106/0A9Q-L2XM-955Y-N469

Lee, L., Rudov-Clark, S., Mouritz, A.P., Bannister, M.K., Herszberg, I.: Effect of weaving damage on the tensile properties of three-dimensional woven composites. Compos. Struct. 57, 405–413 (2002). https://doi.org/10.1016/S0263-8223(02)00108-3

Rudov-Clark, S., Mouritz, A.P., Lee, L., Bannister, M.K.: Fibre damage in the manufacture of advanced three-dimensional woven composites. Compos. Part A Appl. Sci. Manuf. 34, 963–970 (2003). https://doi.org/10.1016/S1359-835X(03)00213-6

Lefebvre, M., Francois, B., Daniel, C.: Influence of high-performance yarns degradation inside three-dimensional warp interlock fabric. J. Ind. Text. 42, 475–488 (2013). https://doi.org/10.1177/1528083712444298

Boussu, F., Cristian, I., Nauman, S.: General definition of 3D warp interlock fabric architecture. Compos. Part B Eng. 81, 171–188 (2015). https://doi.org/10.1016/j.compositesb.2015.07.013

ASTM D 1907 / D1907M-12(2018), Standard Text Method for Linear Density of Yarn (Yarn number) by the Skein Method, ASTM International West Conshonocken, PA, 2018, https://www.astm.org/

Yang, X., Fan Wei., Ge, S., Gao, X., et al.: Advanced textile technology for fabrication of ramie fiber PLA composites with enhanced mechnical properties. Ind. Crop. Prod. (2021). https://doi.org/10.1016/j.indcrop.2021.113312

ISO 2062: 2009. Textiles — Yarns from packages — Determination of single-end breaking force and elongation at break using constant rate of extension (CRE) tester

Li, M., Wang, P., Boussu, F., Soulat, D.: Effect of Fabric Architecture on Tensile Behaviour of the High-Molecular-Weight Polyethylene 3-Dimensional Interlock Composite Reinforcements. Polymers (Basel). 12, 1–18 (2020). https://doi.org/10.3390/polym12051045

Rao, Y., Farris, R.J.: Modeling and experimental study of the influence of twist on the mechanical properties of high-performance fiber yarns. J. Appl. Polym. Sci. 77, 1938–1949 (2000). https://doi.org/10.1002/1097-4628(20000829)77:9%3c1938::AID-APP9%3e3.0.CO;2-D

Chen, X., Taylor, L.W., Tsai, L.J.: An overview on fabrication of three-dimensional woven textile preforms for composites. Text. Res. J. 2011. 81, 932–944 (2011). https://doi.org/10.1016/B978-1-78242-458-1.00013-3

Boussu, F., Dufour, C., Veyet, F., Lefebvre, M.: Weaving processes for composites manufacture. In: Advances in Composites Manufacturing and Process Design. pp. 55–78. Woodhead Publishing (2015)

Shaker, K., Umair, M., Ashraf, W., Nawab, Y.: Fabric manufacturing, (2016)

Syed, U., Jhatial, R.A., Peerzada, M.H.: Influence of Warp Yarn Tension on Cotton Woven Fabric Structures. Mehran Univ. Res. J. Eng. Technol. 32, 125–132 (2013)

Afroz, F., Siddika, A.: Effect of Warp Yarn Tension on Crimp % in Woven Fabric. Eur. Sci. J. 10, 202–207 (2014). https://doi.org/10.19044/esj.2014.v10n24p%25p

Neogi, S.K.: Role of yarn tension in weaving. Woodhead publishing india in textiles (2016)

Ghosh, S., Chary, P., Roy, S.: Development of Warp Yarn Tension During Shedding: A Theoretical Approach. J. Inst. Eng. Ser. E. 96, 107–124 (2015). https://doi.org/10.1007/s40034-014-0044-y

Nauman, S.: Geometrical modelling and characterization of 3D warp interlock composites and their on-line structural health monitoring using flexible textile sensors, (2011)

Acknowledgements

The authors wish to express their gratitude to the China Scholarship Council (Project no. 201708420167) for financially supporting this work.

Author information

Authors and Affiliations

Contributions

Mengru Li: Investigation, Methodology, Data curation, Software, Formal analysis, Writing-original draft. Peng Wang: Project administration, Supervision, Methodology, Data curation, Formal analysis, Writing-review & editing. François Boussu: Project administration, Supervision, Methodology, Software, Resources, Review & editing. Damien Soulat: Project administration, Methodology, Resources, Review & editing.

Corresponding author

Ethics declarations

Conflicting Interests

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, M., Wang, P., Boussu, F. et al. Investigation of the Strength Loss of HMWPE Yarns During Manufacturing Process of 3D Warp Interlock Fabrics. Appl Compos Mater 29, 357–371 (2022). https://doi.org/10.1007/s10443-021-09951-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09951-6