Abstract

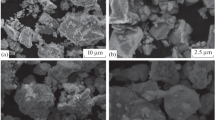

A technique was tested for structuring a finely dispersed bulk ferrosilicoaluminum powder by cryogels based on an aqueous poly(vinyl alcohol) solution to prepare products of a desired shape using porous nitride-containing ceramics as a structural material. The physical and mechanical properties of the produced samples were investigated. It was found that the materials obtained after preliminary cryostructuring of the initial powder and subsequent self-propagating high-temperature synthesis in a nitrogen atmosphere are characterized by high strength and porosity.

Similar content being viewed by others

REFERENCES

Maksimov, Yu.M., Chukhlomina, L.N., Bravermann, B.Sh., and Smirnov, L.A., Samorasprostranyayushchiisya vysokotemperaturnyi sintez azotsoderzhashchikh splavov dlya metallurgii (Self-Propagating High-Temperature Synthesis of Nitrogen-Containing Alloys for Metallurgy), Novosibirsk: Nauka, 2014.

Gromov, A.A., Chukhlomina, L.N., Nitride Ceramics: Combustion Synthesis, Properties and Applications, New York: Wiley-VCH Verlag GmbH & Co, 2015.

Low, I.M., Ceramic Matrix Composites. Microstructure, Proporties and Application, Cambridge: Woodhead, 2006.

Gromov, A.A., Levashov, E.A., Maksimov, Y.M., Mukasyan, A.S., Rogachev, A.S., and Borovinskaya, I.P., Concise Encyclopedia of Self-Propagating High-Temperature Synthesis: History, Theory, Technology, and Products, Amsterdam: Elsevier Inc., 2017. https://doi.org/10.1016/C2015-0-00439-7

Manashev, I.R., Gavrilova, T.O., Shatokhin, I.M., and Ziatdinov, M.Kh., Teoriya Tekhnologiya Metallurg. Proisv., 2019. no. 4, pp. 4–11.

Grigor’ev, O.N., Dubovik, T.V., Vinokurov, V.B., Kotenko, V.A., Bega, N.D., Subotin, V.I., and Klimenko, L.I., Ogneupory Tekhn. Keramika, 2007, no. 2, pp. 10–14.

Lozinsky, V.I., Russ. Chem. Rev., 1998, vol. 67, no. 7, pp. 573–586. https://doi.org/10.1070/RC1998v067n07ABEH000399

Ivanova, Z.I. and Savostin, A.P., Tekhnicheskii analiz (Technical Analysis), Moscow: Metallurgiya, 2011.

Bolgaru, K.A., Braverman, B.Sh., Maksimov, Yu.M., Reger, A.A., and Vereshchagin, V.I., Mezhdunar. Zh. Prikl. Fundam. Issled., 2019, no. 11, pp. 86–91. https://doi.org/10.17513/mjpfi.12937

RU Patent 2736195 (publ. 2020).

Funding

The work was carried out within the framework of the state assignment of the Institute of Petroleum Chemistry of the Siberian Branch of the Russian Academy of Sciences, financed by the Ministry of Science and Higher Education of the Russian Federation, and the state assignment of the Ministry of Science and Higher Education of the Russian Federation for the Tomsk Scientific Center of the Siberian Branch of the Russian Academy of Sciences (project no. 0290-2021-0002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest requiring disclosure in this article.

Additional information

Translated from Zhurnal Prikladnoi Khimii, No. 6, pp. 716–721, January, 2021 https://doi.org/10.31857/S0044461821060050

Rights and permissions

About this article

Cite this article

Manzhai, V.N., Fufaeva, M.S., Bolgaru, K.A. et al. Structuring of Finely Dispersed Ferrosilicoaluminum for Nitride-Containing Ceramics Production. Russ J Appl Chem 94, 731–735 (2021). https://doi.org/10.1134/S1070427221060057

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427221060057