Abstract

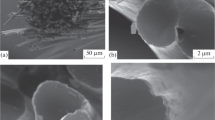

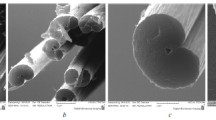

Four types of metal coating consisting of stainless steel, silver, titanium, and copper are applied to the surface of a unidirectional carbon fiber tape by magnetron sputtering. The results of the experimental evaluation of the strength of elementary carbon fibers with metal coatings and interlaminar shear strength of carbon-fiber-reinforced plastics based on them are presented. An epoxide binding agent and vacuum infusion technology are used when fabricating the carbon-fiber-reinforced plastics. The results of the structural analysis of the elementary carbon fibers with metal coatings are presented, and their thicknesses are determined. It is found that all the used metal coatings lead to an increase in the interlaminar shear strength of the carbon-fiber-reinforced plastics. The strength to the greatest extent increases when using a carbon fiber tape with the coating made of stainless steel (by 50%); however, the efficiency of the metallized carbon fiber tapes decreases upon long-term storage.

Similar content being viewed by others

REFERENCES

Bazhenov, S.L., Berlin, A.A., Kul’kov, A.A., and Oshmyan, V.G., Polimernye kompozitsionnye materialy (Composite Polymer Materials. Durability and Technology), Dolgoprudnyi: Intellekt, 2010.

Baurova, N.I. and Zorin, V.A., Primenenie polimernykh kompozitsionnykh materialov pri proizvodstve i remonte mashin: Uchebnoe posobie (Application of Polymer Composite Materials for the Production and Repair of Machines: Handbook), Moscow: MADI, 2016.

Sergeev, A.Y., Turusov, R.A., and Baurova, N.I., Strength of the joint of an anisotropic composite and a cylindrical element of the exhaust system of road vehicles, Mech. Compos. Mater., 2016, vol. 52, no. 3, pp. 89–98.

Sergeyev, A.Y., Turusov, R.A., Baurova, N.I., and Kuperman, A.M., Stresses arising during cure of the composite wound on the cylindrical surface of an element of exhaust system, Mech. Compos. Mater., 2015, vol. 51, no. 3, pp. 321–332.

Maung, P.P., Malysheva, G.V., and Gusev, S.A., A study of the effect of network angle of fabrics on kinetics of impregnation upon molding of articles made from carbon plastics, Polym. Sci., Ser. D, 2016, vol. 9, no. 4, pp. 407–410.

Kobets, L.P., Malysheva, G.V., and Borodulin, A.S., Rheological properties of system “elastomer binder-discrete carbon fiber”, Inorg. Mater.: Appl. Res., 2016, vol. 7, no. 1, pp. 15–19.

Kondrashov, S.V., Shashnev, K.A., Popkov, O.V., and Solov’yanchik, L.V., Prospective producing methods for functional structural materials based on CNT-filled nanocomposites (review), Tr. Vseross. Inst. Aviats. Mater., 2016, no. 3 (39), pp. 54–64.

Bocharov, A., Vigovskiy, V., and Nelyub, V.A., Metal coating of carbon fabric and properties of the carbon-fiber-reinforced plastic, Mater. Today: Proc., 2019, vol. 11, pp. 107–111.

Nelyub, V.A. and Malysheva, G.V., Modern treatment technologies of carbon fibre for ensuring the high strength carbon fibre reinforced plastic, MATEC Web Conf., 2017, vol. 129, art. ID 02001.

Berlin, E.V. and Seidman, L.A., Ionno-plazmennye protsessy v tonkoplenochnoi tekhnologii (Ion-Plasma Processes in Thin Film Technology), Moscow: Tekhnosfera, 2010.

Nelyub, V.A., Berlin, E.V., and Gorberg, B.L., RF Patent 2698809, 2018.

Petrova, A.P. and Malysheva, G.V., Klei, kleevye svyazuyushchie i kleevye prepregi (Glues, Adhesive Binders, and Adhesive Prepregs), Kablov, E.N., Ed., Moscow: VIAM, 2017.

Chudnov, I.V., Nelyub, V.A., and Marycheva, A.N., Molding carbon fiber parts by vacuum infusion technology using a reusable elastic membrane, Polym. Sci., Ser. D, 2020, vol. 13, pp. 197–200. https://doi.org/10.1134/S1995421220020057

Funding

This study was partially supported by the Russian Foundation for Basic Research (grant no. 18‑29‑19034/18 “Development of the Theoretical and Process Grounds of Fabricating High-Strength Carbon-Fiber-Reinforced Plastics with a Set of Novel Functional Properties Based on Metallized Fibers”).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Boltukhina

Rights and permissions

About this article

Cite this article

Nelyub, V.A., Fedorov, S.Y. & Malysheva, G.V. The Study of the Structure and Properties of Elementary Carbon Fibers with Metal Coatings. Inorg. Mater. Appl. Res. 12, 1037–1041 (2021). https://doi.org/10.1134/S2075113321040316

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113321040316