Abstract

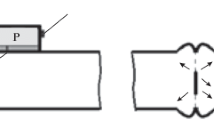

Agglomerations of oxide films are some of the typical defects of friction stir welding. The structure of such defects and their small opening do not allow finding them using the conventional ultrasonic nondestructive testing methods (in particular, by the pulse-echo technique), among other things because of their low reflectivity. We have proposed a technique of artificial introduction of oxide films into a welded joint. We have shown that, to reveal such defects, it is promising to use the diffraction methods of ultrasonic nondestructive testing. The diffraction methods make it possible to detect signals from defects with minimum opening as well as from defects with a partially metallic bonding, which are semitransparent to ultrasonic waves and revealing of which is impossible using other methods of ultrasonic testing, in particular, the pulse-echo technique, along with X-ray testing.

Similar content being viewed by others

REFERENCES

Śliwa, R.E. et al., Possibilities of joining different metallic parts of structure using friction stir welding methods, Procedia Manuf., 2019, vol. 27, pp. 158–165.

ESAB, Friction Stir Welding. Technical Handbook. https://assets.esab.com/asset-bank/assetfile/12296.pdf

Poklyatsky, A.G., Characteristic defects in FSW of sheet aluminium alloys and main causes for their formation, Paton Weld. J., 2008, no. 6, pp. 39–42.

Santos, T., Vilaça, P., and Quintino, L., Developments in NDT for detecting imperfections in friction stir welds in aluminium alloys, Weld. World, 2008, vol. 52, pp. 30–37. https://doi.org/10.1007/BF03266666

Gibson, B.T. et al., Friction stir welding: Process, automation, and control, J. Manuf. Processes, 2014, vol. 16, pp. 56–73.

Wieczorek, P., Lacki, P., and Więckowski, W., Assessment of joints using friction stir welding and refill friction stir spot welding methods, Arch. Metall. Mater., 2015, vol. 60, no. 3. https://doi.org/10.1515/amm-2015-0377

Delrue, S. et al., Applying a nonlinear, pitch-catch, ultrasonic technique for the detection of kissing bonds in friction stir welds, Ultrasonics, 2016, vol. 68, pp. 71–79.

Mandache, C. et al., Non-destructive detection of lack of penetration defects in friction stir welds, Sci. Technol. Weld. Joining, 2012, vol. 17, no. 4, pp. 295–303.

Tabatabaeipour, M. et al., Pulse-inversion chirp-coded weld harmonic imaging (PI-CWHI) of friction stir welded butt-joint, J. Nondestr. Eval., 2017, vol. 36, art. ID 75.

Kuchuk-Yatsenko, S.I., Shvets, V.I., Didkovsky, A.V., Antipin, E.V., and Kapitanchuk, L.M., Defects of joints of high-strength rails produced using flash-butt welding, Paton Weld. J., 2013, no. 9, pp. 2–8.

Khimicheskaya entsiklopediya (Chemical Encyclopedia), Knunyants, I.L., Ed., Moscow: Sov. Entsiklopediya, 1988, vol. 1.

Patel, V. et al., Friction stir welding of dissimilar aluminum alloy combinations: State-of-the-art, Metals, 2019, vol. 9, no. 3, art. ID 270. https://doi.org/10.3390/met9030270

Eslami, N. et al., Optimization of process parameters for friction stir welding of aluminum and copper using the Taguchi method, Metals, 2019, vol. 9, no. 1, art. ID 63. https://doi.org/10.3390/met9010063

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Podymova

Rights and permissions

About this article

Cite this article

Aleshin, N.P., Bakshaev, V.A., Grigor’ev, M.V. et al. Studies of Diffraction Methods of Ultrasonic Testing Applied for Revealing Artificial Defects Simulating Fractured Oxide Films in a Friction Stir Weld. Inorg. Mater. Appl. Res. 12, 1047–1052 (2021). https://doi.org/10.1134/S207511332104002X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207511332104002X