Abstract

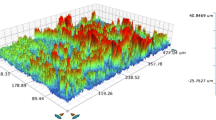

Selective Laser Melting (SLM), one of the metal additive manufacturing methods in the powder bed, is frequently used in the production of 316L stainless steel biomaterial. In this study, the effect of duplex surface modification (metal additive manufacturing and plasma oxidizing) on the corrosion resistance of 316L was investigated. Ti6Al4V layer was formed by additive manufacturing on 316L produced by selective laser melting method. The obtained layered Ti6Al4V/316L samples were oxidized by plasma at 650 °C–750 °C and 1 h–4 h parameter conditions. TiO2 ceramic layer was formed on the Ti6Al4V/316L structure by plasma oxidation process in several layer thicknesses. Corrosion properties of the TiO2 layer were determined by Open Circuit Potential (OCP), potentiodynamic polarization, and Electrochemical Impedance Spectroscopy (EIS) tests in Simulated Body Fluid (SBF) solution. Also, the surface characterizations of the samples were determined by the Vickers micro-hardness tester, Scanning Electron Microscopy (SEM), and X-Ray Diffractometer (XRD) analysis. From the results, it was obtained that the corrosion resistance of the plasma oxidized was higher than the untreated 316L and layered Ti6Al4V/316L samples. The best corrosion resistance was obtained under the 750 °C and 4 h parameter conditions because of the increasing plasma oxidizing time and temperature.

Similar content being viewed by others

References

Yetim A F, Yazici M. Wear resistance and non-magnetic layer formation on 316L implant material with plasma nitriding. Journal Bionic Engineering, 2014, 11, 620–629.

Bloyce A, Qi P Y, Dong H, Bell T. Surface modification of titanium alloys for combined improvements in corrosion and wear resistance. Surface and Coatings Technology, 1998, 107, 125–132.

Bolzoni L, Meléndez I M, Ruiz-Navas E M, Gordo E. Microstructural evolution and mechanical properties of the Ti-6Al-4V alloy produced by vacuum hot-pressing. Materials Science and Engineering A, 2012, 546, 189–197.

Sun Z J, Tan X P, Tor S B, Yeong W Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Materials & Design, 2016, 104, 197–204.

Wysocki B, Maj P, Krawczynska A, Rozniatowski K, Zdunek J, Kurzydłowski K J, Swieszkowsk W. Microstructure and mechanical properties investigation of CP titanium processed by selective laser melting (SLM). Journal of Materials Process Technology, 2017, 241, 13–23.

Çomaklı O, Yazıcı M, Yetim T, Yetim A F, Çelik A. Effect of Ti amount on wear and corrosion properties of Ti-doped Al2O3 nanocomposite ceramic coated CP titanium implant material. Ceramic International, 2018, 44, 7421–7428.

de Damborenea J J, Larosa M A, Arenas M A, Hernández-López J M, Jardini A L, Lerardi M C F, Zavaglia C A, Filho R M, Conde A. Functionalization of Ti6Al4V scaffolds produced by direct metal laser for biomedical applications. Materials & Design, 2015, 83, 6–13.

Murr L A, Quinones S A, Gaytan S M, Lopez M I, Rodela A, Martinez E Y, Hernandez D H, Martinez E, Medina F, Wicker R B. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials, 2009, 2, 20–32.

Liu S Y, Shin Y C. Additive manufacturing of Ti6Al4V alloy: A review. Materials & Design, 2019, 164, 107552.

Jardini A L, Larosa M A, Zavaglia C A, Bernardes L F, Lambert C S, Kharmandayan P, Calderoni D, Filho R M. Customised titanium implant fabricated in additive manufacturing for craniomaxillofacial surgery: This paper discusses the design and fabrication of a metallic implant for the reconstruction of a large cranial defect. Virtual and Physical Prototyping, 2014, 9, 115–125.

Thijs L, Verhaeghe F, Craeghs T, Humbeeck J V, Kruth J P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Materials, 2010, 58, 3303–3312.

Zhang L C, Klemm D, Eckert J, Hao Y L, Sercombe T B. Manufacture by selective laser melting and mechanical behavior of a biomedical Ti-24Nb-4Zr-8Sn alloy. Scripta Materialia, 2011, 65, 21–24.

Prashanth K G, Shahabi H S, Attar H, Srivastava V C, Ellendt N, Uhlenwinkel V, Eckert J, Scudino S. Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Additive Manufacturing, 2015, 6, 1–5.

Zhang L C, Attar H. Selective laser melting of titanium alloys and titanium matrix composites for biomedical spplications: A review. Advanced Engineering Materials, 2016, 18, 463–475.

Gu D, Hagedorn Y C, Meiners W, Meng G, Batista R J S, Wissenbach K, Poprawe R. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Materials, 2012, 60, 3849–3860.

Simson T, Emmel A, Dwars A, Böhm J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Additive Manufacturing, 2017, 17, 183–189.

Attar H, Prashanth K G, Chaubey A K, Calin M, Zhang L C, Scudino S, Eckert J. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Materials Letters, 2015, 142, 38–41.

Zhu Y, Zou J, Yang H. Wear performance of metal parts fabricated by selective laser melting: A literature review. Journal of Zhejiang University: Science A, 2018, 19, 95–110.

Geenen K, Röttger A, Theisen W. Corrosion behavior of 316L austenitic steel processed by selective laser melting, hot-isostatic pressing, and casting. Materials and Corrosion, 2017, 68, 764–775.

Chao Q, Cruz V, Thomas S, Birbilis N, Collins P, Taylor A, Hodgson P D, Fabijanic D. On the enhanced corrosion resistance of a selective laser melted austenitic stainless steel. Scripta Materials, 2017, 141, 94–98.

Kasperovich G, Hausmann J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. Journal of Materials Process Technolgy, 2015, 220, 202–214.

Vrancken B, Thijs L, Kruth J P, Humbeeck J V. Heat treatment of Ti6Al4V produced by selective laser melting: Microstructure and mechanical properties. Journal of Alloys and Compounds, 2012, 541, 177–185.

Dai N W, Zhang L C, Zhang J X, Chen Q M, Wu M L. Corrosion behavior of selective laser melted Ti-6Al-4 V alloy in NaCl solution. Corrosion Science, 2016, 102, 484–489.

Karimi S, Nickchi T, Alfantazi A. Effects of bovine serum albumin on the corrosion behaviour of AISI 316L, Co-28Cr-6Mo, and Ti-6Al-4V alloys in phosphate buffered saline solutions. Corrosion Science, 2011, 53, 3262–3272.

Amaya-Vazquez M R, Sánchez-Amaya J M, Boukha Z, Botana F J. Microstructure, microhardness and corrosion resistance of remelted TiG2 and Ti6Al4V by a high power diode laser. Corrosion Science, 2012, 56, 36–48.

Sansone V, Pagani D, Melato M. The effects on bone cells of metal ions released from orthopaedic implants: A review. Clinical Cases in Mineral and Bone Metabolism, 2013, 10, 34–40.

Yetim A F. Investigation of wear behavior of titanium oxide films, produced by anodic oxidation, on commercially pure titanium in vacuum conditions. Surface and Coatings Technology, 2010, 205, 1757–1763.

Çomaklı O, Yazıcı M, Kovacı H, Yetim T, Yetim A F, Çelik A. Tribological and electrochemical properties of TiO2films produced on Cp-Ti by sol-gel and SILAR in bio-simulated environment. Surface and Coatings Technology, 2018, 352, 513–521.

Yetim A F, Yildiz F, Vangolu F, Alsaran A, Celik A. Several plasma diffusion processes for improving wear properties of Ti6Al4V alloy. Wear, 2009, 267, 2179–2185.

Okazaki Y, Gotoh E. Comparison of metal release from various metallic biomaterials in vitro. Biomaterials, 2005, 26, 11–21.

Shen G X, Chen Y C, Lin C J. Corrosion protection of 316 L stainless steel by a TiO2 nanoparticle coating prepared by sol-gel method. Thin Solid Films, 2005, 489, 130–136.

Shan C X, Hou X H, Choy K L. Corrosion resistance of TiO2 films grown on stainless steel by atomic layer deposition. Surface and Coatings Technology, 2008, 202, 2399–2402.

Alkhateeb E, Ali R, Virtanen S, Popovska N. Electrochemical evaluation of the corrosion behavior of steel coated with titanium-based ceramic layers. The European Corrosion Congress, Stockholm, Sweden, 2011, 1626–1635.

Yetim T. An investigation of the corrosion properties of Ag-doped TiO2-coated commercially pure titanium in different biological environments. Surface and Coatings Technology, 2017, 309, 790–794.

Uzun Y, Kovacı H, Yetim A F, Çelik A. Effect of boronizing on the structural, mechanical and tribological properties of CoCrW dental alloy produced by selective laser melting. Industrial Lubrication and Tribology, 2019, 71, 348–356.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity?. Biomaterials, 2006, 27, 2907–2915.

Zhong Y, Liu L F, Wikman S, Cui D Q, Shen Z J. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. Journal of Nuclear Materials, 2016, 470, 170–178.

Gallardo J, Durán A, de Damborenea J J. Electrochemical and in vitro behaviour of sol-gel coated 316L stainless steel. Corrosion Science, 2004, 46, 795–806.

Stern M, Geary A L. Electrochemical polarization: I. A theoretical analysis of the shape of polarization curves. Journal of the Electrochemical Society, 1957, 104, 56.

Qin P, Liu Y J, Sercombe T B, Li Y H, Zhang C W, Cao C D, Sun H Q, Zhang L C. Improved corrosion resistance on selective laser melting produced Ti-5Cu alloy after heat treatment. ACS Biomaterials Science & Engineering, 2018, 4, 2633–2642.

Kumar S, Narayanan N S, Raman S G, Seshadri S K. Thermal oxidation of CP Ti — An electrochemical and structural characterization. Materials Characterization, 2010, 61, 589–597.

Pujad M P. Carbon Nanotubes as Platforms for Biosensors with Electrochemical and Electronic Transduction, Springer, Barcelona, Spain, 2012. (in Spain)

Man C, Dong C F, Liu T T, Kong D C, Wang D K, Li X G. The enhancement of microstructure on the passive and pitting behaviors of selective laser melting 316L SS in simulated body fluid. Applied Surface Science, 2019, 467–468, 193–205.

Laleh M, Hughes A E, Xu W, Gibson I, Tan M Y. Unexpected erosion-corrosion behaviour of 316L stainless steel produced by selective laser melting. Corrosion Science, 2019, 155, 67–74.

Uhlig H, Revie R W. Corrosion and Corrosion Control, 4th Ed. John Wiley & Sons Inc. New York, USA, 2008, 9–13.

Fontana M G. Corrosion Engineering, 3rd Ed., Tata McGraw Hill, New York, USA, 2010, 14–16.

Bard A J, Parsons R, Jordan J. Standard Potentials in Aqueous Solution, 1st Ed., CRC Press, New York, USA, 1985, 717–725.

Acknowledgment

We would like to thank the Erzurum Technical University High Technology Research and Application Centre (ETÜ-YÜTAM) for their valuable contribution.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tekdir, H., Yetim, T. & Yetim, A.F. Corrosion Properties of Ceramic-Based TiO2 Films on Plasma Oxidized Ti6Al4V/316L Layered Implant Structured Manufactured by Selective Laser Melting. J Bionic Eng 18, 944–957 (2021). https://doi.org/10.1007/s42235-021-0055-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-021-0055-6