Behavior of Offshore Pile in Calcareous Sand—Case Study

Abstract

:1. Introduction

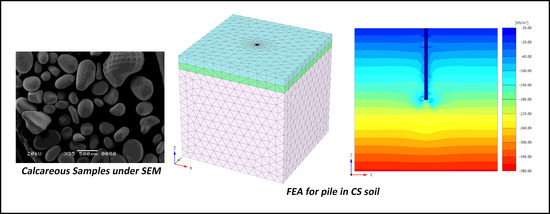

2. Site Investigation of the Study Site

3. Laboratory Testing Program

3.1. Direct Shear Test

3.2. Oedometer Test

4. Verification Model

4.1. Stress–Strain Curves

4.2. Parameters Affecting Pile Capacity in CS

5. Conclusions

- The friction angle increased by 2°, 2.9°, and 4.1° when the broken shells (BS) ratio is raised to 10%, 30%, and 50% by weight, respectively; the modest rise accounted for the angular shape of the broken shell particles.

- Oedometer test results revealed that CS with BSs is more compressible than pure CS since the BSs are weaker than sand particles.

- Under the applied loads used in the recent research (3.20 MN/m2), no significant crushing occurred in particles of CS with BS mixtures specimens.

- Increasing the BS ratio for more than 30% in the CS does not noticeably affect the change of voids ratio in the sample.

- The rise of the BS ratio in the CS soil significantly affects the pile load capacity. The ultimate capacity decreased by 8.8%, 15%, and 16% for CS + 10% BS, CS + 30% BS, and CS + 50% BS, respectively, compared with the CS soil.

- The internal friction of the CS with BS soil had little effect on the pile load-bearing capacity, while soil modulus is the crucial factor influencing the pile capacity in the case of the loose state of the soil. By mixing 10% of the BS with the CS sample, the constrained modulus decreases from 37,900 to 22,000 kN/m2, corresponding to a decrease in the pile load-carrying capacity from 4000 to 3640 kN.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Smith, D.A. Effect of Particle Shape on Grain Size, Hydraulic, and Transport Characteristics of Calcareous Sand. Ph.D. Thesis, University of Hawaii at Manoa, Honolulu, HI, USA, 2003. [Google Scholar]

- Poulos, H.G.; Chua, E.W. Bearing Capacity of Fooundations on Calcareous Sand. In Proceedings of the 11th International Conference on Soil Mechanics and Foundations Engineering, Cambridge, MA, USA, 12–16 August 1985; pp. 1619–1622. [Google Scholar]

- Abdeltawab, S.; El Mashad, M.; El Shinawi, A. Geoengineering Properties of Calcareous and Quartzite Sand Collected from West Alexandria Coastal Line and Abo Rawash Quarry Area. Int. J. Sci. Eng. Res. 2013, 4, 934–943. [Google Scholar]

- Angemeer, J.; Carlson, E.G.; Klick, J.H. Techniques And Results Of Offshore Pile Load Testing In Calcareous Soils. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 28 April 1973. [Google Scholar] [CrossRef]

- Wang, X.-Z.; Jiao, Y.-Y.; Wang, R.; Hu, M.-J.; Meng, Q.-S.; Tan, F.-Y. Engineering Characteristics of The Calcareous Sand in Nansha Islands, South China Sea. Eng. Geol. 2011, 120, 40–47. [Google Scholar] [CrossRef]

- Datta, M.; Gulhati, S.K.; Rao, G.V. Crushing of Calcareous Sands during Drained Shear. Soc. Pet. Eng. J. 1980, 20, 77–85. [Google Scholar] [CrossRef]

- Hardin, B.O. Crushing of Soil Particles. J. Geotech. Eng. 1985, 111, 1177–1192. [Google Scholar] [CrossRef]

- Murff, J.D. Pile Capacity in Calcareous Sands: State If the Art. J. Geotech. Eng. 1987, 113, 490–507. [Google Scholar] [CrossRef]

- Spagnoli, G.; Doherty, P. Comparison of Two Calcareous Sands in Relation to A Novel Offshore Mixed-In-Piace Pile. Oil Gas. Eur. Mag. 2016, 42, 91–94. [Google Scholar]

- Rausche, F.; Hussein, M. Pile driving in calcareous sediments. In Proceedings of the International Conference on Engineering for Calcareous Sediments, Manama, Bahrain, 21–24 February 2000; pp. 345–359. [Google Scholar]

- Yeung, S.K.; Carter, J.P. An Assessment of The Bearing Capacity of Calcareous and Silica Sands. Int. J. Numer. Anal. Methods Geéomeéch. 1989, 13, 19–36. [Google Scholar] [CrossRef]

- Rashad, R.H. Geotechnical characterization of calcareous sand in Egypt. Ph.D. Thesis, Zagazig University, Zagazig, Egypt, 2018. [Google Scholar]

- Randolph, M.; Finnie, I.; Joer, H. Performance of Shallow and Deep Foundations in Calcareous Soil. In Proceedings of the International Seminar in Kagoshima ’93-Regional Soils, Kagoshima, Japan, 1 January 1993; pp. 169–220. [Google Scholar]

- Nauroy, J.; Letirant, P. Driven Piles and Drilled and Grouted Piles in Calcareous Sands. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 1985. [Google Scholar] [CrossRef]

- Demars, K.R. Unique Engineering Properties and Compression Behavior of Deep-Sea Calcareous Sediments. In Geotechnical Properties, Behaviour and Performance of Calcareous Soils; Chaney, R.C., Ed.; ASTM International: West Conshohocken, PA, USA, 2009; p. 97. [Google Scholar] [CrossRef]

- Beringen, F.; Kolk, H.; Windle, D. Cone Penetration and Laboratory Testing in Marine Calcareous Sediments; ASTM International: West Conshohocken, PA, USA, 2009; p. 179. [Google Scholar] [CrossRef]

- Mccarel, S.C.; Beard, R. Laboratory Investigation on Piles in Calcareous Sediments; Naval Civil Engineering Lab Port: Hueneme, CA, USA, 1984. [Google Scholar]

- Lu, B. Axial Behavior and Capacity of Driven Piles in Calcareous Sands. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1986. [Google Scholar] [CrossRef]

- Chin, J.T. Axial Pile Response in Calcareous Sediment. Ph.D. Thesis, University of Sydney, Sidney, Australia, 1992. [Google Scholar]

- Lee, C.Y.; Poulous, H.G. Jacked Model Pile Shafts in Offshore Calcareous Soils. Mar. Geotechnol. 1988, 7, 247–274. [Google Scholar] [CrossRef]

- Abdelmawla, A.M. Characterization of Geogrid Pullout Mechanism for Calcareous Sand Backfill. Master’s Thesis, Cairo University Giza, Cairo, Egypt, 2017. [Google Scholar]

- Arango, J.C. Stress Strain Behavior and Dynamic Properties of Cabo Rojo Calcareous Sands. Ph.D. Thesis, University of Puerto Rico, Mayaguez, Puerto Rico, 2006. [Google Scholar]

- Cai, W.; Rutherford, C.; Zheng, J. Monotonic Behavior of Calcareous Sands with Increasing Particle Crushing. In Geo-Congress 2020: Modeling, Geomaterials, and Site Characterization; American Society of Civil Engineers: Reston, VA, USA, 2020. [Google Scholar] [CrossRef]

- Noorany, I. Side Friction of Piles in Calcareous Sands. In Proceedings of the 11th International Conference of Soil Mechanics and Foundation Engineering, Cambridge, MA, USA, 12–16 August 1985; pp. 12–16. [Google Scholar]

- Li, X.; Liu, J. One-Dimensional Compression Feature and Particle Crushability Behavior of Dry Calcareous Sand Considering Fine-Grained Soil Content and Relative Compaction. Bull. Int. Assoc. Eng. Geol. 2021, 80, 4049–4065. [Google Scholar] [CrossRef]

- Uygar, E.; Doven, A.G. Monotonic and Cyclic Oedometer Tests on Sand at High Stress Levels. Granul. Matter 2005, 8, 19–26. [Google Scholar] [CrossRef]

- Wils, L.; Haegeman, W. One-Dimensional Compression of a Crushable Sand in Dry and Wet Conditions. In 3rd International Symposium on Geomechanics from Micro to Macro; Taylor And Francis Group: London, UK, 2014; pp. 1403–1408. [Google Scholar] [CrossRef] [Green Version]

- Rui, S.; Guo, Z.; Si, T.; Li, Y. Effect of Particle Shape on The Liquefaction Resistance of Calcareous Sands. Soil Dyn. Earthq. Eng. 2020, 137, 106302. [Google Scholar] [CrossRef]

- Salem, T.N.; Ata, A.; Hassan, R. Numerical Analysis of The Effect of Carbonate Particle Crushing on Piles in Calcareous Sand. Int. J. Trend Res. Dev. 2017, 4, 304–309. [Google Scholar]

- Ata, A.; Hassan, R.; Salem, T.N. Numerical Assessment of Piles Behavior in Saturated and Dry Calcareous Sand. Int. J. Trend Res. Dev. 2018, 4, 310–314. [Google Scholar]

- Ata, A.; Salem, T.; Hassan, R. Geotechnical Characterization of The Calcareous Sand in Northern Coast of Egypt. Ain Shams Eng. J. 2018, 9, 3381–3390. [Google Scholar] [CrossRef]

- ASTM D4373 Standard Test Method for Rapid Determination of Carbonate Content of Soils. 2007. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/D4373-02R07.htm (accessed on 27 July 2021).

- ASTM D2488 standard Practice for Description and Identification of Soils (Visual-Manual Procedure). 2009. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/D2488-09A.htm. (accessed on 27 July 2021).

- ASTM D4254 standard Test Methods for Minimum Index Density and Unit Weight of Soils and Calculation of Relative Density. 2006. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/D4254-00R06.htm. (accessed on 27 July 2021).

- ECP 202. “Egyptian Code for Soil Mechanics—Design and Construction of Foundations, Part 1, Site Investigation”. 2005. Available online: https://www.scirp.org/(S(351jmbntvnsjt1aadkposzje))/reference/ReferencesPapers.aspx?ReferenceID=940161 (accessed on 27 July 2021).

- Schanz, T.; Vermeer, P.A.; Bonnier, B.G. The Hardening Soil Model: Formulation and Verification. In Beyond 2000 in Computational Geotechnics; Routledge: London, UK, 1999; pp. 281–296. Available online: https://www.taylorfrancis.com/chapters/edit/10.1201/9781315138206-27/hardening-soil-model-formulation-verification-schanz-vermeer-bonnier (accessed on 27 July 2021).

- El-Mossalamy, Y.M.; El-Nahhas, F.M.; Al-Deab, M.M. Piled Raft Foundation in Calcareous Cemented Sand in Kuwait City. In Proceedings of the 14th International Conference of Structural Geotechnical Engineering (ICSGE 14), New Cairo, Egypt, 20–22 December 2015. Session 3, Paper No: 5. [Google Scholar]

- Bowles, J. Foundation Analysis and Design; Mcgraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- American Petroleum Institute. Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms—Working Stress Design. API Recomm Pract 2A-WSD. 2002. Available online: https://www.apiwebstore.org/publications/item.cgi?58bf26e5-8e94-4eb0-97f3-152abb4c1f37 (accessed on 27 July 2021).

| Parameter | Gs | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CS of the northern coast | 0.17 | 0.20 | 0.25 | 0.28 | 1.70 | 0.90 | 16.7 | 18.1 | 2.8 |

| Shear Box Test | |||||||

|---|---|---|---|---|---|---|---|

| Loose State | Dense State | ||||||

| Peak | Residual | ||||||

() | () | ||||||

| CS | 18.10 | 16.59 | 0.674 | 0.535 | 30.5 | 39.9 | 30.6 |

| CS + 10% | 18.58 | 15.67 | 0.773 | 0.495 | 32.4 | 40.0 | 31.0 |

| CS + 30% | 19.40 | 14.24 | 0.951 | 0.432 | 33.4 | 41.2 | 32.6 |

| CS + 50% | 20.15 | 13.60 | 1.043 | 0.379 | 34.6 | 43.8 | 32.7 |

| Parameters For Undrained A | Symbol | Unit | Soil Layers | |||||

|---|---|---|---|---|---|---|---|---|

| Fill | Medium Coarse Sand with a Trace of Shells | Soft Clay with a Trace of Shells | Clayey Silt/Clayey Sandy Silt | Medium Fine Silty Sand to Sand with a Trace of Silt | Crushed Calcareous Cemented Sand | |||

| Level | 0.0–4.0 | 4.0–6.30 | 6.30–11.0 | 11.0–13.5 | 13.5–16.0 | 16.0–35 | ||

| Saturated unit weight | kN/m3 | 19.0 | 19.0 | 19.0 | 19.0 | 19.0 | 19.0 | |

| Dry unit weight | kN/m3 | 16.0 | 16.0 | 14.0 | 16.0 | 16.0 | 15.5 | |

| Secant stiffness | kN/m2 | 600 | 45,000 | 1000 | 2500 | 30,000 | 56,000 | |

| Tangent stiffness | kN/m2 | 600 | 45,000 | 1000 | 2500 | 30,000 | 45,000 | |

| Unloading/reloading stiffness | kN/m2 | 1800 | 135,000 | 3000 | 7500 | 90,000 | 163,000 | |

| Power for a stress-level | m | - | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Cohesion | kN/m2 | 0.0 | 0 | 20.0 | 20.0 | 15.0 | 0.0 | |

| Friction angle | - | 20 | 34 | 0 | 15 | 30 | 36 | |

| Dilatancy angle | - | 0 | 4.0 | 0 | 0 | 0 | 0 | |

| Poisson ratio | - | 0.3 | 0.2 | 0.3 | 0.3 | 0.2 | 0.2 | |

| Interface strength | - | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | |

| Parameters For Undrained A | Symbol | Unit | CS | CS + 10% BS | CS + 30% BS | CS + 50% BS |

|---|---|---|---|---|---|---|

| Saturated unit weight | kN/m3 | 19.0 | 19.0 | 19.0 | 19.0 | |

| Dry unit weight | kN/m3 | 17.0 | 17.0 | 17.0 | 17.0 | |

| Secant stiffness | kN/m2 | 37,900 | 22,000 | 17,200 | 16,500 | |

| Tangent stiffness | kN/m2 | 37,900 | 22,000 | 17,200 | 16,500 | |

| Unloading/reloading stiffness | kN/m2 | 113,900 | 66,000 | 51,600 | 49,500 | |

| Power for a stress-level | m | - | 0.6 | 0.65 | 0.6 | 0.5 |

| Cohesion | kN/m2 | 0.0 | 0 | 0 | 0 | |

| Friction angle | - | 30.5 | 32.4 | 33.4 | 34.6 | |

| Poisson ratio | - | 0.2 | 0.2 | 0.2 | 0.2 | |

| Interface strength | - | 0.7 | 0.7 | 0.7 | 0.7 |

| Parameters For Undrained A | Symbol | Unit | Calcareous Silty Sand | Calcareous Lean Clay | CS | CS + 10% BS | CS + 30% BS | CS + 50% BS |

|---|---|---|---|---|---|---|---|---|

| Level | 0–2.5 | 2.5–5.0 | 5.0–40 | 5.0–40 | 5.0–40 | 5.0–40 | ||

| Saturated unit weight | kN/m3 | 20.0 | 20.0 | 19.0 | 19.0 | 19.0 | 19.0 | |

| Dry unit weight | kN/m3 | 17.0 | 16.0 | 17.0 | 17.0 | 17.0 | 17.0 | |

| Secant stiffness | kN/m2 | 37,500 | 4200 | 37,900 | 22,000 | 17,200 | 16,500 | |

| Tangent stiffness | kN/m2 | 37,500 | 4200 | 37,900 | 22,000 | 17,200 | 16,500 | |

| Unloading/reloading stiffness | kN/m2 | 112,500 | 12,800 | 113,900 | 66,000 | 51,600 | 49,500 | |

| Power for a stress-level | m | - | 0.5 | 0.5 | 0.6 | 0.65 | 0.6 | 0.5 |

| Cohesion | kN/m2 | 0.0 | 40.0 | 0.0 | 0 | 0 | 0 | |

| Friction angle | - | 33.0 | 0 | 30.5 | 32.4 | 33.4 | 34.6 | |

| Poisson ratio | - | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Interface strength | - | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salem, T.N.; Elkhawas, N.M.; Elnady, A.M. Behavior of Offshore Pile in Calcareous Sand—Case Study. J. Mar. Sci. Eng. 2021, 9, 839. https://doi.org/10.3390/jmse9080839

Salem TN, Elkhawas NM, Elnady AM. Behavior of Offshore Pile in Calcareous Sand—Case Study. Journal of Marine Science and Engineering. 2021; 9(8):839. https://doi.org/10.3390/jmse9080839

Chicago/Turabian StyleSalem, Tarek N., Nadia M. Elkhawas, and Ahmed M. Elnady. 2021. "Behavior of Offshore Pile in Calcareous Sand—Case Study" Journal of Marine Science and Engineering 9, no. 8: 839. https://doi.org/10.3390/jmse9080839