Abstract

An update of research interests is given here on: (i) a historical description of the influence of polycrystal grain size on metal strength properties; (ii) a reciprocal square root of grain size dependence for the strength of steel materials; (iii) a grain-size-dependent transition for steel materials from plastic yielding to brittleness; (iv) thermally-activated dislocation dynamics for temperature and strain rate dependence in α-titanium and extending to shock loading of armco iron; and, (v) the combined influences of grain size and strain rate dependencies for copper, nickel, aluminum, and lead materials spanning grain size strengthening and weakening behaviors measured over meso- to nanograin sizes.

Similar content being viewed by others

Change history

31 August 2021

Corrected issue title

REFERENCES

Panin, V.E., The Foundations of Physical Mesomechanics of Materials: General Review, in Book of Abstracts of V International Conference: Computer Aided Design of Advanced Materials and Technologies (CADAMT’97), 4–6 August, 1997, Baikal Lake, Russia, Tomsk: ISPMS SB RAS, 1997, pp. 15–17.

Panin, V.E., Plastic Deformation and Fracture of Solids at the Mesoscale Level, Mater. Sci. Eng. A, 1997, vol. 234–236, pp. 944–948.

International Conference: Shock Waves in Condensed Matter, Saint-Petersburg, 12–17 July, 1998, Birukov, A.L., Dolgoborodov, A.Yu., Klimenko, I.Yu., Eds., Moscow: Inst. Chem. Phys., 1998, pp. 46–71.

Panin, V.E. and Armstrong, R.W., Hall–Petch Analysis for Temperature and Strain Rate Dependent Deformation of Polycrystalline Lead, Phys. Mesomech., 2016, vol. 19, no. 1, pp. 35–40.

Armstrong, R.W., Plasticity: Grain Size Effects III, in Reference Module in Materials Science and Materials Engineering, Hashmi, S., Ed., Oxford, UK: Elsevier, 2016, pp. 1–23.

Grignon, P.C., On the Metamorphoses of Iron (Memoires de physique sur l’art de fabriquer le fer, P. Boucher, C.S. Smith, Transl.), in Sources for the History of the Science of Steel 1532–1786, Smith, C.S., Ed., Cambridge, MA: The Society for the History of Technology and the MIT Press, 1968, pp. 125–164.

Smith, C.S., Further Notes on the Shape of Metal Grains: Space-Filling Polyhedral with Unlimited Sharing of Corners and Faces, Acta Metall., 1953, vol. 1, pp. 295–300.

Ewing, J.A. and Rosenhain, W., Observations of Slip in Metals, Philos. Trans. R. Soc. Lond. A, 1900, vol. 193, pp. 353–375.

Polanyi, M., Deformation, Rupture and Hardening of Crystals, Trans. Faraday Soc., 1928, vol. 24, pp. 72–83.

Taylor, G.I., Resistance to Shear in Metal Crystals, Trans. Faraday Soc., 1928, vol. 24, pp. 121–126.

Zener, C., A Theoretical Criterion for the Initiation of Slip Bands, Phys. Rev., 1946, vol. 69, pp. 128–129.

Hall, E.O., The Deformation and Ageing of Mild Steel: Discussion of Results, Proc. Phys. Soc. Lond. B, 1951, vol. 64, pp. 747–753.

Petch, N.J., The Cleavage Strength of Polycrystals, J. Iron Steel Inst., 1953, vol. 174, pp. 25–28.

Armstrong, R.W., Material Grain Size and Crack Size Influences on Cleavage Fracture, in Theme Issue: Fracturing Across the Multi-Scales of Diverse Materials, Armstrong, R.W., Antolovich, S.D., Griffiths, J.R., and Knott, J.F., Eds., Philos. Trans. R. Soc. A, 2015, vol. 373, p. 20140124.

Panin, V.E., Derjugin, Ye.Ye., and Wasman, G.I., Shear Bands and Fracture of Imperfect Fe + 3% Si Polycrystals, Int. J. Fracture, 2001, vol. 107, pp. 1–10.

Armstrong, R.W., Size Effects on Material Yield Strength/Deformation/Fracturing Properties, J. Mater. Sci., 2019, vol. 34, no. 13, pp. 2161–2176.

Armstrong, R.W. and Smith, T.R., Dislocation Pile-up Predictions for the Strength Properties of Ultrafine Grain Size FCC Metals, in Processing and Properties of Nanocrystalline Materials, Suryanarayana, C., Singh, J., and Froes, F.H., Eds., Warrendale, PA: TMS-AIME, 1996, pp. 345–354.

Armstrong, R.W., Hall–Petch k Dependencies in Nanopolycrystals, Emerg. Mater. Res., 2014, vol. 3, no. 6, pp. 246–251.

Armstrong, R.W., Codd, I., Douthwaite, R.M., and Petch, N.J., The Plastic Deformation of Polycrystalline Aggregates, Philos. Mag., 1962, vol. 7, pp. 45–58.

Embury, J.D. and Fisher, R.M., The Structure and Properties of Drawn Pearlitic Wire, Acta Metall., 1966, vol. 14, pp. 147–152.

Jang, J.S.C. and Koch, C.C., The Hall–Petch Relationship in Nanocrystalline Iron Produced by Ball Milling, Scripta Metall., 1990, vol. 24, pp. 1599–1604.

Zhang, X., Godfrey, A., Huang, X., Hansen, N., and Liu, Q., Microstructure and Strengthening Mechanisms in Cold-Drawn Pearlitic Steel Wire, Acta Mater., 2011, vol. 59, pp. 3422–3430.

Li, Y., Raabe, D., Herbig, M., Choi, P.-P., Goto, S., Kostka, A., Yarita, H., Borchers, C., and Kirchheim, R., Segregation Stabilizes Nanocrystalline Bulk Steel with Near Theoretical Strength, Phys. Rev. Lett., 2014, vol. 13, p. 106104.

Armstrong, R.W., Crystal Engineering for Mechanical Strength at Nano-Scale Dimensions, Crystals, 2017, vol. 7, p. 315.

Panin, V.E., Moiseenko, D.D., and Elsukova, T.F., Multiscale Model of Deformed Polycrystals. Hall–Petch Problem, Phys. Mesomech., 2014, vol. 17, no. 1, pp. 1–14. https://doi.org/10.1134/S1029959914010019

Panin, V.E., Egorushkin, V.E., Moiseenko, D.D., Maksimov, P.V., Kulkov, S.N., and Panin, S.V., Functional Role of Polycrystal Grain Boundaries and Interfaces in Micromechanics of Metal Ceramic Composites under Loading, Comp. Mater. Sci., 2016, vol. 116, pp. 74–81.

Panin, V.E., Moiseenko, D.D., Maksimov, P.V., and Panin, S.V. Effects of Plastic Distortion in the Lattice Curvature Zone of a Crack Tip, Phys. Mesomech., 2017, vol. 20, no. 3, pp. 280–290. https://doi.org/10.1134/S1029959917030043

Cottrell, A.H., Theory of Brittle Fracture in Steel and Similar Materials, Trans. TMS-AIME, 1958, vol. 212, pp. 192–203.

Petch, N.J., The Ductile-Brittle Transition in the Fracture of α-Iron, Philos. Mag., 1958, vol. 3, pp. 1089–1097.

Armstrong, R.W., Stress–Grain Size Analysis of the Ductile-Brittle Transition for Steel and Similar Metals. Radiation Metallurgy Section, in Solid State Division Progress Report, Oak Ridge, TN: Oak Ridge National Laboratory, 1966, ORNL-4020.

Panin, V.E., Derevyagina, L.S., Lemeshev, N.M., Korznikov, A.V., Panin, A.V., and Kazachenok, M.S., On the Nature of Low-Temperature Brittleness of BCC Steels, Phys. Mesomech., 2014, vol. 17, no. 2, pp. 89–96. https://doi.org/10.1134/S1029959914020015

Al Mundheri, M., Soulat, P., and Pineau, A., Irradiation Embrittlement of a Low Alloy Steel Interpreted in Terms of a Local Approach of Cleavage Fracture, Fatig. Fract. Eng. Mater. Struct., 1989, vol. 12, pp. 19–30.

Panin, V.E., Derevyagina, L.S., Panin, S.V., Shugurov, A.R., and Gordienko, A.I., The Role of Nanoscale Strain-Induced Defects in the Sharp Increase of Low-Temperature Toughness in Low-Carbon and Low-Alloy Steels, Mater. Sci. Eng. A, 2019, vol. 768, p. 138491.

Yokobori, A.T.Jr., Holistic Approach on the Research of Yielding, Creep, and Fatigue Crack Growth Rate of Metals Based on Simplified Model of Dislocation Group Dynamics, Metals, 2020, vol. 10, p. 1048.

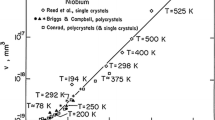

Zerilli, F.J. and Armstrong, R.W., Constitutive Relations for Titanium and Ti-6Al-4V, in Shock Compression of Condensed Matter-1995, Schmidt, S.C. and Tao, W.C., Eds., Woodbury, CT: Am. Inst. Phys., 1996, CP370, part 1, pp. 315–318.

Armstrong, R.W. and Balasubramanian, N., Physically-Based and Power-Law Constitutive Relations for Higher Temperature Metal Processing and Creep-Type Deformations, JOM, 2017, vol. 69, pp. 822–829.

Mocko, W., Kruszka, L., and Brodecki, A., Strain Localization during Tensile Hopkinson Bar Testing of Commercially Pure Titanium and Ti-6Al-4V Titanium Alloy, Euro. Phys. J., 2015, vol. 94, p. 01011.

Zerilli, F.J. and Armstrong, R.W., Dislocation Mechanics Based Constitutive Equation Incorporating Dynamic Recovery and Applied to Thermomechanical Shear Instability, in Shock Compression of Condensed Matter-1997, Schmidt, S.C., Dandekar, D., Forbes, J.W., Eds., Woodbury, CT: Am. Inst. Phys., 1997, CP429, pp. 215–218.

Panin, V.E., Panin, A.V., Perevalova, O.B., and Shugurov, A.R., Mesoscopic Structural States at the Nanoscale in Surface Layers of Titanium and Its Alloy Ti–6Al–4V in Ultrasonic and Electron Beam Treatment, Phys. Mesomech., 2019, vol. 22, no. 5, pp. 345–354. https://doi.org/10.1134/S1029959919050011

Hémery, S., Villechaise, P., and Banerjee, D., Microplasticity at Room Temperature in α/β Titanium Alloys, Metall. Mater. Trans. A, 2020, vol. 51, pp. 4931–4969.

Arnold, W., Dynamisches Werkstoff-verhalten von Armco-Eisen bei Stosswellenbelastung, Fortschritt-Berichte, Düsseldorf: VDI-Verlag GmbH, 1992, Reihe 5, no. 247.

Swegle, J.W. and Grady, D.E., Shock Viscosity and the Prediction of Shock Wave Rise Times, J. App. Phys., 1985, vol. 58, pp. 692–701.

Armstrong, R.W., Arnold, W., and Zerilli, F.J., Dislocation Mechanics of Shock-Induced Plasticity, Metall. Mter. Trans. A, 2007, vol. 38, pp. 2605–2610.

Armstrong, R.W., Arnold, W., and Zerilli, F.J., Dislocation Mechanics of Copper and Iron in High Rate Deformation Tests, J. Appl. Phys., 2009, vol. 105, p. 023511.

Armstrong, R.W., The Yield and Flow Stress Dependence on Polycrystal Grain Size, in Yield, Flow and Fracture of Polycrystals, Baker, T.N., Ed., London: Applied Science Publishers, 1983, pp. 1–31.

Armstrong, R.W., Hall–Petch Description of Nanopolycrystalline Cu, Ni, and Al Strength Levels and Strain Rate Sensitivities, Philos. Mag., 2016, vol. 96, no. 29, pp. 3097–3108.

Armstrong, R.W. and Li, Q.-Z., Dislocation Mechanics of High-Rate Deformations, Metall. Mater. Trans. A, 2015, vol. 46, pp. 4438–4453.

Zerilli, F.J. and Armstrong, R.W., The Effect of Dislocation Drag on the Stress-Strain Behavior of FCC Metals, Acta Metall. Mater., 1992, vol. 40, no. 8, pp. 1803–1808.

Armstrong, R.W. and Rodriguez, P., Flow Stress/ Strain Rate/Grain Size Coupling for FCC Nanopolycrystals, Philos. Mag., 2006, vol. 86, pp. 5787–5796.

Li, H., Liang, Y., Zhao, L., Hu, J., Han, S., and Lian, J., Mapping the Strain Rate and Grain Size Dependence of Deformation Behaviors in Nanocrystalline Face-Centered-Cubic Ni and Ni-Based Alloys, J. Alloys Compds, 2017, vol. 709, pp. 566–574.

Panin, V.E. and Egorushkin, V.E., Nanostructural States in Solids, Phys. Met. Metallog., 2010, vol. 110, no. 5, pp. 464–473.

Egorushkin, V.E. and Panin, V.E., Translation-Rotation Plastic Flow in Polycrystals under Creep, Phys. Mesomech., 2018, vol. 21, no. 5, pp. 401–410. https://doi.org/10.1134/S1029959918050041

Panin, V.E., Kuznetsov, P.V., and Rakhmatulina, T.V., Lattice Curvature and Mesoscopic Strain-Induced Defects as the Basis of Plastic Deformation in Ultrafine-Grained Metal, Phys. Mesomech., 2018, vol. 21, no. 5, pp. 411–418. https://doi.org/10.1134/S1029959918050053

Author information

Authors and Affiliations

Corresponding author

Additional information

In memoriam of Professor Victor E. Panin

Rights and permissions

About this article

Cite this article

Armstrong, R.W. Dislocation and Grain Size Roles in Physical Mesomechanics. Phys Mesomech 24, 418–425 (2021). https://doi.org/10.1134/S1029959921040068

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959921040068