Abstract

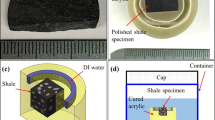

The mechanical properties of shales, a type of heterogeneous and multiphase composite, are of multiscale characteristics in nature. A large number of indentation measurements were performed under the continuous stiffness measurement (CSM) mode on the Longmaxi shale, followed by data segmentation, Gaussian mixture modeling (GMM) deconvolution of segmented datasets, and results re-integration. Accompanying compositional analyses by X-ray powder diffraction and surface imaging were also conducted to assist data interpretation. Results showed that the studied shale consisted of a fine-grained, relatively homogeneous clay matrix with randomly embedded, coarse-grained solid inclusions of up to ~ 100 μm in size. The CSM mode enabled the analysis of phase angle lag, which is an effective indicator for surface roughness. The Young’s moduli of both microscopic constituent phases (e.g., clay matrix, carbonates, quartz, pyrite) and macroscopic bulk shale were precisely determined and, through the probability analysis of the indent locations, the characteristic lengths of the shale’s constituent phases were estimated. The clay matrix and carbonates have relatively large characteristic lengths than quartz and pyrite. The data analytics proposed in this study may provide a feasible framework to assess the multiscale mechanical properties as well as the characteristic lengths of the shale’s constituent phases via a single type of measurement technique on the same piece of sample.

Similar content being viewed by others

References

Abedi S, Slim M, Hofmann R, Bryndzia T, Ulm F (2016) Nanochemo-mechanical signature of organic-rich shales: a coupled indentation–EDX analysis. Acta Geotech 11:559–572

ASTM (2014) Standard Test Methods for Moisture, Ash, and Organic Matter of Peat and Other Organic Soils (D2974-14). ASTM International: West Conshohocken, PA

Ball D (1964) Loss-on-ignition as an estimate of organic matter and organic carbon in non-calcareous soils. J Soil Sci 15:84–92

Bobji MS, Biswas SK (1999) Deconvolution of hardness from data obtained from nanoindentation of rough surfaces. J Mater Res 14:2259–2268

Bobko CP, Ulm F (2008) The nano-mechanical morphology of shale. Mech Mater 40:318–337

Broz ME, Cook RF, Whitney DL (2006) Microhardness, toughness, and modulus of Mohs scale minerals. Am Miner 91:135–142

Bull SJ (2005) Nanoindentation of coatings. J Phys D 38:R393–R413

Chen J, Sorelli L, Vandamme M, Ulm F, Chanvillard G (2010) A coupled nanoindentation/SEM-EDS study on low water/cement ratio portland cement paste: evidence for C-S–H/Ca(OH)2 nanocomposites. J Am Ceram Soc 93:1484–1493

Collins C, Dyer MS, Pitcher MJ, Whitehead GFS, Zanella M, Mandal PK et al (2017) Accelerated discovery of two crystal structure types in a complex inorganic phase field. Nature 546:280–284

Constantinides G, Chandran KSR, Ulm F, Van Vliet KJ (2006) Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater Sci Eng A-struct Mater Prop Microstruct Process 430:189–202

Constantinides G, Ulm F-J (2007) The nanogranular nature of C-S–H. J Mech Phys Solids 55:64–90

Dai J, Zou C, Liao S, Dong D, Ni Y, Huang J et al (2014) Geochemistry of the extremely high thermal maturity Longmaxi shale gas, southern Sichuan Basin. Org Geochem 74:3–12

Deirieh A, Ortega JA, Ulm F, Abousleiman YN (2012) Nanochemomechanical assessment of shale: a coupled WDS-indentation analysis. Acta Geotech 7:271–295

Donnelly E, Baker SP, Boskey AL, Der Meulen MCHV (2006) Effects of surface roughness and maximum load on the mechanical properties of cancellous bone measured by nanoindentation. J Biomed Mater Res, Part A 77:426–435

Du J, Hu L, Meegoda JN, Zhang G (2018) Shale softening: observations, phenomenological behavior, and mechanisms. Appl Clay Sci 161:290–300

Hay J, Pharr G (2000) Instrumented indentation testing. Mater Park OH ASM Int 2000:232–243

Hosni K, Srasra E (2011) Using kaolinitic clay for preparation of a hydrotalcite-like compound. Mater Sci Appl 02:684–691

Hou D, Zhang G, Pant RR, Shen JS, Liu M, Luo H (2016) Nanoindentation characterization of a ternary clay-based composite used in ancient Chinese construction. Materials 9:866

Huang P-T, Patel M, Santagata MC, Bobet A (2009) Classification of organic soils. Joint Transportation Research Program: West Lafayette, Indiana

Huat BB, Prasad A, Asadi A, Kazemian S (2019) Geotechnics of organic soils and peat. CRC Press

Josh M, Esteban L, Piane CD, Sarout J, Dewhurst DN, Clennell MB (2012) Laboratory characterisation of shale properties. J Petrol Sci Eng 88:107–124

Kargbo DM, Wilhelm RG, Campbell DJ (2010) Natural gas plays in the marcellus shale: challenges and potential opportunities. Environ Sci Technol 44:5679–5684

Kumar V, Sondergeld CH, Rai CS (2012) Nano to macro mechanical characterization of shale. Society of Petroleum Engineers: San Antonio, Texas, USA

La H, Hettiaratchi JPA, Achari G, Verbeke TJ, Dunfield PF (2018) Biofiltration of methane using hybrid mixtures of biochar, lava rock and compost. Environ Pollut 241:45–54

Larsson P, Giannakopoulos AE, Soderlund E, Rowcliffe DJ, Vestergaard R (1996) Analysis of Berkovich indentation. International J Solids Structures 33:221–248

Lee J, Papp JK, Clement RJ, Sallis S, Kwon D, Shi T et al (2017) Mitigating oxygen loss to improve the cycling performance of high capacity cation-disordered cathode materials. Nat Commun 8:1–10

Li C, Ostadhassan M, Gentzis T, Kong L, Carvajal-Ortiz H, Bubach B (2018) Nanomechanical characterization of organic matter in the Bakken formation by microscopy-based method. Mar Pet Geol 96:128–138

Li C, Ostadhassan M, Guo S, Gentzis T, Kong L (2018) Application of PeakForce tapping mode of atomic force microscope to characterize nanomechanical properties of organic matter of the Bakken Shale. Fuel 233:894–910

Li C, Ostadhassan M, Abarghani A, Fogden A, Kong L (2019) Multi-scale evaluation of mechanical properties of the Bakken shale. J Mater Sci 54:2133–2151

Liu K, Ostadhassan M, Bubach B (2016) Applications of nano-indentation methods to estimate nanoscale mechanical properties of shale reservoir rocks. J Nat Gas Sci Eng 35:1310–1319

Liu K, Ostadhassan M, Bubach B (2018) Application of nanoindentation to characterize creep behavior of oil shales. J Petrol Sci Eng 167:729–736

Liu K, Ostadhassan M, Bubach B, Dietrich R, Rasouli V (2018) Nano-dynamic mechanical analysis (nano-DMA) of creep behavior of shales: Bakken case study. J Mater Sci 53:4417–4432

Locock AJ, Chesterman D, Caird D, Duke MJM (2012) Miniaturization of mechanical milling for powder X-ray diffraction. Powder Diffr 27:189–193

Lukashuk L, Yigit NO, Rameshan R, Kolar E, Teschner D, Havecker M et al (2018) Operando Insights into CO oxidation on cobalt oxide catalysts by NAP-XPS, FTIR, and XRD. ACS Catal 8:8630–8641

Luo S, Lu Y, Wu Y, Song J, Groot D, Jin Y et al (2020) Cross-scale characterization of the elasticity of shales: statistical nanoindentation and data analytics: ScienceDirect. J Mech Phys Solids 140:103945

Macova P, Viani A (2017) Investigation of setting reaction in magnesium potassium phosphate ceramics with time resolved infrared spectroscopy. Mater Lett 205:62–66

Masotti A, Caputo V, Sacco LD, Pizzuti A, Dallapiccola B, Bottazzo GF (2009) Quantification of small non-coding RNAs allows an accurate comparison of miRNA expression profiles. BioMed Res Int 2009:659028

O’Kelly BC, Sivakumar V (2014) Water content determinations for peat and other organic soils using the oven-drying method. Drying Technol 32:631–643

Oliver D, Bradby JE, Williams JS, Swain MV, Munroe P (2007) Giant pop-ins and amorphization in germanium during indentation. J Appl Phys 101:043524

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19:3–20

Pagonis V, Kitis G (2002) On the possibility of using commercial software packages for thermoluminescence glow curve deconvolution analysis. Radiat Prot Dosimetry 101:93–98

Pant R, Hu L, Zhang G (2013) Anisotropy of mica probed by nanoindentation. Multiphysical testing of soils and shales. Springer, Berlin

Saha R, Nix WD (2002) Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater 50:23–38

Sheng M, Li G, Huang Z, Tian S, Qu H (2013) Experimental study on hydraulic isolation mechanism during hydra-jet fracturing. Exp Thermal Fluid Sci 44:722–726

Sheng M, Li G, Huang Z, Tian S, Shah S, Geng L (2015) Pore-scale modeling and analysis of surface diffusion effects on shale-gas flow in Kerogen pores. J Nat Gas Sci Eng 27:979–985

Shi X, Jiang S, Lu S, He Z, Li D, Wang Z et al (2019) Investigation of mechanical properties of bedded shale by nanoindentation tests: a case study on Lower Silurian Longmaxi Formation of Youyang area in southeast Chongqing, China. Petrol Explorat Develop 46:163–72

Shukla P, Kumar V, Curtis M, Sondergeld CH, Rai CS (2013) Nanoindentation studies on shales. 47th US Rock Mechanics/Geomechanics Symposium. San Francisco, California, USA, American Rock Mechanics Association

Shukla P, Taneja S, Sondergeld C, Rai C (2015) Nanoindentation measurements on rocks. Fracture, fatigue, failure, and damage evolution. Springer, Berlin

Simpson GJ, Sedin DL, Rowlen KL (1999) Surface roughness by contact versus tapping mode atomic force microscopy. Langmuir 15:1429–1434

Singh TB, Rey L, Gartia RK (2011) Applications of PeakFit software in thermoluminescence studies. Indian J Pure Appl Phys 49:297–302

Skempton A, Petley D (1970) Ignition loss and other properties of peats and clays from Avonmouth, King’s Lynn and Cranberry Moss. Géotechnique 20:343–356

Sone H, Zoback MD (2013) Mechanical properties of shale-gas reservoir rocks - part 1: static and dynamic elastic properties and anisotropy. Geophysics 78:D381–D392

Ulm F, Abousleiman YN (2006) The nanogranular nature of shale. Acta Geotech 1:77–88

Ulm F, Vandamme M, Bobko CP, Ortega JA, Tai K, Ortiz C (2007) Statistical indentation techniques for hydrated nanocomposites: concrete, bone, and shale. J Am Ceram Soc 90:2677–2692

Vernik L, Milovac J (2011) Rock physics of organic shales. Leading Edge 30:318–323

Wei Z, Zhang G, Chen H, Luo J, Liu R, Guo S (2009) A simple method for evaluating elastic modulus of thin films by nanoindentation. J Mater Res 24:801–815

Yao K, Cai J, Liu M, Yu Y, Xiong H, Tang S et al (2011) Structure and properties of starch/PVA/nano-SiO2 hybrid films. Carbohyd Polym 86:1784–1789

Yin H, Zhang G (2011) Nanoindentation behavior of muscovite subjected to repeated loading. J Nanomech Micromech 1:72–83

Zhang G, Germaine JT, Martin RT, Whittle AJ (2003) A simple sample-mounting method for random powder X-ray diffraction. Clays Clay Miner 51:218–225

Zhang G, Wei Z, Ferrell RE (2009) Elastic modulus and hardness of muscovite and rectorite determined by nanoindentation. Appl Clay Sci 43:271–281

Zhang G, Wei Z, Ferrell RE, Guggenheim S, Cygan RT, Luo J (2010) Evaluation of the elasticity normal to the basal plane of non-expandable 2:1 phyllosilicate minerals by nanoindentation. Am Miner 95:863–869

Zhang J, Hu L, Pant R, Yu Y, Wei Z, Zhang G (2013) Effects of interlayer interactions on the nanoindentation behavior and hardness of 2: 1 phyllosilicates. Appl Clay Sci 80:267–280

Zhu W, Hughes JJ, Bicanic N, Pearce CJ (2007) Nanoindentation mapping of mechanical properties of cement paste and natural rocks. Mater Charact 58:1189–1198

Zou C, Dong D, Wang S, Li J, Li X, Wang Y et al (2010) Geological characteristics and resource potential of shale gas in China. Pet Explor Dev 37:641–653

Zou C (2017) Unconventional petroleum geology. Elsevier, Amsterdam, Netherlands

Acknowledgements

This research was funded by the National Natural Science Foundation of China (Project No. 51979144) and State Key Laboratory of Hydro-Science and Engineering (SKLHSE-2020-D-07; SKLHSE-2020-KY-01). The authors are grateful to Dr. Yongkang Wu of the University of Massachusetts Amherst for conducting X-ray powder diffraction measurements.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Analyses of the phase angles of the harmonic load and displacement

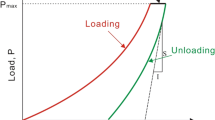

The continuous stiffness measurement (CSM) or dynamic modulus analysis (DMA) mode of nanoindentation testing has been increasingly used for the characterization of non-homogeneous or highly viscous materials, because the stiffness can be determined from the loading section of the indentation measurement. An additional advantage provided by the CSM mode is the determination of the phase angles of the harmonic load and displacement, which cannot be determined by the conventional quasi-static indentation loading or have simply been ignored even with the dynamic loading. Under the CSM mode, a small harmonic oscillation of either force or displacement with a given frequency (e.g., 45 or 75 Hz) and amplitude (e.g., 1 or 2 nm) is superimposed on the primary monotonic quasi-static loading signal. Based on the concept and theory of differential equations and vibrations, the total harmonic force acting on the sample can be described by a second-order ordinary differential equation:

where m is the mass of the indenter column; z is the displacement; D is the combined viscosity coefficient in both the indentation head and sample; K is the equivalent stiffness, which includes the stiffness of the indenter-sample contact, S, the load frame stiffness, Kf, and the stiffness of the support springs, Ks; that is:

\({\text{F(t)}}\) and z(t) are the harmonic force and the resulting displacement, respectively, which can be described as:

As such, the harmonic displacement oscillates at a frequency same as that of the force, but with a phase angle lag \(\phi\). Substituting Eq. (7) into (4) and equating the magnitudes yields:

Based on Eq. (8), the phase angle lag \(\phi\) is affected by both the equivalent stiffness K and damping ratio D. The former depends on the quality of contact between the indenter tip and sample surface or the stiffness of the contact. If the indenter is not in contact with the sample surface at all, the equivalent stiffness K is close to zero and, based on Eq. (8), \({\text{tan}}\phi\) is a negative value being equal to –\({\text{D / (m}}\omega {)}\), resulting in a constant obtuse phase angle lag, as shown in Fig. 8c and d. As the indenter tip approaches the sample surface, the phase angle lag decreases rapidly when the indenter makes a stiff contact with the asperities of the surface (i.e., surface roughness), and finally becomes a small value constant upon the establishment of a stiff, conforming contact with increasing penetration depth into the sample surface. Thus, the relationship between the phase angle lag and indentation depth makes the phase angle lag an effective indicator for the surface roughness of the indented sample and the selection of the depth ranges in the data exclusion process.

However, the phase angle lag does not affect the accuracy of experiments or cannot be used to characterize the properties of materials except viscosity. On the other hand, the surface roughness can affect the measurement accuracy, especially at shallow depths. Therefore, through the phase angle analysis, the influence of surface roughness on the load and depth measurements can be reduced significantly, and thus the accuracy of data interpretation and analysis can be improved.

Rights and permissions

About this article

Cite this article

Du, J., Luo, S., Hu, L. et al. Multiscale mechanical properties of shales: grid nanoindentation and statistical analytics. Acta Geotech. 17, 339–354 (2022). https://doi.org/10.1007/s11440-021-01312-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01312-8