Abstract

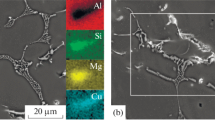

The effect of zirconium and erbium additives on the structure and mechanical properties of the cast alloy Al–5Si–1.3Cu–0.5Mg after the quenching and aging of an ingot and of a deformed sheet has been studied. An increase in the zirconium and erbium content from 0.15 to 0.2 wt % each leads to a substantial modification effect comparable to that via modification with the master alloy AlTi5B1. The grain size decreases from 200 to 80 µm in this case, while it reaches 750 µm in the alloy free of additives. The studied alloys are of a much higher ultimate compression yield stress at both room temperature (290–295 MPa) and 200°C (230–235 MPa) due to the smaller grain size and higher number of phases of crystallization origin. In this case, the formation of the erbium-containing phase, which is insoluble in the process of homogenization before quenching, slightly decreases the copper content in the solid solution. An increase in the zirconium and erbium content elevates the recrystallization-onset temperature and, at the same time, has no significant effect on the properties of deformed alloys after their quenching and aging: the yield strength is 271–285 MPa, the ultimate strength is 337–378 MPa, and the relative elongation is 6.7–17.5%.

Similar content being viewed by others

REFERENCES

A. Zariff, C. Chaudhury, and A. Suryanarayana, “TEM study of decomposition behavior of a melt-quenched A1–Zr alloy,” Metallography 17, 231–250 (1984).

E. Nes, “Precipitation of the metastable cubic Al3Zr-phase in subperitectic Al–Zr alloys,” Acta Metall. 20, 499–506 (1972).

Ü. Xin-yu, G. Er-jun, P. Rometsch, and W. Li-juan, “Effect of one-step and two-step homogenization treatments on distribution of Al3Zr dispersoids in commercial AA7150 aluminum alloy,” Trans. Nonferrous Met. Soc. China 22, 2645–2651 (2012).

K. E. Knipling, D. C. Dunand, and D. N. Seidman, “Precipitation evolution in Al–Zr and Al–Zr–Ti alloys during aging at 450–600°C,” Acta Mater. 56, 1182–1195 (2008).

K. E. Knipling, D. C. Dunand, and D. N. Seidman, “Precipitation evolution in Al–Zr and Al–Zr–Ti alloys during isothermal aging at 375–425°C,” Acta Mater. 56, 114–127 (2008).

A. V. Mikhaylovskaya, V. K. Portnoy, A. G. Mochugovskiy, M. Yu. Zadorozhnyy, N. Yu. Tabachkova, and I. Golovin, “Effect of homogenisation treatment on precipitation, recrystallisation and properties of Al–3% Mg–TM alloys (TM = Mn, Cr, Zr),” Mater. Des. 109, 197–208 (2016).

A. V. Mikhaylovskaya, A. G. Mochugovskiy, V. S. Levchenko, N. Yu. Tabachkova, W. Mufalo, and V. K. Portnoy, “Precipitation behavior of L12 Al3Zr phase in Al–Mg–Zr alloy,” Mater. Charact. 139, 30–37 (2018).

Y. Ma and R. S. Mishra, “Development of ultrafine-grained microstructure and low temperature (0.48 Tm) superplasticity in friction stir processed Al–Mg–Zr,” Scr. Mater. 53, 75–80 (2005).

C. B. Fuller and D. N. Seidman, “Temporal evolution of the nanostructure of Al3(Sc, Zr) alloys: Part II-coarsening of Al3(Sc1 – xZrx) precipitates,” Acta Mater. 53, 5415–5428 (2005).

V. S. Zolotorevskiy, R. I. Dobrozhinskaya, V. V. Cheverikin, E. A. Khamnagdaeva, A. V. Pozdniakov, V. S. Levchenko, and E. S. Besogonova, “Evolution of the structure and mechanical properties of sheets of the Al–4.7Mg–0.32Mn–0.21Sc–0.09Zr alloy due to deformation accumulated upon rolling,” Phys. Met. Metallogr. 117, No. 11, 1163–1169 (2016).

V. S. Zolotorevskiy, R. I. Dobrozhinskaya, V. V. Cheverikin, E. A. Khamnagdaeva, A. V. Pozdniakov, V. S. Levchenko, and E. S. Besogonova, “Strength and substructure of Al–4.7Mg–0.32Mn–0.21Sc–0.09Zr alloy sheets,” Phys. Met. Metallogr. 118, No. 4, 429–436 (2017).

Y. Zhang, K. Gao, S. Wen, H. Huang, Z. Nie, and D. Zhou, “The study on the coarsening process and precipitation strengthening of Al3Er precipitate in Al–Er binary alloy,” J. Alloys Compd. 610, 27–34 (2014).

S. P. Wen, K. Y. Gao, Y. Li, H. Huang, and Z. R. Nie, “Synergetic effect of Er and Zr on the precipitation hardening of Al–Er–Zr alloy,” Scr. Mater. 65, 592–595 (2011).

S. P. Wen, K. Y. Gao, H. Huang, W. Wang, and Z. R. Nie, “Precipitation evolution in Al–Er–Zr alloys during aging at elevated temperature,” J. Alloys Compd. 574, 92–97 (2013).

A. V. Pozdniakov, R. Yu. Barkov, A. S. Prosviryakov, A. Yu. Churyumov, I. S. Golovin, and V. S. Zolotorevskiy, “Effect of Zr on the microstructure, recrystallization behavior, mechanical properties and electrical conductivity of the novel Al–Er–Y alloy,” J. Alloys Compd. 765, 1–6 (2018).

A. V. Pozdnyakov, A. A. Osipenkova, D. A. Popov, S. V. Makhov, and V. I. Napalkov, “Effect of Low Additions of Y, Sm, Gd, Hf and Er on the Structure and Hardness of Alloy Al–0.2% Zr–0.1% Sc,” Met. Sci. Heat Treat. 58, Nos. 9–10, 537–542 (2017).

A. V. Pozdniakov and R. Yu. Barkov, “Effect of impurities on the phase composition and properties of a new Al–Y–Er–Zr–Sc alloy, Metallurg, No. 1, 65–70 (2019).

M. Song, K. Du, Z. Y. Huang, and H. Huang, Z. R. Nie, and H. Q. Ye, “Deformation-induced dissolution and growth of precipitates in an Al–Mg–Er alloy during high-cycle fatigue,” Acta Mater. 81, 409–419 (2014).

H. L. Hao, D. R. Ni, Z. Zhang, D. Wang, B. L. Xiao, and Z. Y. Ma, “Microstructure and mechanical properties of Al–Mg–Er sheets jointed by friction stir welding,” Mater. Des. 52, 706–712 (2013).

S. P. Wen, W. Wang, W. H. Zhao, X. L. Wu, K. Y. Gao, H. Huang, and Z. R. Nie, “Precipitation hardening and recrystallization behavior of Al–Mg–Er–Zr alloys,” J. Alloys Compd. 687, 143–151 (2016).

D. Yang, Lixiaoyan, Hedingyong, and Huanghui, “Effect of minor Er and Zr on microstructure and mechanical properties of Al–Mg–Mn alloy (5083) welded joints,” Mater. Sci. Eng., A 561, 226–231 (2013).

A. V. Pozdniakov, V. Yarasu, R. Yu. Barkov, O. A. Yakovtseva, S. V. Makhov, and V. I. Napalkov, “Microstructure and mechanical properties of novel Al–Mg–Mn–Zr–Sc–Er alloy,” Mater. Lett. 202, 116–119 (2017).

A. G. Mochugovskiy, A. V. Mikhaylovskaya, N. Yu. Tabachkova, and V. K. Portnoy, “The mechanism of L12 phase precipitation, microstructure and tensile properties of Al–Mg–Er–Zr alloy,” Mater. Sci. Eng., A 744, 195–205 (2019).

A. V. Pozdniakov, R. Yu. Barkov, Zh. Sarsenbaev, S.M. Amer, and A. S. Prosviryakov, “Evolution of microstructure and mechanical properties of a new Al–Cu–Er wrought alloy,” Phys. Met. Metallogr. 120, No. 6, 614–619 (2019).

S. M. Amer, R. Yu. Barkov, O. A. Yakovtseva, and A. V. Pozdniakov, “Comparative analysis of structure and properties of quasibinary Al–6.5Cu–2.3Y and Al–6Cu–4.05Er alloys,” Phys. Met. Metallogr. 121, No. 5, 476–482 (2020).

S. M. Amer, R. Yu. Barkov, O. A. Yakovtseva, I. S. Loginova, A. V. Pozdniakov, “Effect of Zr on microstructure and mechanical properties of the Al–Cu–Er alloy,” Mater. Sci. Technol. 36, No. 4, 453–459 (2020).

S. M. Amer, O. A. Yakovtseva, I. S. Loginova, S. V. Medvedeva, A. S. Prosviryakov, A. I. Bazlov, R. Yu. Barkov, A. V. Pozdniakov, “Phase composition and mechanical properties of a novel precipitation strengthening Al–Cu–Er–Mn–Zr alloy,” Appl. Sci. 10, 5345 (2020).

X. Hu, F. Jiang, F. Ai, and H. Yan, “Effects of rare earth Er additions on microstructure development and mechanical properties of die-cast ADC12 aluminum alloy,” J. Alloys Compd. 538, 21–27 (2012).

Z. M. Shi, Q. Wang, G. Zhao, and R. Y. Zhang, “Effects of erbium modification on the microstructure and mechanical properties of A356 aluminum alloys,” Mater. Sci. Eng., A 626, 102–107 (2015).

M. Colombo, E. Gariboldi, and A. Morri, “Er addition to Al–Si–Mg-based casting alloy: effects on microstructure, room and high temperature mechanical properties,” J. Alloys Compd. 708, 1234–1244 (2017).

M. Colombo, E. Gariboldi, and A. Morri, “Influences of different Zr additions on the microstructure, room and high temperature mechanical properties of an Al–7Si–0.4Mg alloy modified with 0.25% Er,” Mater. Sci. Eng., A 713, 151–160 (2018).

R. Yu. Barkov, A. G. Mochugovskiy, M. G. Khomutov, and A. V. Pozdnyakov, “Influence of small additions of Zr and Er on the phase composition and mechanical properties of the Al–5Si–1.3Cu–0.5Mg alloy,” Phys. Met. Metallogr. 122, No. 2, 173–178 (2021).

I. I. Novikov, Hot Brittleness of Non-Ferrous Metals and Alloys (Nauka, Moscow, 1966) [in Russian].

D. G. Eskin, Suyitno, and L, Katgerman, “Mechanical properties in the semi-solid state and hot tearing of aluminium alloys,” Prog. Mater. Sci. 49, 629–711 (2004).

V. S. Zolotorevskiy and A. V. Pozdniakov, “Determining the hot cracking index of Al–Si–Cu–Mg casting alloys calculated using the effective solidification range,” Int. J. Cast Met. Res. 27, No. 4, 193–198 (2014).

V. S. Zolotorevskiy, A. V. Pozdniakov, and A. Yu. Churyumov, “Search for promising compositions for developing new multiphase casting alloys based on Al–Cu–Mg Matrix using thermodynamic calculations and mathematic simulation,” Phys. Met. Metallogr. 113, No. 11, 1052–1060 (2012).

Funding

This study was supported by the Ministry of Science and Higher Education of Russia within the framework of a state task (project code 0718-2020-0030).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Barkov, R.Y., Prosviryakov, A.S., Khomutov, M.G. et al. Effect of the Zr and Er Content on the Structure and Properties of the Al–5Si–1.3Cu–0.5Mg Alloy. Phys. Metals Metallogr. 122, 614–620 (2021). https://doi.org/10.1134/S0031918X21060028

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21060028