Abstract

The solid–electrolyte interphase (SEI), a layer formed on the electrode surface, is essential for electrochemical reactions in batteries and critically governs the battery stability. Active materials, especially those with extremely high energy density, such as silicon (Si), often inevitably undergo a large volume swing upon ion insertion and extraction, raising a critical question as to how the SEI interactively responds to and evolves with the material and consequently controls the cycling stability of the battery. Here, by integrating sensitive elemental tomography, an advanced algorithm and cryogenic scanning transmission electron microscopy, we unveil, in three dimensions, a correlated structural and chemical evolution of Si and SEI. Corroborated with a chemomechanical model, we demonstrate progressive electrolyte permeation and SEI growth along the percolation channel of the nanovoids due to vacancy injection and condensation during the delithiation process. Consequently, the Si–SEI spatial configuration evolves from the classic ‘core–shell’ structure in the first few cycles to a ‘plum-pudding’ structure following extended cycling, featuring the engulfing of Si domains by the SEI, which leads to the disruption of electron conduction pathways and formation of dead Si, contributing to capacity loss. The spatially coupled interactive evolution model of SEI and active materials, in principle, applies to a broad class of high-capacity electrode materials, leading to a critical insight for remedying the fading of high-capacity electrodes.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data that support the findings of this study have been included in the main text, Supplementary Information and Supplementary Videos 1–6. The original data are kept at the Environmental Molecular Sciences Laboratory at Pacific Northwest National Laboratory and are available from the corresponding authors upon request.

References

Chen, J. et al. Electrolyte design for LiF-rich solid–electrolyte interfaces to enable high-performance microsized alloy anodes for batteries. Nat. Energy 5, 386–397 (2020).

Wu, H. et al. Stable cycling of double-walled silicon nanotube battery anodes through solid–electrolyte interphase control. Nat. Nanotechnol. 7, 310–315 (2012).

Chan, C. K. et al. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 3, 31–35 (2008).

Kim, H., Lee, E.-J. & Sun, Y.-K. Recent advances in the Si-based nanocomposite materials as high capacity anode materials for lithium ion batteries. Mater. Today 17, 285–297 (2014).

Choi, S., Kwon, T. W., Coskun, A. & Choi, J. W. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries. Science 357, 279–283 (2017).

Li, Y. et al. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes. Nat. Energy 1, 15029 (2016).

Liu, N. et al. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat. Nanotechnol. 9, 187–192 (2014).

An, W. et al. Scalable synthesis of ant-nest-like bulk porous silicon for high-performance lithium-ion battery anodes. Nat. Commun. 10, 1447 (2019).

Magansinski, A. et al. High-performance lithium-ion anodes using a hierarchical bottom-up approach. Nat. Mater. 9, 353–358 (2010).

Liu, N. et al. A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes. Nano Lett. 12, 3315–3321 (2012).

Lu, Z. et al. Nonfilling carbon coating of porous silicon micrometer-sized particles for high-performance lithium battery anodes. ACS Nano 9, 2540–2547 (2015).

Szczech, J. R. & Jin, S. Nanostructured silicon for high capacity lithium battery anodes. Energy Environ. Sci. 4, 56–72 (2011).

Huang, S., Fan, F., Li, J., Zhang, S. & Zhu, T. Stress generation during lithiation of high-capacity electrode particles in lithium ion batteries. Acta Mater. 61, 4354–4364 (2013).

Kim, H., Han, B., Choo, J. & Cho, J. Three-dimensional porous silicon particles for use in high-performance lithium secondary batteries. Angew. Chem. Int. Ed. 47, 10151–10154 (2008).

Kennedy, T., Brandon, M. & Ryan, K. M. Advances in the application of silicon and germanium nanowires for high-performance lithium-ion batteries. Adv. Mater. 28, 5696–5704 (2016).

Liu, X. H. et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 6, 1522–1531 (2011).

Zhao, K. et al. Concurrent reaction and plasticity during initial lithiation of crystalline silicon in lithium-ion batteries. J. Electrochem. Soc. 159, A238–A243 (2012).

Gohier, A. et al. High-rate capability silicon decorated vertically aligned carbon nanotubes for Li-ion batteries. Adv. Mater. 24, 2592–2597 (2012).

Yoon, T., Nguyen, C. C., Seo, D. M. & Lucht, B. L. Capacity fading mechanisms of silicon nanoparticle negative electrodes for lithium ion batteries. J. Electrochem. Soc. 162, A2325–A2330 (2015).

Wetjen, M. et al. Morphological changes of silicon nanoparticles and the influence of cutoff potentials in silicon-graphite electrodes. J. Electrochem. Soc. 165, A1503–A1514 (2018).

Chan, C. K., Ruffo, R., Hong, S. S. & Cui, Y. Surface chemistry and morphology of the solid electrolyte interphase on silicon nanowire lithium-ion battery anodes. J. Power Sources 189, 1132–1140 (2009).

Krause, L. J., Brandt, T., Chevrier, V. L. & Jensen, L. D. Surface area increase of silicon alloys in Li-ion full cells measured by isothermal heat flow calorimetry. J. Electrochem. Soc. 164, A2277–A2282 (2017).

Cho, J. H. & Picraux, S. T. Silicon nanowire degradation and stablization during lithium cycling by SEI layer formation. Nano Lett. 14, 3088–3095 (2014).

Zhang, Q. et al. Harnessing the concurrent reaction dynamics in active Si and Ge to achieve high performance lithium-ion batteries. Energy Environ. Sci. 11, 669–681 (2018).

Huang, W. et al. Dynamic structure and chemistry of the silicon solid-electrolyte interphase visualized by cryogenic electron microscopy. Matter 1, 1232–1245 (2019).

Midgley, P. A. & Dunin-Borkowski, R. E. Electron tomography and holography in materials science. Nat. Mater. 8, 271–280 (2009).

Zhou, J. et al. Observing crystal nucleation in four dimensions using atomic electron tomography. Nature 570, 500–503 (2019).

Turoňová, B. et al. Benchmarking tomographic acquisition schemes for high-resolution structural biology. Nat. Commun. 11, 876 (2020).

Li, Y. et al. Atomic structure of sensitive battery materials and interfaces revealed by cryo-electron microscopy. Science 358, 506–510 (2017).

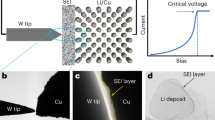

Wang, X. et al. New insights on the structure of electrochemically deposited lithium metal and its solid electrolyte interphases via cryogenic TEM. Nano Lett. 17, 7606–7612 (2017).

Liu, X. H. et al. Anisotropic swelling and fracture of silicon nanowires during lithiation. Nano Lett. 11, 3312–3318 (2011).

Choi, J. W. et al. Stepwise nanopore evolution in one-dimensional nanostructures. Nano Lett. 10, 1409–1413 (2010).

Chen, Q. & Sieradzki, K. Spontaneous evolution of bicontinuous nanostructures in dealloyed Li-based systems. Nat. Mater. 12, 1102–1106 (2013).

Hu, Y. S. et al. Electrochemical lithiation synthesis of nanoporous materials with superior catalytic and capacitive activity. Nat. Mater. 5, 713–717 (2006).

Wang, A., Kadam, S., Li, H., Shi, S. & Qi, Y. Review on modeling of the anode solid electrolyte interphase (SEI) for lithium-ion batteries. npj Comput. Mater. 4, 15 (2018).

Ploehn, H. J., Ramadass, P. & White, R. E. Solvent diffusion model for aging of lithium-ion battery cells. J. Electrochem. Soc. 151, A456–A462 (2004).

Pharr, M., Zhao, K., Wang, X., Suo, Z. & Vlassak, J. J. Kinetics of initial lithiation of crystalline silicon electrodes of lithium-ion batteries. Nano Lett. 12, 5039–5047 (2012).

Zhang, S. Chemomechanical modeling of lithiation-induced failure in high-volume-change electrode materials for lithium ion batteries. npj Comput. Mater. 3, 7 (2017).

Zhu, J. et al. In situ TEM of phosphorus-dopant-induced nanopore formation in delithiated silicon nanowires. ACS Appl. Mater. Interfaces 11, 17313–18320 (2019).

Chen, C. et al. Impact of dual-layer solid-electrolyte interphase inhomogeneities on early-stage defect formation in Si electrodes. Nat. Commun. 11, 3283 (2020).

Zhu, B. et al. Minimized lithium trapping by isovalent isomorphism for high initial Coulombic efficiency of silicon anodes. Sci. Adv. 5, eaax0651 (2019).

Zachman, M. J., Tu, Z., Choudhury, S., Archer, L. A. & Kourkoutis, L. F. Cryo-STEM mapping of solid–liquid interfaces and dendrites in lithium-metal batteries. Nature 560, 345–349 (2018).

Huang, W. et al. Evolution of the solid–electrolyte interphase on carbonaceous anodes visualized by atomic-resolution cryogenic electron microscopy. Nano Lett. 19, 5140–5148 (2019).

Xiao, Q. et al. Inward lithium-ion breathing of hierarchically porous silicon anodes. Nat. Commun. 6, 8844 (2015).

Wang, C. et al. Self-healing chemistry enables the stable operation of silicon microparticle anodes for high-energy lithium-ion batteries. Nat. Chem. 5, 1042–1048 (2013).

Yan, P. et al. Tailoring grain boundary structures and chemistry of Ni-rich layered cathodes for enhanced cycle stability of lithium-ion batteries. Nat. Energy 3, 600–605 (2018).

Sigworth, F. J., Doerschuk, P. C., Carazo, J.-M. & Scheres, S. H. W. An introduction to maximum-likelihood methods in cryo-EM. Methods Enzymol. 482, 263–294 (2010).

Aarle, W. V. et al. The ASTRA Toolbox: a platform for advanced algorithm development in electron tomography. Ultramicroscopy 157, 35–47 (2015).

Chen, L. et al. Modulation of dendritic patterns during electrodeposition: a nonlinear phase-field model. J. Power Sources 300, 376–385 (2015).

Acknowledgements

This work was supported by the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies of the US Department of Energy. This work was performed partly at the William R. Wiley Environmental Molecular Sciences Laboratory, a national scientific user facility sponsored by the US Department of Energy, Office of Biological and Environmental Research and located at Pacific Northwest National Laboratory. Pacific Northwest National Laboratory is operated by Battelle for the US Department of Energy under contract DE-AC05-76RL01830. The cryo-STEM-EDS tomography was performed at the Hillsboro Nanoport of Thermo Fisher Scientific. We thank R. Warren for his assistance on the tomography data processing. This work was also performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the US Department of Energy, Office of Science. S.Z. acknowledges support by the National Science Foundation (CBET-2034899).

Author information

Authors and Affiliations

Contributions

C.W., J.-G.Z. and X.L. conceived the project. Y.H. and X.L. designed the experiment. J.Y. synthesized the Si nanowire on the stainless-steel anode. H.J. and R.Y. assembled and cycled the coin cells. Y.H. and Y.X. performed the cryo-TEM experiments. Y.H., L.J., A.G., and C.B.-M. conducted the cryo-STEM-EDS tomography experiments under the supervision of L.P. and T.T.; L.J. and M.S. conducted the tomography data reconstruction and visualization. T.C., D.X. and S.Z. carried out the modelling calculation. Y.H., L.J., C.W. and S.Z. draughted the manuscript. All authors contributed to the revision of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Nanotechnology thanks Peter Ercius and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–37, Table 1, Discussion, evaluation of electron beam effect and optimization of imaging conditions, additional information about the background and signal intensity, and reference.

Supplementary Video 1

Cryo-STEM-EDS tomography showing 3D structure and elemental distribution of a Si nanowire after the first cycle.

Supplementary Video 2

Cryo-STEM-EDS tomography showing cross-sectional information of a Si nanowire after the first cycle.

Supplementary Video 3

Cryo-STEM-EDS tomography showing 3D structure and elemental distribution of a Si nanowire after the 36th cycle.

Supplementary Video 4

Cryo-STEM-EDS tomography showing cross-sectional information of a Si nanowire after the 36th cycle.

Supplementary Video 5

Cryo-STEM-EDS tomography showing 3D structure and elemental distribution of a Si nanowire after the 100th cycle.

Supplementary Video 6

Cryo-STEM-EDS tomography showing cross-sectional information of a Si nanowire after the 100th cycle.

Rights and permissions

About this article

Cite this article

He, Y., Jiang, L., Chen, T. et al. Progressive growth of the solid–electrolyte interphase towards the Si anode interior causes capacity fading. Nat. Nanotechnol. 16, 1113–1120 (2021). https://doi.org/10.1038/s41565-021-00947-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-021-00947-8

This article is cited by

-

Tracking lithiation with transmission electron microscopy

Science China Chemistry (2024)

-

Comparison of commercial silicon-based anode materials for the design of a high-energy lithium-ion battery

Nano Research (2024)

-

Engineering molecular regulation for SiOx with long-term stable cycle and high Coulombic efficiency as lithium-ion battery anodes

Rare Metals (2024)

-

Roadmap for rechargeable batteries: present and beyond

Science China Chemistry (2024)

-

Revealing the aging process of solid electrolyte interphase on SiOx anode

Nature Communications (2023)