Abstract

As the demand for dried timber has been increasing worldwide, drying of timbers is required to supply the demand in the manufacturing industries of furniture and other interior woodwork. During the drying process, some condensation will occur, resulting in liquids' emission, which requires disposal. In the liquid condensate, there are many substances at low concentrations that make their recovery uneconomic. After revealing the potential of the substances available in these condensates, biotechnological processes can be employed to produce high value-added products. This condensate contains tree sap, including proteins, enzymes, and many natural compounds such as terpenoids, alkaloids, phenolic compounds. Thus, it is considered that these natural compounds might be beneficial in pharmaceutical applications. Natural compounds such as phenolic compounds are bioactive substances that have antioxidant, antimicrobial, and cytotoxic activities.

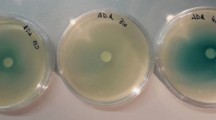

This study was aimed to characterize the condensate from the Rf-vacuum drying process of beech (Fagus sylvatica L.), walnut (Juglans regia L.), and restharrow (Onosis arvensis L.) in terms of antioxidant capacity, total phenol content, antimicrobial activity, and cytotoxicity. Obtained data revealed that condensates from the Rf-vacuum drying process inhibited the growth of both S. epidermidis and E. coli significantly.

Graphic Abstract

Similar content being viewed by others

Abbreviations

- ABTS:

-

2,2′-Azinobis(3-ethylbenzothiazoline-6-sulphonic acid

- DMEM:

-

Dulbecco’s modified eagle medium

- FBS:

-

Fetal bovine serum

- GAE:

-

Gallic acid equivalent

- Rf-V:

-

Radio frequency-vacuum

- TAOC:

-

Total antioxidant capacity

- TEAC:

-

Trolox equivalent antioxidant capacity

- TPC:

-

Total phenol content

References

Dulǎu, M., Madaras, I.: Development of a monitoring and control system for Timber’s drying process. Procedia Manuf. 32, 545–552 (2019)

Partanen, A., Carus, M.: Wood and natural fiber composites current trend in consumer goods and automotive parts. Reinf. Plast. 60, 170–173 (2016)

Espinoza, O., Bond, B.: Vacuum drying of wood—state of the art. Curr. For Rep. 2, 223–235 (2016)

Roffael, E.: Über die Abgabe von Flüchtigen Säuren aus Holzwerkstoffen - Chemische Aspekte - Chemische A. Holz Roh Werkst. 66, 373–378 (2008)

Konno, K.: Plant latex and other exudates as plant defense systems: Roles of various defense chemicals and proteins contained therein. Phytochemistry 72, 1510–1530 (2011)

Dai, J., Mumper, R.J.: Plant phenolics: extraction, analysis and their antioxidant and anticancer properties. Molecules 15, 7313–7352 (2010)

Willför, S.M., Ahotupa, M.O., Hemming, J.E., et al.: Antioxidant activity of knotwood extractives and phenolic compounds of selected tree species. J. Agric. Food Chem. 51, 7600–7606 (2003)

Dénes, T., Bartha, S.G., Kerényi, M., et al.: Histological and antimicrobial study of Ononis arvensis L. Acta Biol. Hung. 68, 321–333 (2017)

Granström, K. Emissions of volatile organic compounds from wood. Karlstad University, 2005.

Svanberg, I., Sõukand, R., Łuczaj, Ł, et al.: Uses of tree saps in northern and eastern parts of Europe. Acta Soc. Bot. Pol. 81, 343–357 (2012)

Papp, N., Czégényi, D., Hegedus, A., et al.: The uses of Betula pendula Roth among Hungarian Csángós and Székelys in Transylvania. Romania. Acta Soc. Bot. Pol. 83, 113–122 (2014)

Zyryanova, A.O., Terazawa, M., Koike, T., et al.: White birch trees as resource species of russia: their distribution, ecophysiological features, Multiple Utilizations. Eurasian J. For Res. 13, 25–40 (2010)

Wnorowski, A., Bilek, M., Stawarczyk, K., et al.: Metabolic activity of tree saps of different origin towards cultured human cells in the light of grade correspondence analysis and multiple regression modeling. Acta Soc. Bot. Pol. 86, 2–10 (2017)

Lazutka, J.R.: Genotoxicity of dill (Anethum graveolens L.), peppermint (Mentha×piperita .L) and pine (Pinus sylvestris L.) essential oils in human lymphocytes and Drosophila melanogaster. Food Chem. Toxicol. 39, 485–492 (2001)

Sacchetti, G., Maietti, S., Muzzoli, M., et al.: Comparative evaluation of 11 essential oils of different origin as functional antioxidants, antiradicals and antimicrobials in foods. Food Chem. 91, 621–632 (2005)

Willför, S., Sundberg, A., Hemming, J., et al.: Polysaccharides in some industrially important softwood species. Wood Sci. Technol. 39, 245–258 (2005)

Rezzoug, S.A.: Optimization of steam extraction of oil from maritime pine needles. J. Wood Chem. Technol. 29, 87–100 (2009)

Meullemiestre, A., Petitcolas, E., Maache-Rezzoug, Z., et al.: Isolation of volatils from maritime pine sawdust waste by different processes: ultrasound, microwave, turbohydrodistillation, and hydrodistillation. Wood Mater. Sci. Eng. 9, 76–83 (2014)

McDonald, A.G., Steward, D., Franich, R.A.: Monoterpene composition of radiata pine (Pinus radiata D.Don) sapwood from a 13 year old progeny trial. Holz Roh Werkst. 57, 301–302 (1999)

Cronn, D.R., Truitt, S.G., Campbell, M.J.: Chemical characterization of plywood veneer dryer emissions. Atmos. Environ. 17, 201–211 (1983)

Rathke, J., Stratev, D.: Analysis of the chemical constituents of dry-kiln condensate and its technological recovery -part 1: Volatile extractives. BioResources 8, 5783–5793 (2013)

McDonald, A.G., Dare, P.H., Gifford, J.S., et al.: Assessment of air emissions from industrial kiln drying of pinus radiata wood. Holz Roh Werkst. 60, 181–190 (2002)

Selik, M.: Applicability of ehrlich’s reagent for differentiation of three turkish firs species (Abies Norbmanniana, A. Bornmülleriana and A. Equi - Trojani) woods. Rev LA Fac DES Sci for L’ Universite D’Istanbul 2, 1–7 (1976)

McDonald, A.G., Gifford, J.S., Dare, P.H., et al.: Characterisation of the condensate generated from vacuum-drying of radiata pine wood. Holz Roh Werkst. 57, 253–258 (1999)

Ledig, S. Lavik, I. Broege, M. Characterization and Treatment of the Condensate Generated from Steaming of Beech Timber prior to Kiln-Drying. In: 8th International IUFRO Wood Drying Conference. (2003).

Ayrilmis, N., Kapti, T., Gürel, A., et al.: Effect of wood-drying condensate on emission of volatile organic compounds and bonding properties of fibreboard. J. Bionic. Eng. 17, 206–214 (2020)

Burtin, P., Jay-Allemand, C., Charpentier, J.P., et al.: Modifications of hybrid walnut (Juglans nigra 23 × Juglans regia) wood colour and phenolic composition under various steaming conditions. Holzforschung 54, 33–38 (2000)

Branca, C., Iannace, A.D., Blasi, C.: Devolatilization and combustion kinetics of Quercus cerris bark. Energy Fuels. 21, 1078–1084 (2007)

Kofujita, H., Ettyu, K., Ota, M.: Characterization of the major components in bark from five Japanese tree species for chemical utilization. Wood Sci. Technol. 33, 223–228 (1999)

Granström, K.M., Sandberg, M.: Characterization of wood-dryer condensate with assessment of toxicity to microorganisms. J. Environ. Eng. 43, 04017019 (2017)

Ali, M., Sreekrishnan, T.R.: Aquatic toxicity from pulp and paper mill effluents: a review. Adv. Environ. Res. 5, 175–196 (2001)

Ashrafi, O., Yerushalmi, L., Haghighat, F.: Wastewater treatment in the pulp-and-paper industry: a review of treatment processes and the associated greenhouse gas emission. J. Environ. Manage. 158, 146–157 (2015)

Kamali, M., Khodaparast, Z.: Review on recent developments on pulp and paper mill wastewater treatment. Ecotoxicol. Environ. Saf. 114, 326–342 (2015)

Stoica, A., Sandberg, M., Holby, O.: Energy use and recovery strategies within wastewater treatment and sludge handling at pulp and paper mills. Bioresour. Technol. 100, 3497–3505 (2009)

Sandberg, M.: Mill case, simulation, and laboratory plant study of black liquor spill effects on a multiple stage biological treatment plant. J. Environ. Eng. Sci. 8, 181–191 (2013)

Bicho, P.A., Chen, T., Avramidis, S., et al.: Characterization and treatment of condensates generated from softwoods that have been radio frequency/vacuum kiln dried. For. Prod J. 46, 51–56 (1996)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Köse, M.D., Uslu, M.E. & Bayraktar, O. Antioxidant, Antimicrobial, and Cytotoxic Activities of Condensate from Rf-Vacuum Timber Drying Process in the Forestry Industry. Waste Biomass Valor 12, 5079–5086 (2021). https://doi.org/10.1007/s12649-021-01378-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01378-1