Abstract

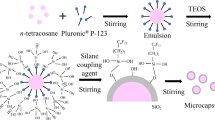

Normal alkane tetracosane (C24) as a representative compound containing alkyl chains was loaded into various porous materials to obtain form-stable phase change materials (PCMs). In the pores of controlled porous glasses (CPGs), silica gels (SGs), SBA-15 and KIT-6, C24 acquired tunable phase transition temperatures. By changing the pore sizes, C24 displayed regulated temperature windows of around 6 K (via melting) and 10 K (via solid phase transition) in the CPGs, 9 K in the SG pores (via melting) and about 13 K in SBA-15 (via melting). Phase transition temperatures, degree of supercooling and enthalpies of phase transitions exhibited linear dependence on the reverse pore diameter. The transition temperature and enthalpy change also had relevance to pore geometries. The phase sequences and solid structures of C24 in the pores changed largely. The study provides an insight into thermal properties of nano-sized PCMs.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this manuscript.

Abbreviations

- ∆H m :

-

Enthalpy of fusion, J g−1

- ∆H s :

-

Enthalpy of solid–solid phase transition, J g−1

- ∆T H :

-

Degree of supercooling, K

- ∆T trs :

-

Decrease of transition temperatures, K

- T m :

-

Melting point, K

- T m,d :

-

Melting point of crystals of size d, K

- V m :

-

Molar volume, L mol–1

- k :

-

Thermal conductivity, W m−1 K−1

- σ sl :

-

Surface energy of solid–liquid interface, N m−1.

- ρ s :

-

Solid phase density of bulk material, g cm−3.

- PCMs:

-

Phase change materials

- CPGs:

-

Controlled porous glasses

- SGs:

-

Silica gels

- s–s:

-

Solid–solid

- s-l:

-

Solid–liquid

References

Kant K, Shukla A, Sharma A (2017) Advancement in phase change materials for thermal energy storage applications. Sol Energy Mater Sol Cells 172:82–92

Qureshi ZA, Ali HM, Khushnood S (2018) Recent advances on thermal conductivity enhancement of phase change materials for energy storage system: A review. Int J Heat Mass Transfer 127:838–856

Yang G, Yim YJ, Lee JW, Heo YJ, Park SJ (2019) Carbon-filled organic phase-change materials for thermal energy storage: a review. Molecules 24(11):2055–2072

Anghel EM, Georgiev A, Petrescu S, Popov R, Constantinescu M (2014) Thermo-physical characterization of some paraffins used as phase change materials for thermal energy storage. J Therm Anal Calorim 117(2):557–566

Wu B, Zhao Y, Liu Q, Zhou C, Zhang X, Lei J (2019) Form-stable phase change materials based on castor oil and palmitic acid for renewable thermal energy storage. J Therm Anal Calorim 137(4):1225–1232

Pethurajan V, Sivan S, Konatt AJ, Reddy AS (2018) Facile approach to improve solar thermal energy storage efficiency using encapsulated sugar alcohol based phase change material. Sol Energy Mater Sol Cells 185:524–535

Wu X, Ding J, Kong Y, Sun Z, Shao G, Li B, Wu J, Zhong Y, Shen X, Cui S (2018) Synthesis of a novel three-dimensional Na2SO4@SiO2@Al2O3-SiO2 phase change material doped aerogel composite with high thermal resistance and latent heat. Ceram Int 44(17):21855–21865

Fu W, Zou T, Liang X, Wang S, Gao X, Zhang Z, Fang Y (2019) Preparation and properties of phase change temperature-tuned composite phase change material based on sodium acetate trihydrate-urea/fumed silica for radiant floor heating system. Appl Therm Eng 162. https://doi.org/10.1016/j.applthermaleng.2019.114253

Mert MS, Mert HH, Sert M (2018) Microencapsulated oleic-capric acid/hexadecane mixture as phase change material for thermal energy storage. J Therm Anal Calorim 136(4):1551–1561

Soodoo N, Raghunanan L, Bouzidi L, Narine S (2019) Phase behavior of monosulfones: Use of high polarity sulfonyl groups to improve the thermal properties of lipid-based materials for PCM applications. Sol Energy Mater Sol Cells 201. https://doi.org/10.1016/j.solmat.2019.110115

Kahraman Döğüşcü D (2019) Synthesis and characterization of ditetradecyl succinate and dioctadecyl succinate as novel phase change materials for thermal energy storage. Sol Energy Mater Sol Cells 200. https://doi.org/10.1016/j.solmat.2019.110006

Xiao Q, Zhang M, Fan J, Li L, Xu T, Yuan W (2019) Thermal conductivity enhancement of hydrated salt phase change materials employing copper foam as the supporting material. Sol Energy Mater Sol Cells 199:91–98

Wang Y, Yu K, Peng H, Ling X (2019) Preparation and thermal properties of sodium acetate trihydrate as a novel phase change material for energy storage. Energy 167:269–274

Galazutdinova Y, Vega M, Grágeda M, Cabeza LF, Ushak S (2018) Preparation and characterization of an inorganic magnesium chloride/nitrate/graphite composite for low temperature energy storage. Sol Energy Mater Sol Cells 175:60–70

Huang X, Chen X, Li A, Atinafu D, Gao H, Dong W, Wang G (2019) Shape-stabilized phase change materials based on porous supports for thermal energy storage applications. Chem Eng J 356:641–661

Seitz S, Ajiro H (2019) Self-assembling weak polyelectrolytes for the layer-by-layer encapsulation of paraffin-type phase change material icosane. Sol Energy Mater Sol Cells 190:57–64

Horpan MS, Şahan N, Paksoy H, Sivrikaya O, Günes M (2019) Direct impregnation and characterization of Colemanite/Ulexite-Mg(OH)2 paraffin based form-stable phase change composites. Sol Energy Mater Sol Cells 195:346–352

Sarı A, Bicer A, Alkan C, Özcan AN (2019) Thermal energy storage characteristics of myristic acid-palmitic eutectic mixtures encapsulated in PMMA shell. Sol Energy Mater Sol Cells 193:1–6

Chen YH, Jiang LM, Fang Y, Shu L, Zhang YX, Xie T, Li KY, Tan N, Zhu L, Cao Z, Zeng JL (2019) Preparation and thermal energy storage properties of erythritol/polyaniline form-stable phase change material. Sol Energy Mater Sol Cells 200. https://doi.org/10.1016/j.solmat.2019.109989

Rao Z, Xu T, Liu C, Zheng Z, Liang L, Hong K (2018) Experimental study on thermal properties and thermal performance of eutectic hydrated salts/expanded perlite form-stable phase change materials for passive solar energy utilization. Sol Energy Mater Sol Cells 188:6–17

Jiang Y, Liu M, Sun Y (2019) Review on the development of high temperature phase change material composites for solar thermal energy storage. Sol Energy Mater Sol Cells 203. https://doi.org/10.1016/j.solmat.2019.110164

Wu H-y, Chen R-t, Shao Y-w, Qi X-d, Yang J-h, Wang Y (2019) Novel Flexible Phase Change Materials with Mussel-Inspired Modification of Melamine Foam for Simultaneous Light-Actuated Shape Memory and Light-to-Thermal Energy Storage Capability. ACS Sustainable Chemistry & Engineering 7(15):13532–13542

Gao C-F, Wang L-P, Li Q-F, Wang C, Nan Z-D, Lan X-Z (2014) Tuning thermal properties of latent heat storage material through confinement in porous media: The case of (1-CnH2n+1NH3)2ZnCl4 (n=10 and 12). Sol Energy Mater Sol Cells 128:221–230

Wang C, Li Q, Wang L, Lan XZ (2016) Phase transition of neopentyl glycol in nanopores for thermal energy storage. Thermochim Acta 632:10–17

Tian F, Zhang S, Zhai M, Sui J, Lan X, Gao J (2017) Thermal properties of nano-sized polyethylene glycol confined in silica gels for latent heat storage. Thermochim Acta 655:211–218

Zhang X, Shen J, Pan S, Qian J, Pan B (2020) Metastable Zirconium Phosphate under Nanoconfinement with Superior Adsorption Capability for Water Treatment. Adv Funct Mater 30 (12). https://doi.org/10.1002/adfm.201909014

Surrey A, Bonatto Minella C, Fechler N, Antonietti M, Grafe H-J, Schultz L, Rellinghaus B (2016) Improved hydrogen storage properties of LiBH4 via nanoconfinement in micro- and mesoporous aerogel-like carbon. Int J Hydrogen Energy 41(12):5540–5548

Milinskiy AY, Baryshnikov SV, Charnaya EV, Egorova IV, Uskova NI (2020) Effect of Nanoconfinement on the Kinetics of Phase Transitions in Organic Ferroelectric DIPAI. Phys Solid State 62(7):1199–1203

Haruk AM, Leng CZ, Fernando PS, Smilgies D-M, Loo Y-L, Mativetsky JM (2020) Tuning Organic Semiconductor Alignment and Aggregation via Nanoconfinement. The Journal of Physical Chemistry C 124(41):22799–22807

Shadpour S, Nemati A, Liu J, Hegmann T (2020) Directing the Handedness of Helical Nanofilaments Confined in Nanochannels Using Axially Chiral Binaphthyl Dopants. ACS Appl Mater Interfaces 12(11):13456–13463

Wu K, Chen Z, Li J, Lei Z, Xu J, Wang K, Li R, Dong X, Peng Y, Yang S, Zhang F, Chen Z, Gao Y (2019) Nanoconfinement Effect on n-Alkane Flow. The Journal of Physical Chemistry C 123(26):16456–16461

Pallaka MR, Unruh DK, Simon SL (2018) Melting behavior of n-alkanes in anodic aluminum oxide (AAO) nanopores using Flash differential scanning calorimetry. Thermochim Acta 663:157–164

Safari M, Leon Boigues L, Shi G, Maiz J, Liu G, Wang D, Mijangos C, Müller AJ (2020) Effect of Nanoconfinement on the Isodimorphic Crystallization of Poly(butylene succinate-ran-caprolactone) Random Copolymers. Macromolecules 53(15):6486–6497

Berube F, Khadraoui A, Florek J, Kaliaguine S, Kleitz F (2015) A generalized method toward high dispersion of transition metals in large pore mesoporous metal oxide/silica hybrids. J Colloid Interface Sci 449:102–114

Zhang C, Sha Y, Zhang Y, Cai T, Li L, Zhou D, Wang X, Xue G (2017) Nanostructures and Dynamics of Isochorically Confined Amorphous Drug Mediated by Cooling Rate, Interfacial, and Intermolecular Interactions. J Phys Chem B 121(47):10704–10716

Peksa P, Trzmiel J, Ptak M, Kostrzewa M, Szatanik R, Barascu A, Enke D, Sieradzki A (2018) Confinement-induced polymorphism in acetylsalicylic acid-nanoporous glass composites. J Mater Sci 54(1):404–413

Cheng S, McKenna GB (2019) Nanoconfinement Effects on the Glass Transition and Crystallization Behaviors of Nifedipine. Mol Pharm 16(2):856–866

Diao Y, Lenn KM, Lee WY, Blood-Forsythe MA, Xu J, Mao Y, Kim Y, Reinspach JA, Park S, Aspuru-Guzik A, Xue G, Clancy P, Bao Z, Mannsfeld SC (2014) Understanding polymorphism in organic semiconductor thin films through nanoconfinement. J Am Chem Soc 136(49):17046–17057

Sui J, Zhang SQ, Zhai M, Tian F, Zhang J, Lan XZ (2017) Polymorphism of a hexadecane–heptadecane binary system in nanopores. RSC Adv 7(18):10737–10747

Cao L, Man T, Kruk M (2009) Synthesis of Ultra-Large-Pore SBA-15 Silica with Two-Dimensional Hexagonal Structure Using Triisopropylbenzene As Micelle Expander. Chem Mater 21(6):1144–1153

Nishihara H, Fukura Y, Inde K, Tsuji K, Takeuchi M, Kyotani T (2008) Carbon-coated mesoporous silica with hydrophobicity and electrical conductivity. Carbon 46(1):48–53

Deng S, Wang D, Wang X, Wei Y, Waterhouse GIN, Lan XZ (2018) Effect of nanopore confinement on the thermal and structural properties of heneicosan. Thermochim Acta 664:57–63

Wang D, Sui J, Qi D, Deng S, Wei Y, Wang X, Lan X (2018) Phase transition of docosane in nanopores. J Therm Anal Calorim 135(5):2869–2877

Zhai M, Zhang S, Sui J, Tian F, Lan XZ (2017) Solid–solid phase transition of tris(hydroxymethyl)aminomethane in nanopores of silica gel and porous glass for thermal energy storage. J Therm Anal Calorim 129(2):957–964

Mondieig D, Rajabalee F, Metivaud V, Oonk HAJ, Cuevas-Diarte MA (2004) n-Alkane Binary Molecular Alloys. Chem Mater 16(5):786–798

Wang X, Wei Y, Zhang D, Lan X, Han F, Lan XZ (2020) Phase behaviors of n-octacosane in nanopores: Role of pore size and morphology. Thermochim Acta 690:178687. https://doi.org/10.1016/j.tca.2020.178687

Yan X, Wang TB, Gao CF, Lan XZ (2013) Mesoscopic Phase Behavior of tridecane–tetradecane mixtures confined in Porous Materials: Effects of Pore Size and Pore Geometry. The Journal of Physical Chemistry C 117(33):17245–17255

Wang LP, Li QF, Wang C, Lan XZ (2014) Size-Dependent phase behavior of the hexadecane–octadecane system confined in nanoporous glass. The Journal of Physical Chemistry C 118(31):18177–18186

Zhang W, Xue Y, Fu Q, Cui Z, Wang S (2017) Size dependence of phase transition thermodynamics of nanoparticles: A theoretical and experimental study. Powder Technol 308:258–265

Sun J, Simon SL (2007) The melting behavior of aluminum nanoparticles. Thermochim Acta 463(1–2):32–40

Zhdanov VP, Schwind M, Zorić I, Kasemo B (2010) Overheating and undercooling during melting and crystallization of metal nanoparticles. Phys E 42(7):1990–1994

Malik M, Dincer I, Rosen MA (2016) Review on use of phase change materials in battery thermal management for electric and hybrid electric vehicles. Int J Energy Res 40(8):1011–1031

Zhang L, Zhou K, Wei Q, Ma L, Ye W, Li H, Zhou B, Yu Z, Lin CT, Luo J, Gan X (2019) Thermal conductivity enhancement of phase change materials with 3D porous diamond foam for thermal energy storage. Appl Energy 233–234:208–219

Acknowledgements

We thank the financial support from National Natural Science Found of China (No. 21973056, 21727805, 21273138) and Natural Science Found of Shandong Province ZR2019MB050.

Funding

This study was funded by National Natural Science Found of China (No. 21973056, 21727805, 21273138) and Natural Science Found of Shandong Province ZR2019MB050.

Author information

Authors and Affiliations

Contributions

Dongxue Zhang: Conceptualization, Methodology, Formal analysis and investigation, Writing-original draft preparation. Xin Wang: Formal analysis and investigation. Yantao Dong: Formal analysis and investigation Nan Lu: Writing-review and editing Xiaozheng Lan: Writing-review and editing, Funding acquisition, Resources, Supervision.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, D., Wang, X., Dong, Y. et al. Nanosized n-tetracosane as heat storage media: adjustable phase transition temperature and thermal property. Heat Mass Transfer 58, 407–417 (2022). https://doi.org/10.1007/s00231-021-03112-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-021-03112-y