Abstract

The operating principle of conventional water electrolysis using heterogenous catalysts has been primarily focused on the unidirectional charge transfer within the heterostructure. Herein, multidirectional charge transfer concept has been adopted within heterostructured catalysts to develop an efficient and robust bifunctional water electrolysis catalyst, which comprises perovskite oxides (La0.5Sr0.5CoO3–δ, LSC) and potassium ion-bonded MoSe2 (K-MoSe2). The complementary charge transfer from LSC and K to MoSe2 endows MoSe2 with the electron-rich surface and increased electrical conductivity, which improves the hydrogen evolution reaction (HER) kinetics. Excellent oxygen evolution reaction (OER) kinetics of LSC/K-MoSe2 is also achieved, surpassing that of the noble metal (IrO2), attributed to the enhanced adsorption capability of surface-based oxygen intermediates of the heterostructure. Consequently, the water electrolysis efficiency of LSC/K-MoSe2 exceeds the performance of the state-of-the-art Pt/C||IrO2 couple. Furthermore, LSC/K-MoSe2 exhibits remarkable chronopotentiometric stability over 2,500 h under a high current density of 100 mA cm−2.

Similar content being viewed by others

Introduction

Hydrogen is one of the cleanest and most sustainable energy sources that can provide high-energy-density fuel for electricity generation. Moreover, hydrogen production via electrocatalytic water splitting has been extensively explored recently1,2. Noble-metal-based Pt/Pd and RuO2/IrO2 electrocatalysts have been widely utilized in the cathodic hydrogen evolution reaction (HER) and anodic oxygen evolution reaction (OER), respectively, for efficient hydrogen generation from water electrolysis. Although noble-metal-based electrocatalysts exhibit excellent water electrolysis performance, these catalysts typically suffer from poor stability and scarcity in alkaline water electrolysis systems3,4, which is undesirable in practical industrial applications. In addition, most noble-metal-based catalysts function optimally only for the half-cell reaction (either HER or OER) under specific electrolytic conditions5. Bifunctional catalysts that can be simultaneously used for both the cathode and anode reactions in the same electrolyte have been developed to improve water electrolysis performance and simplify the electrolysis system6,7. For bifunctional catalysts, the reaction kinetics and efficiency of the OER process can determine the reaction rate of overall water electrolysis due to its sluggish kinetics from the rigid double bond in O–O and multi-proton-coupled electron transfer steps8,9. Therefore, achieving effective OER catalytic activity in bifunctional catalysts is critical in maximizing water electrolysis performance.

To strategically enhance the water electrolysis efficiency of the bifunctional catalyst, heterostructured catalyst configurations, including transition-metal-based nanocrystals (e.g., Co, Ni, Fe, and Cu) or noble-metal-based composites (e.g., Pt, Ag, Pd, Au, and Rh), have often been investigated for their morphology control, compositional combination of the heterostructure, and foreign elemental doping10,11,12,13,14. Charge transfer within the heterostructured catalyst, which can modulate the electronic structure of the heterostructure and directly influence the Faradaic efficiency of the respective electrode15,16, is critical in improving the efficiency of overall water electrolysis for bifunctional catalysts. Thus far, most bifunctional heterostructure-based catalysts have primarily utilized unidirectional charge transfer effects between heterostructure components17,18, which can potentially limit an optimized electronic structure to achieve ideal HER and OER catalytic activities. Therefore, a different perspective on catalyst design is needed to effectively modulate the electronic structure of the catalyst such that its electrocatalytic activity is maximized in water electrolysis. Furthermore, most bifunctional catalysts demonstrate operational stability under relatively low current densities19,20,21,22,23. As the durability of the electrolytic catalyst can be severely degraded at high current densities, e.g., through the Ostwald ripening, aggregation, and detachment during the electrolytic reaction24,25, robust electrochemical stability of the bifunctional catalyst should also be achieved for industrial consideration in addition to the high efficiency of water electrolysis.

In the present work, we have developed a heterostructured catalyst comprising perovskite oxide (La0.5Sr0.5CoO3-δ, LSC) and potassium ion-bonded molybdenum diselenide (K-MoSe2) as the bifunctional catalysts for overall water electrolysis. The semiconducting 2H-phase MoSe2 was moderately converted to metallic 1T-MoSe2 via charge transfer from potassium atoms during the potassium metal intercalation process26. In a previous report, Park et al. reported a heterostructured water electrolysis catalyst structure comprising perovskite oxide and transition-metal dichalcogenides (TMDs) featured with unidirectional charge transfer enabling the in-situ local phase transition in TMDs. Differently, the LSC/K-MoSe2 system in this study characterizes the multidirectional charge transfer phenomenon, involving two-way charge transfer from K to MoSe2 and from LSC to MoSe2, which led to significantly improved water electrolysis performance and operational stability. When K-MoSe2 forms a heterostructure with LSC, the metallic-phase purity of MoSe2 is significantly increased to over 90% through the complementary charge transfer from LSC and potassium atoms. The optimized LSC/K-MoSe2 catalyst exhibits significantly enhanced HER and OER performance compared with those of LSC or K-MoSe2, which is attributed to the increased electrical conductivity of MoSe2 and improved oxygen intermediate adsorption in LSC. In particular, the OER catalytic activity of LSC/K-MoSe2 outperforms that of the noble-metal IrO2 catalyst in 1 M KOH. Consequently, the performance (e.g., overpotential and Tafel slope) and energy efficiency of overall water electrolysis of the LSC/K-MoSe2||LSC/K-MoSe2 couple surpass those of the state-of-the-art Pt/C||IrO2 pair. Furthermore, the integrated overall water electrolysis exhibits excellent operational stability (over 2,500 h) without the decomposition of the catalyst under a high current density of 100 mA cm−2.

Results

Morphology and elemental characteristics of LSC/K-MoSe2

An LSC/K-MoSe2 heterostructure catalyst was synthesized via a simple and mass-producible solution process (Fig. 1a; see “Methods” section for details). In brief, LSC and K-MoSe2 were synthesized via the sol-gel method and molten-metal-assisted intercalation26, respectively; the as-prepared LSC and K-MoSe2 were mixed via ball milling at specified weight percent ratios. The resulting LSC/K-MoSe2 compounds prepared in powder and solution forms are shown in Fig. 1a. Morphological and elemental analyses were conducted via scanning electron microscopy (SEM) and transmission electron microscopy (TEM). Supplementary Fig. 1 shows the SEM image of the LSC/K-MoSe2 heterostructure, indicating that K-MoSe2 was uniformly adsorbed onto the LSC surface without aggregation, which can contribute to the high specific surface area of the heterostructure. Figure 1b shows the high-angle annular dark-field (HAADF) image of LSC/K-MoSe2 and the corresponding TEM energy-dispersive spectroscopy (EDS) elemental mapping profile. All relevant components (La, Sr, Co, O, Mo, Se, and K) were uniformly distributed in the heterostructure, and the elemental compositions of each component of LSC/K-MoSe2 obtained from the TEM–EDS spectrum are presented in Supplementary Fig. 2 with the prescribed elemental ratio. High-resolution TEM (HR-TEM) analysis was further performed to observe the atomic structure of LSC/K-MoSe2 in detail. As shown in Fig. 1c–e, the coexistence of LSC and K-MoSe2 can be clearly observed. LSC shows the well-known ABO3 layered perovskite oxide structure comprising La and Sr at the A site, Co at the B site, and O at the anion site, and the fast Fourier transform (FFT) pattern indicated a highly crystalline structure corresponding to the (110) and (001) planes of the LSC in the [110] zone axis (Fig. 1d). K-MoSe2 exhibits the typical 1T-phase atomic structure, and the FFT pattern on the [001] zone axis shows the desired crystalline structure of K-MoSe2 corresponding to the (100) and (110) planes (Fig. 1e). The K-MoSe2 flakes formed on the as-synthesized LSC/K-MoSe2 are a few layers in thickness, indicating that the as-exfoliated K-MoSe2 flakes were successfully integrated with the LSC without additional restacking (Supplementary Fig. 3).

a Schematic illustrating the synthesis process of LSC/K-MoSe2. Digital image demonstrates the large-scale synthesis capability of the proposed method. b HAADF-STEM image and corresponding EDS elemental mapping of La (red), Sr (blue), Co (yellow green), O (cyan), K (yellow), Mo (purple), and Se (green). c HR-TEM image of LSC/K-MoSe2, showing typical morphological characteristics of the heterostructure comprising the LSC (red square) and K-MoSe2 (yellow square) regions. d Representative HR-TEM image of LSC and corresponding FFT image, indicating the lattice structure of La/Sr, Co, and O with high crystallinity. e Representative HR-TEM image of K-MoSe2 and corresponding FFT image, exhibiting the highly crystalline lattice structure of 1T-phase MoSe2 comprising Mo and Se.

Electrochemical performance

The electrochemical activity of LSC/K-MoSe2 was investigated by analyzing the linear sweep voltammetry (LSV) curve for HER and OER, cyclic voltammograms, double-layer capacitance values, and electrochemical impedance spectroscopy (EIS) results. As shown in Supplementary Figs. 4–7, Supplementary Tables 1 and 2, various weight percent ratios of LSC and K-MoSe2 were first evaluated, and the optimal ratio of LSC/K-MoSe2 (5:4) yielding the best electrochemical catalytic performance was determined. This optimized configuration of LSC/K-MoSe2 heterostructure was utilized for further analyses. The hydrogen generation activity of LSC/K-MoSe2 was evaluated in the half-cell system, and Fig. 2a compares the polarization curves of LSC/K-MoSe2, K-MoSe2, LSC, and Pt/C in N2-saturated 1 M KOH using a three-electrode system. The corresponding Tafel slope of HER in various electrode configurations derived from the obtained LSV profile is shown in Fig. 2b. The Pt/C catalyst exhibited an overpotential of 68 mV at 10 mA cm−2 with a Tafel slope of 31 mV dec−1, which suggests that the Volmer–Tafel reaction is a rate-determining step27. In the case of LSC/K-MoSe2, the catalyst exhibited significantly higher HER activity than that of the LSC and K-MoSe2. LSC/K-MoSe2 showed an overpotential of 128 mV at 10 mA cm−2 and a Tafel slope of 45 mV dec−1, whereas K-MoSe2 and LSC required 288 and 450 mV to reach 10 mA cm−2 with Tafel slopes of 62 and 119 mV dec−1, respectively. The considerably improved Tafel slope, and thus the HER performance, of LSC/K-MoSe2 implies that the primary rate-determining step of the heterostructured catalyst becomes closer to the Volmer–Tafel pathway of noble metals28,29. The enhanced HER performance of LSC/K-MoSe2 was also confirmed through charge transfer resistance (Rct) analysis between the electrode and electrolyte, which can directly affect electrochemical performance. Figure 2c shows the Nyquist plots of LSC/K-MoSe2, K-MoSe2, and LSC for the HER obtained via EIS analysis, and the derived Rct values were 1.30, 2.56, and 5.78 Ω cm2, respectively, which corroborates that charge transfer kinetics is most favorable for LSC/K-MoSe2 than others. We also investigated the OER activity of various catalyst configurations in N2-saturated 1 M KOH using a three-electrode system. Figure 2d shows the LSV curves of LSC/K-MoSe2, K-MoSe2, LSC, and IrO2 for OER. The corresponding Tafel slope is shown in Fig. 2e. IrO2, known as the best performing noble-metal-based catalyst in OER5, showed an overpotential of 350 mV at 10 mA cm−2 with a Tafel slope of 81 mV dec−1. Notably, the OER catalytic performance of LSC/K-MoSe2 exceeded that of IrO2 with an overpotential as low as 230 mV to reach 10 mA cm−2 and a Tafel slope of 79 mV dec−1. In contrast, LSC required an overpotential of 420 mV to reach 10 mA cm−2 with a Tafel slope of 131 mV dec−1 and K-MoSe2 exhibited negligible OER activity. It has been reported that the OER performance of perovskite oxide can be improved by the doping effect of molybdenum30. We thus conducted XPS analysis of Mo and Se in LSC/K-MoSe2 under OER condition after water electrolysis to elucidate the potential doping effect of Mo on the OER performance of LSC/K-MoSe2 (Supplementary Fig. 8 and Supplementary Table 3). The XPS results indicated partial oxidation of Mo and Se, but not the decomposition, in LSC/K-MoSe2 in our proposed heterostructured electrocatalyst system. In general, molybdenum oxide is known to have negligible OER activity in an alkaline environment, which is consistent with the observation of poor OER performance of K-MoSe2 in our study31. Thus, the origin of OER performance enhancement of LSC in the heterostructure is not attributed to the doping effect of molybdenum or its oxide derivatives. In our system, Mo, rather than serving as the main contributor for the OER active site, is believed to participate in the continuous charge transfer process with LSC during the OER reaction, which enhances the electrophilicity of LSC, leading to the increased adsorption of OER intermediates such as OH* and OOH*, and modulates the electronic structure of LSC/K-MoSe2 favorable for OER process. The improvement in OER kinetics of LSC/K-MoSe2 compared to that of LSC owing to the presence of Mo in the OER environment was also previously verified via experimental and computational analyses (low Tafel slope value (Fig. 2e), upshift of XPS spectra of Co 2p peak (Supplementary Fig. 14), and reduced free energy barrier and density of states (Fig. 4f–h and Supplementary Figs. 21–23)). The Rct values of LSC/K-MoSe2, K-MoSe2, and LSC for OER obtained from the EIS analysis were 1.52, 74.0, and 1.91 Ω cm2, respectively (Fig. 2f). The lower Rct in LSC/K-MoSe2 than K-MoSe2 and LSC indicates that the interfacial resistance between the electrode and electrolyte is reduced through heterostructure formation, contributing to the improved OER kinetics. These results suggest that the formation of the LSC/K-MoSe2 heterostructure may induce potential physicochemical interactions between the LSC and K-MoSe2, generating synergistic effects to lead to the observed excellent intrinsic catalytic activities for both the HER and OER processes. Below, we present detailed analyses on the heterogeneous composite structure to elucidate the origin of the enhanced catalytic performance.

a, d HER and OER polarization curves recorded in N2-saturated 1 M KOH at a scan rate of 5 mV s−1. b, e Corresponding Tafel slopes of the HER and OER profiles derived from the polarization curves. c, f EIS analysis of HER and OER for LSC/K-MoSe2, K-MoSe2, and LSC. The Nyquist plots comprise real (Z′) and imaginary (Z″) parts fitted as x and y axes, respectively.

Analysis of physical properties of LSC/K-MoSe2

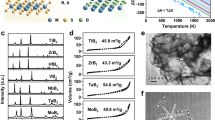

The crystal structures of 2H-MoSe2, LSC/K-MoSe2, K-MoSe2, and LSC were investigated via X-ray diffraction (XRD). As shown in Fig. 3a, the preferred crystallographic orientation of 2H-MoSe2 at (002) plane is observed at 13.8°32, whereas that of K-MoSe2 is blue shifted to 13.4° owing to the increased interlayer spacing between the MoSe2 layers through the formation of potassium-intercalated MoSe2. The preferred orientation of the (002) plane for K-MoSe2 was consistently found at 13.4° for the LSC/K-MoSe2 heterostructure. In addition, as shown in Supplementary Fig. 9, the crystal structures of K-MoSe2 and LSC can be clearly identified from LSC/K-MoSe2, indicating that each crystal structure of K-MoSe2 and LSC is well preserved when forming the heterostructure through the ball mill process. Thermogravimetric analysis (TGA) was performed to examine the surface adsorption capability of the catalysts (Fig. 3b). Target materials, including LSC/K-MoSe2, K-MoSe2, and LSC, were preexposed to wet-air conditions to adsorb various environmental species in the atmosphere such as moisture, H, and OH groups. With incremental heat treatments up to 600 °C, LSC/K-MoSe2 exhibited a weight loss of ~14%, whereas both K-MoSe2 and LSC exhibited only a marginal weight loss of ~2%, demonstrating the improved surface adsorption capability of the heterostructure. Brunauer–Emmett–Teller (BET) analysis was conducted to investigate the specific surface area of LSC/K-MoSe2 (Fig. 3c). Compared with K-MoSe2 and LSC, the heterostructure exhibited significantly enhanced surface areas, i.e., 203.94, 104.51, and 32.54 m2 g−1 for LSC/K-MoSe2, K-MoSe2, and LSC, respectively, indicating that the active sites of the heterostructured catalyst can be increased to improve the efficiency of the electrochemical cell. We further analyzed the BET surface area and water electrolysis performance of various other conditioned samples comprising LSC and K-MoSe2 to gain more insights for the surface area effect according to different ball-milling processes on the water electrolysis performance (Supplementary Figs. 10, 11 and Supplementary Table 4). We note that, overall, there was no significant difference in the morphology for each conditioned samples before and after the ball-milling process (Supplementary Fig. 12). For the individual component materials (LSC and MoSe2), the ball-milled samples showed slightly increased BET surface areas, but the water electrolysis performance remained almost unaffected. When forming the heterostructured catalyst, the ball-milling process to the specific surface area and the electrolytic performance exhibited the most synergistic effects when applied during the heterostructure formation of individual component materials (i.e., LSC and K-MoSe2) rather than to each component of LSC and K-MoSe2 followed with the mixing process. These results indicate that ball milling during the formation of the composite structures increases the active sites for the water electrolysis and facilitates the charge transfer between LSC and K-MoSe2, thereby enabling the improved water electrolysis performance in the heterostructured catalyst. In addition, the pore size of LSC/K-MoSe2 was measured using the Barrett–Joyner–Halenda (BJH) method. LSC/K-MoSe2 exhibited a mesoporous pore size distribution of 2–50 nm (Supplementary Fig. 13). The mesoporous nature of the catalyst can effectively improve the surface area of the catalyst as well as the diffusion of the electrolyte and ionic species33. Further, the desorption of hydrogen and oxygen generated during the overall water electrolysis reaction becomes favorable owing to the rapid mass transfer from the electrolyte to the catalyst surface, which can help to improve the performance of the water electrolysis34,35.

a XRD patterns for 2H-MoSe2, LSC/K-MoSe2, K-MoSe2, and LSC, demonstrating that each of the K-MoSe2 and LSC phases are well preserved in LSC/K-MoSe2. b TGA analysis of LSC/K-MoSe2, K-MoSe2, and LSC, indicating the improved surface adsorption capability of LSC/K-MoSe2. c BET surface area of LSC/K-MoSe2, K-MoSe2, and LSC obtained from N2 adsorption/desorption isotherms. d Raman spectra of LSC/K-MoSe2 and K-MoSe2, illustrating the electronic interaction between LSC and K-MoSe2. e UPS valence band spectra of LSC/K-MoSe2, LSC, and K-MoSe2. f UV–Vis–NIR spectra of 2H-MoSe2, LSC/K-MoSe2, and K-MoSe2, indicating the metallic features of LSC/K-MoSe2 and K-MoSe2. g, h High-resolution XPS spectra of Mo 3d and Se 3d peaks for LSC/K-MoSe2 and K-MoSe2. i Relative fraction of 2H- and 1T-MoSe2 in LSC/K-MoSe2 and K-MoSe2, indicating the substantial increase of the 1T-phase ratio in MoSe2 through complementary charge transfer.

Figure 3d shows the Raman spectra of LSC/K-MoSe2 and K-MoSe2. Characteristic vibrational Raman modes of K-MoSe2 were detected at 106.2, 150.5, 221.6, 165.2, and 289.7 cm−1, corresponding to the J1, J2, J3, E1g, and E12g peaks of 1T-MoSe236. The characteristic Raman peak positions of LSC/K-MoSe2 were red shifted by 2 cm−1, indicating potential electronic interaction between the LSC and K-MoSe237. Ultraviolet photoelectron spectroscopy (UPS) analysis was performed to investigate the charge transfer effect between LSC and K-MoSe2. Work function values were derived from the secondary cutoff energies. Figure 3e shows that the work function of LSC/K-MoSe2 increased compared to LSC and K-MoSe2 alone (5.38 eV vs. 5.15 and 5.22 eV). This verifies that electronic structure modulation in LSC/K-MoSe2 occurs via charge transfer between LSC and K-MoSe2. Compared with LSC, LSC/K-MoSe2 with an increased work function has several merits for improving electrochemical performance. The increased work function enhances the rate constant and preexponential kinetic factor in the electrocatalytic reaction38,39. The high rate constant and kinetic factor reduce the bond strength between active sites and adsorbed intermediates of HER on the catalyst surface, increasing the exchange current density and enabling the Gibbs free energy of hydrogen adsorbed on the active site closer to the thermoneutral point (~0 eV). It also enables overpotential reduction for the Volmer reaction owing to the increase in proton concentration of the electronic double layer of the catalyst, thereby improving HER performance40. UV–Vis–NIR spectroscopy analysis in Fig. 3f reveals that the A and B excitonic peaks observed for semiconducting 2H-MoSe241 disappear in LSC/K-MoSe2 and K-MoSe2, illustrating the metal-like characteristics of the as-synthesized LSC/K-MoSe2 and K-MoSe242.

X-ray photoelectron spectroscopy (XPS) analysis was performed to further elucidate the origin of the enhanced HER and OER performance of LSC/K-MoSe2. First, we analyzed the chemical states of Co 2p and O 1s core levels of LSC and LSC/K-MoSe2 to infer the cause of catalytic electrolysis performance improvement. The Co 2p peaks of LSC and LSC/K-MoSe2 include Co 2p3+, Co 2p2+, and two satellite features. As shown in Supplementary Fig. 14, in LSC, Co3+ and Co2+ peaks are located at 779.6/794.2 and 781.5/797.0 eV, and those of LSC/K-MoSe2 are located at 780.6/795.2 and 782.5/798.0 eV, respectively, illustrating an upshift of 1 eV in the peak position for the heterostructure. This upshift can be attributed to the electronic interaction between LSC and K-MoSe2. In LSC/K-MoSe2, a difference in the electronegativity between Mo and Co induces charge transfer, which can modulate the electronic structure (eg orbital) of Co while maintaining the overall electroneutrality. As the eg-orbital filling of perovskite oxide affects the binding of oxygen-related intermediates at the active site (typically at B site), optimizing the eg-orbital occupancy close to 1 is critical for achieving optimal OER performance43. In Co, which is the B site of LSC, eg-orbital fillings of Co3+ (t52ge1g) and Co2+ (t52ge2g) are 1 and 2, respectively, which suggests that increasing the Co3+ proportion over Co2+ is preferable to obtain the optimized eg-orbital occupancy44,45. The ratio of Co3+/Co2+, the value obtained from the XPS spectra, is summarized in Supplementary Table 5; this ratio was 1.5 and 2.4 for LSC and LSC/K-MoSe2, respectively. Therefore, near-unity eg-orbital occupancy can be expected for LSC/K-MoSe2, confirming improved OER performance in the heterostructure. The chemical state of O 1s in the catalyst can also directly affect OER kinetics46,47. As shown in Supplementary Fig. 15, O 1s peaks of LSC and LSC/K-MoSe2 include four secondary (shoulder) peaks comprising the lattice oxygen at 528.31 eV (O2−, denoted as LO), highly oxidative oxygen species at 531.1 eV (O22−/O−, denoted as OO), surface adsorbed oxygen including hydroxyl groups at 532.11 eV (O2/OH−, denoted as SO), and adsorbed molecular water at 533.2 eV (H2O, denoted as AW). The larger amount of surface adsorbed oxygen species compared to the lattice oxygen on the catalyst surface has a favorable effect on the formation of oxygen vacancy and rate-determining step of the OER process46,47. Thus, the increased SO/LO ratio of LSC/K-MoSe2 over LSC indicates that the formation kinetics of the active sites–O, –OH, and –OO bonds for the heterostructure was improved, which can contribute to the enhanced electrolytic performance in alkaline solutions (Supplementary Table 6).

The chemical state of MoSe2 was also investigated to further elucidate the origin of electrochemical performance improvement in the heterostructure. As shown in Fig. 3g, h, 1T- and 2H-phase MoSe2 with different relative ratios coexist in LSC/K-MoSe2 and K-MoSe2. The XPS peaks of the 1T-phase in these configurations are positioned at 228.3 and 231.4 eV for Mo 3d5/2 and Mo 3d3/2, and at 53.7 and 54.7 eV for Se 3d5/2 and Se 3d3/2, whereas those of the 2H-phase are located at 229.0 and 232.8 eV for Mo 3d5/2 and Mo 3d3/2, and at 54.3 and 55.8 eV for Se 3d5/2 and Se 3d3/2, respectively. Figure 3i summarizes the relative contents of the 1T- and 2H-phase MoSe2 for as-prepared LSC/K-MoSe2 and K-MoSe2 obtained from the XPS spectra. The high-purity 1T-phase MoSe2 (~91%) found in the heterostructure over that of K-MoSe2 (~67%) clearly evidence that electronic interaction occurs between LSC and K-MoSe2 causing the further metallic-phase transition of MoSe2 in K-MoSe2.

Complementary charge transfer in LSC/K-MoSe2

We hypothesize that the drastic increase in the 1T-phase content of MoSe2 in the heterostructured catalyst occurs because of the complementary charge transfer between LSC and K-MoSe2, as schematically illustrated in Fig. 4a. K-MoSe2 is synthesized by intercalating the potassium metal within the MoSe2 interlayers, followed by subsequent exfoliation, where potassium atoms and Se form K–Se ionic bonds. The large electronegativity difference (1.73) between K and Se promotes the charge transfer from K to Se, modulating the Mo 4d orbital configuration of MoSe2 from the occupied 4dz2 level to incompletely filled 4dxz, 4dyz, and 4dyx orbitals. This electronic structure rearrangement causes local phase transition from 2H-MoSe2 to 1T-MoSe2. Following the formation of the LSC/K-MoSe2 heterostructure, charge transfer from the Co of LSC to the 2H-MoSe2 portion of K-MoSe2 occurs, causing an additional 1T-phase transition in MoSe2. This complementary charge transfer in LSC/K-MoSe2 has beneficial effects on both HER and OER performance. The increased 1T-phase MoSe2 concentration in LSC/K-MoSe2 creates a more electron-rich and electrically conducting surface, enabling fast electron transfer at the catalytically active site, thereby improving HER kinetics48. The Co in LSC, after donating the electrons to K-MoSe2, becomes more electrophilic; such charge transfer results in the upshift of the d-band center and improved adsorption capability of oxygen-generating intermediates (e.g., O*, OH*, OO*) at the catalyst surface49, thereby enhancing OER kinetics.

a Schematic of the atomic structure and charge transfer effect for K-MoSe2 and LSC/K-MoSe2. Complementary charge transfer in LSC/K-MoSe2 can modulate the electronic structure of MoSe2, increasing the 1T-MoSe2 ratio in the heterostructure. b Charge transfer from K and LSC to MoSe2 in the optimized LSC/K-MoSe2 heterostructure. c Charge density difference plot for the interface between LSC and K-MoSe2. Side view of the total structure (left) and the cross section of the layers of La0.5Sr0.5O (middle) and CoO2 (right) are demonstrated. d Relative energies of 1T-MoSe2 in monolayer structure (black line) and LSC/K-MoSe2 heterostructure (red line) compared to the energy of the 2H-MoSe2 monolayer. e Free energy diagrams for HER for LSC, 2H-MoSe2, K-MoSe2, and LSC/K-MoSe2. f–h Free energy diagrams for OER for LSC, LSC/K-MoSe2, and LSC/MoSe2.

We computationally analyzed charge transfer and catalytic activities in LSC/K-MoSe2 using density functional theory (DFT) calculations. The evaluated charge transfer into a MoSe2 monolayer from Bader charge analysis50 is 2.48 e (0.88 e and 1.60 e from the K atom and LSC perovskite, respectively) in the LSC/K-MoSe2 structure model (Fig. 4b). We found that the charge transfer from LSC to MoSe2 is unaffected by the K atoms because the LSC to MoSe2 charge transfer in the LSC/MoSe2 structure is the same value of 1.60 e, indicating that the complementary charge transfer from K and LSC into MoSe2 is available in the LSC/K-MoSe2 system. The additional electron transfer from K into MoSe2 layers can lead to a larger portion of 1T-MoSe2 in LSC/K-MoSe2 than in LSC/MoSe2, supporting the experimentally observed results (Fig. 3i). We found that the charge transfer from LSC to MoSe2 mainly occurs in the CoO2 subsurface layer of LSC as depicted in Fig. 4c, wherein drastic changes in the electron density are observed in the CoO2 layer; these changes are expected to boost OER performance with a change in the electronic structure of LSC layers. Charge transfer from the CoO2 layer to MoSe2 was also confirmed via the density of states (DOS) analysis presented in Supplementary Fig. 16 and Supplementary Note 2. The CoO2 layer under the outermost La0.5Sr0.5O surface plays an important role in charge transfer while electrocatalytic activities occur on the La0.5Sr0.5O surface, which is essential in explaining the superiority of LSC perovskite. Furthermore, we found that the complementary charge transfer from K and LSC into MoSe2 layers markedly reduced the energy barrier when MoSe2 underwent 2H- to 1T-phase transition, as shown in Fig. 4d (0.65 eV in MoSe2 to 0.18 eV in LSC/K-MoSe2); this indicates that a high portion of 1T-MoSe2 phase will be present in the LSC/K-MoSe2 heterostructure.

To further elucidate the enhanced water-splitting performance in LSC/K-MoSe2 heterostructure, we analyzed the reaction-free energy for subreactions in both HER and OER. The values of ΔGH* can directly evaluate HER performance51,52,53. Figure 4e shows a comparison of ΔGH* in LSC/K-MoSe2 with LSC, 2H-MoSe2, and K-MoSe2. The LSC/K-MoSe2 structures are suitable catalysts for providing the most favorable HER environment for H2 production with the smallest ΔGH* of 0.25 eV, whereas the ΔGH* values for LSC, 2H-MoSe2, and K-MoSe2 are 2.01, 1.44, and 0.69 eV, respectively. The optimal near-zero ΔGH* in LSC/K-MoSe2 is associated with the increased number of states near the energy of normal hydrogen electrode (NHE) potential (Supplementary Fig. 17), thus increasing the interactions between the hydrogen s orbital and the 1T-MoSe2 states.

Excellent OER performance in LSC/K-MoSe2 was also explained through atomic-level simulations. Figure 4f–h shows the free energy diagrams for OER in LSC, LSC/K-MoSe2, and LSC/MoSe2, respectively. Our DFT calculations strongly suggest that the OER reactions proceed with the lattice-oxygen participation mechanism54,55 dominantly rather than the conventional adsorbate evolving mechanism in the LSC/K-MoSe2 system (Supplementary Fig. 19), and the free energy barriers of reaction-determining steps were evaluated to be 2.53, 2.06, and 1.83 eV for LSC, LSC/MoSe2, and LSC/K-MoSe2, respectively. Taking previously reported DFT-calculated OER free energy barriers (2.05−2.19 eV)56,57,58 in IrO2 catalysts into account, the order of computed free energy barriers (LSC > IrO2 > LSC/K-MoSe2) agrees well with the experimental results where the OER onset potentials decrease according to same descending order of LSC > IrO2 > LSC/K-MoSe2, as shown in Fig. 2d. The reduced free energy barrier in the LSC/K-MoSe2 originates from the well-balanced free energies between two governing reactions: (1) OH* to (VO + OO)* + H+ + e− and (2) (HO + OH)* to OH* + H+ + e−, where OH*, (VO + OO)*, and (HO + OH)* indicate OH absorbed on LSC surface, OO adsorbed on LSC surface with a neighboring oxygen vacancy, and OH adsorbed on LSC surface with a H atom adsorbed on a neighboring lattice O atom, respectively (see Supplementary Fig. 20 for the detailed atomic structures). While the free energy changes in reaction (1) (the red dotted circle) decrease on the order of LSC (2.53 eV) > LSC/K-MoSe2 (1.83 eV) > LSC/MoSe2 (0.67 eV), those in reaction (2) (the violet dotted circle) increase in the opposite order; LSC (0.99 eV) < LSC/K-MoSe2 (1.39 eV) < LSC/MoSe2 (2.06 eV), effectively producing the lowest free energy barrier in LSC/K-MoSe2 with a remarkably ideal balance between the rate-determining steps of reactions (1) and (2). Reaction (1) involves the replacement of the hydrogen in the OH adsorbate with the lattice oxygen that escapes from the lattice, leaving an oxygen vacancy. Therefore, the free energy barrier in reaction (1) is strongly affected by the energy difference between O* and (VO + OO)* structures59 as evaluated in Supplementary Fig. 21, wherein (Vo+OO)* structures are energetically more unfavorable in the same order with the free energy barriers as that in reaction (1); see DOS plots in Supplementary Fig. 22 for additional information on the instability of (VO + OO)* in LSC. In the case of reaction (2), the free energy barrier is related to how easily a hydrogen atom can be detached from the lattice-oxygen atom; see Supplementary Fig. 23, wherein the energy difference between (HO + OH)* and OH* increases on the same order of the free energy barriers as that in reaction (2).

Overall water electrolysis of the LSC/K-MoSe2 couple

The developed LSC/K-MoSe2 demonstrated excellent intrinsic bifunctional catalytic activity in alkaline electrolytes for both HER and OER. Herein, the overall water electrolysis of the LSC/K-MoSe2 configuration (i.e., LSC/K-MoSe2 used for both cathode and anode, denoted as LSC/K-MoSe2||LSC/K-MoSe2) was examined to further demonstrate the overall water-splitting performance and stability of LSC/K-MoSe2 as the bifunctional electrocatalyst in N2-saturated 1 M KOH solution. Efficient generation of the hydrogen (cathode) and oxygen (anode) gases using the LSC/K-MoSe2||LSC/K-MoSe2 couple was confirmed, as illustrated in Fig. 5a and Supplementary Movie 1. Figure 5b shows the cell voltage (Ecell = Eanode − Ecathode) measurement results of Pt/C||IrO2 (Pt/C for cathode and IrO2 for the anode) and LSC/K-MoSe2||LSC/K-MoSe2 obtained during the water electrolysis reaction. Consistent with the result of the half-cell-configured polarization profiles, the LSC/K-MoSe2||LSC/K-MoSe2 couple demonstrated better overall water electrolysis performance than the state-of-the-art noble-metal-based Pt/C||IrO2 couple. The cell voltages needed to attain 10 and 100 mA cm−2 were 1.59 and 1.95 V for LSC/K-MoSe2||LSC/K-MoSe2 and 1.67 and 2.04 V for Pt/C||IrO2. Although the HER performance of LSC/K-MoSe2 in the half-cell reaction was slightly lower than that of Pt/C, the overwhelmingly high OER performance resulted in excellent overall water electrolysis activity for LSC/K-MoSe2, surpassing that of the noble-metal pair Pt/C||IrO2. In addition to performance, electrochemical stability is an equally important criteria to consider when promoting the broad industrial pertinence of water electrolysis catalysts. To examine the electrochemical stability of LSC/K-MoSe2, its chronopotentiometric profile was measured at a high current density of 100 mA cm−2. As shown in Fig. 5c, for the Pt/C||IrO2 reference, a rapid increase in cell voltage, which indicates cell failure, was observed within 60 h under our experimental test conditions. However, the LSC/K-MoSe2||LSC/K-MoSe2 couple exhibited exceptionally high electrochemical durability even after 2,500 h of continuous operation without noticeable performance degradation. To verify the excellent operational durability of LSC/K-MoSe2 as the electrocatalyst, its physical and chemical characteristics were investigated after 2,500 h of stability testing. Supplementary Fig. 24 shows the SEM image of the catalyst electrode before and after the stability test. Even after 2,500 h of the electrocatalytic reaction, the starting electrode structure was well preserved without any significant physical damages or detachment. XPS analysis further reveals the superior chemical stability of LSC/K-MoSe2 (Supplementary Fig. 25 and Supplementary Tables 7, 8). After 2,500 h of overall water electrolysis reaction, each ratio of the Co3+/Co2+ in Co 2p and surface-active oxygen/lattice oxygen in O 1s exhibited almost negligible changes compared with those of pristine LSC/K-MoSe2. MoSe2 may potentially be decomposed into molybdenum oxides and selenate at the potentials of the OER electrode during prolonged electrolysis60. To verify the stability of MoSe2 in LSC/K-MoSe2, we performed XPS analysis for Mo and Se in LSC/K-MoSe2 on the OER electrode after 2,500 h of chronopotentiometric stability test. Although some partial oxidization was observed, the integrity of MoSe2 was well preserved without decomposition (Supplementary Fig. 26 and Supplementary Table 9). Moreover, the energy efficiency of the overall water electrolysis using LSC/K-MoSe2||LSC/K-MoSe2 at 100 mA cm−2 was calculated to be 75.4% (Supplementary Note 1). Considering the energy efficiency of a typical noble-metal-based water electrolysis catalyst is around 70%, our results demonstrate that the developed bifunctional LSC/K-MoSe2 catalyst can be used as a promising electrocatalyst in water electrolysis for efficient hydrogen production. Figure 5d (also summarized in Supplementary Table 10) compares the electrochemical stability of overall water electrolysis for various catalyst configurations reported to date along with the proposed LSC/K-MoSe2 in this work. Additionally, we further investigated the operational durability of the LSC/K-MoSe2 in various harsh environments. Chronopotentiometric stability test of the LSC/K-MoSe2 couple was conducted under high operational temperature and current density (500 and 1,000 mA cm–2 in 1 M KOH at 60 °C) and high electrolyte concentration (100 mA cm–2 in 10 M KOH at room temperature). In 1 M KOH at 60 °C, the LSC/K-MoSe2 couple required cell voltages of 2.25 V at 500 mA cm–2 and 2.52 V at 1000 mA cm–2, respectively (Supplementary Fig. 27). Under such conditions, it exhibited stable operational stability over 1,200 and 800 h at 500 and 1,000 mA cm–2, respectively, without obvious performance degradation (Supplementary Fig. 28). In 10 M KOH at room temperature, the cell voltage needed to achieve 100 mA cm–2 was 1.87 V for the LSC/K-MoSe2 couple (Supplementary Fig. 29). In the two-electrode cell, the chronopotentiometric stability of 1,600 h was achieved at 100 mA cm–2 in 10 M KOH at room temperature without any noticeable performance degradation (Supplementary Fig. 30). Despite the various accelerated test conditions, our heterostructure demonstrates overwhelmingly superior durability for water electrolysis.

a Digital image of full-cell water-splitting system comprising a two-electrode configuration with LSC/K-MoSe2||LSC/K-MoSe2. b, c LSV and chronopotentiometric durability curves of Pt/C||IrO2 and LSC/K-MoSe2||LSC/K-MoSe2 measured in 1 M KOH. d Summary of the overall water electrolysis stability of LSC/K-MoSe2||LSC/K-MoSe2 and other reported electrocatalyst couples.

Discussion

In this work, we developed a heterostructure-based electrocatalyst that demonstrates excellent overall water electrolysis performance and stability. The complementary charge transfer induced within the heterogeneous catalyst, comprising alkali-metal-treated transition-metal dichalcogenides and perovskite oxide, generated synergistic effects in both HER and OER processes. The modulated electronic structure of MoSe2 with high metallic-phase purity and improved electrical conductivity enhanced HER kinetics. The increased electrophilicity of LSC improved the adsorption capability of oxygen-generating intermediates on the catalyst surface, thereby boosting OER performance over that of IrO2. The water electrolysis performance using the LSC/K-MoSe2||LSC/K-MoSe2 couple outperformed the state-of-the-art noble-metal pair of Pt/C||IrO2, exhibiting lower cell voltage for the overpotential at 10 and 100 mA cm−2, improved energy efficiency, and excellent operational stability over 2,500 h. This work can provide a promising perspective for the performance maximization of heterostructure-based catalysts in water electrolysis to substitute precious-metal-based electrocatalysts.

Methods

Synthesis of K-MoSe2

For the preparation of K-MoSe2, 500 mg of bulk MoSe2 (<2 μm, purity >99%, Alfa Aesar) and 200 mg of potassium metal (stored in oil, purity >99.95%, Kojundo, Korea) were added to a glass tube under inert conditions in a glovebox. The tube was sealed and treated at 400 °C for 1 h. The as-prepared potassium-intercalated MoSe2 was rinsed with deionized water and ethanol to remove potassium ion residues. The resulting powder was dried at 80 °C for 24 h.

Synthesis of LSC

To synthesize the LSC perovskite oxides, an aqueous solution containing dissolved La, Sr, and Co nitrites (La(NO3)3 ∙ 6H2O, Sr(NO3)2, Co(NO3)2 ∙ 6H2O, Alfa Aesar) in stoichiometric amounts and citric acid (C6H8O7, Sigma-Aldrich) in deionized water was prepared. Post solvent evaporation, the resulting wet-gel was calcined at 900 °C for 2 h and at 950 °C for 10 h to remove the organic fraction. Finally, the resulting reaction product was mortared to homogenize the LSC.

Synthesis of LSC/K-MoSe2

To synthesize the LSC/K-MoSe2 heterostructure, as-prepared LSC and K-MoSe2 were high-energy milled with 10 wt.% of Ketjen Black (KB) (EC-600JD, Lion Specialty Chemicals Co. Ltd.) via the planetary ball mill system (PM-100, Retsch). To find the optimized weight ratio for LSC and K-MoSe2 for electrochemical performance, various mixture weight ratios were examined with LSC:K-MoSe2:KB of 8:1:1, 7:2:1, 6:3:1, and 5:4:1. The total weight of the mixture was maintained as 600 mg. LSC, K-MoSe2, and KB in ethanol were sealed into the steel jar and ball-milled at 500 rpm for 2 h. After completing the ball-milling process, the resulting product was thoroughly dried and collected.

Material characterizations

The morphology and EDS elemental mapping of the catalysts were characterized using HR-TEM (JEM-2100F, JEOL) with an accelerating voltage of 200 kV. Crystallographic information of catalysts was analyzed through high-power XRD (D/MAX2500V/PC, Rigaku) at 40 kV and 200 mA at a scanning rate of 1° min−1 in the diffraction range of 10°–80°. The chemical state and work function were investigated via XPS (ESCALAB 250XI, Thermo Fisher Scientific) with monochromated Al-Kα radiation. TGA analysis was conducted to investigate the surface adsorption capacity of catalysts at a ramping temperature rate of 10 °C min−1 using thermogravimetric analyzer (Q500, TA). The surface area and pore size of the catalysts were evaluated using N2 desorption/adsorption isotherms of catalysts using a physisorption analyzer (ASAP 2420, Micromeritics Instruments). The optical properties of the catalysts were collected using a UV–Vis–NIR spectrophotometer (Cary 5000, Agilent). Raman spectra were recorded using confocal Raman spectroscopy (Alpha300R, WITec) equipped with a 532-nm laser. The electrode morphologies before and after overall water electrolysis were obtained via cold FE-SEM (S-4800, HITACHI).

Electrochemical measurements

Half-cell electrochemical measurements were performed in 1 M KOH, in which saturated Ag/AgCl and a carbon rod were used as the reference and counter electrodes, respectively, in a three-electrode configuration controlled by an electrochemical workstation (CHI 760E, CH Instruments Inc.). Catalyst ink including LSC/K-MoSe2, K-MoSe2, and LSC was prepared by dispersing 9 mg of the catalyst and 1 mg of KB in a 1 mL binder solution comprising 5 wt.% Nafion solution (Sigma-Aldrich), ethanol, and isopropyl alcohol, followed by bath sonication. A catalyst ink of Pt/C and IrO2 was similarly prepared except for the KB. The working electrode was prepared via drop-casting 5 µL of the as-prepared catalyst inks onto the glassy carbon disk electrode with an area of 0.071 cm2. The HER and OER LSV polarization curves were obtained at a scan rate of 5 mV s−1 in N2-saturated electrolyte, which were measured from 0 to −1.0 V (vs. reversible hydrogen electrode (RHE)) and from 1.0 to 2.0 V (vs. RHE), respectively. Tafel slope values were derived from the LSV curves by plotting the overpotential against current density in log-scale from 1 to 10 mA cm−2. All potentials in this work were measured with respect to Ag/AgCl reference electrode and converted to RHE scale using the following formula in 1 M KOH (pH 14): E(vs.RHE) = E(vs. Ag/AgCl) + EAg/AgCl (=0.197 V) + 0.0592 pH = E(vs. Ag/AgCl) + 1.0258 V. EIS measurements were conducted at an overpotential of −0.2 and 0.7 V (vs. RHE) for HER and OER, respectively, in a frequency range of 100 kHz to 0.01 Hz with an amplitude of 10 mV in 1 M KOH. All half-cell polarization curves were corrected for ohmic losses by the following equation. E = E(RHE) – iRs, where E is the potential after the iR-correction, E(RHE) is the measured potential with respect to RHE (before iR-correction), i is the measured current, and Rs is the uncompensated resistance obtained from EIS analysis. To measure the double-layer capacitance (Cdl) value, the potential window of cyclic voltammograms was cycled in the non-Faradaic region from 0.03 to 0.33 V (vs. RHE) with different scan rates from 20 to 160 mV s−1. Cdl values were derived by plotting the charging current density difference (Δj = (ja − jc)/2) at 0.18 V. Overall water electrolysis testing was conducted using a two-electrode configuration comprising electrosprayed catalyst inks on Ni foam (with a catalyst loading of 1 mg cm−2) as the current collector. Chronopotentiometry stability test results of the overall water electrolysis were obtained under a current density of 100 mA cm−2 using an electrochemical workstation (ZIVE BP2C, Wonatech Co., Ltd.).

Computational details

We performed spin-polarized ab initio calculations using the Vienna ab initio simulation package (VASP)61 within the projector augmented wave (PAW) method62 and Perdew–Burke–Ernzerhof (PBE)63 exchange and correlation functionals. The DFT+U method based on Dudarev’s approach64 was adopted with U = 4.3 and J = 1.0 eV (Ueff = 3.3 eV) for Co-3d and Ueff = 4.0 eV for Mo-4d, as employed in previous studies65,66. First, the LSC slab structure was prepared based on 2√2 × 3√2 × 2 supercells with >20 Å vacuum space. A 1 × 1 × 1 Monkhorst-pack k-points mesh was adopted with 2 × 10−2 eV Å−1 for force criterion in the ionic relaxations and a 400 eV energy cutoff for the plane-wave basis set was used with valance electron configurations of 5s25p65d16s2 (La), 4s24p65s2 (Sr_sv), 3d84s1 (Co), 2s22p4 (O), 4s24p64d55s1 (Mo_sv), 4s24p4 (Se), and 3s23p64s1 (K_sv) orbitals for La, Sr, Co, O, Mo, Se, and K, respectively. The LSC/MoSe2 and LSC/K-MoSe2 structures were modeled using 2 × 5 supercell of 2H- or 1T-MoSe2 monolayer placed on the LSC (001) surfaces with <3% lattice mismatch for LSC/K-MoSe2 (the length of the cell-vectors: a = 11.20 Å, b = 16.57 Å, and c = 35.00 Å), K atoms were attached on the MoSe2 monolayer at the energetically most stable site, where one K atom was adsorbed on the 2 × 5 MoSe2 supercell surface (Fig. 4b). The top two atomic layers of LSC slab structure were relaxed to simulate the heterostructures. The charge transfer in LSC/K-MoSe2 structure was analyzed using Bader population analysis50. Second, the free energy of HER reactions was computed until the residual force components were within 5 × 10−3 eV Å−1 using the equation GH = E(H) + 0.24 eV, wherein E(H) is the adsorption energy of a H atom, calculated for \(1/2\)H2 at pH = 0 and p(H2) = 1 bar, and 0.24 eV correction is for the differences in zero-point-energy and entropy67,68. The free energy of each subreaction for OER was evaluated using the equation G = ΔE + ΔZPE − TΔS at pH = 0, T = 298 K, and zero applied potential (0 V vs. RHE), where ΔG, ΔE, ΔZPE, T, and ΔS represent the change in free energy, total energy difference, change in zero-point-energy, temperature, and change in entropy, respectively. The ΔZPE and TΔS terms were adopted from previous studies and gas phase H2O and O2 were considered references for all the reactions, assuming 0.035 bar H2O gas pressure at room temperature for equilibrium with liquid water. The free energy O2 gas was computed by fixing the free energy changes in the overall reaction (H2O → \(1/2\)O2 + H2) to the experimentally measured value, 2.46 eV, as adopted in previously reported OER computations59,69,70,71,72,73. To model OER on LSC (001) surfaces in LSC/K-MoSe2, we used the cropped 2 × 1.5 MoSe2 supercells to expose the LSC (001) surface to secure enough space for OER adsorbates on the LSC surface. A 4 × 4 × 1 Monkhorst-pack k-points mesh was used to analyze the DOS.

Data availability

The data measured, simulated, and analyzed in this study are available from the corresponding author on reasonable request.

References

Seh, Z. W. et al. Combining theory and experiment in electrocatalysis: Insights into materials design. Science 355, 6321 (2017).

You, B. et al. Enhancing electrocatalytic water splitting by strain engineering. Adv. Mater. 31, 1807001 (2019).

Cheng, N. et al. Platinum single-atom and cluster catalysis of the hydrogen evolution reaction. Nat. Commun. 7, 1–9 (2016).

Yu, F. et al. High-performance bifunctional porous non-noble metal phosphide catalyst for overall water splitting. Nat. Commun. 9, 2551 (2018).

Jiao, Y. et al. Design of electrocatalysts for oxygen-and hydrogen-involving energy conversion reactions. Chem. Soc. Rev. 44, 2060–2086 (2015).

Liang, C. et al. Exceptional performance of hierarchical Ni–Fe oxyhydroxide@NiFe alloy nanowire array electrocatalysts for large current density water splitting. Energy Environ. Sci. 13, 86–95 (2020).

Huang, H. et al. Rapid and energy–efficient microwave pyrolysis for high–yield production of highly–active bifunctional electrocatalysts for water splitting. Energy Environ. Sci. 13, 545–553 (2020).

McCrory, C. C. et al. Benchmarking heterogeneous electrocatalysts for the oxygen evolution reaction. J. Am. Chem. Soc. 135, 16977–16987 (2013).

Liang, Y. et al. Strongly coupled inorganic/nanocarbon hybrid materials for advanced electrocatalysis. J. Am. Chem. Soc. 135, 2013–2036 (2013).

Zhang, T. et al. Heteroatom-doped carbon materials for hydrazine oxidation. Adv. Mater. 31, 1804394 (2019).

Zhu, Q. L. et al. Controlled synthesis of ultrafine surfactant–free NiPt nanocatalysts toward efficient and complete hydrogen generation from hydrazine borane at room temperature. ACS Catal. 4, 4261–4268 (2014).

Zhao, P. et al. NiIr nanoparticles immobilized on the pores of MIL–101 as highly efficient catalyst toward hydrogen generation from hydrous hydrazine. ACS Sustain. Chem. Eng. 3, 1086–1093 (2015).

Kang, Y. et al. Bimetallic AuRh nanodendrites consisting of Au icosahedron cores and atomically ultrathin Rh nanoplate shells: synthesis and light–enhanced catalytic activity. NPG Asia Mater. 9, e407 (2017).

Oh, N. K. et al. In-situ local phase-transitioned MoSe2 in La0.5Sr0.5CoO3-δ heterostructure and stable overall water electrolysis over 1000 h. Nat. Commun. 10, 1723 (2019).

Sarkar, S. et al. Stress-induced electronic structure modulation of manganese-incorporated Ni2P leading to enhanced activity for water splitting. ACS Appl. Energy Mater. 3, 1271–1278 (2020).

Fu, Q. et al. 2D Transition metal dichalcogenides: design, modulation, and challenges in electrocatalysis. Adv. Mater. 33, 1907818 (2021).

Huang, J. et al. Cytomembrane‐structure‐inspired active Ni–N–O interface for enhanced oxygen evolution reaction. Adv. Mater. 30, 1803367 (2018).

Yao, Y. et al. Engineering the electronic structure of single atom Ru sites via compressive strain boosts acidic water oxidation electrocatalysis. Nat. Catal. 2, 304–313 (2019).

Tang, C. et al. NiSe nanowire film supported on nickel foam: an efficient and stable 3D bifunctional electrode for full water splitting. Angew. Chem. Int. Ed. 127, 9483–9487 (2015).

Xing, J. et al. Electro-synthesis of 3D porous hierarchical Ni–Fe phosphate film/Ni foam as a high–efficiency bifunctional electrocatalyst for overall water splitting. J. Mater. Chem. A 4, 13866–13873 (2016).

Yang, Y. et al. Tuning electronic structures of nonprecious ternary alloys encapsulated in graphene layers for optimizing overall water splitting activity. ACS Catal. 7, 469–479 (2017).

Inamdar, A. I. et al. A robust nonprecious CuFe composite as a highly efficient bifunctional catalyst for overall electrochemical water splitting. Small 16, 1905884 (2020).

Zhang, R. et al. Hydrolysis assisted in-situ growth of 3D hierarchical FeS/NiS/nickel foam electrode for overall water splitting. Electrochim. Acta 332, 135534 (2020).

Xie, J. et al. Intralayered ostwald ripening to ultrathin nanomesh catalyst with robust oxygen‐evolving performance. Adv. Mater. 29, 1604765 (2017).

Gong, M. et al. Nanoscale nickel oxide/nickel heterostructures for active hydrogen evolution electrocatalysis. Nat. Commun. 5, 1–6 (2014).

Park, S. et al. Phase engineering of transition metal dichalcogenides with unprecedentedly high phase purity, stability, and scalability via molten‐metal‐assisted intercalation. Adv. Mater. 32, 2001889 (2020).

Zheng, Y. et al. Hydrogen evolution by a metal–free electrocatalyst. Nat. Commun. 5, 3783 (2014).

Shao, F. Q. et al. One-pot synthesis of hollow AgPt alloyed nanocrystals with enhanced electrocatalytic activity for hydrogen evolution and oxygen reduction reactions. J. Colloid Interface sci. 505, 307–314 (2017).

Markovic, N. M. et al. Temperature-dependent hydrogen electrochemistry on platinum low-index single-crystal surfaces in acid solutions. J. Phys. Chem. B 101, 5405–5413 (1997).

Sun, H. et al. Molybdenum and niobium codoped B-site-ordered double perovskite catalyst for efficient oxygen evolution reaction. ACS Appl. Mater. Interfaces 10, 16939–16942 (2018).

Tariq, M. et al. Unraveling the beneficial electrochemistry of IrO2/MoO3 hybrid as a highly stable and efficient oxygen evolution reaction catalyst. ACS Sustain. Chem. Eng. 6, 4854–4862 (2018).

Li, X. et al. Crystallographic-orientation dependent Li ion migration and reactions in layered MoSe2. 2D Mater. 6, 035027 (2019).

Hua, B. et al. A coupling for success: controlled growth of Co/CoOx nanoshoots on perovskite mesoporous nanofibres as high–performance trifunctional electrocatalysts in alkaline condition. Nano Energy 32, 247–254 (2017).

Han, L. et al. Dealloying-directed synthesis of efficient mesoporous CoFe-based catalysts towards the oxygen evolution reaction and overall water splitting. Nanoscale 9, 16467–16475 (2017).

Klingan, K. et al. Water oxidation by amorphous cobalt‐based oxides: volume activity and proton transfer to electrolyte bases. ChemSusChem 7, 1301–1310 (2014).

Gupta, U. et al. Characterization of few-layer 1T-MoSe2 and its superior performance in the visible-light induced hydrogen evolution reaction. APL Mater. 2, 092802 (2014).

Lu, Shi-Yu et al. Greatly boosting electrochemical hydrogen evolution reaction over Ni3S2 nanosheets rationally decorated by Ni3Sn2S2 quantum dots. Appl. Catal. B 267, 118675 (2020).

Brooman, E. W. et al. Correlations between the rate of the hydrogen electrode reaction and the properties of alloys. J. Electroanal. Chem. 49, 325–353 (1974).

Zeradjanin, A. R. et al. Balanced work function as a driver for facile hydrogen evolution reaction–comprehension and experimental assessment of interfacial catalytic descriptor. Phys. Chem. Chem. Phys. 19, 17019–17027 (2017).

Henckel, D. A. et al. Improved HER catalysis through facile, aqueous electrochemical activation of nanoscale WSe2. Nano Lett. 18, 2329–2335 (2018).

Samikannu, S. et al. Dissipative soliton generation in an all–normal dispersion ytterbium–doped fiber laser using few–layer molybdenum diselenide as a saturable absorber. Opt. Eng. 55, 081311 (2016).

Xia, Y. et al. Camphorsulfonic acid fully doped polyaniline emeraldine salt: conformations in different solvents studied by an ultraviolet/visible/near–infrared spectroscopic method. Chem. Mater. 7, 443–445 (1995).

Suntivich, J. et al. A perovskite oxide optimized for oxygen evolution catalysis from molecular orbital principles. Science 334, 1383–1385 (2011).

Maitra, U. et al. Importance of trivalency and the eg1 configuration in the photocatalytic oxidation of water by Mn and Co oxides. Proc. Natl Acad. Sci. USA 110, 11704–11707 (2013).

Wang, Q. et al. La0.8Sr0.2Co1–xMnxO3 perovskites as efficient bi–functional cathode catalysts for rechargeable zinc–air batteries. Electrochim. Acta 254, 14–24 (2017).

Wang, Z. et al. Nickel–doped La0.8Sr0.2Mn1–xNixO3 nanoparticles containing abundant oxygen vacancies as an optimized bifunctional catalyst for oxygen cathode in rechargeable lithium–air batteries. ACS Appl. Mater. Interfaces 8, 6520–6528 (2016).

Hua, B. et al. All–in–one perovskite catalyst: smart controls of architecture and composition toward enhanced oxygen/hydrogen evolution reactions. Adv. Energy Mater. 7, 1700666 (2017).

Ito, Y. et al. High catalytic activity of nitrogen and sulfur co‐doped nanoporous graphene in the hydrogen evolution reaction. Angew. Chem. Int. Ed. 127, 2159–2164 (2015).

Kim, M. et al. Promotion of electrochemical oxygen evolution reaction by chemical coupling of cobalt to molybdenum carbide. Appl. Catal. B 227, 340–348 (2018).

Henkelman, G. et al. A fast and robust algorithm for Bader decomposition of charge density. Comput. Mater. Sci. 36, 354–360 (2006).

Hinnemann, B. et al. Biomimetic hydrogen evolution: MoS2 nanoparticles as catalyst for hydrogen evolution. J. Am. Chem. Soc. 127, 5308–5309 (2005).

Zheng, Y. et al. Toward design of synergistically active carbon-based catalysts for electrocatalytic hydrogen evolution. ACS Nano. 8, 5290–5296 (2014).

Ling, F. et al. Enhancing hydrogen evolution on the basal plane of transition metal dichacolgenide van der Waals heterostructures. Npj Comput. Mater. 5, 20 (2019).

Grimaud, A. et al. Activating lattice oxygen redox reactions in metal oxides to catalyse oxygen evolution. Nat. Chem. 9, 457–465 (2017).

Mefford, J. T. et al. Water electrolysis on La1–xSrxCoO3–δ perovskite electrocatalysts. Nat. Commun. 7, 11053 (2016).

Zagalskaya, A. et al. Role of defects in the interplay between adsorbate evolving and lattice oxygen mechanisms of the oxygen evolution reaction in RuO2 and IrO2. ACS Catal. 10, 3650–3657 (2020).

Buvat, G. et al. OER performances of cationic substituted (100)-oriented IrO2 thin films: a joint experimental and theoretical study. ACS Appl. Energy Mater. 3, 5229–5237 (2020).

Briquet, L. G. V. et al. A new type of scaling relations to assess the accuracy of computational predictions of catalytic activities applied to the oxygen evolution reaction. ChemCatChem 9, 1261–1268 (2017).

Rong, X. et al. A fundamental relationship between reaction mechanism and stability in metal oxide catalysts for oxygen evolution. ACS Catal. 6, 1153–1158 (2016).

Tang, Y. J. et al. In situ oxidation transformation of trimetallic selenide to amorphous FeCo-oxyhydroxide by self-sacrificing MoSe2 for efficient water oxidation. J. Mater. Chem. A 8, 7925–7934 (2020).

Kresse, G. et al. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B. 54, 11169–11186 (1996).

Blöchl, P. E. et al. Projector augmented-wave method. Phys. Rev. B. 50, 17953–17979 (1994).

Perdew, J. P. et al. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Dudarev, S. et al. Electron-energy-loss spectra and the structural stability of nickel oxide: An LSDA+U study. Phys. Rev. B 57, 1505–1509 (1998).

Grimaud, A. et al. Activating lattice oxygen redox reactions in metal oxides to catalyse oxygen evolution. Nat. Chem. 9, 457–465 (2017).

Guguchia, A. et al. Magnetism in semiconducting molybdenum dichalcogenides. Sci. Adv. 4, eaat3672 (2018).

Vikraman, D. et al. Design of basal plane edges in metal-doped nanostripes-structured MoSe2 atomic layers to enhance hydrogen evolution reaction activity. ACS Sustain. Chem. Eng. 7, 458–469 (2019).

Mir, S. H. et al. A comparative study of hydrogen evolution reaction on pseudo-monolayer WS2 and PtS2: insights based on the density functional theory. Catal. Sci. Technol. 7, 687–692 (2017).

Yoo, J. S. et al. Role of lattice oxygen participation in understanding trends in the oxygen evolution reaction on perovskites. ACS Catal. 8, 4628–4636 (2018).

Man, I. C. et al. Universality in oxygen evolution electrocatalysis on oxide surfaces. ChemCatChem 3, 1159–1165 (2011).

Yao, Y. et al. Engineering the electronic structure of single atom Ru sites via compressive strain boosts acidic water oxidation electrocatalysis. Nat. Catal. 2, 304–313 (2019).

Huang, Z. F. et al. Chemical and structural origin of lattice oxygen oxidation in Co–Zn oxyhydroxide oxygen evolution electrocatalysts. Nat. Energy 4, 329–338 (2019).

Seo, M. H. et al. Design of highly active perovskite oxides for oxygen evolution reaction by combining experimental and ab initio studies. ACS Catal. 5, 4337–4344 (2015).

Acknowledgements

This work was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2019R1A2C1009025, 2019R1A4A1029237, and 2020R1A4A3079710). Y.-K.H would like to thank Bohyun Hwang and Sujin Lee for their technical support.

Author information

Authors and Affiliations

Contributions

N.K.O. carried out most of the experimental work and wrote the manuscript. J.S. wrote the manuscript and contributed to the designing of schematics. S.L. and H.-J.K. performed the DFT calculation and wrote the manuscript. U.K. helped the interpretation of electrochemical analysis. J.L. performed XPS measurements. Y.-K.H. directed the theoretical work. H.P. conceived the project and directed the overall work and manuscript writing. All the authors contributed to the discussion and analysis of the results regarding the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks Vera Butova and other, anonymous, reviewers for their contributions to the peer review of this work. Peer review reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Oh, N.K., Seo, J., Lee, S. et al. Highly efficient and robust noble-metal free bifunctional water electrolysis catalyst achieved via complementary charge transfer. Nat Commun 12, 4606 (2021). https://doi.org/10.1038/s41467-021-24829-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-021-24829-8

This article is cited by

-

Perovskite Oxides Toward Oxygen Evolution Reaction: Intellectual Design Strategies, Properties and Perspectives

Electrochemical Energy Reviews (2024)

-

Diversity of platinum-sites at platinum/fullerene interface accelerates alkaline hydrogen evolution

Nature Communications (2023)

-

Solvothermal Synthesized Potassium Niobium Tungstate K2Nb10W7O47 Nanoparticles for Efficient Electrocatalytic Water Splitting and Supercapacitance Activity

Catalysis Letters (2023)

-

Elucidating the Role of Mass Transfer in Electrochemical Redox Reactions on Electrospun Fibers

Transactions of Tianjin University (2023)

-

Electrocatalytic Pt-embedded ZIF-8 on nanocellulose-based flexible conductive electrodes for hydrogen evolution reaction

Cellulose (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.