Abstract

By choosing the dissipation energy as the damage variable, corresponding damage evolution equations are established, respectively, for the mechanical cyclic loading part and the thermal one during the thermo-mechanical cyclic loading of NiTi shape memory alloys (SMAs) involving one-way shape memory effect (simply denoted as the OWSME cycling). And then, the evolution law of total damage is obtained by a superposition of such two damage parts. Finally, the uniaxial OWSME fatigue lives of NiTi SMA micro-tubes are predicted by combining the proposed damage model with an adopted failure criterion. The results show that all the predicted fatigue lives are located within the twice scatter band with regard to the experimental ones, and most of them are located within a scatter band of 1.5 times. It is indicated that the predicted OWSME fatigue lives are in good agreement with the experimental ones.

Similar content being viewed by others

References

Humbeeck JV. Non-medical applications of shape memory alloys. Mater Sci Eng, A. 1999;273:134–48.

Morgan NB. Medical shape memory alloy applications: the market and its products. Mater Sci Eng, A. 2004;378(1):16–23.

Jani JM, Leary M, Subic A, Gibson MA. A review of shape memory alloy research, applications and opportunities. Mater Design. 2014;56:1078–113.

Robertson SW, Pelton AR, Ritchie RO. Mechanical fatigue and fracture of Nitinol. Int Mater Rev. 2012;57(1):1–37.

Kang GZ. Advances in transformation ratcheting and ratcheting-fatigue interaction of NiTi shape memory alloy. Acta Mech Solida Sin. 2013;26(3):221–36.

Maletta C, Sgambitterra E, Furgiuele F, Casati R, Tuissi A. Fatigue of pseudoelastic NiTi within the stress-induced transformation regime: a modified Coffin-Manson approach. Smart Mater Struct. 2012;21(11):112001.

Figueiredo AM, Modenesi P, Buono V. Low-cycle fatigue life of superelastic NiTi wires. Int J Fatigue. 2009;31(4):751–8.

Predki W, Klönne M, Knopik A. Cyclic torsional loading of pseudoelastic NiTi shape memory alloys: damping and fatigue failure. Mater Sci Eng, A. 2006;417(1):182–9.

Song D, Kang GZ, Kan QH, Yu C, Zhang CZ. Experimental observations on uniaxial whole-life transformation ratchetting and low-cycle stress fatigue of super-elastic NiTi shape memory alloy micro-tubes. Smart Mater Struct. 2015;24(7):075004.

Song D, Kang GZ, Kan QH, Yu C, Zhang CZ. Non-proportional multiaxial whole-life transformation ratchetting and fatigue failure of super-elastic NiTi shape memory alloy micro-tubes. Int J Fatigue. 2015;80:372–80.

Tabanli RM, Simha NK, Berg BT. Mean stress effects on fatigue of NiTi. Mater Sci Eng, A. 1999;273–275:644–8.

Kang GZ, Kan QH, Yu C, Song D, Liu YJ. Whole-life transformation ratchetting and fatigue of super-elastic NiTi Alloy under uniaxial stress-controlled cyclic loading. Mater Sci Eng, A. 2012;535:228–34.

Zhang YH, Moumni Z, Zhu JH, Zhang WH. Effect of the amplitude of the training stress on the fatigue lifetime of NiTi shape memory alloys. Scr Mater. 2018;149:66–9.

Xiao Y, Zeng P, Lei LP, Du HF. Experimental investigation on rate dependence of thermomechanical response in superelastic NiTi shape memory alloy. J Mater Eng Perform. 2015;24(10):3755–60.

Xiao Y, Jiang DJ. Rate dependence of transformation pattern in superelastic NiTi tube. Extreme Mech Lett. 2020;39:100819.

Kan QH, Yu C, Kang GZ, Li J, Yan WY. Experimental observations on rate-dependent cyclic deformation of super-elastic NiTi shape memory alloy. Mech Mater. 2016;97:48–58.

Chen ZB, Qin SJ, Shang JX, Wang FH, Chen Y. Size effects of NiTi nanoparticle on thermally induced martensitic phase transformation. Intermetallics. 2018;94:47–54.

Chen JY, Yin H, Sun QP. Effects of grain size on fatigue crack growth behaviors of nanocrystalline superelastic NiTi shape memory alloys. Acta Mater. 2020;195:141–50.

Jones NG, Dye D. Martensite evolution in a NiTi shape memory alloy when thermal cycling under an applied load. Intermetallics. 2011;19(10):1348–58.

Pappas P, Bollas D, Parthenios J, Dracopoulos V, Galiotis C. Transformation fatigue and stress relaxation of shape memory alloy wires. Smart Mater Struct. 2007;16(6):2560–70.

Li YF, Mi XJ, Tan J, Gao BD. Thermo-mechanical cyclic transformation behavior of Ti-Ni shape memory alloy wire. Mater Sci Eng, A. 2009;509(1–2):8–13.

Urbina C, Flor SDL, Ferrando F. Effect of thermal cycling on the thermomechanical behaviour of NiTi shape memory alloys. Mater Sci Eng, A. 2009;501(1):197–206.

Demers V, Brailovski V, Prokoshkin S, Inaekyan K. Thermomechanical fatigue of nanostructured Ti-Ni shape memory alloys. Mater Sci Eng, A. 2009;513:185–96.

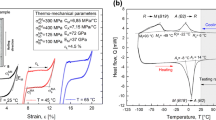

Zhao TX, Kang GZ, Yu C, Kan QH. Experimental study on whole-life one-way shape memory cyclic degradation and fatigue failure of NiTi shape memory alloy. Mater Today Commun. 2020;25:101621.

Paranjape HM, Ng B, Ong I, Vien L, Huntley C. Phase transformation volume amplitude as a low-cycle fatigue indicator in nickel-titanium shape memory alloys. Scr Mater. 2020;178:442–6.

Moumni Z, Herpen AV, Riberty P. Fatigue analysis of shape memory alloys: energy approach. Smart Mater Struct. 2005;14(5):S287.

Kan QH, Kang GZ, Yan WY, Dong YW, Chao Y. An energy-based fatigue failure model for super-elastic NiTi alloys under pure mechanical cyclic loading. Proc SPIE Int Soc Opt Eng. 2012;8409(4):14.

Zhang YH, Zhu JH, Moumni Z, Van HA, Zhang WH. Energy-based fatigue model for shape memory alloys including thermomechanical coupling. Smart Mater Struct. 2016;25(3):035–42.

Song D, Kang GZ, Kan QH, Yu C, Zhang C. Damage-based life prediction model for uniaxial low-cycle stress fatigue of super-elastic NiTi shape memory alloy microtubes. Smart Mater Struct. 2015;24(8):085007.

Song D, Kang GZ, Yu C, Kan QH, Zhang CZ. Non-proportional multiaxial fatigue of super-elastic NiTi shape memory alloy micro-tubes: damage evolution law and life-prediction model. Int J Mech Sci. 2017;131–132:325–33.

Dornelas VM, Oliveira SA, Savi MA. A macroscopic description of shape memory alloy functional fatigue. Int J Mech Sci. 2020;170:105345.

Dornelas VM, Oliveira SA, Savi MA, Pacheco PMCL, de Souza LFG. Fatigue on shape memory alloys: experimental observations and constitutive modeling. Int J Solids Struct. 2021;213:1–24.

Liu BF, Chen KY, Zhou R. Damage evolution and fatigue life prediction of the shape memory alloy under low cycle fatigue. Mater Today Commun. 2021;26:101636.

Simoes M, Martínez-Pañeda E. Phase field modelling of fracture and fatigue in shape memory alloys. Comput Method Appl Mech. 2021;373:113504.

Lagoudas DC, Miller DA, Rong L, Kumar PK. Thermomechanical fatigue of shape memory alloys. Smart Mater Struct. 2009;18(8):085021.

Maletta C, Sgambitterra E, Furgiuele F, Casati R, Tuissi A. Fatigue properties of a pseudoelastic NiTi alloy: Strain ratcheting and hysteresis under cyclic tensile loading. Int J Fatigue. 2014;66:78–85.

Yu C, Kang GZ, Kan QH, Xu X. Physical mechanism based crystal plasticity model of NiTi shape memory alloys addressing the thermo-mechanical cyclic degeneration of shape memory effect. Mech Mater. 2017;112:1–17.

Liang C, Rogers CA. One-dimensional thermomechanical constitutive relations for shape memory materials. J Inter Mat Syst Str. 1990;1(2):207–34.

Lagoudas DC, Entchev PB. Modeling of transformation-induced plasticity and its effect on the behavior of porous shape memory alloys. Part I: constitutive model for fully dense SMAs. Mech Mater. 2004;36(9):865–92.

Brinson CL. One-dimensional constitutive behavior of shape memory alloys: thermomechanical derivation with non-constant material functions and redefined martensite internal variable. J Intelli Mater Syste Struct. 1993;4(2):229–42.

Xu X, Xu B, Jiang HM, Kang GZ, Kan QH. A multi-mechanism model describing reorientation and reorientation-induced plasticity of NiTi shape memory alloy. Acta Mech Solida Sin. 2018;31(4):445–58.

Charkaluk E, Constantinescu A. An energetic approach in thermomechanical fatigue for silicon molybdenum cast iron. High Temp Tech. 2007;17(3):373–80.

Skelton RP, Vilhelmsen T, Webster GA. Energy criteria and cumulative damage fatigue crack growth. Int J Fatigue. 1998;20(9):641–9.

Acknowledgements

Financial support of the National Natural Science Foundation of China (No. 11532010) is appreciated

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, T., Kang, G. Fatigue Life Prediction for NiTi Shape Memory Alloy Micro-tubes Under Uniaxial Stress-Controlled One-Way Shape Memory Cyclic Loading. Acta Mech. Solida Sin. 35, 15–25 (2022). https://doi.org/10.1007/s10338-021-00255-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-021-00255-7