Abstract

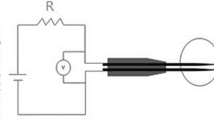

This study is an effort to comprehend the description of the vapour-liquid flows associated with the transformation of the phase, which may assist in determining mass, momentum and energy transfer within the interfacial region containing the steam and water. This study describes the development of a void fraction measurement sensory system, which is based on AC based electrodes, referred scientifically as Electrical Resistance Tomography (ERT) system. ERT sensors based system was applied to emphasize the phenomenon involving supersonic steam injection into a column of water. Data acquisition system supporting the ERT technique was applied for the given time interval and the acquired data was processed by using a free code known as EIDORS. Images thus obtained by use of EIDORS provided a planar picture of supersonic steam jet surrounding by the water in a vessel. Images represent the broadly visible boundaries among steam and water phases, and the turbulent interface between them. It has been found that with rising temperature 30–60°C, the area under the effect of the steam jet has been increased from 46.51–65.40% at 3.0 bar of steam’s inlet pressure.

Similar content being viewed by others

Change history

14 September 2021

An Erratum to this paper has been published: https://doi.org/10.1134/S0020441221050249

REFERENCES

WuX.-Z., Yan J.-J., Li W.-J., Pan D.-D., and Chong, D.-T., Chem. Eng. Sci., 2009, vol. 64, p. 5002. https://doi.org/10.1016/J.CES.2009.08.007

Chan, C.K. and Lee, C.K.B., Int. J. Multiphase Flow, 1982, vol. 8, p. 11. https://doi.org/10.1016/0301-9322(82)90003-9

Kerney, P.J., Faeth, G.M., and Olson, D.R., AIChE J., 1972, vol. 18, p. 548. https://doi.org/10.1002/aic.690180314

Weimer, J.C., Faeth, G.M., and Olson, D.R., AIChE J., 1973, vol. 19, p. 552. https://doi.org/10.1002/aic.690190321

Del Ttin, G., Lavagno, E., and Malandrone, M., Proc. 3rd Multi-Phase Flow and Heat Transfer Symposium-Workshop, Miami Beach, FL, 1983, pp. 134–136.

Khan, A., Haq, N.U., Chughtai, I.R., Shah, A., and Sanaullah, K., Int. J. Heat Mass Transfer, 2014, vol. 73, p. 521. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2014.02.035

Sanaullah, K., Khan, A., Takriff, M.S., Zen, H., Shah, A., Chughtai, I.R., Jamil, T., Fong, L.S., and Haq, N.U., Int. J. Heat Mass Transfer, 2015, vol. 84, p. 178. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2014.12.073

Khan, A., Sanaullah, K., Takriff, M.S., Zen, H., Ri-git, A.R.H., Shah, A., Chughtai, I.R., and Jamil, T., Chem. Eng. Sci., 2016, vol. 146, p. 44. https://doi.org/10.1016/J.CES.2016.01.056

Datta, D. and Jang, C., Proc. IAEA 2nd Int. Symposium on Nuclear Power Plant Life Management, Shanghai, 2007.

Shah, A., Chughtai, I.R., and Inayat, M.H., Chin. J. Chem. Eng., 2010, vol. 18, p. 577. https://doi.org/10.1016/S1004-9541(10)60261-3

Khan, A., Sanaullah, K., Sobri Takriff, M., Hussain, A., Shah, A., and Rafiq Chughtai, I., Flow Meas. Instrum., 2016, vol. 47, p. 35. https://doi.org/10.1016/J.FLOWMEASINST.2015.12.002

Davies, J.T. and Ting, S.T., Chem. Eng. Sci., 1967, vol. 22, p. 1539. https://doi.org/10.1016/0009-2509(67)80192-1

Jeffries, R.B., Scott, D.S., and Rhodes, E., Proc. Inst. Mech. Eng., Conf. Proc., 1969, vol. 184, p. 204. https://doi.org/10.1243/pime_conf_1969_184_097_02

Van Meulenbroek, B.M. and van de Wakker, B.M., Int. J. Heat Mass Transfer, 1985, vol. 28, p. 886. https://doi.org/10.1016/0017-9310(85)90240-6

Woodmansee, D.E. and Hanratty, T.J., Chem. Eng. Sci., 1969, vol. 24, p. 299. https://doi.org/10.1016/0009-2509(69)80038-2

Wu, X.Z., Yan, J.J., Li, W.J., Pan, D.D., and Chong, D.T., Chem. Eng. Sci., 2009, vol. 64, p. 5002. https://doi.org/10.1016/j.ces.2009.08.007

Huang, C.N., Yu, F.M., and Chung, H.Y., IEEE Trans. Instrum. Meas., 2008, vol. 57, p. 1193. https://doi.org/10.1109/TIM.2007.915149

Jia, J., Babatunde, A., and Wang, M., Flow Meas. Instrum., 2015, vol. 41, p. 75. https://doi.org/10.1016/j.flowmeasinst.2014.10.010

Dyakowski, T., Meas. Sci. Technol., 1996, vol. 7, p. 343. https://doi.org/10.1088/0957-0233/7/3/015

Woldesemayat, M.A. and Ghajar, A.J., Int. J. Multiphase Flow, 2007, vol. 33, p. 347. https://doi.org/10.1016/j.ijmultiphaseflow.2006.09.004

Hanratty, T.J., Gas-Liquid Flow in Pipelines, Lemont, IL: Argonne, 2005. https://doi.org/10.2172/837116

Zucrow, M.J. and Hoffman, J.D., Gas Dynamics, New York: John Wiley & Sons, 1976.

P2000 Electrical Resistance Tomography System ITS System 2000 Version 5.0 Software Operating Manual, 2005.

York, T.A., Process Imaging for Automatic Control, McCann, H. and Scott, D.M., Eds., SPIE, 2001, p. 175. https://doi.org/10.1117/12.417163

Pinheiro, P.A.T., Loh, W.W., and Dickin, F.J., Electron. Lett., 1998, vol. 34, p. 69. https://doi.org/10.1049/el:19980092

Polydorides, N. and Lionheart, W.R.B., Meas. Sci. Technol., 2002, vol. 13, p. 1871. https://doi.org/10.1088/0957-0233/13/12/310

Khan, A., Sanaullah, K., Takriff, M.S., Zen, H., Ri-git, A.R.H., Shah, A., Chughtai, I.R., and Jamil, T., Chem. Eng. Sci., 2016, vol. 146, p. 44. https://doi.org/10.1016/j.ces.2016.01.056

Steam Tables, A-to-Z Guide to Thermodynamics, Heat & Mass Transfer, and Fluids Engineering, New York: Begell House. https://doi.org/10.1615/AtoZ.s.steam_tables

Thompson, C.M. and Shure, L., Image Processing Toolbox: For Use with MATLAB [User’s Guide], Natick, MA: MathWorks, 1995.

ACKNOWLEDGMENTS

The authors are thankful to the Russian Government and Institute of Engineering and Technology, Department of Hydraulics and Hydraulic and Pneumatic Systems, South Ural State University for their support to this work through Act 211 Government of the Russian Federation, contract no. 02. A03.21.0011.

Author information

Authors and Affiliations

Corresponding author

Additional information

The name of the seventh author should read Ahmad Salam Farooqi.

Rights and permissions

About this article

Cite this article

Khan, A., Sanaullah, K., Spiridonov, E.K. et al. Conductivity Sensors Based System Development and Application to Investigate the Interfacial Behaviour between Supersonic Steam Jet and Water. Instrum Exp Tech 64, 630–639 (2021). https://doi.org/10.1134/S0020441221040126

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441221040126