Abstract

Additive Manufacturing (AM) is becoming data-intensive. The ability to identify Data Analytics (DA) opportunities for effective use of AM data becomes a critical factor in the success of AM. To successfully identify high-potential DA opportunities in AM requires a set of distinctive interdisciplinary knowledge. This paper proposes a methodology that enables collaborative knowledge management for identifying and prioritizing DA opportunities in AM. The framework of the proposed methodology has three components: a team of experts, a DA Opportunity Knowledge Base (DOKB), and a prioritization tool. The team of experts provides diverse knowledge that can be used to identify and prioritize DA opportunities. The DOKB, developed by using the Web Ontology Language (OWL), captures diverse knowledge from the experts to identify DA opportunities. The prioritization tool ranks the identified DA opportunities by using the Fuzzy integrated Technique of Order Preference Similarity to the Ideal Solution (Fuzzy-TOPSIS). A case study, in which National Institute of Standards and Technology (NIST) researchers participated, demonstrates our methodology. As a result, 264 DA opportunities for AM’s Laser-Powder Bed Fusion (L-PBF) process are identified and prioritized. The prioritized DA opportunities help set a DA direction for L-PBF AM. Our methodology keeps knowledge sharable, reusable, revisable, and extendable. Thus, this methodology can continue to facilitate collaboration within the AM community to identify high potential and high impact DA opportunities in AM.

Similar content being viewed by others

References

Abecker, A., & van Elst, L. (2009). Ontologies for Knowledge Management. In S. Staab & R. Studer (Eds.), Handbook on Ontologies (pp. 713–734). Berlin, Heidelberg: Springer Berlin Heidelberg. https://doi.org/10.1007/978-3-540-92673-3_32

Adrian, W. T., LigĘza, A., Nalepa, G. J., & Kaczor, K. (2014). Distributed and collaborative knowledge management using an ontology-based system. In IFIP Advances in Information and Communication Technology (Vol. 422, pp. 112–130). https://doi.org/10.1007/978-3-642-54897-0_7

Alberti-Alhtaybat, V. L., Al-Htaybat, K., & Hutaibat, K. (2019). A knowledge management and sharing business model for dealing with disruption: The case of Aramex. Journal of Business Research. https://doi.org/10.1016/j.jbusres.2017.11.037

Ameri, F., Urbanovsky, C., & McArthur, C. (2012). A systematic approach to developing ontologies for manufacturing service modeling. In CEUR Workshop Proceedings (Vol. 886, pp. 1–14).

ASTM International. (2012). ASTM F2792–12a, Standard Terminology for Additive Manufacturing Technologies (Withdrawn 2015). West Conshohocken, PA. www.astm.org

Bosio, F., Aversa, A., Lorusso, M., Marola, S., Gianoglio, D., Battezzati, L., et al. (2019). A time-saving and cost-effective method to process alloys by Laser Powder Bed Fusion. Materials and Design, 181, 107949. https://doi.org/10.1016/j.matdes.2019.107949

Bugatti, M., & Colosimo, B. M. (2021). Towards real-time in-situ monitoring of hot-spot defects in L-PBF: A new classification-based method for fast video-imaging data analysis. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-021-01787-y

Chang, C. H., Lin, J. J., Lin, J. H., & Chiang, M. C. (2010). Domestic open-end equity mutual fund performance evaluation using extended TOPSIS method with different distance approaches. Expert Systems with Applications, 37(6), 4642–4649. https://doi.org/10.1016/j.eswa.2009.12.044

Costa, R., Lima, C., Sarraipa, J., & Jardim-Gonçalves, R. (2013). Facilitating knowledge sharing and reuse in building and construction domain: An ontology-based approach. Journal of Intelligent Manufacturing, 27(1), 263–282. https://doi.org/10.1007/s10845-013-0856-5

Davtalab, O., Kazemian, A., Yuan, X., & Khoshnevis, B. (2020). Automated inspection in robotic additive manufacturing using deep learning for layer deformation detection. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-020-01684-w

Dessì, N., Milia, G., Pascariello, E., & Pes, B. (2016). COWB: A cloud-based framework supporting collaborative knowledge management within biomedical communities. Future Generation Computer Systems, 54, 399–408. https://doi.org/10.1016/j.future.2015.04.012

Eyers, D. R., & Potter, A. T. (2017). Industrial additive manufacturing: A manufacturing systems perspective. Computers in Industry, 92–93, 208–218. https://doi.org/10.1016/j.compind.2017.08.002

Feng, S. C., Lu, Y., & Jones, A. T. (2020). Meta-data for in-situ monitoring of laser powder bed fusion processes. In Proceedings of the ASME 2020 15th International Manufacturing Science and Engineering Conference (pp. 1–10). https://doi.org/10.1115/msec2020-8344

Gagnon, R., Kurata, K., & Chin, S. (2017). Data & Advanced Analytics: High Stakes, High Rewards. Forbes Insight, 1–59. www.forbes.com/forbesinsights HIGH

Gibson, I., Rosen, D., & Stucker, B. (2015). Design for Additive Manufacturing. In Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer, New York. pp. 399–435. https://doi.org/10.1007/978-1-4939-2113-3_17

Gruber, T. R. (1993). A translation approach to portable ontology specifications. Knowledge Acquisition, 5(2), 199–220. https://doi.org/10.1006/knac.1993.1008

Grüninger, M., & Fox, M. S. (1995). Methodology for the Design and Evaluation of Ontologies. In International Joint Conference on Artificial Inteligence (IJCAI95), Workshop on Basic Ontological Issues in Knowledge Sharing (pp. 1–10). http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.44.8723

Horrocks, I., Patel-Schneider, P. F., Bechhofer, S., & Tsarkov, D. (2005). OWL rules: A proposal and prototype implementation. Web Semantics, 3(1), 23–40. https://doi.org/10.1016/j.websem.2005.05.003

Horrocks, I., Patel-Schneider, P. F., Boley, H., Tabet, S., Grosof, B., & Dean, M. (2004). SWRL: A Semantic Web RUle Language Combining OWL and RuleML. W3C. https://www.w3.org/Submission/SWRL/

Hwang, C.-L., & Yoon, K. (1981). Multiple Attribute Decision Making: Methods and Applications, A State-of-the-Art Survey. Springer. https://doi.org/10.1007/978-3-642-48318-9

Im, K., & Cho, H. (2013). A systematic approach for developing a new business model using morphological analysis and integrated fuzzy approach. Expert Systems with Applications, 40(11), 4463–4477. https://doi.org/10.1016/j.eswa.2013.01.042

Kamsu-Foguem, B., & Noyes, D. (2013). Graph-based reasoning in collaborative knowledge management for industrial maintenance. Computers in Industry, 64(8), 998–1013. https://doi.org/10.1016/j.compind.2013.06.013

Keet, C. M. (2018). An Introduction to Ontology Engineering. http://www.meteck.org/teaching/OEbook/

Kim, D. B., Witherell, P., Lu, Y., & Feng, S. (2017). Toward a digital thread and data package for metals-additive manufacturing. Smart and Sustainable Manufacturing Systems, 1(1), 20160003. https://doi.org/10.1520/ssms20160003

Kim, S., Rosen, D. W., Witherell, P., & Ko, H. (2019). A design for additive manufacturing ontology to support manufacturability analysis. Journal of Computing and Information Science in Engineering, 19(4), 041014. https://doi.org/10.1115/1.4043531.

Ko, H., Witherell, P., Lu, Y., Kim, S., & Rosen, D. W. (2021). Machine learning and knowledge graph based design rule construction for additive manufacturing. Additive Manufacturing, 37, 101620. https://doi.org/10.1016/j.addma.2020.101620

Koohang, A., & Nord, J. H. (2021). Critical components of data analytics in organizations: A research model. Expert Systems with Applications. https://doi.org/10.1016/j.eswa.2020.114118

Kwon, O., Kim, H. G., Ham, M. J., Kim, W., Kim, G. H., Cho, J. H., et al. (2020). A deep neural network for classification of melt-pool images in metal additive manufacturing. Journal of Intelligent Manufacturing, 31(2), 375–386. https://doi.org/10.1007/s10845-018-1451-6

Lane, B. M., Mekhontsev, S., Grantham, S. E., Vlasea, M., Whiting, J. G., Yeung, H., et al. (2016). Design, Developments, and Results From the Nist Additive Manufacturing Metrology Testbed (AMMT). In Proceedings of the Solid Freeform Fabrication Symposium (p. 1021407). http://ws680.nist.gov/publication/get_pdf.cfm?pub_id=921551%0Ahttp://ws680.nist.gov/publication/get_pdf.cfm?pub_id=921551%0Ahttps://sffsymposium.engr.utexas.edu/sites/default/files/2016/093-Lane.pdf

Leong, G. K., Snyder, D. L., & Ward, P. T. (1990). Research in the process and content of manufacturing strategy. Omega, 18(2), 109–122. https://doi.org/10.1016/0305-0483(90)90058-H

Li, Y., Tarafdar, M., & Rao, S. S. (2012). Collaborative knowledge management practices: Theoretical development and empirical analysis. International Journal of Operations and Production Management, 32(4), 398–422. https://doi.org/10.1108/01443571211223077

Liang, J. S. (2018). An ontology-oriented knowledge methodology for process planning in additive layer manufacturing. Robotics and Computer-Integrated Manufacturing. https://doi.org/10.1016/j.rcim.2018.03.003

Lima Junior, F. R., Osiro, L., & Carpinetti, L. C. R. (2014). A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Applied Soft Computing, 21, 194–209. https://doi.org/10.1016/j.asoc.2014.03.014

Liu, J., & Wei, Q. (2018). Risk evaluation of electric vehicle charging infrastructure public-private partnership projects in China using fuzzy TOPSIS. Journal of Cleaner Production, 189, 211–222. https://doi.org/10.1016/j.jclepro.2018.04.103

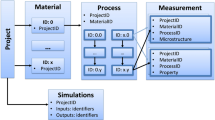

Lu, Y., Choi, S., & Witherell, P. (2015). Towards an integrated data schema design for additive manufacturing: Conceptual modeling. In Proceedings of the ASME Design Engineering Technical Conference (Vol. 1A-2015). https://doi.org/10.1115/DETC2015-47802

Lu, Y., & Jones, A. T. (2020). Data Integration and Management for Additive Manufacturing. National Institute of Standards and Technology. https://www.nist.gov/programs-projects/data-integration-and-management-additive-manufacturing

Mahato, V., Obeidi, M. A., Brabazon, D., & Cunningham, P. (2020). Detecting voids in 3D printing using melt pool time series data. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-020-01694-8

Majeed, A., Lv, J., & Peng, T. (2019). A framework for big data driven process analysis and optimization for additive manufacturing. Rapid Prototyping Journal, 25(2), 308–321. https://doi.org/10.1108/RPJ-04-2017-0075

Maniraj, V., & Sivakumar, R. (2010). Ontology languages - A review. International Journal of Computer Theory and Engineering, 2(6), 1793–8201.

Mbow, M. M., Grandvallet, C., Vignat, F., Marin, P. R., Perry, N., & Pourroy, F. (2021). Mathematization of experts knowledge: example of part orientation in additive manufacturing. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-020-01719-2

Mycroft, W., Katzman, M., Tammas-Williams, S., Hernandez-Nava, E., Panoutsos, G., Todd, I., & Kadirkamanathan, V. (2020). A data-driven approach for predicting printability in metal additive manufacturing processes. Journal of Intelligent Manufacturing, 31(7), 1769–1781. https://doi.org/10.1007/s10845-020-01541-w

NǍdǍban, S., Dzitac, S., & Dzitac, I. (2016). Fuzzy TOPSIS: A General View. In Procedia Computer Science (Vol. 91, pp. 823–831). https://doi.org/10.1016/j.procs.2016.07.088

National Institute of Standards and Technology. (1993). Integration Definition for Function Modeling (IDEF0). Draft Federal Information Processing Standards Publication 183.

Noy, N. F., & McGuiness, D. L. (2001). Ontology development 101: A guide to creating your first ontology. Stanford University, 102(2), 393–411. https://doi.org/10.1007/s00607-018-0687-5

OWL Web Ontology Language Overview. (2004). W3C recommendation. http://www.w3.org/TR/owl-features/

Park, H., Ko, H., Lee, Y. T. T., Cho, H., & Witherell, P. (2019). A Framework for Identifying and Prioritizing Data Analytics opportunities in Additive Manufacturing. In Proceedings - 2019 IEEE International Conference on Big Data, Big Data 2019 (pp. 3458–3467). IEEE. https://doi.org/10.1109/BigData47090.2019.9006489

Peng, G., Wang, H., Zhang, H., Zhao, Y., & Johnson, A. L. (2017). A collaborative system for capturing and reusing in-context design knowledge with an integrated representation model. Advanced Engineering Informatics, 33, 314–329. https://doi.org/10.1016/j.aei.2016.12.007

Razvi, S. S., Feng, S., Narayanan, A., Lee, Y.-T. T., & Witherell, P. (2019). A review of machine learning applications in additive manufacturing. In Proceeding of the ASME 2019 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference.

Sallam, R., Steenstrup, K., Eriksen, L., & Jacobson, S. (2014). Industrial Analytics Revolutionizes Big Data in the Digital Business. Gartner Research.

Sanchez, S., Rengasamy, D., Hyde, C. J., Figueredo, G. P., & Rothwell, B. (2021). Machine learning to determine the main factors affecting creep rates in laser powder bed fusion. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-021-01785-0

Sanfilippo, E. M., Belkadi, F., & Bernard, A. (2019). Ontology-based knowledge representation for additive manufacturing. Computers in Industry, 109, 182–194. https://doi.org/10.1016/j.compind.2019.03.006

Sekhar, C., Patwardhan, M., & Vyas, V. (2015). A Delphi-AHP-TOPSIS based framework for the prioritization of intellectual capital indicators: A SMEs perspective. Procedia - Social and Behavioral Sciences, 189, 275–284. https://doi.org/10.1016/j.sbspro.2015.03.223

Sharma, S., & Balan, S. (2013). An integrative supplier selection model using Taguchi loss function, TOPSIS and multi criteria goal programming. Journal of Intelligent Manufacturing, 24(6), 1123–1130. https://doi.org/10.1007/s10845-012-0640-y

Shen, H. T., Zhu, X., Zhang, Z., Wang, S. H., Chen, Y., Xu, X., & Shao, J. (2021). Heterogeneous data fusion for predicting mild cognitive impairment conversion. Information Fusion. https://doi.org/10.1016/j.inffus.2020.08.023

Sirisawat, P., & Kiatcharoenpol, T. (2018). Fuzzy AHP-TOPSIS approaches to prioritizing solutions for reverse logistics barriers. Computers and Industrial Engineering, 117(January), 303–318. https://doi.org/10.1016/j.cie.2018.01.015

Solangi, Y. A., Tan, Q., Mirjat, N. H., & Ali, S. (2019). Evaluating the strategies for sustainable energy planning in Pakistan: An integrated SWOT-AHP and Fuzzy-TOPSIS approach. Journal of Cleaner Production, 236, 117655. https://doi.org/10.1016/j.jclepro.2019.117655

Swarnkar, R., Choudhary, A. K., Harding, J. A., Das, B. P., & Young, R. I. (2012). A framework for collaboration moderator services to support knowledge based collaboration. Journal of Intelligent Manufacturing, 23(5), 2003–2023. https://doi.org/10.1007/s10845-011-0528-2

Wang, C., Tan, X. P., Tor, S. B., & Lim, C. S. (2020). Machine learning in additive manufacturing: State-of-the-art and perspectives. Additive Manufacturing, 36(August), 101538. https://doi.org/10.1016/j.addma.2020.101538

Wang, L., & Alexander, C. A. (2016). Additive manufacturing and big data. International Journal of Mathematical, Engineering and Management Sciences, 1(3), 107–121. https://doi.org/10.33889/ijmems.2016.1.3-012

Wang, P., Zhu, Z., & Huang, S. (2017). The use of improved TOPSIS method based on experimental design and Chebyshev regression in solving MCDM problems. Journal of Intelligent Manufacturing, 28(1), 229–243. https://doi.org/10.1007/s10845-014-0973-9

Witherell, P., & Lee, Y.-T. T. (2020). Data Driven Decision Support for Additive Manufacturing. National Institute of Standards and Technology. https://www.nist.gov/programs-projects/data-driven-decision-support-additive-manufacturing

Wu, X., & Gu, Y. (2009). Collaborative Knowledge Management System (CKMS) and Strategic Management. In 2009 International Joint Conference on Artificial Intelligence (pp. 190–193). https://doi.org/10.1109/JCAI.2009.178

Xia, C., Pan, Z., Polden, J., Li, H., Xu, Y., & Chen, S. (2021). Modelling and prediction of surface roughness in wire arc additive manufacturing using machine learning. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-020-01725-4

Ye, D., Hsi Fuh, J. Y., Zhang, Y., Hong, G. S., & Zhu, K. (2018). In situ monitoring of selective laser melting using plume and spatter signatures by deep belief networks. ISA Transactions, 81(July), 96–104. https://doi.org/10.1016/j.isatra.2018.07.021

Yuan, S., Li, J., Yao, X., Zhu, J., Gu, X., Gao, T., et al. (2020). Intelligent optimization system for powder bed fusion of processable thermoplastics. Additive Manufacturing, 34(January), 101182. https://doi.org/10.1016/j.addma.2020.101182

Zadeh, L. A. (1965). Fuzzy Sets. Information and Control, 8(1), 338–353.

Zhou, L., Hyer, H., Park, S., Pan, H., Bai, Y., Rice, K. P., & Sohn, Y. (2019). Microstructure and mechanical properties of Zr-modified aluminum alloy 5083 manufactured by laser powder bed fusion. Additive Manufacturing, 28(May), 485–496. https://doi.org/10.1016/j.addma.2019.05.027

Acknowledgements

The authors acknowledge the support of the Additive Manufacturing Program at the National Institute of Standards and Technology (NIST), US Department of Commerce. The authors thank Dr. Yan Lu, Dr. Zhuo Yang, and Dr. Tesfaye Moges for their time and efforts evaluating the DA opportunities. Certain commercial systems are identified in this article. Such identification does not imply recommendation or endorsement by NIST; nor does it imply that the products identified are necessarily the best available for the purpose. Further, any opinions, findings, conclusions, or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of NIST or any other supporting U.S. government or corporate organizations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, H., Ko, H., Lee, Yt.T. et al. Collaborative knowledge management to identify data analytics opportunities in additive manufacturing. J Intell Manuf 34, 541–564 (2023). https://doi.org/10.1007/s10845-021-01811-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-021-01811-1