Abstract

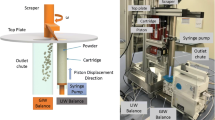

Surveys were carried out to study the opportunities for increasing homogeneity of a medicated feed mixture, taking into consideration the kinetics (trajectory, speed, and vector) of certain ingredient particles in the material and airflow stream during mixing the medicated feedingstuffs and mineral-and-vitamin premixes in the mixer with a spherical chamber under the centrifugal, aerodynamic, inertial, and Coriolis forces. Separation (division or segregation) of the components in the mixture, depending on their physical and mechanical properties, such as density, particle sizes, coefficients of friction, windage, etc., occurs under the centrifugal force acting on the rotating blade surface. Leaving the blade, the material and airflow stream strikes the bottom cylindrical tank surface and, slowing down, changes its direction of movement through 90° and even 180° at the cover. In addition, the operational conditions for segregation are not limited in the applied mixers with vertical cylindrical tanks, working in the regime of fluidization. The technology and design opportunities for increasing mixture homogeneity have been revealed, since their realization in a single unit can make it possible to increase homogeneity in the medicated feedingstuff up to 95–98%.

Similar content being viewed by others

REFERENCES

Kryukov, V.S., Problems of biochemistry and technology of using selenium in bird nutrition, Probl. Biol. Prod. Zhivotn., 2017, no. 4, pp. 24–38.

Sosipatrov, G.V., Helminthiasis and recommendations for their prevention in farms specialized in fattening of pigs, Tr. Vses. Inst. Gel’mintol., 1974, vol. 21, pp. 61–66.

Kibakin, V.V., The main helminthiases of chickens and measures to combat them in the Altai krai and Eastern Siberia, Doctoral (Vet.) Dissertation, Krasnoyarsk, 2006.

Spesivtsev, A., The mixing process in the production of compound feeds, Kombikorma, 2016, no. 3, pp. 37–41.

Klychev, E.M. and Syrovatka, V.I., Investigation of the process of mixing bulk feed in a fluidized bed, Nauchn. Tr. VIESKh., 1973, vol. 34, pp. 95–129.

Goryachkin, V.P., Sobranie sochinenii (Collected Works), Moscow: Kolos, 1963.

Targ, S.M., Kratkii kurs teoreticheskoi mekhaniki (A Short Course in Theoretical Mechanics), Moscow: Fiz.-Mat. Liter., 1963.

Vasilenko, P.M., Teoriya dvizheniya chastits po sherokhovatym poverkhnostyam sel’skokhozyaistvennykh mashin (The Theory of Particle Motion on Rough Surfaces of Agricultural Machinery), Kiev: Izd. Akad. S.-kh. Nauk USSR, 1960.

Smirnov, V.I., Kurs vneshnei matematiki (Course of External Mathematics), Moscow: Fiz.-Mat. Liter., 1958.

Lachuga, Yu.F. and Ksendzov, V.A., Teoreticheskaya mekhanika (Theoretical Mechanics), Moscow: Kolos, 2005.

Berezin, I.S. and Zhidkov, I.P., Metody vychislenii (Calculation Methods), Moscow: Gosizdat Fiz.-Mat. Liter., 1962.

Syrovatka, V.I., The main patterns in the process of grinding grain in a hammer mill, Nauchn. Tr. VIESKh., 1964, vol. 14, pp. 89–155.

Kil’chevskii, N.A., Teoriya soudoreniya tverdykh tel (Collision Theory for Solids), Moscow: Rostekhizdat, 1953.

Syrovatka, V.I., Mashinnye tekhnologii prigotovleniya kombikormov v khozyaistvakh (Machine Technologies for the Preparation of Compound Feeds on Farms), Moscow: Tipogr. Rossel’khozakad., 2010.

Kerber, M.L., Vinogradov, V.M., and Golovkin, G.S., Polimernye kompozitsionnye materialy (Polymer Composite Materials), St. Petersburg: Khimiya, 2008.

Todes, O.M. and Tsitovich, O.B., Apparaty s kipyashchim zernistym sloem (Units with Fluidized Granular Beds), Leningrad: Khimiya, 1986.

Gavrilov, D.M. and Lebedev, I.F., Behavior of material particles in a flow on a curved surface, Gorn. Inf.-Anal. Byull., 2007, no. 3, pp. 368–372.

Syrovatka, V.I., Zhdanova, N.V., and Obukhov, A.D., RU Patent 2730651, Byull. Izobret., 2020, no. 24.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest. This article does not contain any studies involving animals or human participants performed by any of the authors.

Additional information

Translated by O. Zhiryakova

About this article

Cite this article

Syrovatka, V.I., Zhdanova, N.V. & Obukhov, A.D. Analyzing Kinetics of Medicated-Feed Ingredients in a Ball Mixer Mill. Russ. Agricult. Sci. 47, 290–295 (2021). https://doi.org/10.3103/S1068367421030186

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068367421030186