Abstract

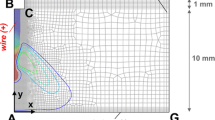

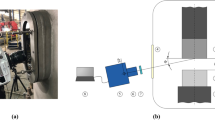

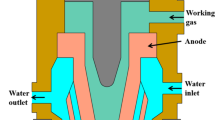

This paper presents the analytical and experimental results for transient temperature fields induced in a stainless steel plate by a low-powered arc plasma torch for plasma-assisted milling. For this purpose, we first measured arc efficiencies by using the calorimetric method for plasma power levels of (3–4) kW. The measurement results showed that low arc currents of ≤ 30 A can produce relatively low arc efficiencies of (35–36) %. Then, the heated stainless steel plate was cut to reveal the very shallow surface erosion by arc plasma heating that occurred within 1 mm depth. These experimental results indicate that the relatively low arc efficiencies resulted from the low arc currents designed to thermally soften the workpiece, rather than form a melting pool. Considering these arc heating effects confined to a shallow area near the surface, we employed a 2D surface Gaussian distributed heat source model in analytical modeling of the temperature evolution in the stainless steel plates. The unsteady temperature fields predicted by the analytical solutions show relatively good agreement with the experimental data, although the analytic results show the temperatures rising earlier and descending faster. From these comparisons, we expect that this work can contribute to the optimization of the plasma-assisted milling process.

Similar content being viewed by others

References

C.E. Leshock, J.N. Kim, Y.C. Shin, Int. J. Mach. Tools Manuf. 41, 877 (2001)

E.O. Ezugwu, Int. J. Mach. Tools Manuf. 45, 1353 (2005)

S. Sun, M. Brandt, M.S. Dargusch, Int. J. Mach. Tools Manuf. 50, 663 (2010)

Y. Xiang, D. Yu, Q. Li, H. Peng, X. Cao, J. Yao, J. Mater. Process. Technol. 226, 238 (2015)

R. Ichiki, H. Nagamatsu, Y. Yasumatsu, T. Iwao, S. Akamine, S. Kanazawa, Mater. Lett. 71, 134 (2012)

A.J. Hick, Heat Treat. Met. 1, 3–11 (1983)

S. Valkov, M. Ormanova, P. Petrov, Metals 10, 1219 (2020)

L.N. Lopez de Lacalle, J.A. Sanchez, A. Lamikiz, A. Celaya, J. Manuf. Sci. Eng. 126, 274 (2004)

Y.H. Lee, C.M. Lee, Materials 12, 25950 (2019)

S. Elhami, M.R. Razfar, M. Farahnakian, Int. J. Mech. Sci. 103, 158 (2015)

H.G. Woo, H.S. Cho, Proc. Inst. Mech. Eng. 213(Part B), 695 (1999)

G. Araya, G. Gutierrez, Int. J. Heat Mass Transf. 49, 4124 (2006)

J. Goldak, M. Bibby, A. Chakravarti, Metall. Trans. B 15, 299 (1985)

N.T. Nguyen, A. Ohta, K. Matsuoka, N. Suzuki, Y. Maeda, Weld. J. 78, 265-s (1999)

A. Ghosh, N. Barman, H. Chattopadhyay, S. Hloch, J. Mech. Eng. 59, 333 (2013)

T.F. Flint, J.A. Francis, M.C. Smith, A.N. Vasileiou, Int. J. Therm. Sci. 138, 586 (2019)

S.K. Jeong, H.S. Cho, Weld. J. 76, 223-s (1997)

N.S. Tsai, T.W. Eager, Metall. Trans. B 16, 841 (1985)

A.B. Murphy, M. Tanaka, K. Yamamoto, S. Tashiro, J.J. Lowke, K. Ostrikov, Vacuum 85, 579 (2010)

K.D. Cole, A. Haji-Sheikh, J.V. Beck, B. Litkouhi, Heat Conduction Using Greens Functions, 2nd edn. (Taylor and Francis, New York, 2011)

Acknowledgements

This work was supported by research funds from Jeonbuk National University in 2021. This research was also supported by the Korea Hydro & Nuclear Power (KHNP) Co.(G18IO16). We thank the Korea Institute of Energy Technology Evaluation and Planning (KETEP) for their Grant (20191510301420) funded by the Korea government (MOTIE), and the support of Jeollannam-do (‘2020 R&D supporting program’ operated by Jeonnam Technopark).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choi, MG., Lee, DH., Jeong, SM. et al. Experimental and analytical investigations of the transient temperature fields induced in stainless steel plate by an arc plasma jet for plasma-assisted milling. J. Korean Phys. Soc. 79, 283–289 (2021). https://doi.org/10.1007/s40042-021-00218-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-021-00218-8