Abstract

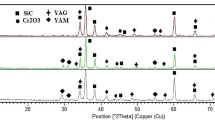

In this study, ceramics was prepared by slip casting (no pressure was used during shaping step) and atmospheric pressure sintering with low-melting point glass (LPG) powder as the binding material to facilitate the transformation of spodumene flotation tailings (SFTs) into ceramics at lower temperatures. The influence of sintering temperature and mass ratio of LPG on the mechanical properties (flexural strength and compressive strength) of ceramic materials was studied by orthogonal test. The results showed that when the mass ratio of LPG powder was higher than or equal to 20 wt% and the sintering temperature was higher than or equal to 550 °C, mutual adhesion between the sample particles was realised and consequently the ceramic materials could be prepared with good mechanical properties (the maximum flexural strength=19.55 MPa, the maximum compressive strength=42.25 MPa, average porosity=24.52%, average apparent density=1.66 g/cm3, and average water absorption=14.79%). The sintered ceramics were characterized by XRF, XRD, optical microscopy analysis, SEM, TGA-DSC and FT-IR. The formation of liquid phase at high temperature may lead to the mutual bonding between particles, which might be the main reason for the improvement of mechanical properties of ceramic materials. Overall, SFTs were successfully sintered at low temperature to prepare ceramic materials with good mechanical properties, which are crucial for energy conservation and environmental preservation.

摘要

本文以锂辉石浮选尾矿为主要原料, 低熔点玻璃粉(LPG)为高温粘结材料, 通过湿法注模成型, 常压烧结制备陶瓷材料。通过正交试验研究了烧结温度和LPG 质量分数对陶瓷材料抗折强度和抗压 强度的影响。结果表明, 当LPG 质量比不低于20 wt%, 烧结温度不低于550 °C 时, 尾矿颗粒间相互 粘结紧密, 制备出了力学性能优异的陶瓷材料(最大抗折强度=19.55 MPa, 最大抗压强度= 42.25 MPa, 平均显气孔率24.52%, 体积密度1.66 g/cm3, 吸水率14.79%)。采用XRF, XRD, 光学显微镜, SEM, TGA-DSC 和FT-IR 等对陶瓷材料低温烧结机理进行了测试分析。结果表明, 高温下液相的生成使得 颗粒间相互粘结可能为陶瓷材料力学性能提高的主要原因。

Similar content being viewed by others

References

ZAMAN A U. A comprehensive review of the development of zero waste management: Lessons learned and guidelines [J]. Journal of Cleaner Production, 2015, 91: 12–25. DOI: https://doi.org/10.1016/j.jclepro.2014.12.013.

BURLAKOVS J, JANI Y, KRIIPSALU M, VINCEVICA-GAILE Z, KACZALA F, CELMA G, OZOLA R, ROZINA L, RUDOVICA V, HOGLAND M, VIKSNA A, PEHME K M, HOGLAND W, KLAVINS M. On the way to “zero waste” management: Recovery potential of elements, including rare earth elements, from fine fraction of waste [J]. Journal of Cleaner Production, 2018, 186: 81–90. DOI: https://doi.org/10.1016/j.jclepro.2018.03.102.

ZAMAN A U. Identification of key assessment indicators of the zero waste management systems [J]. Ecological Indicators, 2014, 36: 682–693. DOI: https://doi.org/10.1016/j.ecolind.2013.09.024.

HENCKENS M, van IERLAND E C, DRIESSEN P, WORRELL E. Mineral resources: Geological scarcity, market price trends, and future generations [J]. Resources Policy, 2016, 49: 102–111. DOI: https://doi.org/10.1016/j.resourpol.2016.04.012.

WEST J. Extractable global resources and the future availability of metal stocks: “Known Unknowns” for the foreseeable future [J]. Resources Policy, 2020, 65: 101574. DOI: https://doi.org/10.1016/j.resourpol.2019.101574.

ZHANG L, XU Z. A critical review of material flow, recycling technologies, challenges and future strategy for scattered metals from minerals to wastes [J]. Journal of Cleaner Production, 2018, 202: 1001–1025. DOI: https://doi.org/10.1016/j.jclepro.2018.08.073.

GUO Y G, HUANG P, ZHANG W G, YUAN X W, FAN F X, WANG H L, LIU J S, WANG Z H. Leaching of heavy metals from Dexing copper mine tailings pond [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(10): 3068–3075. DOI: https://doi.org/10.1016/S1003-6326(13)62835-6.

LI X F, YE Y Z, XUE S G, JIANG J, WU C, KONG X F, HARTLEY W, LI Y W. Leaching optimization and dissolution behavior of alkaline anions in bauxite residue [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(6): 1248–1255. DOI: https://doi.org/10.1016/S1003-6326(18)64763-6.

ZHU X, HAN Y, SUN Y, LI Y, WANG H. Siderite as a novel reductant for clean utilization of refractory iron ore [J]. Journal of Cleaner Production, 2020, 245: 118704. DOI: https://doi.org/10.1016/j.jclepro.2019.118704.

AALDERING L J, SONG C H. Tracing the technological development trajectory in post-lithium-ion battery technologies: A patent-based approach [J]. Journal of Cleaner Production, 2019, 241: 118343. DOI: https://doi.org/10.1016/j.jclepro.2019.118343.

SCOTT S R, SHAFER M M. A new method for measurement of lithium isotopes with nuclear applications [J]. Progress in Nuclear Energy, 2020, 120: 103234. DOI: https://doi.org/10.1016/j.pnucene.2019.103234.

SHAO L, JIN S. Resilience assessment of the lithium supply chain in China under impact of new energy vehicles and supply interruption [J]. Journal of Cleaner Production, 2020, 252: 119624. DOI: https://doi.org/10.1016/j.jclepro.2019.119624.

ZHANG Y C, BRIAT O, DELÉTAGE J Y, MARTIN C, CHADOURNE N, VINASSA J M. Efficient state of health estimation of Li-ion battery under several ageing types for aeronautic applications [J]. Microelectronics Reliability, 2018, 88–90: 1231–1235. DOI: https://doi.org/10.1016/j.microrel.2018.07.038.

TIAN J, XU L, WU H, FANG S, DENG W, PENG T, SUN W, HU Y. A novel approach for flotation recovery of spodumene, mica and feldspar from a lithium pegmatite ore [J]. Journal of Cleaner Production, 2018, 174: 625–633. DOI: https://doi.org/10.1016/j.jclepro.2017.10.331.

WU H, TIAN J, XU L, FANG S, ZHANG Z, CHI R. Flotation and adsorption of a new mixed anionic/cationic collector in the spodumene-feldspar system [J]. Minerals Engineering, 2018, 127: 42–47. DOI: https://doi.org/10.1016/j.mineng.2018.07.024.

SHU Kai-qian, XU Long-hua, WU Hou-qin, TANG Zhen, LUO Li-ping, YANG Jie, XU Yan-bo, FENG Bo. Selective flotation separation of spodumene from feldspar using sodium alginate as an organic depressant [J]. Separation and Purification Technology, 2020, 248: 117122. DOI: https://doi.org/10.1016/j.seppur.2020.117122.

ZHU G L, WANG Y H, WANG X M, MILLER J D, LU D F, ZHENG X Y, ZHAO Y H, ZHENG H T. Effects of grinding environment and lattice impurities on spodumene flotation [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(7): 1527–1537. DOI: https://doi.org/10.1016/S1003-6326(19)65060-0.

GARRETT D E. Lithium [M]// Handbook of Lithium and Natural Calcium Chloride. Amsterdam: Elsevier, 2004. DOI: https://doi.org/10.1016/B978-0-12-276152-2.X5035-X.

MANETA V, BAKER DR. The potential of lithium in alkali feldspars, quartz, and muscovite as a geochemical indicator in the exploration for lithium-rich granitic pegmatites: A case study from the spodumene-rich Moblan pegmatite, Quebec, Canada [J]. Journal of Geochemical Exploration, 2019, 205: 106336. DOI: https://doi.org/10.1016/j.gexplo.2019.106336.

CHOUBEY P K, KIM M S, SRIVASTAVA R R, LEE J C, LEE J Y. Advance review on the exploitation of the prominent energy-storage element: Lithium. Part I: From mineral and brine resources [J]. Minerals Engineering, 2016, 89: 119–137. DOI: https://doi.org/10.1016/j.mineng.2016.01.010.

BURRITT R L, CHRIST K L. Water risk in mining: Analysis of the Samarco dam failure [J]. Journal of Cleaner Production, 2018, 178: 196–205. DOI: https://doi.org/10.1016/j.jclepro.2018.01.042.

PARK I, TABELIN C B, JEON S, LI X, SENO K, ITO M, HIROYOSHI N. A review of recent strategies for acid mine drainage prevention and mine tailings recycling [J]. Chemosphere, 2019, 219: 588–606. DOI: https://doi.org/10.1016/j.chemosphere.2018.11.053.

QI C, FOURIE A. Cemented paste backfill for mineral tailings management: Review and future perspectives [J]. Minerals Engineering, 2019, 144: 106025. DOI: https://doi.org/10.1016/j.mineng.2019.106025.

MENG X, KHOSO S A, KANG J, WU J, GAO J, LIN S, WU M, SUN W, HU Y. A novel scheme for flotation tailings pulp settlement and chemical oxygen demand reduction with polyferric sulfate [J]. Journal of Cleaner Production, 2019, 241: 118371. DOI: https://doi.org/10.1016/j.jclepro.2019.118371.

WANG C, HARBOTTLE D, LIU Q, XU Z. Current state of fine mineral tailings treatment: A critical review on theory and practice [J]. Minerals Engineering, 2014, 58: 113–131. DOI: https://doi.org/10.1016/j.mineng.2014.01.018.

RITCEY G M. Tailings management in gold plants [J]. Hydrometallurgy, 2005, 78(1): 3–20. DOI: https://doi.org/10.1016/j.hydromet.2005.01.001.

YIN Z, SUN W, HU Y, ZHANG C, GUAN Q, WU K. Evaluation of the possibility of copper recovery from tailings by flotation through bench-scale, commissioning, and industrial tests [J]. Journal of Cleaner Production, 2018, 171: 1039–1048.

LIU W, WU T, LI Z, HAO X, LU A. Preparation and characterization of ceramic substrate from tungsten mine tailings [J]. Construction and Building Materials, 2015, 77: 139–144. DOI: https://doi.org/10.1016/j.conbuildmat.2014.12.094.

LEMOUGNA P N, YLINIEMI J, ISMAILOV A, LEVANEN E, TANSKANEN P, KINNUNEN P, RONING J, ILLIKAINEN M. Recycling lithium mine tailings in the production of low temperature (700-900 °C) ceramics: Effect of ladle slag and sodium compounds on the processing and final properties [J]. Construction and Building Materials, 2019, 221: 332–344. DOI: https://doi.org/10.1016/j.conbuildmat.2019.06.078.

LEMOUGNA P N, YLINIEMI J, ISMAILOV A, LEVANEN E, TANSKANEN P, KINNUNEN P, RONING J, ILLIKAINEN M. Spodumene tailings for porcelain and structural materials: Effect of temperature (1050–1200 °C) on the sintering and properties [J]. Minerals Engineering, 2019, 141: 105843. DOI: https://doi.org/10.1016/j.mineng.2019.105843.

AYODE OTITOJU T, UGOCHUKWU OKOYE P, CHEN G, LI Y, ONYEKA OKOYE M, LI S. Advanced ceramic components: Materials, fabrication, and applications [J]. Journal of Industrial and Engineering Chemistry, 2020, 85: 34–65. DOI: https://doi.org/10.1016/j.jiec.2020.02.002.

DENG L, FENG B, ZHANG Y. An optimization method for multi-objective and multi-factor designing of a ceramic slurry: Combining orthogonal experimental design with artificial neural networks [J]. Ceramics International, 2018, 44(13): 15918–15923. DOI: https://doi.org/10.1016/j.ceramint.2018.06.010.

ZHANG S, CAO K, WANG C, WANG X, DENG G, WEI P. Influence of the porosity and pore size on the compressive and splitting strengths of cellular concrete with millimeter-size pores [J]. Construction and Building Materials, 2020, 235: 117508. DOI: https://doi.org/10.1016/j.conbuildmat.2019.117508.

FLÁDR J, BÍLÝ P. Specimen size effect on compressive and flexural strength of high-strength fibre-reinforced concrete containing coarse aggregate [J]. Composites Part B: Engineering, 2018, 138: 77–86. DOI: https://doi.org/10.1016/j.compositesb.2017.11.032.

XI C, ZHOU J, ZHENG F, GAO J M, HU P, LI Y, ZHEN Q, BASHIR S, LIU J L. Conversion of extracted titanium tailing and waste glass to value-added porous glass ceramic with improved performances [J]. Journal of Environmental Management, 2020, 261: 110197. DOI: https://doi.org/10.1016/j.jenvman.2020.110197.

WILLE G, LAHONDERE D, SCHMIDT U, DURON J, BOURRAT X. Coupling SEM-EDS and confocal Raman-in-SEM imaging: A new method for identification and 3D morphology of asbestos-like fibers in a mineral matrix [J]. Journal of Hazardous Materials, 2019, 374: 447–458. DOI: https://doi.org/10.1016/j.jhazmat.2019.04.012.

YANG Z, WANG R, CHE X, YIN R, XIE L, HU H. Formation of columbite and microlite after alteration of Nb-and Ta-bearing biotite from the Lizaizhai pegmatite (Guangning ore district, Guangdong, South China): Identification of a new potential Nb-Ta mineralization type [J]. Journal of Asian Earth Sciences, 2020, 190: 104154. DOI: https://doi.org/10.1016/j.jseaes.2019.104154.

QI L, WENG X, WEI B, YUAN L, HUANG G, DU X, WU X, LIU H. Effects of low-melting glass powder on the thermal stabilities of low infrared emissivity Al/polysiloxane coatings [J]. Progress in Organic Coatings, 2020, 142: 105579. DOI: j.porgcoat.2020.105579.

ZHANG B, CHEN Q, SONG L, LI H, HOU F, ZHANG J. Fabrication and properties of novel low-melting glasses in the ternary system ZnO-Sb2O3-P2O5 [J]. Journal of Non-Crystalline Solids, 2008, 354(18): 1948–1954. DOI: https://doi.org/10.1016/j.jnoncrysol.2007.11.007.

JIN J, GAO Y, WU Y, LI R, LIU R, WEI H, QIAN G, ZHENG J. Performance evaluation of surface-organic grafting on the palygorskite nanofiber for the modification of asphalt [J]. Construction and Building Materials, 2021, 268: 121072. DOI: https://doi.org/10.1016/j.conbuildmat.2020.121072.

JIN J, GAO Y, WU Y, LIU S, LIU R, WEI H, QIAN G, ZHENG J. Rheological and adhesion properties of nano-organic palygorskite and linear SBS on the composite modified asphalt [J]. Powder Technology, 2021, 377: 212–221. DOI: https://doi.org/10.1016/j.powtec.2020.08.080.

JIN J, LIU S, GAO Y, LIU R, HUANG W, WANG L, XIAO T, LIN F, XU L, ZHENG J. Fabrication of cooling asphalt pavement by novel material and its thermodynamics model [J]. Construction and Building Materials, 2021, 272: 121930. DOI: https://doi.org/10.1016/j.conbuildmat.2020.121930.

MENAA B, MIZUNO M, TAKAHASHI M, TOKUDA Y, YOKO T. Polycarboxylic acids as network modifiers for water durability improvement of inorganic-organic hybrid tin-silico-phosphate low-melting glasses [J]. Journal of Solid State Chemistry, 2006, 179(2): 492–499. DOI: https://doi.org/10.1016/j.jssc.2005.11.001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Projects(51674207, 51922091) supported by the National Natural Science Foundation of China; Project(2018QNRC001) supported by the Young Elite Scientists Sponsorship Program by CAST, China; Projects(2019YFS0453, 2018JY0148) supported by the Sichuan Science and Technology Program, China

Contributors

XU Long-hua provided the concept, conducted the literature reviews and edited the draft of manuscript. YANG Jie wrote the first draft of the manuscript. WU Hou-qin and WANG Zhou-jie analyzed the experimental data. SHU Kai-qian and XU Yan-bo advised some experimental methods. LUO Li-ping and TANG Zhen designed the experimental program.

Conflict of interest

YANG Jie, XU Long-hua, WU Hou-qin, WANG Zhou-jie, SHU Kai-qian, XU Yan-bo, LUO Li-ping and TANG Zhen declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Yang, J., Xu, Lh., Wu, Hq. et al. Sintering behavior and mechanical properties of sintered ceramics based on spodumene tailings. J. Cent. South Univ. 28, 1637–1651 (2021). https://doi.org/10.1007/s11771-021-4723-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4723-9