Abstract

The electrodeposition of nickel-silicon carbide coatings on a copper electrode was done by mixing SiC particles in the nickel electrodeposition solution. The influence of surfactants and silicon carbide particle size on uniformity and quantity of silicon carbide particles in nickel-silicon carbide composite coatings was investigated. It was found that particle size affects the nucleation overpotential, with 40 nm silicon carbide nanoparticles more effective in promoting nickel nucleation than 500 nm particles due to an increase in active nucleation sites. In terms of surfactants, anionic surfactant sodium dodecyl sulfate (SDS) produced better dispersion of 40 nm silicon carbide particles than cationic surfactant cetyltrimethyl ammonium bromide (CTAB), but little difference was found between the two when 500 nm silicon carbide particles were used. Thus, although the suspension of silicon carbide particles can be improved and their co-deposition can be promoted with a cationic surfactant CTAB, it is less effective than an anionic surfactant SDS in terms of surface finish.

摘要

本文在电沉积镍的镀液中添加SiC 颗粒于铜基体上制备Ni-SiC 复合镀层, 研究了表面活性剂 种类和增强颗粒粒度对Ni-SiC 复合镀层中碳化硅含量及分布均匀性的影响。SiC 颗粒的粒度影响形核 过电位, 40 nm SiC 颗粒比500 nm SiC 颗粒提供更多成核活性点, 且对于镍电结晶形核促进作用更明 显。表面活性SDS 对40 nm SiC 颗粒的分散效果较CTAB 更好, 二者对500 nm SiC 颗粒分散效果相 似。CTAB 从某种程度上增加了SiC 颗粒的含量, 但对于SiC 颗粒的分散效果不佳, SiC 颗粒仍有大 量团聚, 且通过阳离子表面活性剂CTAB 所获镀层表面比较暗淡、粗糙。

Similar content being viewed by others

References

CALDERÓN J A, HENAO J E, GÓMEZ M A. Erosion-corrosion resistance of Ni composite coatings with embedded SiC nanoparticles [J]. Electrochimica Acta, 2014, 124: 190–198. DOI: https://doi.org/10.1016/j.electacta.2013.08.185.

SUN Chu-feng, LIU Xiao-qin, ZHOU Chun-yu, WANG Chao-nan, CAO Hong-wei. Preparation and wear properties of magnetic assisted pulse electrodeposited Ni-SiC nanocoatings [J]. Ceramics International, 2019, 45(1): 1348–1355. DOI: https://doi.org/10.1016/j.ceramint.2018.07.242.

ALIZADEH M, TEYMURI A. Structure, indentation and corrosion characterizations of high-silicon Ni-Si nano-composite coatings prepared by modified electrodeposition process [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(3): 608–616. DOI: https://doi.org/10.1016/S1003-6326(19)64970-8.

ZHOU Hai-fei, DU Nan, ZHU Li-wei, SHANG Jian-ku, QIAN Zhou-hai, SHEN Xiao-ming. Characteristics investigation of Ni-diamond composite electrodeposition [J]. Electrochimica Acta, 2015, 151: 157–167. DOI: https://doi.org/10.1016/j.electacta.2014.10.122.

LI Bao-song, ZHANG Wei-wei, HUAN Yu-xing, DONG Jia. Synthesis and characterization of Ni-B/Al2O3 nanocomposite coating by electrodeposition using trimethylamine borane as boron precursor [J]. Surface and Coatings Technology, 2018, 337: 186–197. DOI: https://doi.org/10.1016/j.surfcoat.2018.01.018.

JIANG Wei, SHEN Li-da, QIU Ming-bo, WANG Xin, FAN Ming-zhi, TIAN Zong-jun. Preparation of Ni-SiC composite coatings by magnetic field-enhanced jet electrodeposition [J]. Journal of Alloys and Compounds, 2018, 762: 115–124. DOI: https://doi.org/10.1016/j.jallcom.2018.05.097.

JIANG Yan-cheng, XU Yun-hua, WANG Mei, YAO Han-chao. Effects of pulse plating parameters on the microstructure and properties of high frequency pulse electrodeposited Ni-Co/ZrO2 nanocomposite coatings [J]. Journal of Materials Science: Materials in Electronics, 2017, 28(1): 610–616. DOI: https://doi.org/10.1007/s10854-016-5565-3.

GYAWALI G, KIM H S, TRIPATHI K, KIM T H, LEE S W. Fabrication and characterization of electrodeposited Ni-SiC-h/BN composite coatings [J]. Journal of Materials Science & Technology, 2014, 30(8): 796–802. DOI: https://doi.org/10.1016/j.jmst.2014.05.008.

LARI BAGHAL S M, AMADEH A, HEYDARZADEH S M. Investigation of mechanical properties and operative deformation mechanism in nano-crystalline Ni-Co/SiC electrodeposits [J]. Materials Science and Engineering A, 2012, 542: 104–112. DOI: https://doi.org/10.1016/j.msea.2012.02.039.

CORNI I, CHATER R J, BOCCACCINI A R, RYAN M P. Electro co-deposition of Ni-Al2O3 composite coatings [J]. Journal of Materials Science, 2012, 47(14): 5361–5373. DOI: https://doi.org/10.1007/s10853-012-6381-7.

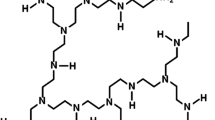

EROGLU D, VILINSKA A, SOMASUNDARAN P, WEST A C. Effect of a cationic polymer, polyethyleneimine, on Ni/SiC Co-deposition [J]. Journal of the Electrochemical Society, 2012, 160(2): D35–D40. DOI: https://doi.org/10.1149/2.041302jes.

LEKKA M, LANZUTTI A, CASAGRANDE A, de LEITENBURG C, BONORA P L, FEDRIZZI L. Room and high temperature wear behaviour of Ni matrix micro- and nano-SiC composite electrodeposits [J]. Surface and Coatings Technology, 2012, 206(17): 3658–3665. DOI: https://doi.org/10.1016/j.surfcoat.2012.03.016.

EROGLU D, VILINSKA A, SOMASUNDARAN P, WEST A C. Use of dispersants to enhance incorporation rate of nano-particles into electrodeposited films [J]. Electrochimica Acta, 2013, 113: 628–634. DOI: https://doi.org/10.1016/j.electacta.2013.09.113.

CUI Wei, WANG Ke, WANG Kai-yu, WANG P. Effects of jet rate on microstructure, microhardness, and wear behavior of jet electrodeposited Ni-SiC composites [J]. Ceramics International, 2018, 44(6): 7214–7220. DOI: https://doi.org/10.1016/j.ceramint.2018.01.169.

JIANG Wei, SHEN Li-da, XU Ming-yang, WANG Zhan-wen, TIAN Zong-jun. Mechanical properties and corrosion resistance of Ni-Co-SiC composite coatings by magnetic field-induced jet electrodeposition [J]. Journal of Alloys and Compounds, 2019, 791: 847–855. DOI: https://doi.org/10.1016/j.jallcom.2019.03.391.

MA E. Materials science: Watching the nanograins roll [J]. Science, 2004, 305(5684): 623–624. DOI: https://doi.org/10.1126/science.1101589.

ZARGHAMI V, GHORBANI M. Alteration of corrosion and nanomechanical properties of pulse electrodeposited Ni/SiC nanocomposite coatings [J]. Journal of Alloys and Compounds, 2014, 598: 236–242. DOI: https://doi.org/10.1016/j.jallcom.2014.01.220.

ÜNAL E, KARAHAN İ H. Effects of ultrasonic agitation prior to deposition and additives in the bath on electrodeposited Ni-B/hBN composite coatings [J]. Journal of Alloys and Compounds, 2018, 763: 329–341. DOI: https://doi.org/10.1016/j.jallcom.2018.05.312.

GHAZIOF S, GAO Wei. The effect of pulse electroplating on Zn-Ni alloy and Zn-Ni-Al2O3 composite coatings [J]. Journal of Alloys and Compounds, 2015, 622: 918–924. DOI: https://doi.org/10.1016/j.jallcom.2014.11.025.

ZHOU Y, XIE F Q, WU X Q, ZHAO W D, CHEN X. A novel plating apparatus for electrodeposition of Ni-SiC composite coatings using circulating-solution co-deposition technique [J]. Journal of Alloys and Compounds, 2017, 699: 366–377. DOI: https://doi.org/10.1016/j.jallcom.2016.12.331.

LI Bao-song, ZHANG Wei-wei, LI Dan-dan, HUAN Yu-xing, DONG Jia. Microstructural, surface and electrochemical properties of a novel Ni-B/Ni-W-BN duplex composite coating by co-electrodeposition [J]. Applied Surface Science, 2018, 458: 305–318. DOI: https://doi.org/10.1016/j.apsusc.2018.07.100.

ÜNAL E, KARAHAN İ H. Production and characterization of electrodeposited Ni-B/hBN composite coatings [J]. Surface and Coatings Technology, 2018, 333: 125–137. DOI: https://doi.org/10.1016/j.surfcoat.2017.11.016.

HE Teng, HE Yi, LI Han, SU Zu-bo, FAN Yi, HE Ze. Fabrication of M-W-B4C composite coatings and evaluation of its micro-hardness and corrosion resistance properties [J]. Ceramics International, 2018, 44(8): 9188–9193. DOI: https://doi.org/10.1016/j.ceramint.2018.02.128.

LI Bao-song, ZHANG Wei-wei. Microstructural, surface and electrochemical properties of pulse electrodeposited Ni-W/Si3N4 nanocomposite coating [J]. Ceramics International, 2018, 44(16): 19907–19918. DOI: https://doi.org/10.1016/j.ceramint.2018.07.254.

ALLAHYARZADEH M H, ALIOFKHAZRAEI M, ROUHAGHDAM A R S, TORABINEJAD V. Electrodeposition of Ni-W-AhO3 nanocomposite coating with functionally graded microstructure [J]. Journal of Alloys and Compounds, 2016, 666: 217–226. DOI: https://doi.org/10.1016/j.jallcom.2016.01.031.

LI Han, HE Yi, HE Teng, FAN Yi, YANG Qiang-bin, ZHAN Ying-qing. The influence of pulse plating parameters on microstructure and properties of Ni-W-Si3N nanocomposite coatings [J]. Ceramics International, 2016, 42(16): 18380–18392. DOI: https://doi.org/10.1016/j.ceramint.2016.08.171.

GUGLIELMI N. Kinetics of the deposition of inert particles from electrolytic baths [J]. Journal of the Electrochemical Society, 1972, 119(8): 1009. DOI: https://doi.org/10.1149/1.2404383.

FRANSAER J, CELIS J P, ROOS J R. Analysis of the electrolytic codeposition of non-Brownian particles with metals [J]. Journal of the Electrochemical Society, 1992, 139(2): 413–425. DOI: https://doi.org/10.1149/1.2069233.

HWANG B J, HWANG C S. Mechanism of codeposition of silicon carbide with electrolytic cobalt [J]. Journal of the Electrochemical Society, 1993, 140(4): 979–984. DOI: https://doi.org/10.1149/1.2056239.

EROGLU D, WEST A C. Mathematical modeling of Ni/SiC Co-deposition in the presence of a cationic dispersant [J]. Journal of the Electrochemical Society, 2013, 160(9): D354–D360. DOI: https://doi.org/10.1149/2.052309jes.

Acknowledgements

The authors would like to thank the University of Alabama for providing the experimental and analytical facilities. In addition, KAN Hong-min would like to express her gratitude for awarding a scholarship to purse her research in the United States of America (the University of Alabama) as a visiting scholar by China Scholarship Council (CSC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(20180550242) supported by the Liaoning Science and Technology Plan, China

Contributors

KAN Hong-min conducted the investigation, wrote the first draft of manuscript and edited the draft of manuscript. MENG Yuan-yuan conducted the literature review and investigation. Ramana G REDDY edited the draft of manuscript.

Conflict of interest

KAN Hong-min, MENG Yuan-yuan and Ramana G REDDY declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kan, Hm., Meng, Yy. & Reddy, R.G. Influence of particle size and surfactants on uniformity and quantity of silicon carbide particles in electrodeposited nickel-silicon carbide coatings. J. Cent. South Univ. 28, 1627–1636 (2021). https://doi.org/10.1007/s11771-021-4722-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4722-x

Key words

- nickel-silicon carbide composite coating

- cyclic voltammetry

- potentiostatic transients

- sodium dodecyl sulfate surfactant

- cetyltrimethyl ammonium bromide surfactant