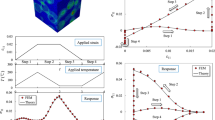

The effective elastic modulus of composites with network microstructures is studied by micromechanics methods. Based on their network morphology, a mesoscopic model for them is developed. The predictions found by the model are compared with previous experimental results, and a good agreement between them is found to exist. The effect of some parameters, including the particle size, volume fraction and distribution, on the composite stiffness is analyzed. Finally, the reinforcing mechanism of network morphology is investigated by finite-element method.

Similar content being viewed by others

References

L. J. Huang, L. Geng, and H. X. Peng, “In situ (TiBw+TiCp)/Ti6Al4V composites with a network reinforcement distribution,” Mater. Sci. Eng. A, 527, No. 24, 6723-6727 (2010).

L. J. Huang, L. Geng, H. X. Peng, and J. Zhang, “Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture,” Scripta Mater., 64, No. 9, 844-847 (2011).

L. J. Huang, L. Geng, H. X. Peng, K. Balasubramaniam, and G. S. Wan, “Effects of sintering parameters on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with a novel network architecture,” Mater. Design, 32, No. 6, 3347-3353 (2011).

L. J. Huang, L. Geng, B. Wang, H. Y. Xu, and B. Kaveendran, “Effects of extrusion and heat treatment on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composite with a network architecture,” Compos. Part A, 43, 486-491 (2012).

H. T. Hu, L. J. Huang, L. Geng, B. X. Liu, and B. Wang, “Oxidation behavior of TiB-whisker-reinforced Ti60 alloy composites with three-dimensional network architecture,” Corros. Sci., 85, 7-14 (2014).

Y. Jiao, L. J. Huang, L. Geng, R. Zhang, S. Jiang, X. T. Li, and Y. N. Gao, “Strengthening and plasticity improvement mechanisms of titanium matrix composites with two-scale network microstructure,” Powder Technol., 356, 980-989 (2019).

Y. Zhou, D. L. Sun, D. P. Jiang, X. L. Han, Q. Wang, and G. H. Wu, “Microstructural characteristics and evolution of Ti2AlN/TiAl composites with a network reinforcement architecture during reaction hot pressing process,” Mater. Charact., 80, 28-35 (2013).

S. Tahamtan, A. Halvaee, M. Emamy, Z. Y. Jiang, and A. F. Boostani, “Exploiting superior tensile properties of a novel network-structure AlA206 matrix composite by hybridizing micron-sized Al3Ti with Al2O3 nano particulates,” Mater. Sci. Eng. A, 619, 190-198 (2014).

Z. Y. Zhang, G. Chen, S. L. Zhang, Y. T. Zhao, R. Yang, and M. P. Liu, “Enhanced strength and ductility in ZrB2/2024Al nanocomposite with a quasi-network architecture,” J. Alloy. Comp., 778, 833-838 (2019).

C. Y. Shang, T. F. Liu, F. M. Zhang, and F. Chen, “Effect of network size on mechanical properties and wear resistance of titanium/nanodiamonds nanocomposites with network architecture,” Compos. Commun., 19, 74-81 (2020).

H. B. Yang, S. Tian, T. Gao, J. F. Nie, Z. S. You, G. L. Liu, H. C. Wang, and X. F. Liu, “High-temperature mechanical properties of 2024 Al matrix nanocomposite reinforced by TiC network architecture,” Mater. Sci. Eng. A, 763, 138121 (2019).

Y. P. Jiang, L. G. Sun, Q. Q. Wu, and K. Qiu, “Enhanced tensile ductility of metallic glass matrix composites with novel microstructure,” J. Non-Cryst. Solids, 459, 26-31 (2017).

C. Xiao, L. Chen, Y. L. Tang, X. Zhang, K. Zheng, and X. Y. Tian, “Three dimensional porous alumina network for polymer composites with enhanced thermal conductivity,” Composit. Part A, 124, 105511 (2019).

C. Xiao, L. Chen, Y. L. Tang, X. Zhang, K. Zheng, and X. Y. Tian, “Enhanced thermal conductivity of silicon carbide nanowires (SiCw)/epoxy resin composite with segregated structure,” Composit. Part A, 116, 98-105 (2019).

M. C. Hu, J. Y. Feng, and K. M. Ng, “Thermally conductive PP/AlN composites with a 3-D segregated structure,” Compos. Sci. Technol., 110, 26-34 (2015).

F. E. Alam, W. Dai, M. H. Yang, S. Y. Du, X. M. Li, J. H. Yu, N. Jiang, and C. T. Lin, “In situ formation of a cellular graphene framework in thermoplastic composites leading to superior thermal conductivity,” J. Mater. Chem. A, 5, No. 13, 6164-6169 (2017).

L. C. Jia, D. X. Yan, C. H. Cui, X. Jiang, X. Jib, and Z. M. Li, “Electrically conductive and electromagnetic interference shielding of polyethylene composites with devisable carbon nanotube networks,” J. Mater. Chem. C, 3, No. 10, 9369 (2015).

M. H. Al-Saleh, “Electrical and electromagnetic interference shielding characteristics of GNP/UHMWPE composites,” J. Phys. D Appl. Phys., 49, No. 16, 195302 (2016).

P. Zhang, X. Ding, Y. Y. Wang, Y. Gong, K. Zheng, L. Chen, X. Y. Tian, and X. Zhang, “Segregated double network enabled effective electromagnetic shielding composites with extraordinary electrical insulation and thermal conductivity,” Composit. Part A, 117, 56-64 (2019).

M. Q. Sun, G. Gao, B. Dai, L. Yang, K. Liu, S. Zhang, S. Guo, J. C. Han, and J. Q. Zhu, “Enhancement in thermal conductivity of polymer composites through construction of graphene/nanodiamond bi-network thermal transfer paths,” Mater. Lett., 271, 127772 (2020).

H. Altenbach and V. Eremeyev, Thin-Walled Structural Elements: Classification, Classical and Advanced Theories, New Applications. In: Altenbach H., Eremeyev V. (eds) Shell-like Structures. CISM International Centre for Mechanical Sciences (Courses and Lectures), Springer (2017).

C. Kröner, H. Altenbach, and K. Naumenko, “Coupling of a structural analysis and flow simulation for short-fiberreinforced polymers: property prediction and transfer of results,” Mech. Compos. Mater., 45, No. 3, 249-256 (2009).

Y. P. Jiang and H. L. Fan, “A micromechanics model for predicting the stress–strain relations of filled elastomers,” Comput. Mater. Sci., 67, 104-108 (2013).

Y. P. Jiang, X. P. Shi, and K. Qiu, “A micromechanics-based incremental damage model for carbon black filled rubbers,” Composit. Part B, 75, 11-16 (2015).

R. M. Christensen and K. H. Lo, “Solutions for effective shear properties in three phase sphere and cylinder models,” J. Mech. Phys. Solids, 27, No. 4, 315-330 (1979).

J. C. Halpin and J. L. Kardos, “The Halpin–Tsai equations: A review,” Polym. Eng. Sci., 16, No. 5, 344-352 (1976).

L. H. Dai, Z. P. Huang, and R. Wang, “Explicit expressions for bounds for the effective moduli of multi-phased composites by the generalized self-consistent method,” Compos. Sci. Technol., 59, No. 11, 1691-1699 (1999).

J. Ba, X. H. Zheng, R. Ning, J. H. Lin, J. L. Qi, J. Cao, W. Cai, and J. C. Feng, “C/SiC composite-Ti6Al4V joints brazed with negative thermal expansion ZrP2WO12 nanoparticle reinforced AgCu alloy,” J. Eur. Ceram. Soc., 39, No. 4, 755-761 (2018).

K. B. Panda and K. S. R. Chandran, “First principles determination of elastic constants and chemical bonding of titanium boride (TiB) on the basis of density functional theory,” Acta Mater., 54, No. 6, 1641-1657 (2006).

Y. P. Jiang, H. Yang, and P. H. Chen, “Analytical study of morphologies for ultra high elastic stiffness of composites with aligned cylindrical fibers,” Compos. Struct., 94, No. 8, 2390-2396 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 57, No. 3, pp. 591-602, May-June, 2021.

Rights and permissions

About this article

Cite this article

Jiang, Y.P., Wu, J. & Zhu, Y. A Mesoscopic Model for Particle-Filled Composites with Network Microstructures. Mech Compos Mater 57, 415–424 (2021). https://doi.org/10.1007/s11029-021-09964-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-021-09964-z