Abstract

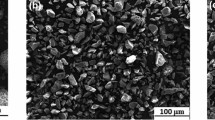

Thermal barrier coatings are widely used as surface modifications to enhance the surface properties of the material and protect from surface degradations such as erosion and corrosion. Ceramic-based coatings are highly recommended to increase wear resistance in the industrial sector. In this paper, an alumina-titania ceramic powder was deposited on an aluminum alloy using an atmospheric plasma spray technique. Experimental investigations were performed to study the behavior and erosion rate of the material. Solid particle erosion studies were performed by varying the particle velocity and particle flow rate. The angle impingement and stand-off distance were constant for comparison. The base metal has a clinging effect and the mass change was negative at a maximum particle flow rate of 4 g·min−1. Under the same process conditions, the coated sample had a reduced lifetime and reached a maximum erosion rate of 0.052 (Δg/g). The solid particle erosion studies confirmed that the base metal aluminum alloy had severe surface damage with erodent reinforcement when compared to the coated samples. The influence of the particle velocity, particle flow rate, and input process parameters were also identified.

Similar content being viewed by others

References

G.E. Totten and D.S. MacKenzie, Handbook of Aluminum, Vol. 2: Alloy Production and Materials Manufacturing, CRC Press, New York, 2003.

G.K. Nikas, Modeling dark and white layer formation on elastohydrodynamically lubricated steel surfaces by thermomechanical indentation or abrasion by metallic particles, J. Tribol., 137(2015), No. 3, art. No. 031504.

H.S. Grewal, A. Agrawal, and H. Singh, Slurry erosion performance of Ni-Al2O3 based composite coatings, Tribol. Int., 66(2013), p. 296.

S. Das, D.P. Mondal, and S. Sawla, Solid particle erosion of Al alloy and Al-alloy composites: Effect of heat treatment and angle of impingement, Metall. Mater. Trans. A, 35(2004), No. 4, p. 1369.

A.K. Jha, A. Gachake, B.K. Prasad, R. Dasgupta, M. Singh, and A.H. Yegneswaran, High stress abrasive wear behavior of some hardfaced surfaces produced by thermal spraying, J. Mater. Eng. Perform., 11(2002), No. 1, p. 37.

S. Fidan, E. Avcu, E. Karakulak, R. Yamanoglu, M. Zeren, and T. Sinmazcelik, Effect of heat treatment on erosive wear behaviour of Ti6Al4V alloy, Mater. Sci. Technol., 29(2013), No. 9, p. 1088.

T. Deng, M.S. Bingley, and M.S.A. Bradley, Understanding particle dynamics in erosion testers—A review of influences of particle movement on erosion test conditions, Wear, 267(2009), No. 11, p. 2132.

R.G. Rateick, J.L. Routbort, K.R. Karesk, and K. Elliot, Solid particle erosion of hard anodised and uncoated 6061-T651 aluminium alloy, Mater. Sci. Technol., 13(1997), No. 3, p. 217.

M.A. Chowdhury, U.K. Debnath, D.M. Nuruzzaman, and M.M. Islam, Experimental analysis of aluminum alloy under solid particle erosion process, Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol., 230(2016), No. 12, p. 1516.

J.R. Davis, Alloying: Understanding the Basics, ASM International, 2001.

M.A. Khan, S. Sundarrajan, and S. Natarajan, Influence of plasma coatings on Inconel 617 for gas turbine applications, Surf. Eng., 30(2014), No. 9, p. 656.

P. Uday Chandra Rao, P. Suresh Babu, D. Srinivasa Rao, S.V. Gopala Krishna, and K. Venkateswara Rao, Effect of tribo-layer on the sliding wear behavior of detonation sprayed aluminatitania coatings, [in] A.N.R. Reddy, D. Marla, M. Simic, M.N. Favorskaya, and S. Chandra Satapathy, eds., Intelligent Manufacturing and Energy Sustainability: Proceedings of ICIMES 2019, Springer, Singapore, 2020, p. 289.

P. Bagde, S.G. Sapate, R.K. Khatirkar, and N. Vashishtha, Friction and abrasive wear behaviour of Al2O3-13TiO2 and Al2O3-13TiO2+Ni Graphite coatings, Tribol. Int., 121(2018), p. 353.

M. Michalak, L. Łatka, P. Sokołowski, A. Niemiec, and A. Ambroziak, The microstructure and selected mechanical properties of Al2O3 + 13wt% TiO2 plasma sprayed coatings, Coatings, 10(2020), No. 2, art. No. 173.

S. Mehar, S.G. Sapate, N. Vashishtha, and P. Bagde, Effect of Y2O3 addition on tribological properties of plasma sprayed Al2O3-13% TiO2 coating, Ceram. Int., 46(2020), No. 8, p. 11799.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duraipandi, C., Khan M, A., Winowlin, J.J.T. et al. Solid particle erosion studies of thermally deposited alumina-titania coatings on an aluminum alloy. Int J Miner Metall Mater 28, 1186–1193 (2021). https://doi.org/10.1007/s12613-020-2099-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2099-8