Abstract

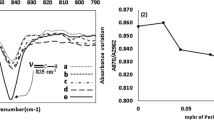

Liquid epoxidised natural rubber (LENR) is a low molecular weight form of epoxidised natural rubber (ENR) which was prepared via degradation of the said rubber in latex stage with redox reagent as degrading agents. The chemical behaviour of ENR latex as a starting material and LENR as a product upon storage were studied. The number average molecular weight (Mn), weight average of molecular weight (Mw), gel content and epoxidation level of ENR latex were consistent as the storage time increased. This indicated that the ENR latex was stable and suitable to be used up to six months of storage as the starting material for LENR preparation. The molecular weight of LENR prepared in reactor scale (LENR B) decreased by 24% from LENR A which prepared in laboratory scale. There were slight changes in the ring opening which was confirmed by nuclear magnetic resonance (NMR) and Fourier transform infrared (FTIR) spectroscopy. It was observed the properties of LENR such as molecular weight, epoxidation level, epoxy derivatives and gel content were almost consistent for one year of storage at room temperature.

Similar content being viewed by others

References

Baker CSL, Gelling IR (1987) Epoxidized natural rubber. Dev Rubber Technol 4:87–117

Hoon TC (2006) Epoxidized natural rubber (ENR-50) stabilized gold and platinum organosols. MSc dissertation, University of Sains, Malaysia

Azhar NH, Rasid HM, Yusoff SF (2017) Epoxidation and hydroxylation of liquid natural rubber. Sains Malays 46(3):485–491

Li SD, Chen Y, Zhou J, Li PS, Zhu CS, Lin ML (1998) Study on the thermal degradation of epoxidized natural rubber. J Appl Polym Sci 67(13):2207–2211

Solanky SS, Singh RP (2001) Ozonolysis of natural rubber: a critical review. Prog Rubber Plast Technol 17(1):13–58

Harmon DJ, Jacobs HL (1996) Degradation of natural rubber during mill mastication. J Appl Polym Sci 10(2):253–257

Gazeley KF, Mente PG (1990) Method for reducing the molecular weight of rubber latex. Malaysian Patent 1,00304-A 1990

Huy HT, Nga NT, Hong LQ, Son CP (1996) Depolymerization of natural rubber latex using phenylhydrazine-FeCl2 system. J Macromol Sci Part A Pure Appl Chem 33(12):1923–1930

Lemoine AJ (1989) Production of liquid natural rubber on a Pilot scale. RRIM

Chaikumpollert O, Sae-Heng K, Wakisaka O, Mase A, Yamamoto Y, Kawahara S (2011) Low temperature degradation and characterization of natural rubber. Polym Degrad Stab 96(11):1989–1995

Nor HM, Ebdon JR (1998) Telechelic liquid natural rubber: A review. Prog Polym Sci 23(2):143–177

Ibrahim S, Mustafa A (2014) Effect of reagents concentration and ratio on degradation of natural rubber latex in acidic medium. Malays J Anal Sci 18(2):405–414

Yusof NH, Nesan KVB, Rasdi FRM (2020) Controlling the characteristics of raw natural rubber by partial degradation in the latex stage using a water-soluble degrading agent. J Rubber Res 23:1–10

Tan KS, Yusof A (2003) Some studies on the effect of solvents in ENR 60 gel content measurements. J Rubber Res 6(4):189–194

Gelling IR (1985) A method of making epoxidized cis 1,4-polyisoprene rubber, UK Patent GB211113692

Kirichenko E, Dickerson KY, Lei MW (2015) Heat transfer in reactor scale-up, Thesis Worcester Polythecnic Institute, Massachusetts

González-González VA, Neira-Velázquez G, Angulo-Sánchez JL (1998) Polypropylene chain scissions and molecular weight changes in multiple extrusion. Polym Degrad Stab 60(1):33–42

Razak NA, Nor H, Wan Ali WK (2016) Synthesis of hydroxyl terminated epoxidized natural rubber as a binder for solid rocket propellant. Trans Tech Publ 695:127–130

Gelling IR (1991) Epoxidised natural rubber. J Nat Rubber Res 6(3):184–205

Davey JE, Loadman MJ (1984) A chemical demonstration of the randomness of epoxidation of natural rubber. Br Polym J 16(3):134–138

Hamzah R, Bakar MA, Khairuddean M, Mohammed IA, Adnan R (2012) A structural study of epoxidized natural rubber (ENR-50) and its cyclic dithiocarbonate derivative using NMR spectroscopy techniques. Molecules 17(9):10974–10993

Klinklai W, Kawahara S, Mizumo T, Yoshizawa M, Sakdapipanich JT, Isono Y, Ohno H (2003) Depolymerization and ionic conductivity of enzymatically deproteinized natural rubber having epoxy group. Eur Polym J 39(8):1707–1712

Yusof NH, Darji D, Baratha NKV, Rasdi FRM (2021) Preparation and characterization of liquid epoxidised natural rubber in latex stage by chemical degradation. J Rubber Res 24:93–106

Perera MSJ, Elix JA, Bradbury JH (1988) Furanized rubber studied by NMR spectroscopy. Polym Sci Part A Polym Chem 26:637

Saito T, Yoshimasa Y, Seiichi K, Yoshito O (2011) Characterization of Poly(1-methyl-1,4-butanediol-1,4-diyl/2,3,4-trihydro-5-methylfuran-2,5-diyl) prepared from natural rubber through 2D NMR spectroscopy. J Appl Polym Sci 122:3423

Sakdapipanich J (2014) Current study on structural characterization and unique film formation of Hevea brasiliensis natural rubber latex. Adv Mater Res 844:498–501

Yamamoto Y, Norulhuda SNB, Nghia PT, Kawahara S (2018) Thermal degradation of deproteinized natural rubber. Polym Degrad Stab 156:144–150

Rooshenass P, Yahya R, Gan SN (2016) Comparison of three different degradation methods to produce liquid epoxidized natural rubber. Rubber Chem Technol 89(1):177–198

Acknowledgements

The authors would like to thank the Malaysian Rubber Board for the research funding (SEAC-S17SRP0653B) and permission to publish this paper. Mr. Badroll Hisham Mohd Nazir, Mr. Hamdan Abu Bakar, Mr. Hishamuddin Samat, Mr Muhammad Saiful Mohamad Arip, Mr. Mohd Faizal Abd Aziz, Mr.Shafuddin Omar, Mrs Faezah Ismail Mrs Siti Mahirah.Romli are acknowledged for their excellent technical assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Darji, D., Yusof, N.H., Rasdi, F.R.M. et al. Characterisation of liquid epoxidised natural rubber (LENR) upon storage. J Rubber Res 24, 435–446 (2021). https://doi.org/10.1007/s42464-021-00112-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-021-00112-9