Abstract

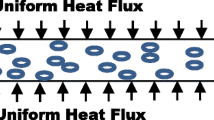

Air-cooling process is a very complex heat transfer involving the heat transfer theory and the fluid dynamics. In the paper, the experiment and numerical simulation methods are used to study the interfacial heat transfer and gas flow in the process of air-cooling, and an axisymmetric model is established to simulate the air-cooling process based on the fluid-thermal-solid coupling method. In the experiment and numerical simulation, the high-speed compressed air is used to impinge and cool the hot metallic surface. The temperatures attained in the experiment and numerical simulation are used to calculate the interfacial heat transfer coefficient (IHTC) by a self-developed inverse heat transfer analysis software. Considering the influence of turbulence model on flow, it found that the SST \(k - \omega\) turbulence model is more appropriate for the air-cooling process. Based on the SST \(k - \omega\) model, the effect of sample diameter and jet distance (distance from jet to cooling surface) on the flow pattern and temperature fields is studied, the results show that the temperatures attained in the numerical simulation are in good agreement with those of experiment, and the smaller the jet distance is, the bigger the IHTC is. Finally, the IHTCs under the different jet distance and inlet flow velocity are calculated based on the temperature curves attained in the numerical simulation.

Similar content being viewed by others

Abbreviations

- T :

-

Temperature (°C)

- ρ :

-

Density (kg·m−3)

- C p :

-

Specific heat (J·kg−1·°C−1)

- λ :

-

Thermal conductivity (W·m−1·°C−1)

- t :

-

Time (s)

- Z :

-

Direction in cylindrical coordinate system (m)

- r :

-

Direction in cylindrical coordinate system (m)

- q :

-

Surface heat flux (W·m−2)

- T f :

-

Temperature of compressed air (°C)

- τ :

-

Total shear stress (Pa)

- τ l :

-

Shear stress due to the laminar flow (Pa)

- τ T :

-

Shear stress due to the wall turbulence (Pa)

- u :

-

Flow velocity (m·s−1)

- v :

-

Kinematic viscosity (m2·s−1)

- ε m :

-

Turbulent momentum diffusivity (m2·s−1)

- q T :

-

Heat flux in wall turbulence (W·m−2)

- q r :

-

Heat flux contributed by wall turbulence (W·m−2)

- α :

-

Laminar thermal diffusivity (m2·s−1)

- ε T :

-

Turbulent thermal diffusivity (m2·s−1)

- μ T :

-

Turbulent viscosity (m2·s−1)

- u i :

-

Flow velocity (m·s−1)

- μ :

-

Dynamic viscosity (m2·s−1)

- k :

-

Turbulence Kinetic Energy (m3·s−2)

- ω :

-

Turbulent Dissipation Rate (m2·s−3)

- H :

-

Jet distance (m)

- d :

-

Diameter of sample(m)

- Nu :

-

Nusselt number

- G k :

-

Generation of k

- G ω :

-

Generation of ω

- Γ k :

-

Effective diffusivity of k

- Γ ω :

-

Effective diffusivity of ω

- Y k :

-

Dissipation of k

- Y ω :

-

Dissipation of ω

- D ω :

-

Generation of ω

References

Xu R, Li LX, Yao ZQ (2017) Numerical simulation and experimental verification of extrusion online quenching process of aluminum profile used for traffic. J Cent South Univ T 12:3263–3270. https://doi.org/10.11817/j.issn.1672−7207.2017.12.017

Fu P, Zhou P, Zhao TY, Song YP, Huang ZW (2020) Study of the heat transfer coefficient of a nickel-based superalloy in the end-quench test with air. Int J Therm Sci 155:106416. https://doi.org/10.1016/j.ijthermalsci.2020.106416

Kang H, Wu D, Zhao XM (2013) Surface Temperature Change of U75V 60 kg/m Heavy Rail During Heat Treatment. J Iron Steel Res Int 20(33–37):67. https://doi.org/10.1016/S1006-706x(13)60053-9

Guo Q, Wen Z, Dou RF (2017) Experimental and numerical study on the transient heat-transfer characteristics of circular air-jet impingement on a flat plate. Int J Heat Mass Tran 104:1177–1188. https://doi.org/10.1016/j.ijheatmasstransfer.2016.09.048

Li HP, Zhao GQ, Niu ST, Luan YG (2006) Inverse heat conduction analysis of quenching process using finite-element and optimization method. Finite Elem Anal Des 42:1087–1096. https://doi.org/10.1016/j.finel.2006.04.002

Hu P, Ying L, Li Y, Liao Z (2013) Effect of oxide scale on temperature-dependent interfacial heat transfer in hot stamping process. J Mater Process Tech 213:1475–1483. https://doi.org/10.1016/j.jmatprotec.2013.03.010

Li HP, He LF, Zhang CZ, Cui HZ (2015) Research on the effect of boundary pressure on the boundary heat transfer coefficients between hot stamping die and boron steel. Int J Heat Mass Tran 91:401–415. https://doi.org/10.1016/j.ijheatmasstransfer.2015.07.102

Wang HM, Yu W, Cai QW (2012) Experimental study of heat transfer coefficient on hot steel plate during water jet impingement cooling. J Mater Process Tech 212:1825–1831. https://doi.org/10.1016/j.jmatprotec.2012.04.008

Cheng H, Xie J, Li J (2004) Determination of surface heat-transfer coefficients of steel cylinder with phase transformation during gas quenching with high pressures. Comp Mater Sci 29:453–458. https://doi.org/10.1016/j.commatsci.2003.11.003

Luo X, Yang Z (2017) A new approach for estimation of total heat exchange factor in reheating furnace by solving an inverse heat conduction problem. Int J Heat Mass Tran 112:1062–1071. https://doi.org/10.1016/j.ijheatmasstransfer.2017.05.009

Liu XC, Ji K, El Fakir O, Fang HM, Gharbi MM, Wang LL (2017) Determination of the interfacial heat transfer coefficient for a hot aluminium stamping process. J Mater Process Tech 247:158–170. https://doi.org/10.1016/j.jmatprotec.2017.04.005

Ilkhchy AF, Jabbari M, Davami P (2012) Effect of pressure on heat transfer coefficient at the metal/mold interface of A356 aluminum alloy. Int Commun Heat Mass 39:705–712. https://doi.org/10.1016/j.icheatmasstransfer.2012.04.001

Taler J, Zima W (1999) Solution of inverse heat conduction problems using control volume approach. Int J Heat Mass Tran 42:1123–1140. https://doi.org/10.1016/s0017-9310(98)00280-4

Li HP, He LF, Zhang CZ, Cui HZ (2015) Solution of boundary heat transfer coefficients between hot stamping die and cooling water based on FEM and optimization method. Heat Mass Transfer 52:805–817. https://doi.org/10.1007/s00231-015-1602-7

Yang JT, Chen W, Li GF, Shi JH (2012) Numerical Simulation of Quenching Air Cooling Process for Steel Rail Based on Fluent. Hot Working Tech 41:165–167. https://doi.org/10.14158/j.cnki.1001-3814.2012.04.04616

Yang J, Zhang Y, Gao MX, Fu LH, Song H (2019) Numerical study of transient conjugate heat transfer of the cryo-supersonic air-quenching based on a Mach-weighted pressure-based method. Int J Heat Mass Tran 134:586–599. https://doi.org/10.1016/j.ijheatmasstransfer.2019.01.064

Xu ZZ, Liu XJ, Kim HK, Shin JH, Lyu SK (2011) Thermal error forecast and performance evaluation for an air-cooling ball screw system. Int J Mach Tool Manu 51:605–611. https://doi.org/10.1016/j.ijmachtools.2011.04.001

Ding CE, Dou RF, Chen C, Tian DP, Guo Q, Wen Z (2017) Experimental measurement of air jet impinging heat transfer coefficient based on 2D transient inverse heat conduction method. Energy Metall Ind 36:28–33. https://doi.org/10.3969/j.issn.1001-1617.2017.01.007

Wang XW, Li HP, He LF, Li ZC, Wang ZZ (2019) Estimated temperature-dependent interfacial heat transfer coefficient during gas cooling based on firefly algorithm and finite element method. Heat Mass Transfer 55:2545–2558. https://doi.org/10.1007/s00231-019-02608-y

Dou RF, Wen Z, Zhou G (2015) Heat transfer characteristics of water spray impinging on high temperature stainless steel plate with finite thickness. Int J Heat Mass Tran 90:376–387. https://doi.org/10.1016/j.ijheatmasstransfer.2015.06.079

Martin H (1977) Heat and mass transfer between impinging gas jets and solid surfaces. Adv Heat Tran Elsevier 13:1–60. https://doi.org/10.1016/S0065-2717(08)70221-1

Zargarabadi MR, Rezaei E, Yousefi-Lafouraki B (2018) Numerical analysis of turbulent flow and heat transfer of sinusoidal pulsed jet impinging on an asymmetrical concave surface. Appl Therm Eng 128:578–585. https://doi.org/10.1016/j.applthermaleng.2017.09.059

Liu X, Yue S, Lu L, Gao W, Li J (2018) Numerical Simulations of a Gas–Solid Two-Phase Impinging Stream Reactor with Dynamic Inlet Flow. Energies 11:1913. https://doi.org/10.3390/en11071913

Illyas SM, Bapu BRR, Rao VVS (2018) Heat transfer and flow visualization of swirling impinging jet on flat surface using helicoid inserts. J Visual-Japan 21:729–749. https://doi.org/10.1007/s12650-018-0493-3

Bazdidi-Tehrani F, Karami M, Jahromi M (2011) Unsteady flow and heat transfer analysis of an impinging synthetic jet. Heat Mass Tran 47:1363–1373. https://doi.org/10.1007/s00231-011-0801-0

Yu PP, Zhu KQ, Shi Q, Yuan NY, Ding JN (2017) Transient heat transfer characteristics of small jet impingement on high-temperature flat plate. Int J Heat Mass Tran 114:981–991. https://doi.org/10.1016/j.ijheatmasstransfer.2017.06.112

Zhu KQ, Yu PP, Yuan NY, Ding JN (2018) Transient heat transfer characteristics of array-jet impingement on high-temperature flat plate at low jet-to-plate distances. Int J Heat Mass Tran 127:413–425. https://doi.org/10.1016/j.ijheatmasstransfer.2018.07.099

Yang SM, Tao WQ (2006) Heat Transfer, 3rd edn. Higher Education Press, Beijing

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (51575324), Natural Science Foundation of Shandong Province (2019GGX104009), Shandong Province Key Laboratory of Mine Mechanical Engineering (2019KLMM104).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Below is the link to the electronic supplementary material.

Appendix 2

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zou, L., Ning, L., Wang, X. et al. Evaluation of interfacial heat transfer coefficient based on the experiment and numerical simulation in the air-cooling process. Heat Mass Transfer 58, 337–354 (2022). https://doi.org/10.1007/s00231-021-03113-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-021-03113-x