Abstract

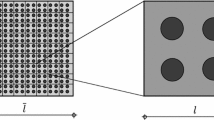

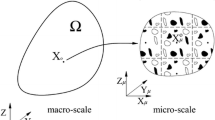

Multi-scale models enriched with the second gradient of the displacement field and based on the concept of representative volume element (RVE) are examined and discussed in detail in this paper. The development of new models relies on the Method of Multi-Scale Virtual Power from which equilibrium equations and homogenisation relations are derived employing variational arguments. Two classes of enhanced multi-scale constitutive models are analysed: standard second-order homogenisation and fully second-order homogenisation. On the computational side, the numerical treatment of second gradient equilibrium problems with a mixed approach is addressed systematically within an implicit finite element discretisation in conjunction with the full Newton–Raphson scheme for the iterative solution of the corresponding non-linear systems of equations. Different formulations available in the literature for standard second-order homogenisation are presented, along with a critical appraisal of their assumptions and limitations. A macroscopic second-gradient constitutive law with an orthotropic length scale is developed based on numerical findings. The impact of finite strains, the micro constituents’ behaviour, and the RVE morphology on the resulting macroscopic length scale parameter’s evolution is assessed. A fully second-order homogenisation-based model at finite strains is also presented. The suitability of this class of models to capture size effects due to the micro-constituent’s size is illustrated by an FE2 simulation.

Similar content being viewed by others

References

Abdoul-Anziz H, Seppecher P (2018) Strain gradient and generalized continua obtained by homogenizing frame lattices. Math Mech Complex Syst 6(3):213–250

Aifantis EC (1987) The physics of plastic deformation. Int J Plast 3(3):211–247

Akbarzadeh Khorshidi M (2018) The material length scale parameter used in couple stress theories is not a material constant. Int J Eng Sci 133:15–25. https://doi.org/10.1016/j.ijengsci.2018.08.005

Ameen M, Peerlings R, Geers M (2018) A quantitative assessment of the scale separation limits of classical and higher-order asymptotic homogenization. Eur J Mech A/Solids 71:89–100

Amstutz S, Giusti SM, Novotny AA, de Souza Neto EA (2010) Topological derivative for multi-scale linear elasticity models applied to the synthesis of microstructures. Int J Numer Meth Eng 84(6):733–756

Andrade F, Andrade Pires F, César de Sá J, Malcher L (2009) Nonlocal integral formulation for a plasticity-induced damage model. Comput Methods Mater Sci 9(1):49–54

Andrade F, de Sa JC, Pires FA (2011) A ductile damage nonlocal model of integral-type at finite strains: formulation and numerical issues. Int J Damage Mech 20:515–557

Andrade F, Andrade Pires F, César de Sá J (2014) Consistent tangent operators for implicit non-local models of integral type. Comput Struct 141(Supplement C):59 – 73

Andreaus U, Giorgio I, Placidi L, Lekszycki T, Luigi N (2016) Numerical simulations of classical problems in two-dimensional (non) linear second gradient elasticity. Int J Eng Sci 108:34–50. https://doi.org/10.1016/j.ijengsci.2016.08.003

Askes H, Aifantis EC (2011) Gradient elasticity in statics and dynamics: an overview of formulations, length scale identification procedures, finite element implementations and new results. Int J Solids Struct 48(13):1962–1990. https://doi.org/10.1016/j.ijsolstr.2011.03.006

Bacigalupo A (2014) Second-order homogenization of periodic materials based on asymptotic approximation of the strain energy: formulation and validity limits. Meccanica 49(6):1407–1425

Bagni C, Askes H (2015) Unified finite element methodology for gradient elasticity. Comput Struct 160:100–110. https://doi.org/10.1016/j.compstruc.2015.08.008

Barbagallo G, Madeo A, Azehaf I, Giorgio I, Morestin F, Boisse P (2017a) Bias extension test on an unbalanced woven composite reinforcement: experiments and modeling via a second-gradient continuum approach. J Compos Mater 51(2):153–170

Barbagallo G, Madeo A, Morestin F, Boisse P (2017b) Modelling the deep drawing of a 3D woven fabric with a second gradient model. Math Mech Solids 22(11):2165–2179. https://doi.org/10.1177/1081286516663999

Bažant Z, Lin FB (1988) Nonlocal yield-limit degradation. Int J Numer Methods Eng 26:1805–1823

Bažant Z, Pijaudier-Cabot G (1988) Nonlocal continuum damage, localization instability and convergence. J Appl Mech 55:287–290

Bazant Z, Jirásek M (2002) Nonlocal integral formulations of plasticity and damage: survey of progress. J Eng Mech 128(11):4133–4145

Bertram A (2017) Compendium on gradient materials. http://www.redaktion.tu-berlin.de/fileadmin/fg49/publikationen/bertram/Compendium_on_Gradient_Materials_Dec_2017.pdf

Bessa M, Bostanabad R, Liu Z, Hu A, Apley DW, Brinson C, Chen W, Liu WK (2017) A framework for data-driven analysis of materials under uncertainty: countering the curse of dimensionality. Comput Methods Appl Mech Eng 320:633–667

Biswas R, Poh L (2017) A micromorphic computational homogenization framework for heterogeneous materials. J Mech Phys Solids 102:187–208

Biswas R, Shedbale A, Poh L (2019) Nonlinear analyses with a micromorphic computational homogenization framework for composite materials. Comput Methods Appl Mech Eng 350:362–395

Bittencourt E (2018) On the effects of hardening models and lattice rotations in strain gradient crystal plasticity simulations. Int J Plast 108:169–185. https://doi.org/10.1016/j.ijplas.2018.05.004

Blanco P, Sánchez P, de Souza Neto E, Feijóo R (2016a) The method of multiscale virtual power for the derivation of a second order mechanical model. Mech Mater 99:53–67

Blanco PJ, Sánchez PJ, de Souza Neto EA, Feijóo RA (2016b) Variational foundations and generalized unified theory of RVE-based multiscale models. Arch Comput Methods Eng 23(2):191–253. https://doi.org/10.1007/s11831-014-9137-5

Boisse P, Hamila N, Madeo A (2016) Modelling the development of defects during composite reinforcements and prepreg forming. Philos Trans R Soc A 374(2071). https://doi.org/10.1098/rsta.2015.0269

Boisse P, Colmars J, Hamila N, Naouar N, Steer Q (2018a) Bending and wrinkling of composite fiber preforms and prepregs: a review and new developments in the draping simulations. Compos: Part B Eng 141:234–249. https://doi.org/10.1016/j.compositesb.2017.12.061

Boisse P, Hamila N, Madeo A (2018b) The difficulties in modeling the mechanical behavior of textile composite reinforcements with standard continuum mechanics of Cauchy: some possible remedies. Int J Solids Struct 154:55–65. https://doi.org/10.1016/j.ijsolstr.2016.12.019

Bosco E, Kouznetsova VG, Coenen EWC, Geers MGD, Salvadori A (2014) A multiscale framework for localizing microstructures towards the onset of macroscopic discontinuity. Comput Mech 54(2):299–319. https://doi.org/10.1007/s00466-014-0986-4

Bosco E, Kouznetsova VG, Geers MGD (2015) Multi-scale computational homogenization-localization for propagating discontinuities using X-fem. Int J Numer Meth Eng 102(3–4):496–527. https://doi.org/10.1002/nme.4838

Brand L (1947) Vector and tensor analysis. Wiley, London

Chakravarty S, Hadjesfandiari AR, Dargush GF (2017) A penalty-based finite element framework for couple stress elasticity. Finite Elem Anal Des 130:65–79. https://doi.org/10.1016/j.finel.2016.11.004

Coelho PG, Cardoso JB, Fernandes PR, Rodrigues HC (2011) Parallel computing techniques applied to the simultaneous design of structure and material. Adv Eng Softw 42(5):219–227. https://doi.org/10.1016/j.advengsoft.2010.10.003

Coenen E, Kouznetsova V, Geers M (2012a) Multi-scale continuous-discontinuous framework for computational-homogenization-localization. J Mech Phys Solids 60(8):1486–1507

Coenen EWC, Kouznetsova VG, Bosco E, Geers MGD (2012b) A multi-scale approach to bridge microscale damage and macroscale failure: A nested computational homogenization-localization framework. Int J Fract 178(1–2):157–178

Cosserat E, Cosserat F (1909) Théorie des Corps Déformables. Hermann and Fils

Dahlberg CF, Boåsen M (2019) Evolution of the length scale in strain gradient plasticity. Int J Plast 112:220–241. https://doi.org/10.1016/j.ijplas.2018.08.016

De Borst R, Mühlhaus H (1992) Gradient-dependent plasticity: formulation and algorithmic aspects. Int J Numer Meth Eng 35:521–539

de Souza Neto E, Amstutz S, Giusti S, Novotny AA (2010) Topological derivative-based optimization of micro-structures considering different multi-scale models 62(1):23–56

de Souza Neto E, Blanco P, Sánchez P, Feijóo R (2015) An RVE-based multiscale theory of solids with micro-scale inertia and body force effects. Mech Mater 80:136–144

de Souza Neto E, Feijóo R (2006) Variational foundations of multi-scale constitutive models of solid:: Small and large strain kinematical formulation. LNCC R&D Report 16/2006, LNCC

de Souza Neto E, Feijóo R (2010) Variational foundations of large strain multiscale solid constitutive models: Kinematical formulation. In: Júnior MV, de Souza Neto E, Muñoz Rojas PA (eds) Advanced Computational Materials Modeling: from Classical to Multiscale Techniques. Wiley-VCH

Dell’Isola F, Steigmann D (2015) A two-dimensional gradient-elasticity theory for woven fabrics. J Elast 118(1):113–125. https://doi.org/10.1007/s10659-014-9478-1

Dell’Isola F, Sciarra G, Vidoli S (2009) Generalized Hooke’s law for isotropic second gradient materials. Proc R Soc A 465(2107):2177–2196. https://doi.org/10.1098/rspa.2008.0530

Dell’Isola F, Della Corte A, Giorgio I (2017) Higher-gradient continua: the legacy of Piola, Mindlin, Sedov and Toupin and some future research perspectives. Math Mech Solids 22(4):1–21

Domenico DD, Askes H (2016) A new multi-scale dispersive gradient elasticity model with micro-inertia: formulation and C0-finite element implementation. Int J Numer Methods Eng 108(5):485–512. https://doi.org/10.1002/nme.5222

Eringen AC (1968) Mechanics of micromorphic continua. In: Kröner E (ed) Mechanics of generalized continua, Springer, Berlin, pp 18–35. http://link.springer.com/10.1007/978-3-662-30257-6_2

Ferrer A, Oliver J, Cante JC, Lloberas-Valls O (2016) Vademecum-based approach to multi-scale topological material design. Adv Model Simul Eng Sci 3(1):23

Ferretti M, Madeo A, Dell’Isola F, Boisse P (2014) Modeling the onset of shear boundary layers in fibrous composite reinforcements by second-gradient theory. Z für angewandte Math und Phys 65(3):587–612. https://doi.org/10.1007/s00033-013-0347-8

Feyel F, Chaboche JL (2000) FE2 multiscale approach for modelling the elastoviscoplastic behaviour of long fibre SiC/Ti composite materials. Comput Methods Appl Mech Eng 183:309–330

Fish J, Jiang T, Yuan Z (2012) A staggered nonlocal multiscale model for a heterogeneous medium. Int J Numer Methods Eng 91:142–157

Fish J, Yang Z, Yuan Z (2019) A second-order reduced asymptotic homogenization approach for nonlinear periodic heterogeneous materials. International Journal for Numerical Methods in Engineering https://onlinelibrary.wiley.com/doi/abs/10.1002/nme.6058

Fleck NA, Hutchinson JW (1997) Strain gradient plasticity. Advances in Applied Mechanics 33

Fleck NA, Willis JR (2015) Strain gradient plasticity: energetic or dissipative? Acta Mech Sin 31(4):465–472. https://doi.org/10.1007/s10409-015-0468-8

Fleck NA, Muller GM, Ashby MF, Hutchinson JW (1994) Strain gradient plasticity: theory and experiment. Acta Metall Mater 42(2):475–487

Fleck NA, Hutchinson JW, Willis JR (2015) Guidelines for constructing strain gradient plasticity theories. Trans ASME J Appl Mech 82(7):1–10

Fleischhauer R, Thomas T, Kato J, Terada K, Kaliske M (2019) Finite thermo-elastic decoupled two-scale analysis. Int J Numer Methods Eng. https://doi.org/10.1002/nme.6212

Forest S (2016) Nonlinear regularization operators as derived from the micromorphic approach to gradient elasticity, viscoplasticity and damage. Proc R Soc A 472. https://doi.org/10.1098/rspa.2015.0755

Forest S, Sievert R (2006) Nonlinear microstrain theories. Int J Solids Struct 43(24):7224–7245

Fritzen F, Leuschner M (2015) Nonlinear reduced order homogenization of materials including cohesive interfaces. Comput Mech 56(1):131–151

Fritzen F, Forest S, Böhlke T, Kondo D, Kanit T (2012) Computational homogenization of elasto-plastic porous metals. Int J Plast 29:102–119

Fritzen F, Hodapp M, Leuschner M (2014) GPU accelerated computational homogenization based on a variational approach in a reduced basis framework. Comput Methods Appl Mech Eng 278:186–217

Geers M, Kouznetsova V, Brekelmans W (2010) Multi-scale computational homogenization: trends and challenges. J Comput Appl Math 234(7):2175–2182

Geers MGD, Peerlings RHJ, Hoefnagels JPM, Kasyanyuk Y (2009) On a Proper Account of First- and Second-Order Size Effects in Crystal Plasticity. Advanced Engineering Materials 11(3):143–147, http://doi.wiley.com/10.1002/adem.200800287

Gitman I, Askes H, Sluys L (2008) Coupled-volume multi-scale modelling of quasi-brittle material. Eur J Mech A Solids 27:302–327

Giusti S, Blanco P, de Souza Neto E, Feijóo R (2009) An assessment of the Gurson yield criterion by a computational multi-scale approach. Eng Comput 26(3):281–301

Giusti SM (2009) Análise de sensibilidade topológica em modelos constitutivos multi-escalas. PhD thesis, Laboratório Nacional de Computação Científica

Goncalves BR, Karttunen AT, Romanoff J (2019) A nonlinear couple stress model for periodic sandwich beams. Compos Struct 212:586–597. https://doi.org/10.1016/j.compstruct.2019.01.034

Gortsas TV, Tsinopoulos SV, Rodopoulos D, Polyzos D (2018) Strain gradient elasticity and size effects in the bending of fiber composite plates. Int J Solids Struct 143:103–112

Gudmundson P (2004) A unified treatment of strain gradient plasticity. J Mech Phys Solids 52(6):1379–1406

Guedes JM, Kikuchi N (1990) Preprocessing and postprocessing for materials based on the homogenization method with adaptive finite element methods. Comput Methods Appl Mech Eng 83(2):143–198

Guha S, Sangal S, Basu S (2015) A review of higher order strain gradient theories of plasticity: origins, thermodynamics and connections with dislocation mechanics. Sadhana 40(4):1205–1240

Gurtin ME (2000) On the plasticity of single crystals: free energy, microforces, plastic-strain gradients. J Mech Phys Solids 48(5):989–1036

Hernández J, Oliver J, Huespe A, Caicedo M, Cante J (2014) High-performance model reduction techniques in computational multiscale homogenization. Comput Methods Appl Mech Eng 276:149–189

Hutchinson JW (2012) Generalizing J2 flow theory: fundamental issues in strain gradient plasticity. Acta Mech Sinica/Lixue Xuebao 28(4):1078–1086

Hütter G (2017) Homogenization of a Cauchy continuum towards a micromorphic continuum. J Mech Phys Solids 99:394–408. https://doi.org/10.1016/j.jmps.2016.09.010

Hütter G (2018) A theory for the homogenisation towards micromorphic media and its application to size effects and damage. Ph.D. thesis, Technische Universität Bergakademie Freiberg

Hütter G (2019) On the micro-macro relation for the microdeformation in the homogenization towards micromorphic and micropolar continua. J Mech Phys Solids 127:62–79

Hwang KC, Jiang H, Huang Y, Gao H, Hu N (2002) A finite deformation theory of strain gradient plasticity. J Mech Phys Solids 50(1):81–99

Jirásek M (1998) Nonlocal models for damage and fracture: comparison of approaches. Int J Solids Struct 35:4133–4145

Jirásek M, Patzák B (2002) Consistent tangent stiffness for nonlocal damage models. Comput Struct 80:1279–1293

Jirásek M, Rolshoven S (2003) Comparison of integral-type nonlocal plasticity models for strain-softening materials. Int J Eng Sci 41:1553–1602

Kaczmarczyk Ł, Pearce CJ, Bićanić N (2008) Scale transition and enforcement of RVE boundary conditions in second-order computational homogenization. Int J Numer Methods Eng 74(3):506–522. https://doi.org/10.1002/nme.2188

Kaczmarczyk Ł, Pearce CJ, Bićanić N (2010) Studies of microstructural size effect and higher-order deformation in second-order computational homogenization. Comput Struct 88(23–24):1383–1390

Kahrobaiyan MH, Rahaeifard M, Ahmadian MT (2014) A size-dependent yield criterion. Int J Eng Sci 74:151–161. https://doi.org/10.1016/j.ijengsci.2013.09.004

Kato J, Yachi D, Terada K, Kyoya T (2014) Topology optimization of micro-structure for composites applying a decoupling multi-scale analysis. Struct Multidiscip Optim 49(4):595–608

Keip MA, Steinmann P, Schröder J (2014) Two-scale computational homogenization of electro-elasticity at finite strains. Computer Methods in Applied Mechanics and Engineering 278:62–79

Khoei AR, Saadat MA (2019) A nonlocal computational homogenization of softening quasi-brittle materials. Int J Numer Methods Eng 98. https://doi.org/10.1002/nme.6070

Kouznetsova V (2002) Computational homogenization for the multi-scale analysis of multi-phase materials. PhD thesis, Technische Universiteit Eindhoven

Kouznetsova V, Brekelmans W, Baaijens F (2001) Approach to micro-macro modeling of heterogeneous materials. Comput Mech 27:37–48

Kouznetsova V, Geers M, Brekelmans W (2002) Multi-scale constitutive modelling of heterogeneous materials with a gradient-enhanced computational homogenization scheme. Int J Numer Meth Eng 54:1235–1260

Kouznetsova V, Geers M, Brekelmans W (2004a) Multi-scale second-order computational homogenization of multi-phase materials: a nested finite element solution strategy. Comput Methods Appl Mech Eng 193(48–51):5525–5550

Kouznetsova VG, Geers Professor MGD, Brekelmans WAM (2004b) Size of a representative volume element in a second-order computational homogenization framework. Int J Multiscale Comput Eng 2(4):575–598

Kwon YR, Lee BC (2017) Three dimensional elements with lagrange multipliers for the modified couple stress theory. Comput Mech https://doi.org/10.1007/s00466-017-1487-z

Lakes RS (2016) Physical meaning of elastic constants in cosserat, void, and microstretch elasticity. J Mech Mater Struct 11(3):217–229

Larsson R, Diebels S (2007) A second-order homogenization procedure for multi-scale analysis based on micropolar kinematics. Int J Numer Methods Eng 69(12):2485–2512. https://doi.org/10.1002/nme.1854

Lei J, He Y, Zhang B, Liu D, Shen L, Guo S (2015) A size-dependent FG micro-plate model incorporating higher-order shear and normal deformation effects based on a modified couple stress theory. Int J Mech Sci 104:8–23. https://doi.org/10.1016/j.ijmecsci.2015.09.016

Lesičar T (2015) Multiscale modeling of heterogeneous materials using second-order homogenization. PhD thesis, University of Zagreb

Lesičar T, Sorić J, Tonković Z (2016) Large strain, two-scale computational approach using C1 continuity finite element employing a second gradient theory. Comput Methods Appl Mech Eng 298:303–324

Lesičar T, Tonković Z, Sorić J (2017) Two-scale computational approach using strain gradient theory at microlevel. Int J Mech Sci 126:67–78

Li Z, He Y, Lei J, Guo S, Liu D, Wang L (2018) A standard experimental method for determining the material length scale based on modified couple stress theory. Int J Mech Sci 141:198–205. https://doi.org/10.1016/j.ijmecsci.2018.03.035

Liebenstein S, Zaiser M (2018) Determining Cosserat constants of 2D cellular solids from beam models. Mater Theory 2(2). http://arxiv.org/abs/1708.03545

Ling C, Forest S, Besson J, Tanguy B, Latourte F (2018) A reduced micromorphic single crystal plasticity model at finite deformations: application to strain localization and void growth in ductile metals. Int J Solids Struct 134:43–69

Liu D, Dunstan DJ (2017) Material length scale of strain gradient plasticity: a physical interpretation. Int J Plast 98:156–174. https://doi.org/10.1016/j.ijplas.2017.07.007

Lubarda VA (2016) On the recoverable and dissipative parts of higher order stresses in strain gradient plasticity. Int J Plast 78:26–43. https://doi.org/10.1016/j.ijplas.2015.10.010

Luscher DJ (2010) A hierarchical framework for the multiscale modeling of microstructure evolution in heterogeneous materials

Luscher DJ, McDowell DL, Bronkhorst CA (2010) A second gradient theoretical framework for hierarchical multiscale modeling of materials. Int J Plast 26(8):1248–1275. https://doi.org/10.1016/j.ijplas.2010.05.006

Lyu H, Hamid M, Ruimi A, Zbib HM (2017) Stress/strain gradient plasticity model for size effects in heterogeneous nano-microstructures. Int J Plast 97:46–63. https://doi.org/10.1016/j.ijplas.2017.05.009

Madeo A, Ferretti M, Dell’Isola F, Boisse P (2015) Thick fibrous composite reinforcements behave as special second-gradient materials: three-point bending of 3D interlocks. Z für Angew Math Phys 66(4):2041–2060. https://doi.org/10.1007/s00033-015-0496-z

Madeo A, Barbagallo G, D’Agostino MV, Placidi L, Neff P (2016) First evidence of non-locality in real band-gap metamaterials: determining parameters in the relaxed micromorphic model. Proc R Soc A: Math Phys Eng Sci 472. https://doi.org/10.1098/rspa.2016.0169

Marty J, Réthoré J, Combescure A (2016) Experimental investigation of higher-order homogenization schemes under large strain. Int J Solids Struct 88—-89:263–273

Massart TJ (2003) Multi-scale modeling of damage in masonry structures. PhD thesis, Technische Universiteit Eindhoven

Matouš K, Geers MG, Kouznetsova VG, Gillman A (2017) A review of predictive nonlinear theories for multiscale modeling of heterogeneous materials. J Comput Phys 330:192–220. https://doi.org/10.1016/j.jcp.2016.10.070

Matsui K, Terada K, Yuge K (2004) Two-scale finite element analysis of heterogeneous solids with periodic microstructures. Comput Struct 82:593–606

Matsushima T, Chambon R, Caillerie D (2002) Large strain finite element analysis of a local second gradient model: application to localization. Int J Numer Methods Eng 54(4):499–521. https://doi.org/10.1002/nme.433

Maugin GA, Metrikine AV (2010) Mechanics of Generalized Continua: One Hundred Years After the Cosserats, Advances in Mechanics and Mathematics, vol 21. Springer New York, New York, http://link.springer.com/10.1007/978-1-4419-5695-8

Mazzoni-Leduc L, Pardoen T, Massart T (2008) Strain gradient plasticity analysis of transformation induced plasticity in multiphase steels. Int J Solids Struct 45(20):5397–5418

Melro A, Camanho P, Pinho S (2008) Generation of random distribution of fibres in long-fibre reinforced composites. Compos Sci Technol 68(9):2092–2102

Miehe C, Koch A (2002) Computational micro-to-macro transitions of discretized microstructures undergoing small strains. Arch Appl Mech 72:300–317

Miehe C, Schotte J, Schröder J (1999a) Computational micro-macro transitions and overall moduli in the analysis of polycrystals at large strains. Comput Mater Sci 16:372–382

Miehe C, Schröder J, Schotte J (1999b) Computational homogenization analysis in finite plasticity simulation of texture development in polycrystalline materials. Comput Methods Appl Mech Eng 171:387–418

Mindlin R, Eshel N (1968) On first strain-gradient theories in linear elasticity. Int J Solids Struct 4(1):109–124

Mindlin RD (1964) Micro-structure in linear elasticity. Arch Ration Mech Anal 16:51–78

Monchiet V, Auffray N, Yvonnet J (2020) Strain-gradient homogenization: a bridge between the asymptotic expansion and quadratic boundary condition methods. Mech Mater 143:103309

Nellemann C, Niordson CF, Nielsen KL (2017) An incremental flow theory for crystal plasticity incorporating strain gradient effects. Int J Solids Struct 110–111:239–250. https://doi.org/10.1016/j.ijsolstr.2017.01.025

Nguyen VD, Noels L (2014) Computational homogenization of cellular materials. Int J Solids Struct 51(11–12):2183–2203. https://doi.org/10.1016/j.ijsolstr.2014.02.029

Nguyen VD, Becker G, Noels L (2013) Multiscale computational homogenization methods with a gradient enhanced scheme based on the discontinuous Galerkin formulation. Comput Methods Appl Mech Eng 260:63–77

Nguyen VP, Lloberas-Valls O, Stroeven M, Sluys LJ (2010) On the existence of representative volumes for softening quasi-brittle materials: a failure zone averaging scheme. Comput Methods Appl Mech Eng 199:3028–3038

Nguyen VP, Lloberas-Valls O, Stroeven M, Sluys LJ (2012a) Computational homogenization for multiscale crack modeling: implementation and computational aspects. Int J Numer Meth Eng 89:192–226

Nguyen VP, Stroeven M, Sluys LJ (2012b) Multiscale failure modeling of concrete: Micromechanical modeling, discontinuous homogenization and parallel computations. Comput Methods Appl Mech Eng 201–204:139–156

Oliver J, Caicedo M, Roubin E, Huespe A, Hernández J (2015) Continuum approach to computational multiscale modeling of propagating fracture. Comput Methods Appl Mech Eng 294:384–427

Otero F, Oller S, Martinez X (2018) Multiscale computational homogenization: review and proposal of a new enhanced-first-order method. Arch Comput Methods Eng 25(2):479–505. https://doi.org/10.1007/s11831-016-9205-0

Otero Gruer F (2015) Multiscale numerical modelling of microstructured reinforced composites. PhD thesis, Universitat Polit‘ecnica de Catalunya

Panteghini A, Bardella L (2018) On the role of higher-order conditions in distortion gradient plasticity. J Mech Phys Solids 118:293–321. https://doi.org/10.1016/j.jmps.2018.05.019

Papanicolopulos SA, Zervos A, Vardoulakis I (2009) A three-dimensional C1 finite element for gradient elasticity. Int J Numer Methods Eng 77(10):1396–1415. https://doi.org/10.1002/nme.2449

Peerlings R, De Borst R, Brekelmans W, De Vree J (1996) Gradient-enhanced damage for quasi-brittle materials. Int J Numer Meth Eng 39:1512–1533

Peerlings R, Geers M, De Borst R, Brekelmans W (2001) A critical comparison of nonlocal and gradient-enhanced softening continua. Int J Solids Struct 38(44–45):7723–7746

Petera J, Pittman JFT (1994) Isoparametric Hermite elements. Int J Numer Methods Eng 37(20):3489–3519. https://doi.org/10.1002/nme.1620372006

Phunpeng V, Baiz PM (2015) Mixed finite element formulations for strain-gradient elasticity problems using the FEniCS environment. Finite Elem Anal Des 96(C):23–40. https://doi.org/10.1016/j.finel.2014.11.002

Pijaudier-Cabot G, Bazant Z (1987) Nonlocal damage theory. J Eng Mech 113(10):1512–1533

Pinto Carvalho R, Rodrigues Lopes IA, Andrade Pires FM (2018) Prediction of the yielding behaviour of ductile porous materials through computational homogenization. Eng Comput 35(2):604–621. https://doi.org/10.1108/EC-03-2017-0069

Placidi L (2016) A variational approach for a nonlinear one-dimensional damage-elasto-plastic second-gradient continuum model. Continuum Mech Thermodyn 28(1–2):119–137

Poh LH, Sun G (2017) Localizing gradient damage model with decreasing interactions. International Journal for Numerical Methods in Engineering 110(6):503–522, http://doi.wiley.com/10.1002/nme.5364

Polizzoto C (2016) A note on the higher order strain and stress tensors within deformation gradient elasticity theories: physical interpretations and comparisons. Int J Solids Struct 90:116–121

Polizzotto C (2009) A nonlocal strain gradient plasticity theory for finite deformations. Int J Plast 25(7):1280–1300. https://doi.org/10.1016/j.ijplas.2008.09.009

Polizzotto C (2010) Strain gradient plasticity, strengthening effects and plastic limit analysis. Int J Solids Struct 47(1):100–112. https://doi.org/10.1016/j.ijsolstr.2009.09.019

Polizzotto C (2018) Anisotropy in strain gradient elasticity: simplified models with different forms of internal length and moduli tensors. Eur J Mech A/Solids 71:51–63

Quey R, Dawson P, Barbe F (2011) Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput Methods Appl Mech Eng 200(17–20):1729–1745

Reis F (2014) Multi-Scale Modelling and Analysis of Heterogeneous Solids at Finite Strains. PhD thesis, Faculdade de Engenharia da Universidade do Porto

Reis F, Andrade Pires F (2014) A mortar based approach for the enforcement of periodic boundary conditions on arbitrarily generated meshes. Comput Methods Appl Mech Eng 274:168–191

Reis F, Rodrigues Lopes I, Andrade Pires F, Andrade F (2018) Microscale analysis of heterogeneous ductile materials with nonlocal damage models of integral type. Comput Struct 201:37–57

Riesselmann J, Ketteler JW, Schedensack M, Balzani D (2020) Three-field mixed finite element formulations for gradient elasticity at finite strains. GAMM Mitteilungen 43(1):1–17. https://doi.org/10.1002/gamm.202000002

Roca D, Lloberas-Valls O, Cante J, Oliver J (2018) A computational multiscale homogenization framework accounting for inertial effects: application to acoustic metamaterials modelling. Comput Methods Appl Mech Eng 330:415–446

Rocha FF, Blanco PJ, Sánchez PJ, Feijóo RA (2018) Multi-scale modelling of arterial tissue: linking networks of fibres to continua. Comput Methods Appl Mech Eng 341:740–787. https://doi.org/10.1016/j.cma.2018.06.031

Rodrigues H, Guedes JM, Bendsoe MP (2002) Hierarchical optimization of material and structure. Struct Multidiscip Optim 24(1):1–10

Rodrigues Lopes IA (2019) Multi-scale modelling and analysis of multi-phase solids using second-order computational homogenisation at finite strains with parallel computing. PhD thesis, Faculdade de Engenharia, Universidade do Porto, https://repositorio-aberto.up.pt/bitstream/10216/120992/2/341468.pdf

Rodrigues Lopes IA, Andrade Pires FM. A fully second-order homogenisation formulation for the multi-scale modelling of heterogeneous materials. Submitted

Rodrigues Lopes IA, Andrade Pires FM. An assessment of multi-scale models based on second-order computational homogenisation. Submitted

Rodrigues Lopes IA, Andrade Pires FM. Formulation and numerical implementation of a variationally consistent multi-scale model based on second-order computational homogenisation at finite strains for quasi-static problems. Submitted

Rodrigues Lopes IA, Andrade Pires FM, Reis FJP (2018) A mixed parallel strategy for the solution of coupled multi-scale problems at finite strains. Comput Mech 61(1–2):157–180. https://doi.org/10.1007/s00466-017-1472-6

Rodrigues Lopes IA, Ferreira BP, Andrade Pires FM (2021) On the efficient enforcement of uniform traction and mortar periodic boundary conditions in computational homogenisation. Comput Methods Appl Mech Eng 384:113930. https://doi.org/10.1016/j.cma.2021.113930

Rokoš O, Ameen M, Peerlings R, Geers M (2019) Micromorphic computational homogenization for mechanical metamaterials with patterning fluctuation fields. J Mech Phys Solids 123:119–137

Rosi G, Auffray N (2016) Anisotropic and dispersive wave propagation within strain-gradient framework. Wave Motion 63:120–134. https://doi.org/10.1016/j.wavemoti.2016.01.009

Ryś M, Petryk H (2018) Gradient crystal plasticity models with a natural length scale in the hardening law. Int J Plast 111:168–187

Saavedra Flores E, de Souza Neto E, Pearce C (2011) A large strain computational multi-scale model for the dissipative behaviour of wood cell-wall. Comput Mater Sci 50(3):1202–1211

Saeb S, Steinmann P, Javili A (2016) Aspects of Computational Homogenization at Finite Deformations: a unifying review from Reuss’ to Voigt’s bound. Appl Mech Rev 68(5):050801

Sánchez PJ, Blanco PJ, Huespe AE, Feijóo RA (2013) Failure-oriented multi-scale variational formulation: micro-structures with nucleation and evolution of softening bands. Comput Methods Appl Mech Eng 257:221–247

Shekarchizadeh N, Abali BE, Barchiesi E, Bersani AM (2021) Inverse analysis of metamaterials and parameter determination by means of an automatized optimization problem. ZAMM Zeitschrift fur Angewandte Mathematik und Mechanik (January)

Shu JY, King WE, Fleck NA (1999) Finite elements for materials with strain gradient effects. Int J Numer Meth Eng 44(3):373–391

Smit R, Brekelmans W, Meijer H (1998) Prediction of the mechanical behavior of nonlinear heterogeneous systems by multi-level finite element modeling. Comput Methods Appl Mech Eng 155(1–2):181–192

Sridhar A, Kouznetsova VG, Geers MGD (2016) Homogenization of locally resonant acoustic metamaterials towards an emergent enriched continuum. Comput Mech 57(3):423–435. http://link.springer.com/10.1007/s00466-015-1254-y

Sridhar A, Kouznetsova V, Geers M (2018) A general multiscale framework for the emergent effective elastodynamics of metamaterials. J Mech Phys Solids 111:414–433, https://doi.org/10.1016/j.jmps.2017.11.017

Terada K, Hori M, Kyoya T, Kikuchi N (2000) Simulation of the multi-scale convergence in computational homogenization approaches. Int J Solids Struct 37(16):2285–2311

Toro S, Sánchez P, Huespe A, Giusti S, Blanco P, Feijóo R (2014) A two-scale failure model for heterogeneous materials: numerical implementation based on the finite element method. Int J Numer Meth Eng 97(5):313–351

Toro S, Sánchez P, Blanco P, de Souza Neto E, Huespe A, Feijóo R (2016a) Multiscale formulation for material failure accounting for cohesive cracks at the macro and micro scales. Int J Plast 76:75–110

Toro S, Sánchez PJ, Podestá JM, Blanco PJ, Huespe AE, Feijóo RA (2016b) Cohesive surface model for fracture based on a two-scale formulation: computational implementation aspects. Comput Mech 58(4):549–585. https://doi.org/10.1007/s00466-016-1306-y

Toupin RA (1962) Elastic materials with couple-stresses. Arch Ration Mech Anal 11:385–414. https://doi.org/10.1007/BF00253945

Toupin RA (1964) Theories of elasticity with couple-stress. Arch Ration Mech Anal 17(2):85–112

Voyiadjis GZ, Song Y (2019) Strain gradient continuum plasticity theories: theoretical, numerical and experimental investigations. Int J Plast 121:21–75. https://doi.org/10.1016/j.ijplas.2019.03.002

Willis JR (2019) Some forms and properties of models of strain-gradient plasticity. J Mech Phys Solids 123:348–356. https://doi.org/10.1016/j.jmps.2018.09.011

Wohlmuth BI (2001) Discretization methods and iterative solvers based on domain decomposition. Springer, Berlin

Wulfinghoff S, Böhlke T (2015) Gradient crystal plasticity including dislocation-based work-hardening and dislocation transport. Int J Plast 69:152–169

Xia L, Breitkopf P (2014) Concurrent topology optimization design of material and structure within FE2 nonlinear multiscale analysis framework. Comput Methods Appl Mech Eng 278:524–542. https://doi.org/10.1016/j.cma.2014.05.022

Xu M, Gitman IM, Askes H (2019) A gradient-enriched continuum model for magneto-elastic coupling: formulation, finite element implementation and in-plane problems. Comput Struct 212:275–288. https://doi.org/10.1016/j.compstruc.2018.11.004

Xu Y, Poh LH (2019) Localizing gradient-enhanced Rousselier model for ductile fracture. Int J Numer Methods Eng. https://doi.org/10.1002/nme.6074

Yang J, Lacroix R, Bergheau JM, Leblond JB, Mas F (2019) Some new applications of a second-gradient model for porous ductile materials. Eur J Mech A/Solids 76:180–192. https://doi.org/10.1016/j.euromechsol.2019.03.013

Yvonnet J, Auffray N, Monchiet V (2020) Computational second-order homogenization of materials with effective anisotropic strain-gradient behavior. Int J Solids Struct 191–192:434–448

Zervos A (2008) Finite elements for elasticity with microstructure and gradient elasticity. Int J Numer Meth Eng 73(4):564–595. https://doi.org/10.1002/nme.2093

Zervos A, Papanicolopulos SA, Vardoulakis I (2009) Two finite-element discretizations for gradient elasticity. J Eng Mech 135(3):203–213. https://doi.org/10.1002/nme.2449

Zhang X, Aifantis KE (2011) Interpreting strain bursts and size effects in micropillars using gradient plasticity. Mater Sci Eng A 528(15):5036–5043. https://doi.org/10.1016/j.msea.2011.02.049

Zhang X, Aifantis KE (2015) Interpreting the internal length scale in strain gradient plasticity. Rev Adv Mater Sci 41(1):72–83

Zybell L, Muehlich U, Kuna M, Zhang ZL (2012) A three-dimensional finite element for gradient elasticity based on a mixed-type formulation. Comput Mater Sci 52:268–273

Funding

The first author has been supported by Fundação para a Ciência e a Tecnologia (scholarship SFRH/BD/100093/2014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Determination of the Strong Form of a Second-gradient Equilibrium Problem

The strong form of the equilibrium problem may be determined from its weak version defined in Eq. (2) by developing each of the terms with integration by parts. This procedure is also described by Blanco et al. [23], Kouznetsova [88], Lesičar [97], Luscher [105].

The first term is developed as in a standard Cauchy continuum:

The development of the term related to the second gradient is performed in index notation:

hence

The gradient \(\nabla _X\delta {\varvec{u}}\) is not independent from \(\delta {\varvec{u}}\) thus it must be decomposed into its normal and surface components before proceeding:

As a consequence, the same decomposition can be applied to the divergence operator:

where \({{\,\mathrm{div}\,}}\delta {\varvec{u}}= \nabla _X\delta {\varvec{u}}: {\varvec{I}}\), \({{\,\mathrm{div}\,}}^t\delta {\varvec{u}}= \nabla _X^t\delta {\varvec{u}}: {\varvec{I}}\) and \({{\,\mathrm{div}\,}}^n\delta {\varvec{u}}= \left( D_0\delta {\varvec{u}}\otimes {\varvec{N}}\right) : {\varvec{I}}\).

Therefore, the term \(\left( {\mathsf{\bf Q}}\cdot {\varvec{N}}\right) : \nabla _X\delta {\varvec{u}}\) is developed according to this decomposition. Assuming that \({\varvec{A}} = {\mathsf{\bf Q}}\cdot {\varvec{N}}\), for the sake of simplification, then

The second term of the right-hand-side may be simply rewritten by

Regarding the first term, it is developed as follows:

According to Brand [30]

where \({\varvec{m}}\) denotes the external unit vector normal to the closed boundary curve \(\varGamma\) and tangent to the surface, obtained as \({\varvec{m}} = {{\boldsymbol{\tau }}} \times {\varvec{N}}\), with \({{\boldsymbol{\tau }}}\) denoting the unit vector tangent to the curve. The last term vanishes in the presence of a surface \(\partial \varOmega\) without the presence of edges or corners. If the surface has \(n_e\) edges, then the line integral can be expressed as [88]

Therefore, the integral

Finally, including the above developments, Eq. (2) is rewritten as

By standard variational arguments, since Eq. (313) must be satisfied for any admissible displacement variation \(\delta {\varvec{u}}\), the strong form of the equilibrium problem is expressed by the following set of equations:

Appendix 2: Determination of the Strong Form of the Micro-scale Equilibrium Problem

1.1 General Formulation

The strong form of the equilibrium problem is determined by setting \(\delta {\varvec{L}}= {\bf 0}\) and \(\delta {\mathsf{\bf M}}= {\bf 0}\) in Eq. (228), which leads to

Integrating by parts, the first term is developed to:

Similarly, the second term may be expressed as:

The first term of the above right-hand-side is further developed through integration by parts and decomposition of the gradient into its normal and surface components [155], leading to:

Including Eqs. (315)–(317) into (314), taking into account that \({\mathsf{\bf M}}\) is constant over the RVE, thus \({{\,\mathrm{div}\,}}{\mathsf{\bf M}}= 0\), results in

Therefore, by variational arguments, the strong form of this equilibrium equation is defined as:

1.2 Mixed Formulation

The strong form of the equilibrium problem is obtained by defining \(\delta {\boldsymbol{{\lambda }}} = {\bf 0}\), \(\delta {\varvec{L}}= {\bf 0}\) and \(\delta {\mathsf{\bf M}}= {\bf 0}\) in Eq. (268), and developing the remaining terms as shown next. The standard decomposition of the first term is repeated here:

Similarly, the second term is rewritten as:

Thereafter:

The terms related to the micro-scale constraints are expressed as

and

Finally, including these decompositions, the following expression arises:

The corresponding differential form is given by:

Rights and permissions

About this article

Cite this article

Rodrigues Lopes, I.A., Andrade Pires, F.M. Unlocking the Potential of Second-order Computational Homogenisation: An Overview of Distinct Formulations and a Guide for their Implementation. Arch Computat Methods Eng 29, 1339–1393 (2022). https://doi.org/10.1007/s11831-021-09611-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11831-021-09611-9