Abstract

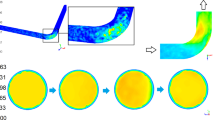

The erosive wear rate caused by slurry flow is the worst phenomenon associated with complex geometry like bend, curved cross section and rotating machinery. The numerous quantitative research is available in the past for findings of erosive wear rate through pipe bend, but findings of erosive wear rate through pipe bend using Fluent based various erosion models are not yet established. In the present work, erosion wear rate using four computational-based erosion models viz. Generic, Oka, Finnie and Mclaury through horizontal mitre pipe bend instigated by bottom ash particulates slurry has been investigated using Fluent code. The solid particulates of spherical shapes 162 µm, 300 µm and 445 µm having density 2219 kg/m3 were tracked to compute the erosion wear rate using Discrete Phase Model (DPM). The particulates were tracked using Eulerian–Lagrangian approach coupled with k−ɛ turbulent model at volume fraction ranging from 2.5 to 10% for wide range of velocities viz. 1–10 ms−1. Additionally, the results of DPM concentration, turbulence intensity, velocity and particle tracking using particulate residence time were predicted to analyze the erosive rate through pipe bend. The simulated outcomes show that the maximum erosion wear rate exists at the extrados of pipeline near the bend exit. Finally, the effects of particulate size, concentration and velocity were discussed on erosion wear rate. Furthermore, the simulated outcomes obtained through computational erosion models were verified with the available experimental data and findings show that the outcomes obtained with Generic model could be the benchmark for designing the slurry pipeline bend.

Similar content being viewed by others

Abbreviations

- C v :

-

Concentration by volume

- d p :

-

Particulate diameter

- D :

-

Pipe diameter [mm]

- \(g_{{o.PP}}\) :

-

Distribution Function [−]

- K fP :

-

Fluid particle exchange coefficient [−]

- K Pf :

-

Particle fluid exchange coefficient [−]

- \(\dot{m}_{{fP}}\) :

-

Mass transformation from f to p [kg s−1]

- \(\dot{m}_{{Pf}}\) :

-

Mass transformation from p to f [kg s−1]

- \(\overrightarrow {U} _{F}\) :

-

Mean velocity of fluid phase [ms−1]

- \(\overrightarrow {V} _{P}\) :

-

Mean velocity of particulate phase [ms−1

- ρ f :

-

Fluid phase density [Kg/m3]

- ρ m :

-

Pipe material density [Kg/m3]

- ρ P :

-

Particulate phase density [Kg/m3]

- \(\overline{\overline{\tau }} _{f}\) :

-

Stress tensor for fluid phase [N/m2]

- \(\overline{\overline{\tau }} _{P}\) :

-

Stress tensor for particle phase [N/m2]

- μ P ,col :

-

Collosional viscosity [Pa s]

- μ P ,fr :

-

Frictional viscosity [Pa s]

- μ P ,kin :

-

Kinetic viscosity [Pa s

- F :

-

Fluid

- P :

-

Particulate

References

Brown, G.J.: Erosion prediction in slurry pipeline tee-junctions. Appl. Math. Model 26(2), 155–170 (2002)

Mazumder, Q.H.; Shirazi, S.A.; McLaury, B.: Experimental investigation of the location of maximum erosive wear damage in elbows. J. Press. Vessel Technol. 130(1), 1–7 (2008)

Li, S.K.K.; Humphrey, J.A.; Levy, A.V.: Erosive wear of ductile metals by a particle-laden high velocity liquid jet. Wear 73(2), 295–309 (1981)

Tsai, W.J.A.I.; Humphrey, J.A.C.; Cornet, I.; Levy, A.V.: Experimental measurement of accelerated erosion in a slurry pot tester. Wear 68(3), 289–303 (1981)

Finnie, I.: Erosion of surfaces by solid particles. Wear 3(2), 87–103 (1960)

Bitter, J.G.A.: A study of erosion phenomena: part I. Wear 6(1), 2–5 (1963)

Grant, G.; Tabakoff, W.: Erosion prediction in turbomachinery resulting from Environmental solid particles. J Aircr 12(5), 471–478 (1975)

Hutchings, I.M.; Winter, R.E.; Field, J.E.: Solid particle erosion of metals: the removal of surface material by spherical projectiles. Proc. R. Soc. Lond. Math. Phys. Sci. 348(1654), 379–392 (1976)

Lushchik, V.G.; Yakubenko, A.E.: Comparative analysis of turbulence models for calculating a near-wall boundary layer. Fluid Dyn. 33(1), 36–47 (1998)

Oka, Y.I.; Okamura, K.; Yoshida, T.: Practical estimation of erosion damage caused by solid particle impact: part 1: effects of impact parameters on a predictive equation. Wear 259(1–6), 95–101 (2005)

McLaury, B.S.; Chen, X.; Shirazi, S.A.: Application and experimental validation of a computational fluid dynamics (CFD)-based erosion prediction model in elbows and plugged tees. Comput. Fluids 33(10), 1251–1272 (2004)

Neilson, J.H.; Gilchrist, A.: Erosion by a stream of solid particles. Wear 11, 111–122 (1968)

Meng, H.C.; Ludema, K.C.: Wear models and predictive equations: their form and content. Wear 181, 443–457 (1995)

Huang, C.S.; Chiovelli, P.; Minev Luo, J.; Nandakumar, K.: A comprehensive phenomenological model for erosion of materials in jet flow. Powder Technol. 187(3), 273–279 (2008)

Wood, R.J.K.; Jones, T.F.; Ganeshalingam, J.; Miles, N.J.: Comparison of predicted and experimental erosion estimates in slurry ducts. Wear 256(9–10), 937–947 (2004)

Tan, Y.; Zhang, H.; Yang, D.; Jiang, S.; Song, S.; Sheng, Y.: Numerical simulation of concrete pumping process and investigation of wear mechanism of the piping wall. Tribol. Int. 46(1), 137–144 (2012)

Zhang, H.; Tan, Y.; Yang, D.; Trias, F.X.; Jiang, S.; Sheng, Y.; Olivan, A.: Numerical investigation of the location of maximum erosive wear damage in elbow: effect of slurry velocity, bend orientation and angle of elbow. Powder Technol. 217, 467–476 (2012)

Njobuenwu, D.O.; Fairweather, M.: Modelling of pipe bend erosion by dilute particle suspensions. Comput. Chem. Eng. 42, 235–247 (2012)

Zeng, L.; Zhang, G.A.; Guo, X.P.: Erosion–corrosion at different locations of X65 carbon steel elbow. Corros. Sci. 85, 318–330 (2014)

Jafari, M.; Mansoori, Z.; Saffar Avval, M.; Ahmadi, G.; Ebadi, A.: Modeling and numerical investigation of erosion rate for turbulent two-phase gas–solid flow in horizontal pipes. Powder Technol. 267, 362–370 (2014)

Mahdi, E.; Rauf, A.; Eltai, E.O.: Effect of temperature and erosion on pitting corrosion of X100 steel in aqueous silica slurries containing bicarbonate and chloride content. Corros. Sci. 83, 48–58 (2014)

Safaei, M.R.; Mahian, O.; Garoosi, F.; Hooman, K.; Karimipour, A.; Kazi, S.N.; Gharehkhani, S.: Investigation of micro and nanosized particle erosion in a 90° pipe bend using a two-phase discrete phase model. Sci. World J. 74057, 1–12 (2014)

Chen, J.Y.; Wang, X.; Li, R.; He, S.; Han Chen, Y.: Erosion prediction of liquid-particle two-phase flow in pipeline elbows via CFD–DEM coupling method. Powder Technol. 275, 182–187 (2015)

Peng, W.; Cao, X.: Numerical prediction of solid particle erosion in pipe bends with liquid-solid flow. Powder Technol. 294, 266–279 (2016)

Duarte, C.A.R.; de Souza, F.J.: Innovative pipe wall design to mitigate elbow erosion: a CFD analysis. Wear 380, 176–190 (2017)

Singh, J.; Kumar, S.; Singh, J.P.; Kumar, P.; Mohapatra, S.K.: CFD modeling of erosion wear in pipe bend for the flow of bottom ash suspension. Particul. Sci. Technol. 37(3), 275–285 (2019)

Singh, K.P.; Kumar, A.; Kaushal, D.R.: Experimental investigation on effects of solid concentration, chemical additives, and shear rate on the rheological properties of bottom ash (BA) slurry. Int. J. Coal. Prep. Util. (2019). https://doi.org/10.1080/19392699.2019.1636787

Tarodiya, R.; Khullar, S.; Gandhi, B.K.: CFD modeling of multi-sized particulate slurry flow through pipe bend. J. Appl. Fluid Mech. 13(4), 1311–1321 (2020)

Cheng, L.; Mewes, D.: Advances in Multiphase Flow and Heat Transfer, Vol. 3. Bentham Science Publishers, Sharjah (2012)

Das, R.; Mishra, S.C.; Ajith, M.; Uppaluri, R.: An inverse analysis of a transient 2-D conduction–radiation problem using the lattice Boltzmann method and the finite volume method coupled with the genetic algorithm. J. Quant. Spectrosc. Radiat. Transf. 109(11), 2060–2077 (2008)

Mishra, S.C.; Kim, M.Y.; Das, R.; Ajith, M.; Uppaluri, R.: Lattice Boltzmann method applied to the analysis of transient conduction-radiation problems in a cylindrical medium. Numer. Heat Transf. A 56(1), 42–59 (2009)

Das, R.: A simulated annealing-based inverse computational fluid dynamics model for unknown parameter estimation in fluid flow problem. Int. J. Comut. Fluid Dyn. 26(9–10), 499–513 (2012)

Das, R.: Inverse analysis of Navier-Stokes equations using simplex search method. Inverse Probl Sci Eng 20(4), 445–462 (2012)

Singla, R.K.; Das, R.: Application of Adomian decomposition method and inverse solution for a fin with variable thermal conductivity and heat generation. Int. J. Heat Mass Transf. 66, 496–506 (2013)

Kaushal, D.R.; Kumar, A.; Tomita, Y.; Tsukamoto, K.S.H.: Flow of mono-dispersed particles through horizontal bend. Int. J. Multiph. Flow 52, 71–91 (2013)

Edwards, J.K.: Development, validation, and application of a three-dimensional, CFD-based erosion prediction procedure, Doctoral dissertation, University of Tulsa (2000)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Parkash, O., kumar, A. & Sikarwar, B.S. Computational Erosion Wear Model Validation of Particulate Flow Through Mitre Pipe Bend. Arab J Sci Eng 46, 12373–12390 (2021). https://doi.org/10.1007/s13369-021-05931-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05931-x