Abstract

This paper analyses and re-evaluates current explanations and interpretations of the origins, development and societal context of metallurgy in the Balkans (c. 6200–3700 BC). The early metallurgy in this region encompasses the production, distribution and consumption of copper, gold, tin bronze, lead and silver. The paper draws upon a wide range of existing archaeometallurgical and archaeological data, the diversity and depth of which make the Balkans one of the most intensively investigated of all early metallurgical heartlands across the world. We focus specifically on the ongoing debates relating to (1) the independent invention and innovation of different metals and metal production techniques; (2) the analysis and interpretation of early metallurgical production cores and peripheries, and their collapses; and (3) the relationships between metals, metallurgy and society. We argue that metal production in the Balkans throughout this period reflects changes in the organisation of communities and their patterns of cooperation, rather than being the fundamental basis for the emergence of elites in an increasingly hierarchical society.

Similar content being viewed by others

Introduction

This paper analyses the evidence for early metallurgy in the Balkans from the earliest use of copper minerals at c. 6200 BC (Late Mesolithic–Early Neolithic) to c. 3700 BC (end of the Chalcolithic) (Figs. 1, 2, 3; except where stated otherwise all dates given here are based on calibrated radiocarbon values). Early metallurgy in this region encompasses the production, distribution and consumption of copper, gold, tin bronze, lead and silver, all being either in the form of pure metals or natural, self-alloying bronze (i.e. produced as a result of smelting complex ores—in this case, copper-tin-bearing ores—as opposed to having been deliberately produced by exposing two or more metallic elements to high temperature treatment through co-smelting, cementation or alloying of metals, ores, or metallic mixtures, such as speiss).

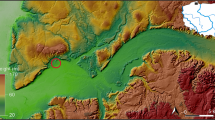

Map of the Early Neolithic sites (c. 6200–5500 BC) mentioned here. 1: Obre I; 2: Divostin; 3: Zmajevac; 4: Szarvas 23; 5: Gornea; 6: Lepenski Vir; 7: Vlasac; 8: Rudna Glava; 9: Balomir; 10: Iernut; 11: Cernica; 12: Durankulak; 13: Ovcharovo I; 14: Usoe I; 15: Karanovo; 16: Kolubara-Jaričište. Map CC BY-NC-ND 4.0 J. Pendić and M. Radivojević

There are, arguably, a total of six major heartlands of early metallurgical invention and/or innovation in western Eurasia (Radivojević et al. 2010b), each of which is—not coincidentally—also geologically rich in copper mineral deposits with widespread surface expressions. In addition to the Balkans—our focus here—these are Iberia (Kunst, 2013; Montero Ruiz & Murillo-Barroso, 2016; Montero Ruiz et al. 2021), Anatolia (Lehner & Yener, 2014), the Levant (Golden, 2010; Klimscha, 2013), the Caucasus (Courcier, 2014), and Iran (Helwing, 2013; Thornton, 2009a). Currently the Balkans are perhaps the most intensively investigated of these, from both archaeological and archaeometallurgical perspectives (see papers in Roberts & Thornton, 2014). We recognise the different cultural, historical and geographical meanings of the widely-used term Balkans (Todorova, 1997) and the complex way these have influenced archaeological research (cf. Gori & Ivanova, 2017); for the purposes of this paper, while we use the term Balkans geopolitically as a region defined by the Adriatic Sea to the west, the Ionian and Aegean seas to the southeast and southwest, and the Black Sea to the east, we focus only on those sites that display evidence of mining and metal production and/or use during the indicated time frame. Observing current political divisions, we recognise such sites as located in Serbia, Bulgaria, Romania, Hungary, Bosnia and Herzegovina (BiH or, informally, Bosnia), Northern Macedonia, and Greece. Evidence of the heaviest concentration of metal production and consumption is present in the first four countries (see Figs. 1, 2, 3 and Table 1). However, due to the nature of the evidence and of the current debates, archaeological and archaeometallurgical research from surrounding geographical regions will also be referenced throughout this paper.

In bringing together current analysis of metallurgical and archaeological data from across the Balkans, we aim to re-examine three major questions that relate to metal in its global prehistoric context:

-

1.

How did metallurgy in the Balkans develop?

-

2.

Why did metallurgy emerge in the Balkans?

-

3.

What was the relationship between early Balkan metallurgy and society?

These are classic and fundamental questions, and each is connected to its own deep history of scholarship and has produced answers in terms of a wide range of competing explanatory models. These questions are closely interrelated, and that they can now be re-evaluated is due to the application of an integrated science-based, theoretical and methodological approach that emphasises not simply the ‘when’ and the ‘where’ of early metallurgy but also the ‘how’ and the ‘why’. This paper thus seeks to contribute to an emerging trend in archaeological and archaeometallurgical scholarship, highlighted by Thornton (2009b) as marking a paradigm shift in global early metallurgical scholarship (see the special double issue of the Journal of World Prehistory, volume 22 [2009]; Thornton & Roberts, 2009), subsequently expanded in Roberts and Thornton (2014). There is now an identifiable convergence in early metallurgy scholarship towards recognizing the need to define and analyse the theories and underlying evidence surrounding concepts of invention (see papers in Roberts & Radivojević, 2015) and innovation (e.g. Burmeister et al. 2013; Frieman, 2021; Maran & Stockhammer, 2017; Ottaway, 2001; Rosenstōck et al. 2016; Scharl, 2016). In addition, there is also a much stronger expectation of robust interpretation of phenomena, given that all the available evidence from the production cycle, from ore sources to finished objects and their eventual recycling, loss or deposition, is analysed using a more holistic approach (cf. Ottaway, 1994; Shimada, 2007), and that the results are then compared, contrasted and integrated with comparable analyses of contemporary craft production in other materials (Miller, 2005, 2007). Moreover, we are increasingly witnessing a much more critical assessment of the value of long-held Childean ideas regarding early metallurgy, including the claimed close association with emerging elites and major societal transformations (e.g. Bartelheim, 2007; Biehl & Marciniak, 2000; Chapman, 1991, 2020; Kienlin, 2010; Kienlin & Zimmermann, 2012; Lichardus 1991c; Porčić, 2012b, 2019).

Scholarship in Early Balkan Metallurgy

The subject of early metallurgy in the Balkans has attracted scholarly attention for almost a century and was closely associated with early twentieth century investigations of Vinča-Belo Brdo (Vasić 1932–1936), the eponymous settlement of the Vinča culture, c. 5400–4600 BC (Fig. 2); the discovery of metal artefacts at the tell settlement of Pločnik in south Serbia (Grbić, 1929); and the excavation of Vinča-style pottery in copper-mining shafts at Jarmovac in southwestern Serbia (Davies, 1937). The Balkan Peninsula, and specifically its northern part, subsequently became a major focus for scholarship concentrating on early mining and metallurgy as a result of four key developments or factors.

Map of the Late Neolithic/Early Chalcolithic sites (c. 5500–4600 BC) mentioned here. 1: Mlynárce; 2: Neszmély; 3: Csöszhalom; 4: Hérpály; 5: Berettyószentmárton; 6: Zsáka-Markó; 7: Hódmezővársárhely-Kopáncs-Kökénydomb; 8: Gorsza; 9: Gomolava; 10: Gornja Tuzla; 11: Stapari; 12: Jarmovac; 13: Selevac; 14: Mali Šturac; 15: Divostin; 16: Ratina; 17: Pločnik; 18: Merovac; 19: Mačina; 20: Belovode; 21: Gornea; 22: Rudna Glava; 23: Hisarluka; 24: Anzabegovo; 25: Slatino; 26: Kamnik; 27: Dimini; 28: Sesklo; 29: Sitagroi; 30: Dikili Tash; 31: Maritsa; 32: Azmashka Mogila; 33: Ai Bunar; 34: Karanovo; 35: Medni Rid; 36: Golyamo Delchevo; 37: Targovište; 38: Varna; 39: Devnja; 40: Vinitsa; 41: Ovcharovo; 42: Radingrad; 43: Kubrat; 44: Ruse; 45: Polyanica; 46: Durankulak; 47: Cernavodă; 48: Izvoare I; 49: Lukavrublevetskaya; 50: Karbuna; 51: Pietrele; 52: Foeni; 53: Ždrelo; 54: Okolište; 55: Stubline; 56: Reșca (map CC BY-NC-ND 4.0 J. Pendić and M. Radivojević)

The first of these was the excavation of the copper mining sites Rudna Glava in Serbia and Ai Bunar in Bulgaria (Chernykh, 1978a; Jovanović, 1971, 1980, 1982), which were the subject of pioneering provenance studies (Pernicka et al. 1993, 1997). These two sites were identified as the cores of the Carpatho-Balkan Metallurgical Province (CBMP), an archaeometallurgical model which has been highly influential in the understanding of community interconnections across the Balkans and the Eurasian steppes (Chernykh & Kuzminykh, 1989; Chernykh et al. 2004; Chernykh, 1978b, 1992, 2013; Kohl, 2007; Koryakova & Epimakhov, 2007; Kuzmina, 2008; Yang et al. 2020). The abundance of copper deposits and the general richness of polymetallic veins across the Balkans has already been discussed at length as crucial for early access to minerals and experimentation. It is worth noting that, in the modern era, this rich metallogenic profile still supports a key industry in the region (e.g. Bogdanov, 1982; Janković, 1967, 1977, 1982; Jelenković et al. 2010; Monthel et al. 2002; Neubauer & Heinrich, 2003; Pernicka et al. 1993, 1997; Sillitoe, 1983).

The second development was the application of radiocarbon dating and, subsequently, archaeometallurgical research, which together revealed both the earliest known dates and the characteristics of copper metallurgy. Assessed against the evidence, this implied the independent invention of this technology in the Balkans (Glumac, 1991; Jovanović, 1980; Jovanović & Ottaway, 1976; Pernicka et al. 1997; Renfrew, 1969; Ryndina & Ravich, 2000, 2001; Todorova, 1978). The recent analysis of copper slag at the eastern Serbian Vinča culture site of Belovode, dating to c. 5000 BC (Radivojević & Kuzmanović-Cvetković, 2014; Radivojević & Rehren, 2016; Radivojević et al. 2010b; Radivojević, 2013, 2013b) served to reinvigorate the debate around the multiple inventions of metallurgy across Eurasia (see Montero Ruiz et al. 2021; Pearce, 2015; Pernicka, 2020; Radivojević, 2015; Roberts & Radivojević, 2015; Roberts et al. 2009; Rosenstock et al. 2016); in summary, however, we can now say that the Balkans have the earliest known evidence for the metallurgy of:

-

1.

Lead, dating probably from the end of the 6th millennium BC (Radivojević & Kuzmanović-Cvetković, 2014) but occurring more regularly from the mid 5th millennium BC in the central Balkans (Glumac & Todd, 1987), and later in the eastern Balkans (Hansen et al. 2019);

-

2.

Copper, from c. 5000 BC onwards in eastern Serbia (Radivojević & Kuzmanović-Cvetković, 2014; Radivojević & Rehren, 2016; Radivojević et al. 2010b; Radivojević, 2013, 2013b);

-

3.

Gold, dating from c. 4650 BC onwards in eastern Bulgaria (Higham et al. 2007, 2018; Krauss et al. 2014, 2017; Leusch et al. 2014);

-

4.

Bronze, from c. 4650 BC in southern Serbia and across Bulgaria (Chernykh, 1978b; Radivojević et al. 2013a, b, 2014a, b); and finally

-

5.

Silver (probably) by the end of the 5th/early 4th millennium BC in Greece (Maran, 2000; Muhly, 2002), produced by cupellation (i.e. not originating in native silver in its rare, nugget form).

The third factor was the emergence and development of a distinctive and well-supported scholarly tradition, best exemplified by the Prähistorische Bronzefunde series, that focussed on the construction of detailed typo-chronologies for all the catalogued early metal objects, around four thousand three hundred in number. These objects, primarily copper implements, were then placed at the core of archaeological narratives concerning the prehistoric Balkans and its surrounding regions (e.g. Antonović, 2014; Chernykh, 1992; Diaconescu, 2014; Driehaus, 1952–1955; Govedarica, 2001; Heeb, 2014; Kuna, 1981; Patay, 1984; Ryndina, 2009; Schubert, 1965; Taylor, 1999; Todorova, 1981; Vulpe, 1975; Žeravica, 1993).

The fourth and final development was the discovery, excavation, publication, and high-profile exhibition of the fifth millennium BC cemetery at Varna in Bulgaria, with its spectacular metallic grave inclusions (still unparalleled in volume by any other single site). Varna became central to the ongoing major debates relating to the existence (or non-existence) of elites, and the dynamics of apparent inequality, in the 5th and 4th millennia BC (e.g. Biehl & Marciniak, 2000; Chapman, 1991, 2013; Chapman et al. 2006; Crnobrnja, 2011; Fol and Lichardus, 1988; Hansen, 2013a; Higham et al. 2018; Ivanov, 1978b; Klimscha, 2014, 2020; Krauss et al. 2017; Leusch et al. 2017; Müller, 2012; Porčić, 2012b, 2019; Reingruber, 2014; Renfrew, 1978, 1986; Slavchev 2008).

With these four factors in mind, we can say that it is still the case that in Balkan prehistory metallurgy is understood mostly through the presence of copper mining and the typology and distribution of metal artefacts (mainly copper and gold), although such information reflects only the two extreme ends of the metal production process or cycle. Production debris such as slags and crucibles, despite its rarity (and infrequent recovery in the field or subsequent analysis) in the archaeological record of the Chalcolithic, is far more informative about the metalmaking recipes, and the transmission of metallurgical knowledge or ore provenance, than the morphology of the final products or their metallic origins (cf. Hauptmann, 2014; Killick, 2014; Martinón-Torres & Rehren, 2008, 2014; Rehren, 2003, 2008; Rehren et al. 2007). Slag, a by-product of metal extraction, is a vitreous, usually amorphous and highly magnetic material that typically contains traces of all components contributing to its formation while remaining largely resistant to post-depositional processes and dislocation (Bachmann, 1982). Slags can be found as free pieces but also attached to the walls of crucibles, furnaces, or slagged sherds, as is the case for early metal production in the Balkans (Radivojević & Rehren, 2016).

It should be noted that the deteriorating political situation in the Balkans from the 1990s onward, in the aftermath of the collapse of communism, hugely disrupted many early metal-orientated archaeological and archaeometallurgical research projects. The negative impact on fieldwork, publication and collaboration has been reversed only relatively recently, as evidenced by the successful growth of the Balkan Early Metallurgy Symposia (BEMS) meetings in London, UK (2007); Prokuplje, Serbia (2010); Sozopol, Bulgaria (2013) and Târgu Jiu, Romania (2015). This upsurge can also be seen in the continued prominence of metallurgical research within the festschrifts of major Neolithic–Copper Age Balkan archaeologists whose students and colleagues now occupy prominent positions in archaeological museums, university departments and research institutes (e.g. Forţiu & Cîntar, 2014; Stefanovich & Angelova, 2007; Ţerna & Govedarica, 2016). Metal-orientated scholarship is also very evident, not simply in the classic and still influential conference proceedings published as Die Kupferzeit als Historische Epoche (Lichardus, 1991b), but also in more recent proceedings from the three major international conferences published on the region: The Neolithic and Eneolithic in Southeast Europe (Schier & Draşovean, 2014); Neolithic and Copper Age between the Carpathians and the Aegean Sea: Chronologies and Technologies from the 6th to the 4th Millennium BC (Hansen et al. 2015); and Der Schwarzmeerraum vom Neolithikum bis in die Früheisenzeit (6000–600 V. Chr) (Schier and Nikolov 2016). All reflect the depth and influence of German scholarship—and the increasing use of English in publications.

It is therefore not surprising that, despite the rapid growth of settlement, landscape and environmental research and perspectives, interpretations of the life of prehistoric Balkan communities (and especially those of the 5th millennium BC) have been frequently influenced by the conventional, metal-orientated approaches in archaeological research in the area. These are derived from the seductive idea that the presence of craft specialisation indicated the presence of a complex social organisation (Childe, 1950), and that metal technology is tightly correlated with an increase in social complexity (e.g. Childe, 1944; Morgan, 1985 [1877]; White, 1959). This notion led to the pursuit of evidence for centralised decision making in any society with metallurgical practice. In turn, it made the Balkan case, with the earliest traces of metal making and the earliest large scale production and circulation of metal ornaments and implements, central to arguments concerning the advent of highly specialised knowledge in combination with the accumulation of individual wealth and emerging social hierarchy (e.g. Hansen, 2013b; Renfrew, 1978, 1986).

This metal construct is still frequently dominant in scholarship seeking to define the (elite) socio-economic dynamics of prehistoric communities, despite the fact that other materials such as ceramics, flint, polished stone, obsidian and spondylus (e.g. Amicone et al. 2019; Amicone et al. 2020a; Amicone et al. 2020b; Ifantidis & Nikolaidou, 2011; Klimscha, 2016; Milić, 2015; Spataro, 2018; Whittle et al. 2016; Windler 2018) were also comparably, or much more extensively, sourced, shaped, traded and/or deposited in settlements and graves both prior to and, later, along with metal objects. It is evident that, especially in the last decade, many major Balkan Neolithic/Chalcolithic projects have explicitly sought to push beyond traditional metal-orientated perspectives, especially given the significantly increased scale and depth of understanding of the non-metallurgical archaeological andenvironmental record in recent years. This is reflected in recent syntheses, whether encompassing the Balkans (Chapman, 2020) or the Black Sea region (Ivanova, 2013). In particular, research engaging with population dynamics, subsistence strategies, settlement practices, and responses to local and regional environmental and climatic change is thriving (e.g. Benecke et al. 2013; Chapman & Souvatzi, 2020; Filipović et al. 2017, 2018; Gaastra et al. 2018; Ivanova, 2012, 2020; Ivanova et al. 2018; Marić, 2013, 2015, 2017; Müller, 2012; Orton, 2010, 2017; Orton et al. 2016; Porčić et al. 2016; Porčić, 2011, 2012b, 2020; Silva & Vander Linden, 2017). It is also worth noting that several major, modern excavation and survey projects of Neolithic–Chalcolithic sites in the Balkans, such as Okolište (Bosnia), Uivar (Romania), and Vinča (Serbia) (Draşovean et al. 2017; Müller, 2013; Schier, 2014b; Tasić et al. 2016), have yet to document substantial metal objects or any clear evidence for metal production. However, where metal objects and/or metallurgical remains are found, as at Pietrele (Romania) (Hansen & Toderaş, 2012; Hansen et al. 2019), familiar interpretative narratives relating to metals and elites are proposed (Hansen, 2012, 2013a; Klimscha, 2020). The primary challenge, at least at the broader interpretative scale, in investigating the origins, development and societal inter-relationships of early metal objects and metallurgy in the Balkans, is to analyse and interpret the metal-orientated evidence, not in technological or intellectual isolation, but in relation to the other practices and activities of communities living in the region in the Late Neolithic and throughout the Chalcolithic (c. 6200–3700 BC).

Chronological Frameworks of Balkan Early Mineral and Metal Use, c. 6200–3700 BC

The relative chronological frameworks spanning the Balkans during the absolute date range of this paper (c. 6200–3700 BC) are notoriously complex, largely due to the accumulation of over a century of scholarly traditions that have varied significantly from country to country. In order to avoid confusion, the period related to the emergence of metallurgy throughout southeast Europe is referred to here as the Chalcolithic, in preference to either the Eneolithic (as used in the former Yugoslavia and Romania) or the Copper Age (as used in Hungary). The potential for confusion is especially pertinent to the term Eneolithic, used by archaeologists in the former Yugoslavia to refer to a period starting with the beginning of the use of metals from the mid–late 5th millennium BC; for Bulgarian archaeologists, this correlates with the Middle-to-Late Chalcolithic, when metals had already been widespread for centuries (e.g. Todorova, 1995). To facilitate navigation through the various labels used by Balkan archaeologists for the same phenomenon, we follow the Chalcolithic periodisation in the Balkans (Early, Middle, Late and Final) as it has been elaborated by Bulgarian scholars (see below).

The application of radiocarbon dating in the past few decades with, more recently, Bayesian statistics, has significantly influenced and strengthened the independent and relative temporal frameworks for Balkan prehistory between c. 6200 BC and 3700 BC (e.g. Bojadžiev, 2002; Forenbaher, 1993; Georgieva, 2012; Görsdorf & Bojadžiev, 1996; Higham et al. 2007, 2018; Krauss, 2008; Krauss et al. 2014, 2017; Lazarovici, 2006; Luca, 1999; Müller et al. 2013; Orton, 2017; Patay, 1974; Pernicka et al. 1993, 1997; Radivojević et al. 2010b; Schier, 1996, 2014a; Todorova, 1981, 1995; Vander Linden et al. 2014; Weninger et al. 2009; Whittle et al. 2016). This is especially true of recent intensive radiocarbon dating and Bayesian modelling of entire stratigraphic sequences at selected, well-excavated sites. Major radiocarbon dating projects across Neolithic Europe led by Alasdair Whittle (Whittle et al. 2002, 2016, 2018) have encompassed the sequences of the Balkan Neolithic–Chalcolithic Age sites of Uivar in Romania and Vinča-Belo Brdo in Serbia (Draşovean et al. 2017; Tasić et al. 2015, 2016). A further radiocarbon dating project across Late Neolithic–Early Bronze Age Greece and Bulgaria led by Zoï Tsirtsoni has also been recently completed (Tsirtsoni 2016b). These two major projects are further complemented by a range of smaller radiocarbon dating projects at specific sites, such as Belovode and Pločnik in Serbia (Radivojević & Kuzmanović-Cvetković, 2014; Radivojević et al. 2010b; Radivojević et al. in press). However, extensive radiocarbon dating remains absent at the majority of late 7th to early 4th millennium BC sites and, invariably, at potential copper mining sites and depositions of metal objects, right across the Balkans. It is still, therefore, the relative chronological frameworks based on ceramic types, and the traditional archaeological culture units—most of them identified a century ago—whose absolute date ranges are constantly being refined, as recently with Vinča culture ceramics (cf. Whittle et al. 2016). Further, the emergence in the twentieth century of rival national traditions of archaeological scholarship across the Balkans has frequently meant that virtually identical archaeological phenomena whose distribution crosses modern national borders have been assigned different nomenclatures, as in the case of the Starčevo-Criş-Körös cultural complex, where Körös and Criş are two names for the same river after which an Early Neolithic cultural phenomenon was named in Hungarian and Romanian respectively, while Starčevo refers to the down-river type site in northern Serbia. As a result, regional scholarship has been tasked with identifying the connections between these culture-historical sequences and then proposing new nomenclatures that integrate the pre-existing terms.

It is therefore not uncommon to see debates on the connections between the emergence of metallurgy and the Gradac phase of Vinča culture ceramic sequence, or the relationship between the development of metallurgy and the widespread graphite painted decoration on the ceramics of the Kodžadermen–Gumelniţa–Karanovo (KGK) IV cultural complex (e.g. Amicone et al. 2019, 2020b; Garašanin, 1995; Jovanović, 1971, 1994, 2006; Radivojević & Kuzmanović-Cvetković, 2014; Radivojević et al. 2010b; Renfrew, 1969; Spataro & Furholt, 2020; Spataro et al. 2019; Todorova, 1995; Todorova & Vajsov, 1993). As is now widely acknowledged in Balkan and world prehistory, the creation of spatial and temporal frameworks through the identification of similarities and differences in materials and practices continues to evade researchers; straightforward explanations are unlikely (cf. Gori & Ivanova, 2017; Roberts & Vander Linden, 2011; Shennan, 2013). It would seem inevitable that, despite well-argued proposals for abandoning relative typologies and cultures in the Balkans due to increased availability of improved independent scientific dating techniques (Tsirtsoni, 2016b), they will endure into future generations of archaeological scholarship.

The major interpretative problem that this creates with regards to early metallurgy is the need to connect a scientifically-based metallurgical practice or sequence with the pre-existing and convoluted culture-historical framework. The consequence is that an archaeological culture (now implicitly rather than explicitly related to a vaguely defined, large population group) becomes ‘metal producers’ and/or ‘metal consumers’, along with the intellectual baggage outlined above. The persistent influence of the culture-historical paradigm hampers the ability of metallurgical data, both old and new, to make an independent contribution to understandings of social and economic phenomena in the periods and regions under review.

Despite this less than ideal starting point, the recent application of complex network analyses to the chemical data of more than four hundred copper-based objects from 79 archaeological sites across the 7th to the 4th millennium BC in the Balkans has enabled the creation of statistically significant models of interconnections that are independent of traditional culture-chronologies (Grujić and Radivojević in press; Radivojević & Grujić, 2018). These not only enable pre-existing spatial and temporal cultural frameworks to be exposed to scrutiny, but also produce identifiable patterns of community interactions and cooperation whose changes through time can be investigated (see below). Importantly, the complex networks approach has engendered an interest in expanding the current compositional dataset of copper objects beyond the territories of modern-day Serbia, Bulgaria, and Bosnia-Herzegovina, and into Romania (e.g. Lazar et al. 2019; Stefan, 2008).

While the complex networks approach continues to develop, for the purposes of this paper we use the available relative and absolute dating, spanning c. 6200–3700 BC throughout the Balkans. We identify six periods, reflecting the changing characteristics of the metallurgical evidence, which enable questions surrounding metallurgical origins, development and societal inter-relationships to be addressed. These are: Early Neolithic (c. 6200–5500 BC); Late Neolithic (c. 5500–5000 BC); Early Chalcolithic (c. 5000–4600 BC); Middle Chalcolithic (c. 4600–4450 BC); Late Chalcolithic (c. 4450–4100 BC); and Final Chalcolithic (c. 4100–3700 BC). It should be stressed, however, that in certain areas the limited level of published and modern excavation makes it hard to evaluate the framework, as neither the radiocarbon-dating framework nor the available archaeometallurgical data are adequate. Our strongest focus remains, therefore, on the modern-day territories of Serbia, Bulgaria, Romania and Hungary (see Figs. 1, 2, 3), as the core area of activities related to mineral use and metallurgy. The majority of the period-definitions used to construct the chronological scheme for this article have been employed in earlier frameworks. The identification of a new 150-year period, spanning the mid 5th millennium BC (c. 4600–4450 BC: Middle Chalcolithic), reflects recent dating and current interpretations centred on the iconic—and still unparalleled—site of Varna, Bulgaria. One possibility here is that the site reflects a relatively short regional phenomenon, encompassing distinctive metal production and consumption evidenced by a growth in wealth (e.g. Biehl & Marciniak, 2000; Chapman, 2013; Schier, 2014a), although other factors may also have had a role.

Map of the Middle, Late and Final Chalcolithic sites (4600–3700 BC) mentioned here. 1: Zengővárkony; 2: Tiszapolgár-Basatanya; 3: Tibava; 4: Lucska; 5: Tiszapolgár–Hajdúnánás Road; 6: Moigrad; 7: Lazareva cave; 8: Gradeshnitsa; 9: Ariuşd; 10: Dolnoslav; 11: Dikili Tash; 12: Hotnica; 13: Bereketska Mogila; 14: Ai Bunar; 15: Karanovo; 16: Chatalka; 17: Kačica; 18: Smjadovo; 19: Kasla-–Dere; 20: Varna; 21: Kodžadermen; 22: Janka; 23: Mečkjur; 24: Ruse; 25: Vidra; 26: Gumelniţa; 27: Traian; 28: Alepotrypa Cave; 29: Akladi Cheiri; 30: Poduri; 31: Kmpije; 32: Bubanj (map CC BY-NC-ND 4.0 J. Pendić and M. Radivojević)

The extensive programmes of radiocarbon dating at Varna placing activities there between 4690 and 4330 BC (e.g. Higham et al., 2007, 2018; Krauss et al., 2017) have ensured that it is one of the most accurately-dated of all Chalcolithic sites in the Balkans at which evidence of metal production or metal objects have been found. Furthermore, the recent identification of a tin bronze object dating to c. 4650 BC at Pločnik, Serbia (Radivojević et al., 2013a, b) also appears to be the product of a distinct phase that may relate metals to the emerging socio-economic networks and community relationships across the eastern and central Balkans. The major changes in copper sources that occur during the mid 5th millennium BC (see networks section below), and the potential presence of contemporary silver objects, taken together with the evidence for gold and tin bronze, all suggest that further programmes of dating and analysis should explore the possibility of a technologically distinct and short-lived polymetallic horizon.

How and Why Did Metallurgy Emerge in the Balkans?

The possibility of being able to establish the origin of a defined phenomenon in prehistoric archaeology can be powerfully motivating, but as Clive Gamble suggested when he coined his playful concept of ‘Originsland’ (Gamble, 2007), it is usually more about imagination than actual evidence. While the present authors have argued elsewhere that an exception should be made for certain pyrotechnologies where preserved processes of invention and innovation might be analysed and identified (see papers in Roberts & Radivojević, 2015), we acknowledge that questions of origins are rarely straightforward. Scholarship debating the origins of metallurgy in the Balkans dates to the early antiquarian period in the mid 19th to the early 20th century (Childe, 1944; Grbić, 1929; Von de Pulsky, 1884), and consistently equated technological advancement, as expressed through evidence of pyrotechnological abilities, with temporal and societal change (see also reviews by Pearce, 2019; Schier, 2014a). This model also acknowledged the unique historical circumstances that may have dictated variations in the dynamics of innovations, and in their adoption and adaptation (Childe, 1951). The mid-to-late twentieth century saw the emergence of two highly influential opposing ideas that still structure many discussions. The first argued for the introduction of metallurgy to the Balkans by an external population group – that is, by archaeological cultures in-migrating from the east (e.g. Childe, 1929; Garašanin, 1973). The second was the identification of indigenous metal-using communities considered to represent the emergence of new Copper Age, Chalcolithic or Eneolithic societies at a local level in the Balkans (e.g. Gimbutas, 1980; Jovanović, 1971; Lichardus, 1991; Renfrew, 1969c). The debates surrounding the origin of metallurgy in the Balkans and Anatolia/Near East divided scholars into advocates of either independent invention or of migration/diffusion (see Bognár-Kutzián, 1976 for a summary). The perceived importance of the issues prompted some of the earliest applications of radiocarbon dating in world archaeology, and these were used to challenge the various Ex Oriente Lux interpretations with a model of independent invention (Jovanović & Ottaway, 1976; Renfrew, 1969, 1970; contra Wertime, 1964, 1973). Although highly controversial at the time (Makkay, 1976, p. 263), the overall temporal framework indicated by the early radiocarbon dates has now become widely accepted.

The independent invention model for Balkan metallurgy was subsequently further strengthened through various research initiatives and methodological advances. These included: assessment of the quantity, typology and metallurgy of cast shaft-hole axes (Charles, 1969); calibration of the new radiocarbon dates using dendrochronology (Renfrew, 1973); and stratigraphical observations at the excavations at Sitagroi (Greece; Fig. 2) that showed that the Serbian Vinča culture preceded the Early Bronze Age of Anatolia (i.e. Troy I) by more than two millennia (Renfrew, 1979, p. 139). Further supporting evidence accumulated during the 1970s, with the excavation and dating of copper mines at Ai Bunar (Chernykh, 1978a, 2008a) and the discovery of substantial numbers of gold and copper objects at the cemetery of Varna in Bulgaria (Ivanov & Avramova, 2000; Ivanov, 1978b). The ‘Ex Balcanae Lux’ model (Todorova, 1978) represented a new paradigm and caused a widespread re-appraisal of the origins of early technologies in the region (see Sterud et al., 1984 for a summary). As Thornton (2001) dryly noted, the major advocates for an independent invention of southeastern European metallurgy were also the most adamant diffusionists when it came to the spread of Neolithic subsistence practices and the origins of the Indo-European language zone (Gimbutas, 1973; Renfrew, 1987).

In addition to dominating the agenda for the ‘when’ and ‘where’ for the origins of metallurgy, Renfrew’s (1969) suggestion of a direct connection between the production of graphite-painted ceramics and the invention of copper metallurgy also provided a new explanatory framework for the ‘how’. His pyrotechnological transfer model was subsequently also advocated by Gimbutas (1976), although it was not to be investigated from a comparative pyrotechnological perspective until nearly four decades later (Amicone, 2017; Amicone et al., 2020b). A partial model for the ‘why’ that went beyond the back-projection of assumed ideas concerning value (e.g. Renfrew’s ‘prime value’ concept for gold: Renfrew, 1986) and the innate desirability of metals, as used by advocates both of independent invention and diffusion, was provided by Glumac (1991). Glumac made the connection between the use of ores for decoration and early metal use in the context of the Balkans—an approach subsequently extended across Anatolia and the Near East by Thornton (2001). The early use, across the Starčevo and (subsequently) early Vinča occupation horizons, of specific types of copper minerals (black-and-green manganese-rich copper carbonates) that were later smelted to produce the earliest known copper metal, has most recently been shown to be a unique technological trait of Balkan metallurgy, and further reinforces the idea that an independent invention of metal making took place here, even if symbolic practices involving the decorative use of metallic minerals had previously diffused in from the Near East (Radivojević et al., 2010b; Radivojević, 2013a, b, 2015).

There are consequently three definable, yet partially interrelated, models for the origins of metallurgy in the Balkans. All are primarily focussed on copper minerals/ores (rather than gold, tin bronze or lead) and the ambiguous relationship with ceramic pyrotechnology. Underlying each of these models are the motivations of the people involved in identifying, selecting and smelting copper ores and their knowledge of and relationship with pre-existing pyrotechnologies.

These models are:

-

1.

The migration of individuals and groups from the east with the necessary knowledge of the selection of copper minerals/ores, and expertise in pyrotechnology;

-

2.

The transmission, via existing socio-economic networks, of knowledge and expertise relating to copper ores, copper minerals and pyrotechnology from the east into communities in the Balkans;

-

3.

The independent invention of metallurgy by communities in the Balkans who exploited the rich abundance of copper minerals and their knowledge of them and, through time, adapted their pyrotechnological expertise to smelt metal.

The three models can be evaluated against established data as well as recent research leading up to and including the Rise of Metallurgy in Eurasia project (Radivojević et al. in press). Each of the models will be evaluated below, looking at both the Early Neolithic (c. 6200–5500 BC) and the Late Neolithic (c. 5500–5000 BC).

Mineral and Ore Selection

Copper minerals in the archaeological record are not necessarily copper ores. Ore is a culturally-defined concept, referring to agglomerations of minerals from which the extraction of one or more metals is seen as a profitable action, and in pre-industrial times criteria of profitability may have been different (e.g. Radivojević & Rehren, 2016; Rapp, 2009; Rehren, 1997). In other words, what the modern mining industry considers the economically feasible exploitation of mineral resources today differs from what prehistoric miners saw as an acceptable investment of labour. Put simply, if a mineral is smelted then it can be considered to have been an ore. The significance of this distinction in the context of metallurgical activities has been raised by Muhly (1989), who compared the relationship of malachite (copper carbonate) and copper metallurgy at an archaeological site to that of haematite (iron oxide) in a cave painting and iron metallurgy. Muhly’s point was that, just as Palaeolithic cave painters were not making iron, and had other reasons for collecting ochre, the presence of malachite manuports in prehistoric contexts should not be seen only in direct relation to copper metallurgy. This distinction between the use of copper minerals and smelting of copper ores is of immense importance in understanding the economic value ascribed to raw materials used for making copper metal. It nonetheless remains fundamentally important to record the presence of copper minerals and ores, especially within the context of debates regarding early metallurgy.

The earliest evidence for the use of copper minerals in the Balkans occurs during the transition to the Early Neolithic (or the emergence of Starčevo-Criş-Körös culture groups) in c. 6200–5500 BC, with evidence spanning the Carpathian Basin, Moldavia, western Ukraine and northern Balkans (Bognár-Kutzián, 1976, pp. 70–73). The earliest exploitation of copper minerals was possibly by hunter-fisher-gatherer communities (likely mixed with the early farming population migrating from Anatolia; see, for instance, Mathieson et al. 2018). This is indicated by samples discovered at Lepenski Vir, Vlasac and Kolubara-Jaričište (Fig. 1) and dated to c. 6200 BC (Radivojević, 2015: 325; Srejović & Letica, 1978, pp. 11–14). The processing of copper minerals and native copper developed within the subsequent Neolithic Starčevo-Criş-Körös culture groups; these groups mostly produced beads from malachite [Cu2CO3(OH)2] or azurite [Cu3(CO3)2(OH)2]. In addition to malachite and azurite beads from Lepenski Vir and Divostin I (Glumac, 1988, p. 460; Radivojević, 2012; Srejović, 1969, p. 173; 1972, p. 146), similar items were found in the cemeteries of Cernica in southern Romania and Durankulak in north-eastern Bulgaria, and the settlements of Obre I in Bosnia, and Ovcharovo I and Usoe I in Bulgaria (Cantacuzino & Morintz, 1963, pp. 72–75, fig. 28: 18, 19; Pernicka et al. 1997, p. 44; Sterud & Sterud, 1974, p. 258; Stratton et al. 2019; Todorova, 1981, p. 4; Vlassa, 1967). Lumps and flakes of copper minerals were also identified in the settlements of Zmajevac in eastern Serbia and at Szarvas 23 in Hungary (cf. Bailey, 2000, p. 210; Chapman, 1981, p. 131; Chapman & Tylecote, 1983, p. 375; Comşa, 1991, p. 51; Fig. 1). Malachite beads and copper minerals are also commonly found in early Vinča culture settlements (pre-5000 BC) at the sites of Belovode, Pločnik, Vinča-Belo Brdo, Selevac and Medvednjak (Fig. 2), and occur continually until the abandonment of the settlements, as well as throughout other, later Vinča culture manifestations, such as Gomolava (Glumac & Tringham, 1990; Radivojević, 2012; Radivojević & Kuzmanović-Cvetković, 2014; Šljivar 1993–2009; Šljivar and Kuzmanović-Cvetković 1996–2009). At the sites of Belovode and Pločnik, also excavated by the authors of this article (Radivojević et al. in press), green malachite was found in every excavation spit, every feature, and every defined horizon; it was dispersed across the excavated areas, at times without an obvious spatial pattern, although much more frequently in the later stages of the occupation of each site (post-5000 BC). Significantly, at Divostin II (Vinča D phase), malachite beads were predominantly found in a group of rather large houses, where a metal bracelet was also present (McPherron & Srejović, 1988). The beads and bracelet were interpreted as a possible indication of the higher status of the occupants, on the basis that larger households would have a larger labour force available to create a surplus and therefore an economic advantage (Porčić, 2012b).

The provenance analyses of most of the minerals found at Lepenski Vir, Vlasac and the Vinča culture sites indicated the use of local sources, predominantly Majdanpek in eastern Serbia, then Ždrelo (near Belovode; Fig. 2), and an as yet unidentified copper source consistent with most of the Pločnik minerals and metal artefacts and copper slags from Belovode (Pernicka et al. 1993, p. 6; 1997, p. 93 ff.; Radivojević, 2012; Radivojević et al. 2010b, p. 2784; Fig. 10). The only securely dated source where there is evidence for copper mineral exploitation within this period is at the site of Rudna Glava, in Serbia (Fig. 2), where copper mining activities intensify from c. 5500 BC in parallel with copper mineral use at nearby Belovode (O'Brien, 2015; Radivojević & Kuzmanović-Cvetković, 2014). Importantly, the inhabitants of this site appear to have distinguished between pure green copper minerals (malachite) as a resource suitable for bead making (hence bead minerals) and what they may have considered ‘tainted’ manganese-rich black-and-green copper ores, used for the smelting charge (Fig. 4a). This supposition is strengthened by the identification of distinctively different lead isotope signatures for the bead minerals and ores smelted at Belovode, indicating existing knowledge of the different properties of these materials (Radivojević et al. 2010b, p. 2784). A similar practice of differentiation between pure green copper minerals and black-and-green manganese-rich copper ores has been detected throughout the Vinča occupation at the sites of Vinča-Belo Brdo and Pločnik (Fig. 2), indicating an awareness of the material properties of these distinctive copper occurrences for around eight hundred years across all these settlements (Radivojević & Rehren, 2016, p. 215).

Copper mineral and metallurgical evidence from mid 6th–mid 5th millennium BC. a typical malachite bead on the left and a black-and-green mineral on the right (Belovode); b copper slag from Belovode; c ceramic sherd with copper slag overflowing its top, most likely used to line a hole-in-the-ground smelting installation (Belovode); d ceramic sherd with copper slag (Foeni); e & f ceramic nozzle, potentially used for (s)melting (Bubanj, see also in Bulatović, 2015) (adapted after Radivojević, 2012; CC BY-NC-ND 4.0 M. Radivojević and Lj. Radivojević)

Artefacts made of native copper appear in the Balkans only at the start of the Late Neolithic (c. 5500–5000 BC), but most have been only relatively dated and their cultural provenience is debatable. One out of three such artefacts, a fragmented copper object from Iernut (Horedt, 1976; Lazarovici, 1979, 2014; Mareş, 2002), a site located deep in the Carpathian Mountains in Romania (Fig. 1), has been ascribed to the last phase of the Starčevo-Criş-Körös phenomenon (mid 6th millennium BC). A 14 cm-long double pointed awl, discovered at the site of Balomir (Fig. 1) is the earliest identified implement made of native copper in the Balkans (Vlassa, 1967, pp. 407, 423; Fig. 6). It is relatively dated to the mid 6th millennium BC, around the same time as a fish hook from the site of Gornea in the Danube Gorges (Lazarovici, 1970, p. 477). While it is challenging to distinguish between the use of native copper and metal made from smelted copper ores, Pernicka (1990) argues that increased concentrations of cobalt (Co) and nickel (Ni) are a useful indicator of copper artefacts made of smelted copper. Pernicka synthesised Balkan and Anatolian copper metal artefact trace element data and compared these to the analyses of native copper from these same regions. The Co and Ni concentrations in native copper (approximately < 20 ppm) are extremely low in comparison to the much higher concentrations of these elements in both Balkan and Anatolian copper metal artefacts (Pernicka et al. 1997, pp. 124, 159–160, fig. 23, table A3a). Interestingly, a few copper implements from Pločnik show borderline concentrations of Co and Ni (Pernicka et al. 1997, pp. 147–148, table A1), which might indicate a native copper origin. There is no evidence for the exploitation of native gold or silver in this period, despite the geological potential throughout the Balkans (e.g. Jovanović, 2001).

Evidence suggests that use of copper mineral and native copper in neighbouring Anatolia and the Near East occurred much earlier than in the Balkans. The earliest example dates back to the 11th millennium BC Epipalaeolithic burial site of Shanidar Cave, where a malachite bead was deposited as a grave offering (Bar-Yosef, 2008; Solecki et al. 2004, p. 96). By the 9th millennium BC, native copper and copper minerals were increasingly worked, as at the settlement of Çayönü Tepesi in eastern Turkey, a site which also yielded evidence for the annealing of native copper (Maddin et al. 1999; Özdoğan & Özdoğan, 1999). This settlement was conveniently located near the rich copper mineralisation outcrop of Ergani Maden, but the prehistoric exploitation of this source has not yet been demonstrated. By 6000 BC, the use of copper minerals spreads beyond its ‘core’ zone in Anatolia and northern Mesopotamia to the Levant (Golden, 2010), Transcaucasia (Courcier, 2014; Kavtaradze, 1999), the Balkans (Glumac & Tringham, 1990; Thornton, 2001; see below), Iran (Helwing, 2013; Pigott, 1999; Thornton, 2009), and Pakistan (Hoffmann & Miller, 2014; Kenoyer & Miller, 1999). The strong association of intensive copper mineral use and agriculture is apparent, and has been explained by Bar-Yosef Mayer and Porat (2008) as inherently related to the powerful symbolism of the colour green in relation to crop fertility. Their study also showed that copper minerals were not the only ‘green’ option for the Near Eastern (Pre)Neolithic communities, since ornaments made of apatite, turquoise, amazonite or serpentinite were also made, valued presumably primarily for their visual properties (Bar-Yosef Mayer & Porat, 2008, p. 8549, table 1).

Balkan–Anatolian Connections and Pyrotechnology

It is beyond doubt that the practice of using green minerals was transmitted to the Balkans from Anatolia, particularly given its association with early agricultural communities and attested migration movements (e.g. Ammerman & Cavalli-Sforza, 1971; Furholt, 2017; Mathieson et al. 2018; Racimo et al. 2020; Rosenstock et al. 2016; Shennan, 2018; Silva & Vander Linden, 2017). Nevertheless, the use of copper minerals for decorative purposes and their use for copper smelting involve different selection practices and intent, as Radivojević and colleagues have shown in extensive analytical studies across the Neolithic and Chalcolithic Balkan sites in recent years (Radivojević, 2015; Radivojević & Rehren, 2016; Radivojević et al. 2010b). Discriminating between pure green and black-and-green indicated not only aesthetic differences, but also compositional variations, suggesting that copper smiths distinguished between material properties of differently coloured minerals. This is particularly evident in the abundance of manganese oxide in the post-5000 BC Vinča culture copper slags, which is known to facilitate the formation of a melt under variable redox conditions that one would expect from hole-in-the-ground smelting installations (Huebner, 1969: 463; Radivojević & Rehren, 2016, p. 221 ff.). Such a technological practice and clear distinction between minerals for ornaments and those for smelting has not yet been identified in Anatolia or in the Near East. This was the foundation of Radivojević’s (2012, 2015) claim that the preference for the black-and-green appearance in the selection of copper minerals by Late Mesolithic/Early Neolithic communities in the Danube Gorges and western Serbia (c. 6200 BC; Fig. 1) prompted early experimentation and subsequent copper smelting between c. 5000 and 4400 BC in the Vinča culture sites of Belovode, Vinča-Belo Brdo, Pločnik and Gornja Tuzla (Fig. 2). This is also the principal new argument underlying renewed claims for an independent technological trajectory for copper metallurgy in the Balkans.

Given the presented evidence, while the practice of sourcing copper minerals and native copper originated outside the Balkans and was brought into the region—presumably accompanying other broadly contemporary materials that were being exploited, such as obsidian—the development of copper metallurgy took a technologically distinctive and independent route in the Balkans from as early as 6200 BC (Radivojević, 2015). The moment of ‘invention’, though, is difficult to pinpoint but is certainly no later than 5000 BC, when we already see the developed and repetitive process of smelting under similar redox conditions and with similar ‘recipes’ across the Vinča culture sites (Radivojević & Rehren, 2016). From this perspective, the invention of copper metallurgy could have taken place any time between 6200 and 5000 BC, but most likely during the second half of the 6th millennium BC.

In Eurasia, the closest evidence to the approximately seven-thousand-year-old copper smelting event at Belovode comes from Tal-i Iblis in southeastern Iran in the early centuries of the 5th millennium BC; it is only relatively dated to due to the fact that it comes from excavation of spoil heaps (Frame, 2012). Until very recently, the assumed metallurgical activities at Çatalhöyük had stimulated scholarly debate due to an unusually early date, set at c. 6500 BC, for a find that appeared to display features of a metallurgical ‘slag’ (Cessford, 2005; Mellaart, 1964; Neuninger et al. 1964). The argument that the Neolithic Çatalhöyük communities were possibly smelting metal has since been discussed in the literature, and been both supported (Hauptmann, 2000; Hauptmann et al. 1993; Strahm, 1984) and called into significant question (Birch et al. 2013; Craddock, 2001; Muhly, 1989; Pernicka, 1990; Radivojević et al. 2010b; Roberts et al. 2009; Tylecote, 1976). A full re-analysis of the original metallurgical ‘slag’ from Çatalhöyük and revised contextualisation showed that this sample was a burnt copper mineral, probably deposited as a green pigment in a burial and subsequently baked during a destructive fire event in the dwelling in which it was discovered (Radivojević et al. 2017). Further analytical evidence for copper smelting in Anatolia dates from late 5th/early 4th millennium BC occupation of the eastern Anatolian site of Değirmentepe (Lehner & Yener, 2014), although no further analysis of this find is known to the present authors. In summary, the evidence for metal smelting in the Balkans is earlier, more substantial, and technologically distinctive when set against comparable evidence to the east (southwest Asia).

It is important to note that the smelting of copper ores was by no means the earliest application of pyrotechnology in either the Balkans or Anatolia. The transmission of ceramic forms and pyrotechnology from Anatolia to the Balkans occurred from c. 6600 BC, with ceramic production and consumption subsequently being extensively practised and developed by early farming communities (Amicone et al. 2019; de Groot, 2019; Spataro & Furholt, 2020). This process started around 1500 years before the earliest evidence for metallurgy in the Balkans or elsewhere, which leads us to the issue of the interdependence of pottery and metal pyrotechnologies. The most common question about this relationship is whether the ability to create and manage high temperatures (exceeding c. 1000 °C) could have led to discovery of means for the transformation of copper ore to copper metal. Earlier studies of Vinča pottery have already indicated that potters were not achieving temperatures beyond c. 900 °C (1083 °C is the melting temperature for copper) (Kingery & Frierman, 1974, pp. 204–205). Compositional analysis of the Vinča culture pottery revealed that all fine, medium and coarse fabrics were made of low calcareous clay (less than 6% CaO), and so were normally fired under reducing conditions below 800 °C (Maniatis & Tite, 1981, p. 73).

In new research on the interdependence of pottery and metal technology at the Vinča sites of Belovode and Pločnik within the Rise of Metallurgy in Eurasia project, Amicone et al. (2020b) dismiss the importance of high temperatures in pottery firing for proving this relationship. In terms of the mastery of the Vinča potters’ pyrotechnological skills, they highlight the more critical skill of controlling firing atmosphere conditions, explaining that the production of a functional pot required temperatures only in the range of 600–700 °C, rather than in excess of 1000 °C; they contend that previous scholarship overestimated the role of firing temperatures in seeking the best fit with the model of interdependence between pottery and metal technologies.

Their findings, however, do not preclude the idea that other advances in pyrotechnology, such as mastery of fire control, could have laid the groundwork for further technological advances such as copper extraction. The only hypothesis from previous scholarship on pottery pyrotechnology that Amicone et al. (2020b) confirmed was that of Frierman (1969), who reports the two-step process for firing graphite-painted pottery, broadly similar to the two-step process of the earliest metal smelting reconstructed by Radivojević and colleagues (2010b, p. 2777). Specifically, experiments showed that graphite burns at 725 °C in an oxidising atmosphere, leading Frierman (1969, p. 43) to assume that pots coated with the graphite slip were fired in an oxidising atmosphere up to c. 500 °C or 600 °C, after which the atmosphere for the remainder of the firing had to be strongly reducing over a prolonged period. The use of a slow firing process under the reducing conditions is further corroborated by the evenness and the black colour of resulting surfaces. The principle of two-step firing also applies to the reduction of copper ores to copper metal, but in reverse order: chemical reduction from ore to metal requires reducing conditions and temperatures from c. 700 °C upwards (Budd, 1991), while the melting of the copper metal takes place under temperatures in excess of 1080 °C, but has fewer constraints on the redox conditions.

Graphite use in the Late Neolithic and Chalcolithic Balkans has been extensively documented (Chokhadzhiev, 2000; Gaul, 1948; Leshtakov, 2005; Todorova, 1986, 1993). While cones of graphite were used to decorate pottery (cf. Gaul, 1948, p. 98), Ryndina and Ravich (2000, pp. 16–17) also speculate on the possibility of graphite-rich moulds being used for metal casting, arguing that craftspeople understood the protective role of graphite against oxidation of freshly cast metal. Although this remains to be confirmed archaeologically, the roughly contemporary emergence of copper smelting and the practice of graphite decoration at the dawn of the 5th millennium BC suggests that they influenced each other. This is particularly true for settlements with strong evidence for metallurgical practice and adjacent graphite deposits, such as Pločnik in south Serbia (Fig. 2), on which Amicone et al. (2020b) build their case. Hence, these technologies are seen as ‘close cousins’ clearly impacting each other; this highlights the need for future programmes to date the emergence of graphite painted pottery in conjunction with early metallurgy in the Balkans.

The current state of research largely indicates a technology that is unique and has, arguably, an independent route of development in the Balkans, embedded in a long tradition of selecting dark-coloured copper minerals, and potentially also connected to pyrotechnologies that produced dark and shiny materials such as pots—a combination that remains unparalleled in any cultural context anywhere else. Although the authors of this research have had, and continue to have, a divergence of opinions on this particular topic (see opposing views in Radivojević et al. 2010b; Roberts et al. 2009), we agree that the state of early Balkan metallurgy research should inspire similarly detailed studies across Eurasia with respect to the 5th millennium BC, or earlier, as the way to rule among alternative scenarios, as has now been enabled for the claimed, and now rejected, Çatalhöyük metal smelting at c. 6500 BC (Radivojević et al. 2017).

How did Metallurgy in the Balkans Develop?

The development of extractive metallurgy in the Balkans, starting from the time of the earliest evidence of copper smelting at c. 5000 BC and continuing throughout the 5th and into the early 4th millennium BC has been traditionally framed in terms of a regionally coherent technological phenomenon (cf. Chernykh, 1978b; Renfrew, 1969 and literature therein). Furthermore, since the identification of the major early copper mines at Rudna Glava, Serbia (Jovanović, 1978), and Ai Bunar, Bulgaria (Chernykh, 1978a), as well as the discovery of the lavish gold and copper objects in the graves at Varna, Bulgaria (Ivanov, 1978b, 2000), scholarship has focussed on interpreting the metallurgical evidence in terms of major cores and peripheries of metal production and consumption. This approach was refined and elevated by Chernykh (1978b, 1992) with his proposed structure known as the Carpatho-Balkan Metallurgical Province. These two models, of regional coherence and core–periphery structures, can be evaluated against the evidence for: mining and minerals; smelting; making and shaping objects; and copper supply networks.

Mining

Copper mining activities in the Balkans are securely (AMS) dated only at Rudna Glava in eastern Serbia. This mine shows evidence for working from around the mid 6th millennium BC and an intensification of mining activities at around c. 5000 BC (Jovanović, 1971; O'Brien, 2015; Pernicka et al. 1993; Radivojević & Kuzmanović-Cvetković, 2014). At roughly the same time, we see the first copper smelting at the eastern Serbian site of Belovode. Another important and productive copper mine was located in Ai Bunar, central Bulgaria (Fig. 2), which can be relatively dated to c. 4600 BC on the basis of ceramic typo-chronology (Chernykh, 1978a; Pernicka et al. 1997). More recently, Medni Rid in southeast Bulgaria has been confirmed as yet another large copper deposit probably exploited from the mid 5th millennium BC, although this dating is currently based only on provenance analysis and the strong elemental consistency observed between the metal production evidence at Akladi Cheiri and regional copper metal implements (Kunze & Pernicka, 2020; Rehren et al. 2021).

Rudna Glava is the earliest documented copper mine in the whole of Eurasia. It consisted of eight groups of mine shafts with access platforms, all following veins rich in magnetite, chalcopyrite and carbonate copper ores. Near the entrances and inside the shafts, hoards of distinctive Vinča culture-style ceramics were found, dating from the Gradac phase, broadly between the early and mid 5th millennium BC (the later dates associated with prolonged Gradac phase in the southern Serbian sites), together with stone mallets and deer-antler tools. Despite this extensive evidence for mining, no analyses have yet confirmed that any analysed metal artefact from the Balkans was made from the Rudna Glava copper ores (for an opposing view see Jovanović, 1993; Pernicka et al. 1993, p. 2; Pernicka et al. 1997, p. 143). Intriguingly, trace element analysis of metal production evidence (slag) from the Vinča culture sites of Belovode, Vinča-Belo Brdo and Gornja Tuzla exhibit a very close match with Rudna Glava copper ores; however, both the lead isotope and trace element analysis should be consistent with this metal production evidence. The Rudna Glava lead isotope signature exhibits a wide scatter (due to the radiogenic nature of the deposit), and does not show a close fit to any of the Vinča culture metal implements analysed thus far (Pernicka et al. 1997; Radivojević et al. in press, see also below). Conversely, Majdanpek—one of the most abundant deposits of copper in eastern Serbia and one which has remained viable into the modern period—is only 19 km away from Rudna Glava, and provenance analysis has long indicated Majdanpek copper as one of the main sources for Vinča copper implements (Pernicka et al. 1993, 1997; Radivojević, 2012).

Ancient mining activities are also known from several localities within Serbia, some potentially dating to the 5th millennium BC. These are: Ždrelo in eastern Serbia (near Belovode); Mali Šturac in central Serbia; Medvednik in western Serbia; and Jarmovac in the southwest (Fig. 2) (Antonović, 2014; Jovanović, 1971; Pecikoza, 2011; Radivojević et al. 2010b). In Mali Šturac on Mt. Rudnik in central Serbia, grooved stone mallets resembling those from Rudna Glava were recovered, leading scholars to believe that they were of Vinča-culture provenance (Bogosavljević, 1995; Jovanović, 1983). More recent and ongoing excavations at this site yielded additional material that roughly dates this mine to the mid-to-late 5th millennium BC (Antonović & Vukadinović, 2012; Antonović et al. 2014). Furthermore, grooved stone tools, identical to those discovered at Rudna Glava and Mali Šturac, were found during field surveys of the Vinča culture settlements of Mačina and Merovac (Fig. 2), both situated in the vicinity of the ore-rich deposits at Mt. Kopaonik and Radan in southern Serbia (Kuzmanović-Cvetković, 1998; Radivojević, 1998); these are comparable with stone tools at mining sites throughout Europe (cf. De Pascale, 2003; O'Brien, 2015).

Another potentially Chalcolithic mining site is documented at Jarmovac (southwest Serbia), a complex of ancient mines first mentioned by Davies (1937), who identified Vinča culture sherds in one of the shafts. The site was also excavated by the local museum authorities, who discovered an associated settlement with a late Vinča culture phase (Vinča D) only 300 m away (Bunardžić et al. 2008, p. 86; Derikonjić, 2010). However, subsequent excavations as part of the Rise of Metallurgy in Eurasia project, in conjunction with the Priboj-on-Lim Homeland Museum and the German Mining Museum in Bochum, recovered an antler pick fragment from a stratified sequence, which was radiocarbon dated to the mid 4th millennium BC (Peter Thomas, pers. comm.). Comparisons to existing trace-element and lead-isotope analyses demonstrate that the mine was most likely in use much earlier to produce metal for copper objects. It is highly likely that further mining sites remain to be discovered along the rich metallogenic belt running through the Balkans (cf. Janković, 1977).

The Mid–Late Chalcolithic (c. 4600–(4450)–4100 BC) was dominated by exploitation of Bulgarian sources, predominantly at Ai Bunar in Bulgaria (Chernykh, 1978b, pp. 54–75). This source, near Stara Zagora in central Bulgaria (Fig. 2), was much larger and had greater production capacity than Rudna Glava, with tunnels up to 500 m long. The material associated with the site belongs to the KGK VI cultural complex, and is therefore relatively dated to the mid–late 5th millennium BC (Chernykh, 1978a, 1978b, 1992). Metal from Ai Bunar is known to have travelled long distances within the Balkans, as far south as Thessaly, and as far north as the northern Black Sea coast (see also below) (Chernykh, 1978b, pp. 122, 263; Gimbutas, 1977, p. 44; Pernicka et al. 1997; Radivojević & Grujić, 2018; Renfrew, 1972, p. 308, fig. 16/2). However, provenance analysis suggested the exploitation of more than one copper deposit in this period, with Medni Rid in southeastern Bulgaria being a very likely candidate (Pernicka et al. 1997, pp. 143–146). The most recent excavations in this location revealed materials from Roman and later times, although some indicate exploitation activities by the communities of the KGK VI cultural complex (Leshtakov, 2013), and this is also supported by recently analysed metal production evidence from Akladi Cheiri (Fig. 3), a settlement nearby. Metal production at this site is argued to date to the late KGK VI, or broadly to the middle of the second half of the 5th millennium BC, based on the typology and ornamentation of pottery found in the same pit as metallurgical evidence (Rehren et al. 2016, p. 207; Rehren et al. 2021). The exploitation of the Medni Rid ores may have started earlier, given the finds of late 6th millennium BC malachite in nearby settlements and the use of malachite for making metal items in the Karbuna hoard, Moldova, which was deposited in a typical Tripolye A pot dating to c. 4700–4600 BC (Fig. 2) (cf. Pernicka et al. 1997; Rehren et al. 2016).

Rather than being mined, starting from around 4650 BC Balkan gold was most likely collected from river streams as alluvial (washed) nuggets that had eroded from primary deposits (Avramova, 2002; Boyadžiev, 2002; Makkay, 1995, p. 70). This suggestion has been elaborated recently in a study of Varna gold, where Leusch et al. (2014) presented a diversity of gold, copper and silver ratios in the excavated gold artefacts, explaining that they originated from natural compositional variations in (alluvial) gold nuggets. This in turn demonstrates that various gold occurrences were exploited for the making of Varna gold, and possibly acquired through a well-organised gold supply network (Leusch et al. 2015). Such supply networks also could have supplied the copper, Spondylus, carnelian, marble, serpentinite, long yellow flint blades (superblades) and other prestige commodities unearthed as paraphernalia in the Varna cemetery (Leusch et al. 2017).

Smelting

Smelting evidence from the Early Chalcolithic is extremely scarce and mostly limited to the Vinča culture phenomenon in the central Balkans (Table 1; Fig. 4b–f). Even before the appearance of analytically extensive studies of the early metal production debris from a selected number of Vinča culture sites (Glumac, 1991; Radivojević, 2007, 2012), there had been hints that smelting was taking place. For example, in 1976 Marija Gimbutas had mentioned a copper slag lump from the site of the Anzabegovo settlement in the eastern part of Northern Macedonia (Gimbutas, 1976). Anzabegovo generally dates to c. 5200 BC, but the find itself has never been chronologically or analytically verified. Moreover, in its relative regional vicinity, in the valley of the Strymon River at the Greek–Bulgarian border, is the site of Promachon-Topolnica, which has yielded indicative field structures (‘hollows’ with traces of copper), of which the most important is a small clay crucible with a spout, dated broadly to the first half of the 5th millennium BC (Koukouli-Chryssanthaki et al. 2007, p. 51; Fig. 7.4). While the authors reported that the crucible contained traces of non-slagging copper processing with distinct traces of heavy burning, no analyses are available, which makes a more accurate identification challenging. A similarly vague situation pertains at the site of Stapari, where an alleged lump of slag was dated relatively to within the late Vinča culture phase (Jurišić, 1959). Pieces of ‘greenish slag resulting from intense fire’ were reported at depths of below 6.2 m, below 6.4 m, and below 7.0 m at Vinča-Belo Brdo (Vasić excavations), however, no further analysis or details of these finds are available (Antonović, 2002, p. 36, note 59).

Microstructural, chemical and isotopic analysis of copper slag and other production evidence from the sites of Belovode, Vinča-Belo Brdo (Tasić excavations), Pločnik, Gornja Tuzla and Selevac are the first secure evidence for sustained metallurgical activities within the Vinča culture, and highlight its role as the core archaeological phenomenon in the evolution of Balkan metallurgy (cf. Čović, 1961; Glumac & Todd, 1991; Govedarica, 2016; Radivojević, 2012; Radivojević & Rehren, 2016).

The approximate chronological sequence for the finds studied by Radivojević (2015) starts with the Belovode slags at c. 5000 BC, a date confirmed by further slags and copper metal debris excavated, analysed and directly dated in new excavations to c. 4900 BC (Radivojević et al. in press). It continues until c. 4600 BC, with an overlap of around 200 years with the Vinča-Belo Brdo production evidence, itself dated in the range c. 4800–4600 BC. Copper smelting continued at the settlement of Gornja Tuzla for as long as two hundred years following the abandonment of Belovode and Vinča, that is, down to c. 4400 BC. Both macro- and micro-analytical approaches demonstrate that copper smelting was, in total, practised throughout a period of about six hundred years, with remarkable similarities in the level of expertise and the technological choices made, although with clear differences in the composition of the ores smelted. The striking detail that underlines the chemistry of ores smelted at the sites of Belovode, Vinča, and Gornja Tuzla is their dominant colour: whatever were the exact minerals present in the ore charge, they most likely had strong colours in the range of green/blue (vivianite, arthurite, apatite, scorodite), and violet (strengite), in addition to black-and-green, manganese-rich malachite (Belovode and Vinča only). Such a conclusion has been corroborated by a detailed inspection of the slag matrix and the residual ores found in it. It is also important to underline that the indicated ores were not necessarily especially rich in copper; rather, it was their striking green/blue/violet colours that seem to have attracted the Vinča prospectors (Radivojević & Rehren, 2016, p. 225 ff.). Although it is not clear from the analyses whether black-and-green minerals were selected separately or as a mixed ore, the conclusion that emerges from the analytical discussion is that there was common knowledge of the suitability for smelting of distinctively coloured mixed minerals at this time at these various sites.

The Vinča-culture metal production practice fits well within the ‘ephemeral model’ of Chalcolithic metallurgy in western Eurasia (Bourgarit, 2007); the individual slags weigh a little less than 10 g in total (see example in Fig. 4b). This is commonly explained by the use of much cleaner ore in the early stages, resulting in a ‘slagless’ or nearly slagless metallurgy (cf. Craddock, 1995). Depending on the relative proportions of (slag-forming) dark components in the ore and pure green mineral, a large amount of copper may have formed with only a small quantity of slag, and this is the favoured scenario in the recent analytical studies (Radivojević & Rehren, 2016, p. 227 ff). Noteworthy, though, is the discovery of a lead-based slag cake weighing nearly 800 g in an undisturbed horizon dated to 5200 BC in Belovode. As this is a unique find currently unsupported by wider evidence indicating established lead metal production, it will be addressed in detail in the ‘lead and silver’ section below.

The structures in which smelting took place—so-called smelting ‘furnaces’, are evidenced primarily by slagged sherds at both Belovode and Gornja Tuzla (example in Fig. 4c–d). These suggest the presence of a hole-in-the-ground installation lined with broken pottery. Such installations were possibly operated using blowpipes/tuyères or bellows, where five or six blowpipes would normally suffice to bring the temperature up to around 1100–1200 °C (cf. Rehder, 1994, p. 221). The only indication of what these blowpipes may have looked like is found in the ceramic nozzles recovered from the sites of Bubanj (Fig. 4e–f) and Kmpije in Bor. In the absence of any other evidence, the hole-in-the-ground installations appear to be the only technological possibility for primary metal production in the early-to-mid 5th millennium BC (see Fig. 4c, d). In addition, although no crucibles have yet been properly analytically identified in the record, their presence must be assumed, given that they would have been needed for (re)melting and casting of the thousands of heavy metal objects known from this period. It may be legitimate to identify two vessels from the site of Reșca–Dâmbul Morii in Wallachia, Romania, as crucibles. These are oval, ladle-like vessels with a short, vertically pierced handle, displaying secondary traces of firing (Fig. 2; Stefan, 2018, p. 119, table VII/1, 2). These have not yet been analysed, and their context is still under discussion, although they are argued to belong to the Vădastra culture horizon, which dates to between 5200 and 5000 BC; nevertheless, they may well be the best clue concerning the appearance of crucibles during this period. Curiously, the casting moulds that were unequivocally necessary for producing the vast number of metal implements produced in this period are also absent from the archaeological record (Heeb, 2014; Kienlin, 2010, p. 42 ff).

Copper production evidence is still scarce in the Mid–Late Chalcolithic (c. 4600–4100 BC), although it is documented in more settlements than for the previous period. In Bulgaria, copper smelting evidence comes from the sites of Dolnoslav, Chatalka and Akladi Cheiri (Fig. 3), all dated to the mid-to-late 5th millennium BC (Rehren et al. 2016, 2021; Ryndina et al. 1999). All three sites yielded crucibles, amongst other finds, although only the Dolnoslav and Akladi Cheiri examples were preserved. The crucible from Dolnoslav was a vessel with an oval plan, round bottom and 10–25 mm thick walls (Ryndina et al. 1999); the reconstructed example from Akladi Cheiri had a similar oval base though the frontal part was slightly profiled to serve as a spout (Rehren et al. 2016, p. 207; Fig. 2). Microstructural and compositional analyses of the Dolnoslav crucible indicated smelting of polymetallic ores (a mix of malachite with primary copper ores), which were rich in zinc and lead oxide (Ryndina et al. 1999, p. 1066, table 2). The dominant presence of zinc and lead in the slag matrix, together with copper oxide in trace amounts, presents a copper smelting technology that is different from, and possibly more efficient than, that encountered in the Vinča culture with its slags rich in manganese oxide (Radivojević, 2015, p. 332, table 2). The Akladi Cheiri example on the other hand was for (re)melting: its inside was contaminated with copper and there was no other evidence for gangue elements such as iron, cobalt or sulfur (Rehren et al. 2021: p. 152). These are the earliest definitively identified crucibles in the Balkans, and they become more common only from the mid 4th millennium BC, notably in the Baden culture in the north-central Balkans (Ecsedy, 1990, p. 224; Glumac & Todd, 1991; Radivojević et al. 2010a).

More examples, although not analytically confirmed, come from the late 5th millennium BC Tiszapolgár culture cemetery of Tibava (Fig. 3), in the form of a cylinder vessel with a crude inner surface, identified amongst pottery grave goods (Andel, 1958, Plate I/7; Šiška, 1964, p. 317; Fig. 12/5); this was thought to be a melting pot but it was never analysed (Bognár-Kutzián, 1972, p. 134). Another crucible described as a ‘vessel covered with blue verdigris and with two small copper crumbs’ was discovered among grave goods in the cemetery of Tiszapolgár-Hajdúnánás Road, and has unfortunately been lost (Bognár-Kutzián, 1972, pp. 98, 134). The ceramic vessels widely interpreted as crucibles at the Cucuteni A2 and B1 levels at the site of Poduri-Dealul Ghindaru in Romania (Fig. 3; Mareş, 2002, pp. 85, 138–139, table 64/8) have yet to be subjected to archaeometallurgical analyses and so cannot be considered as confirmed metal production evidence, despite the presence of two copper ingots from the same site (Monah et al. 2002). A similar situation is encountered in Sitagroi (phase III, roughly contemporary with KGK VI), where an assemblage of 36 slagged sherds, accompanied by copper metal artefacts, present convincing evidence for local copper smelting as well as a distinctively similar slagging pattern to contemporaneous Akladi Cheiri, for instance (Renfrew & Elster, 2003, pp. 306). These sherds are yet to be subjected to detailed technological analysis.